Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Diesel Exhaust Particulate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A complex mixture of combustion products of diesel fuel including carbon monoxide, carbon dioxide, sulfur oxides, nitrogen oxides, volatile hydrocarbons, aldehydes, alkenes, alkanes and nitroarenes, polycyclic aromatic hydrocarbons and other derivates. Lymphocyte-DNA adduct formation is associated with exposure to diesel exhaust particulates and may be associated with an increased risk of developing lung cancer. Diesel Exhaust Particulate is reasonably anticipated to be a human carcinogen. (NCI05)

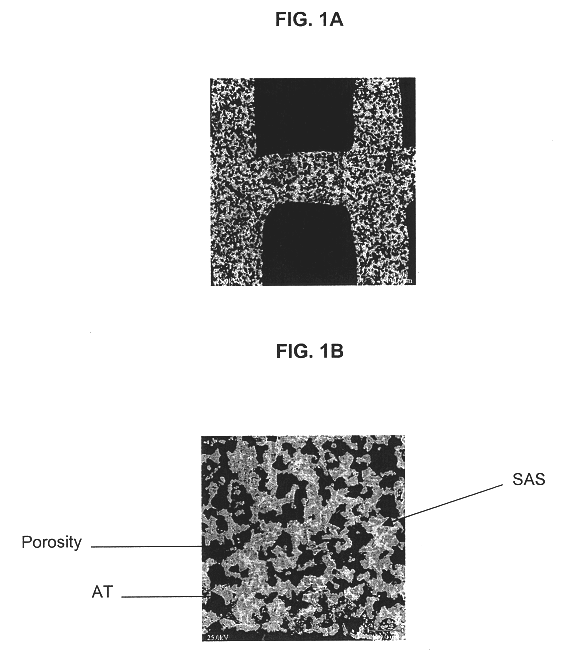

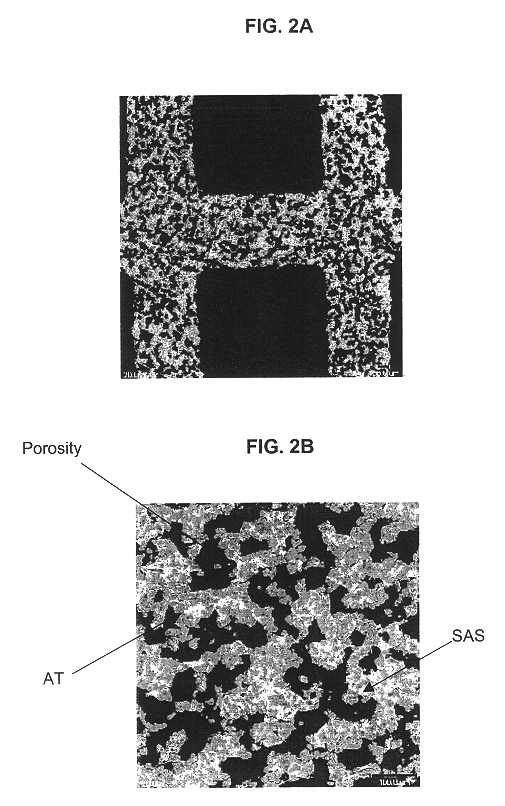

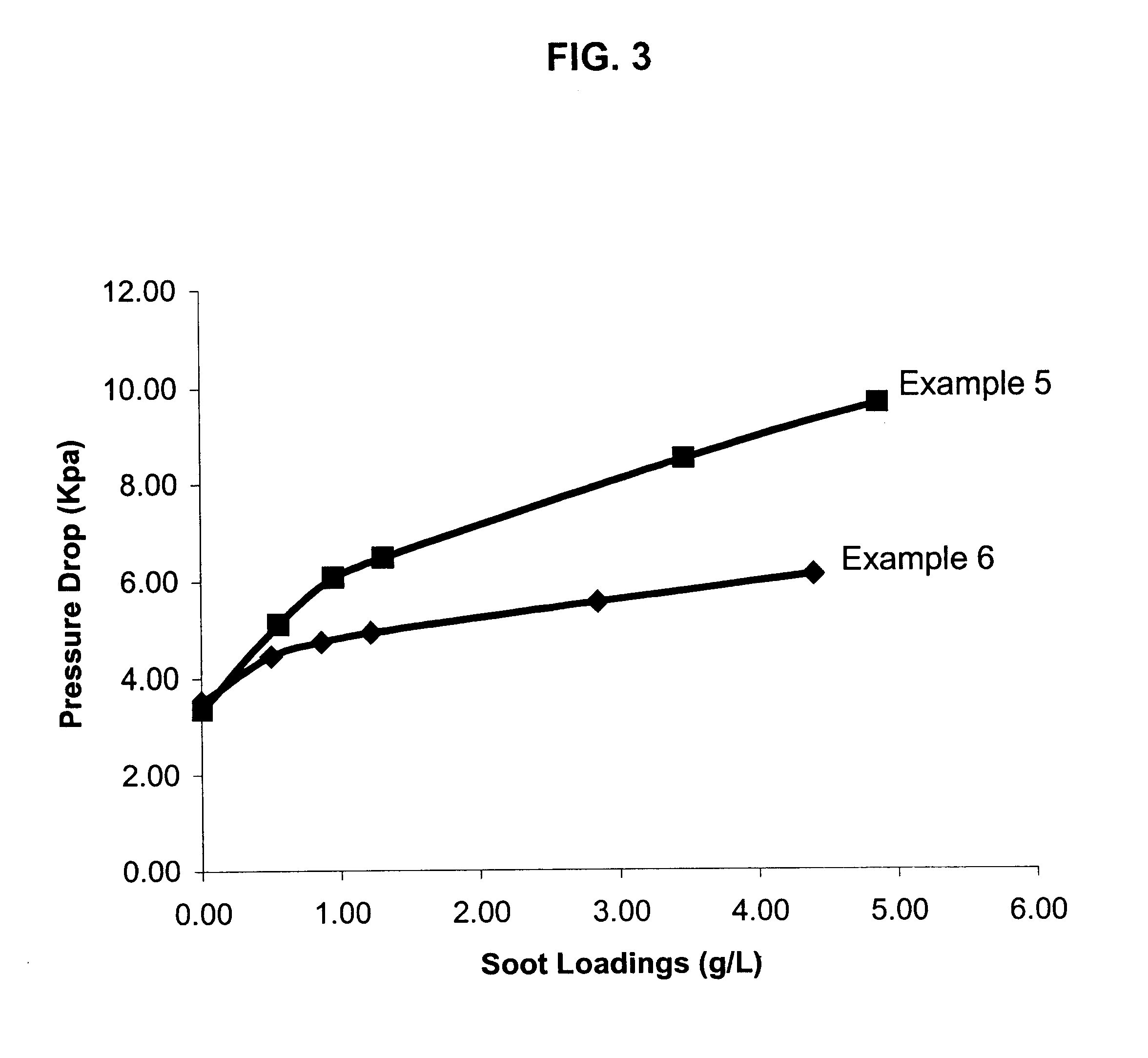

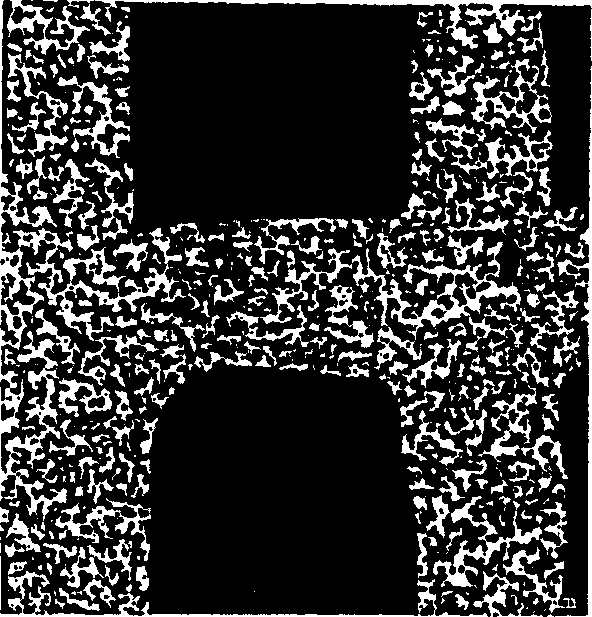

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

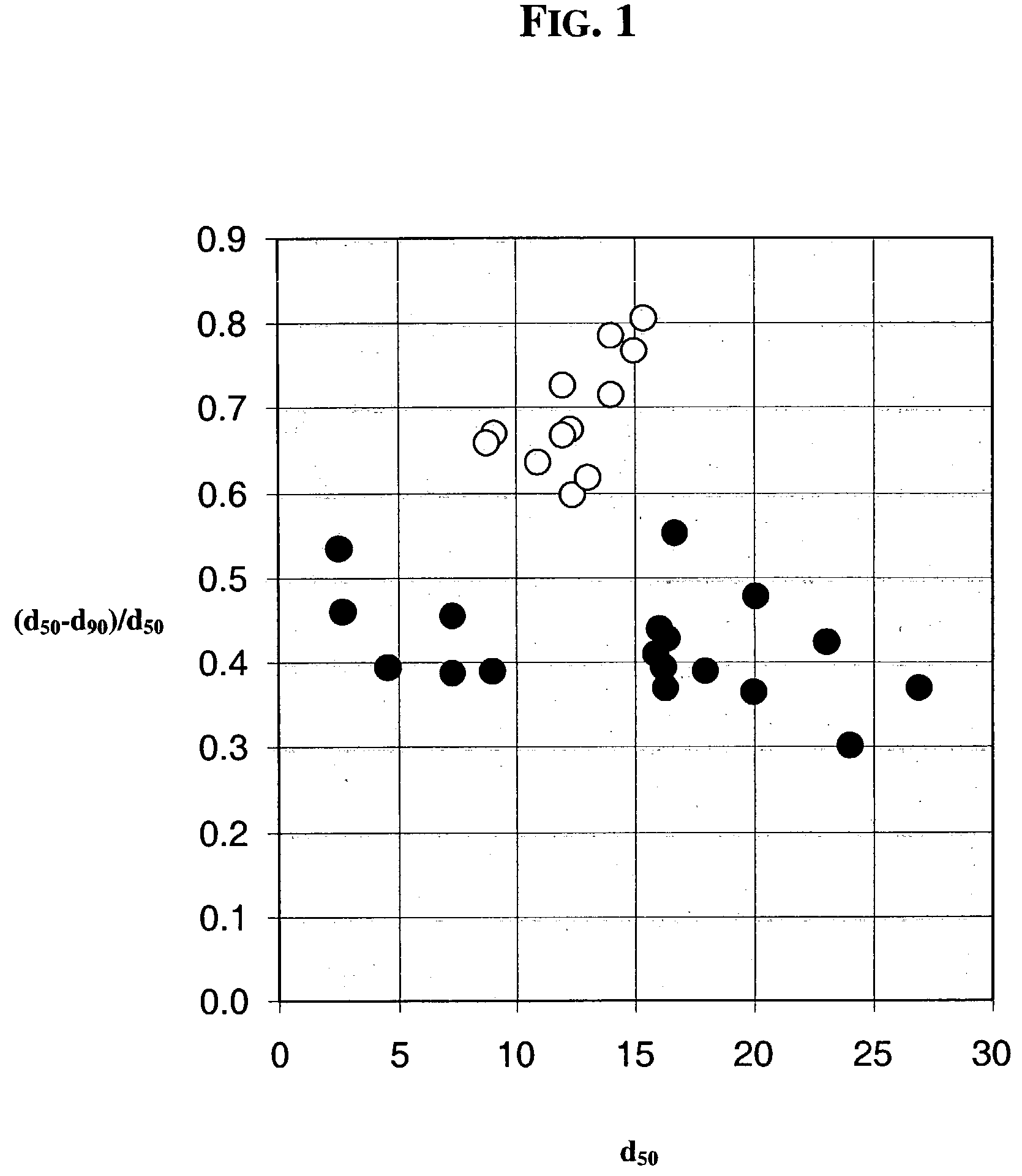

