Chromium-free passivation solution and hot-dip galvanized metal material

A chromium-free passivation, hot-dip galvanizing technology, applied in metal material coating process, hot-dip plating process, coating and other directions, can solve the problems of poor corrosion resistance, heat resistance and fingerprint resistance, and achieve good resistance. Corrosive, easy to use, save the effect of oiling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

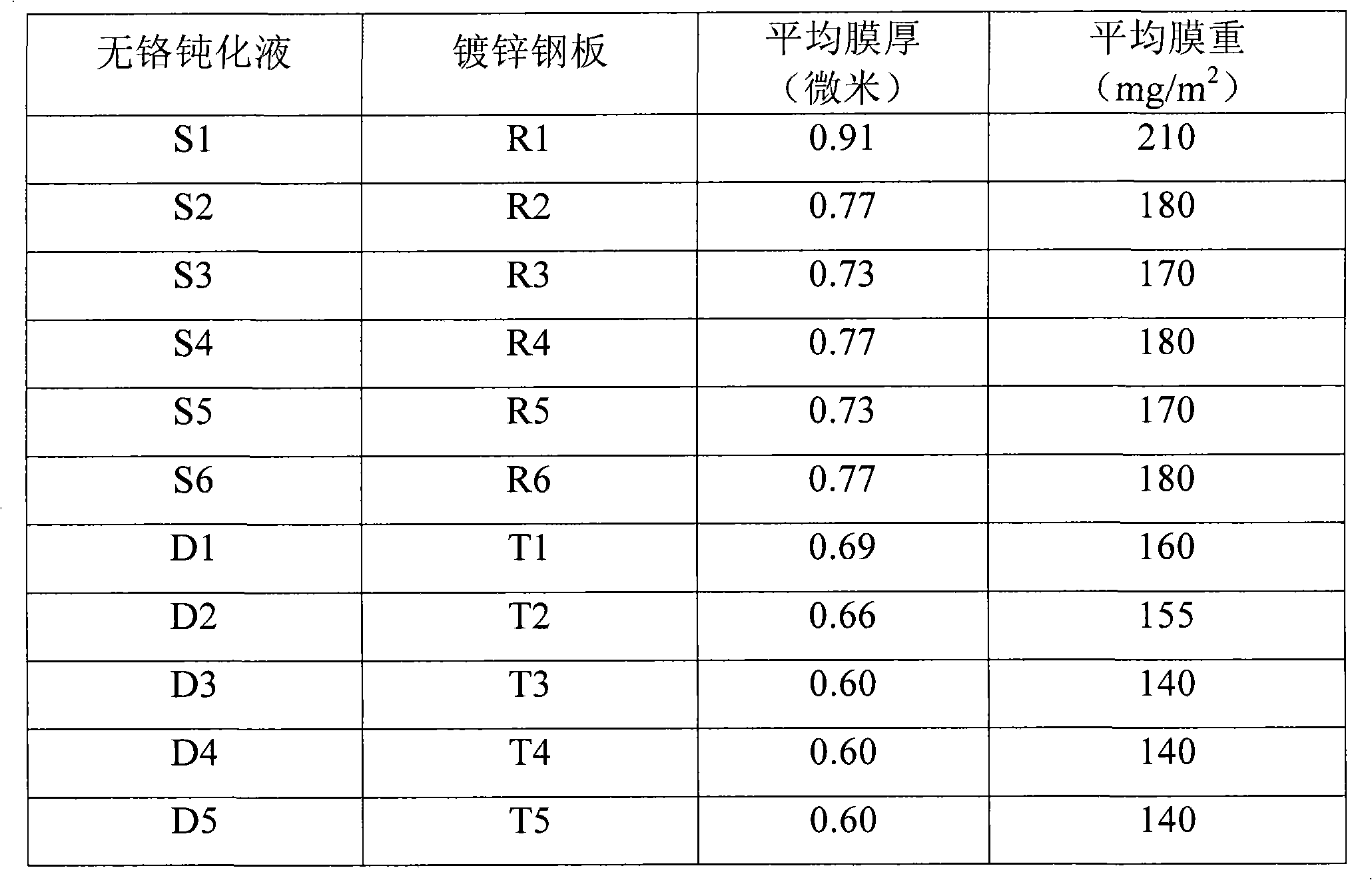

Embodiment 1

[0042] This embodiment is used to illustrate the chromium-free passivation solution provided by the present invention and its preparation method.

[0043] Put 20g of tannic acid in the container, add 100mL of distilled water to dissolve it completely; slowly drop 20mL of silane coupling agent KH550 into the above container within 2 minutes, stir for 5 minutes until the reaction is complete; add 0.5g of dispersing Agent (boric acid), 0.005g defoamer (polyether modified polydimethylsiloxane, Guangzhou Silok, silok2243) and 0.005g stabilizer (isopropanol), stir until completely dissolved; add 25 grams of H 2 TiF 6 Aqueous solution (30% by weight), stirred for 5 minutes until uniform; Added 10g nanometer SiO 2 powder (purchased from GE Company of the United States, RNS-E, average particle size 20nm), stirred for 10 minutes until the solution was in a uniform and stable phase; added 180mL silicon acrylic emulsion (purchased from Nantong Shengda, SD-5281), and then distilled water ...

Embodiment 2

[0045] This embodiment is used to illustrate the chromium-free passivation solution provided by the present invention and its preparation method.

[0046] Put 24g of phytic acid in the container, add 100mL of distilled water to dissolve it completely; slowly drop 15mL of silane coupling agent KH560 into the above container within 2 minutes, stir for 5 minutes until the reaction is complete; add 0.5g of dispersant (boric acid), 0.005g defoamer (polyether modified polydimethylsiloxane, Guangzhou Silok, silok2243) and 0.010g stabilizer (isopropanol), stir until completely dissolved; add 25 grams of sulfuric acid oxygen Titanium solution (40% by weight), stirred for 5 minutes until uniform; added 30g of silica sol (30% by weight), stirred for 10 minutes until the solution was in a uniform and stable phase; added 180mL of acrylic resin film-forming agent (purchased from A-3418), then the volume is fixed to 1L with distilled water to obtain the chromium-free passivation solution S2 pr...

Embodiment 3

[0048] This embodiment is used to illustrate the chromium-free passivation solution provided by the present invention and its preparation method.

[0049] Put 15g of tannic acid in the container, add 100mL of distilled water to dissolve it completely; slowly drop 10mL of silane coupling agent KH570 into the above container within 2 minutes, stir for 5 minutes until the reaction is complete; add 0.5g of dispersing Agent (boric acid), 0.010g defoamer (polyether modified polydimethylsiloxane, Guangzhou Silok, silok2243) and 0.010g stabilizer (isopropanol), stirred until completely dissolved; add 20 grams of sulfuric acid Aqueous titanyl oxide solution (40% by weight), stirred for 5 minutes until uniform; adding 30 g of sodium silicate aqueous solution with a modulus of 2 at a concentration of 30% by weight, stirred for 10 minutes until the solution was a uniform and stable phase; added 180 mL of polyurethane resistant Yellow resin (purchased from Jinjiang Jianhua, Fujian, 812), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com