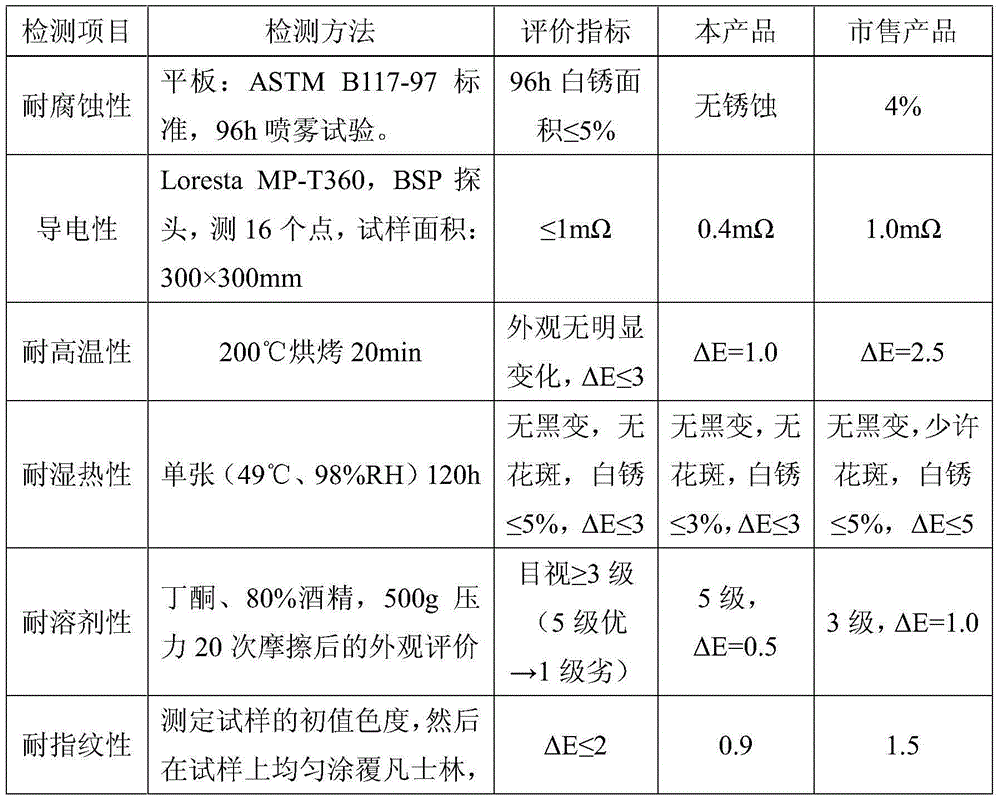

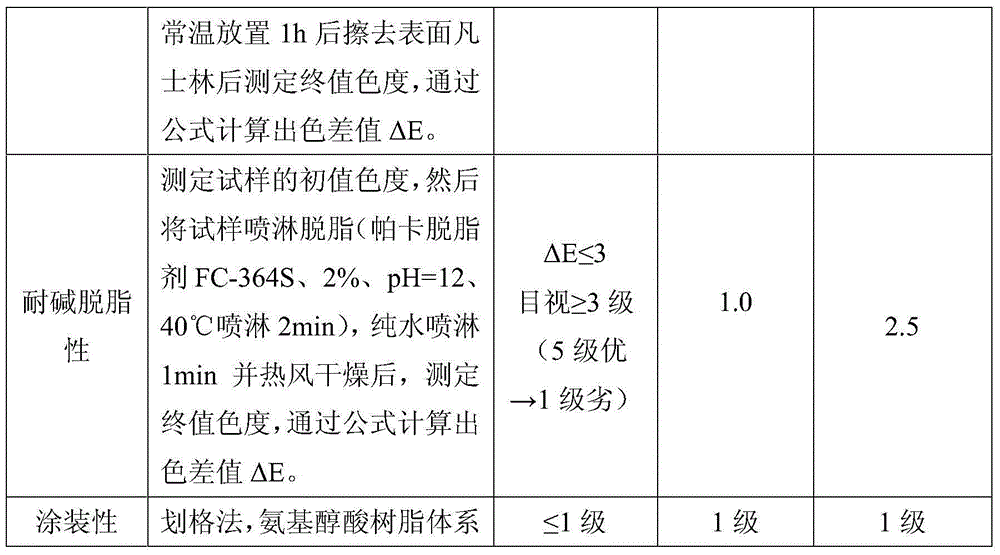

Water-based chromium-free fingerprint-resistant paint for galvanized steel plate

A galvanized steel sheet, fingerprint-resistant technology, applied in the field of coatings, can solve the problems of excessive curing capacity requirements of production lines, failure to achieve self-lubricating effects, and inability to guarantee performance, reduce energy consumption, solve pollution problems, and improve molding processing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A water-based chromium-free anti-fingerprint coating for galvanized steel sheets is characterized in that it is composed of the following raw materials in parts by weight:

[0034] Fluorine-modified water-based self-crosslinking acrylate emulsion 30.0-55.0, neutralizer 0.1-1.5, silane coupling agent 0.5-1.0, laurozone 0.1-0.2, chlorinated paraffin 0.6-1.0, inorganic sol 4.0-8.0, metal Salt 1.5-3.5, glycerin 0.1-0.3, sodium carboxymethylcellulose 0.1-0.2, simethicone 0.1-0.2, cosolvent 1.5-5.5, aluminum dihydrogen phosphate 1.0-2.5, water 40-50;

[0035] The neutralizing agent is one or more mixtures of ammonia water, triethylamine, dimethylethanolamine, N,N-dimethylethanolamine, and AMP-95;

[0036] The inorganic sol is MgO, CaO, SiO 2 , ZnO, Al 2 o 3 One or a mixture of several of them;

[0037] The metal salt is one or more mixtures of tetrakis(triethanolamine) zirconate, zirconium acetylacetonate, sodium fluozirconate, potassium fluozirconate, sodium molybdate, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com