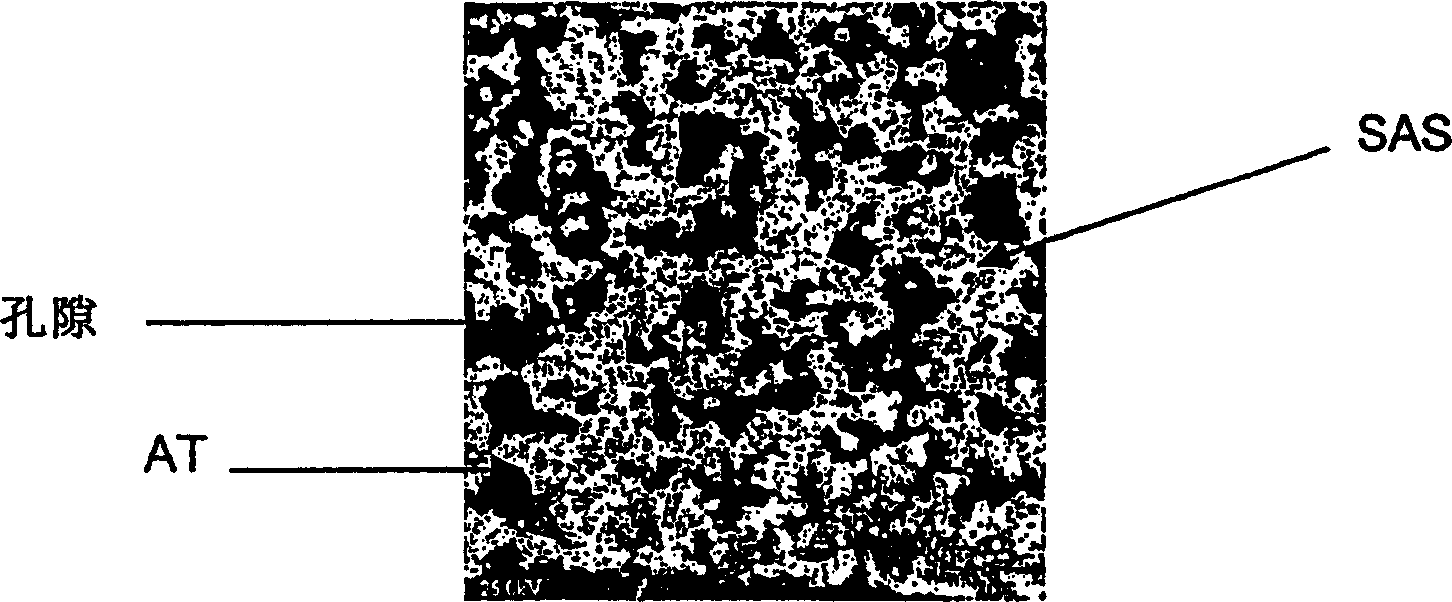

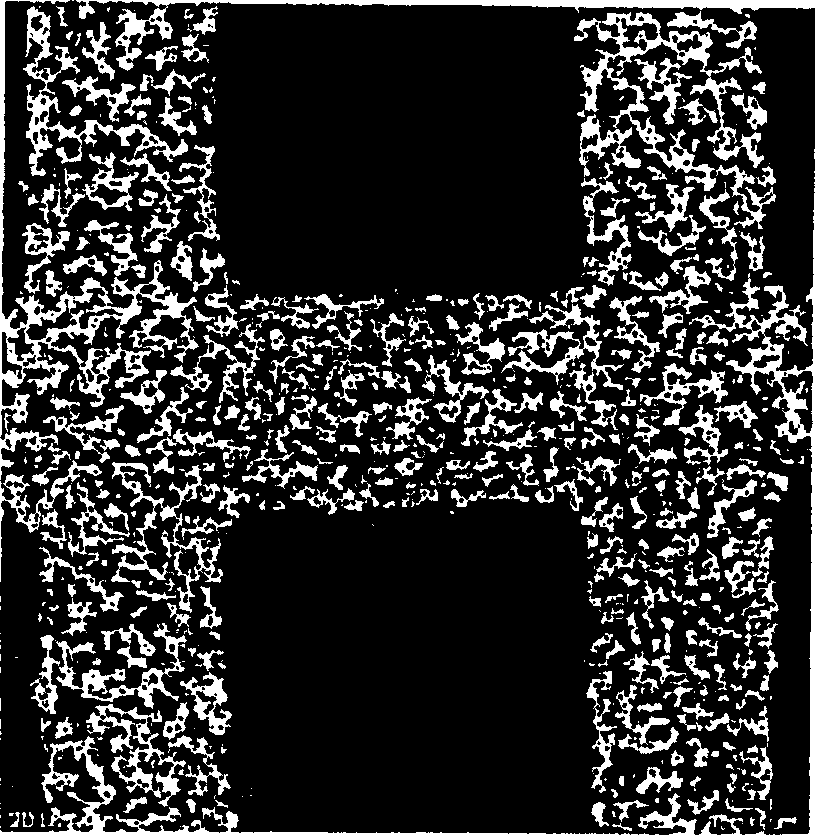

Magnesium aluminum silicate structures for DPF applications

ActiveUS7141089B2Reduce anisotropyGood pore connectivityCombination devicesAuxillary pretreatmentParticulatesAluminum silicate

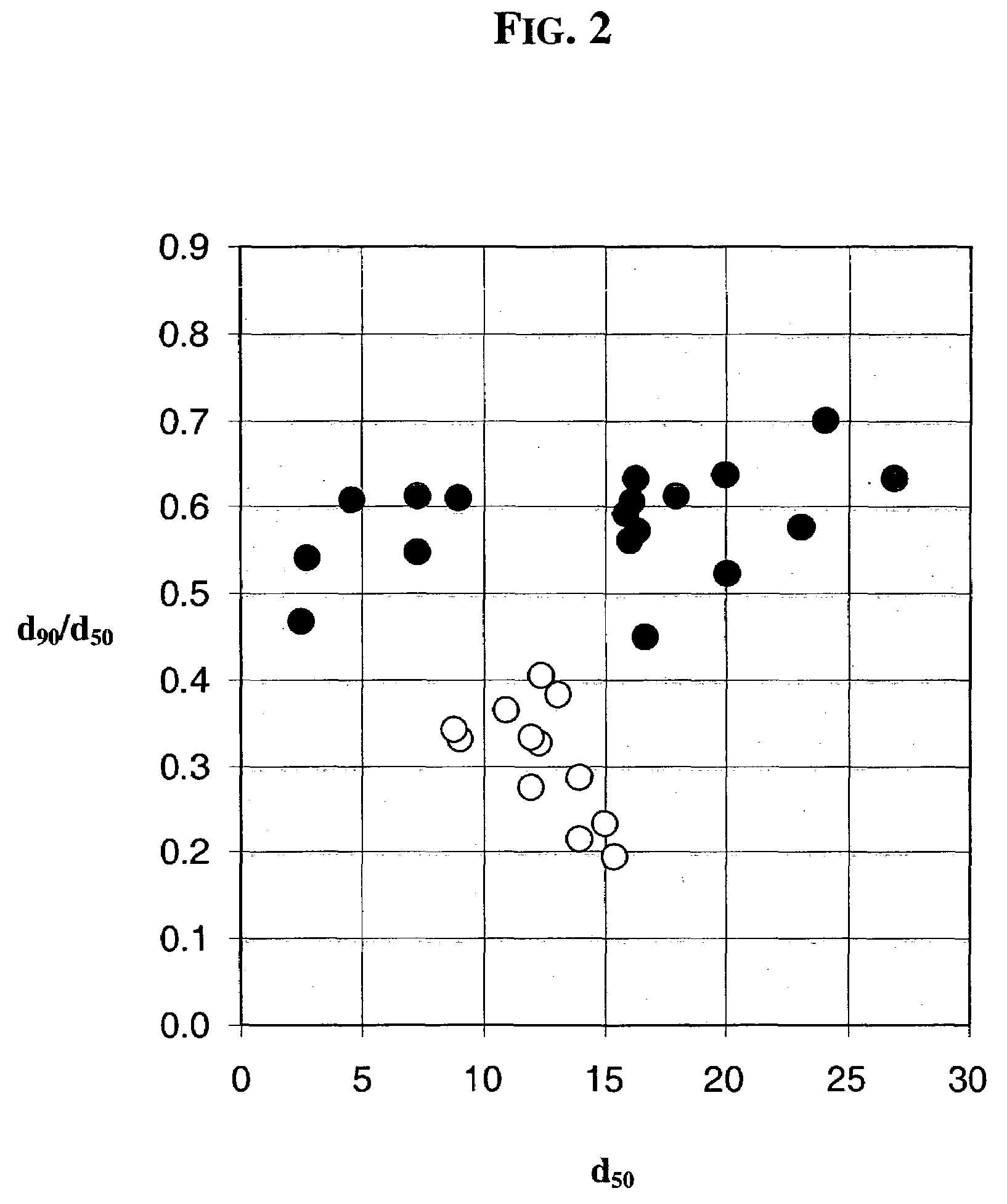

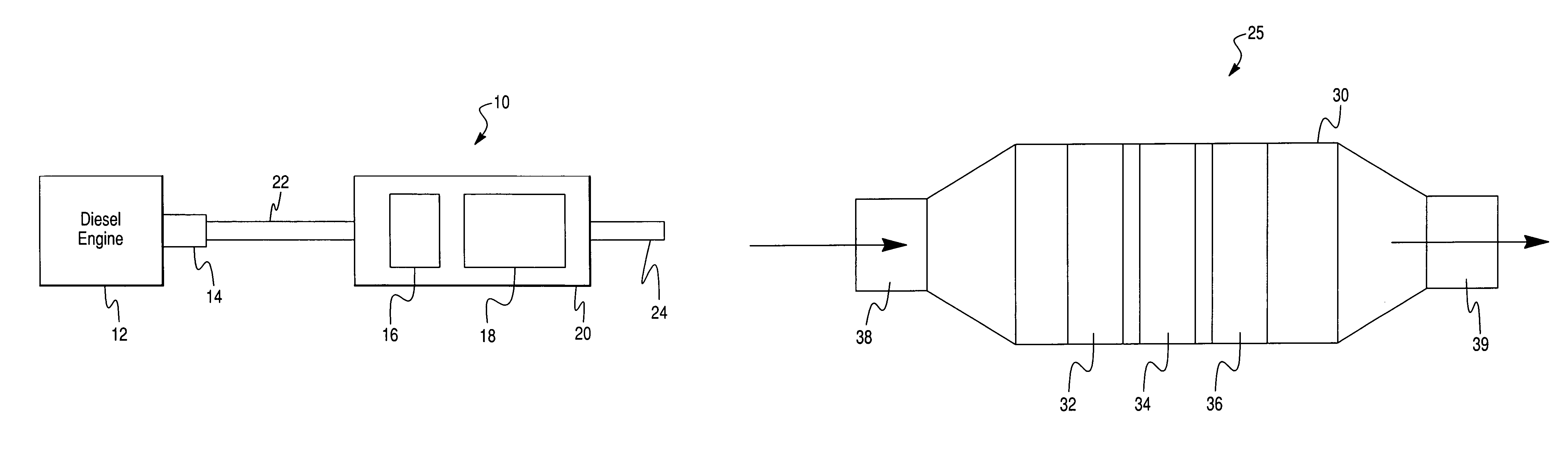

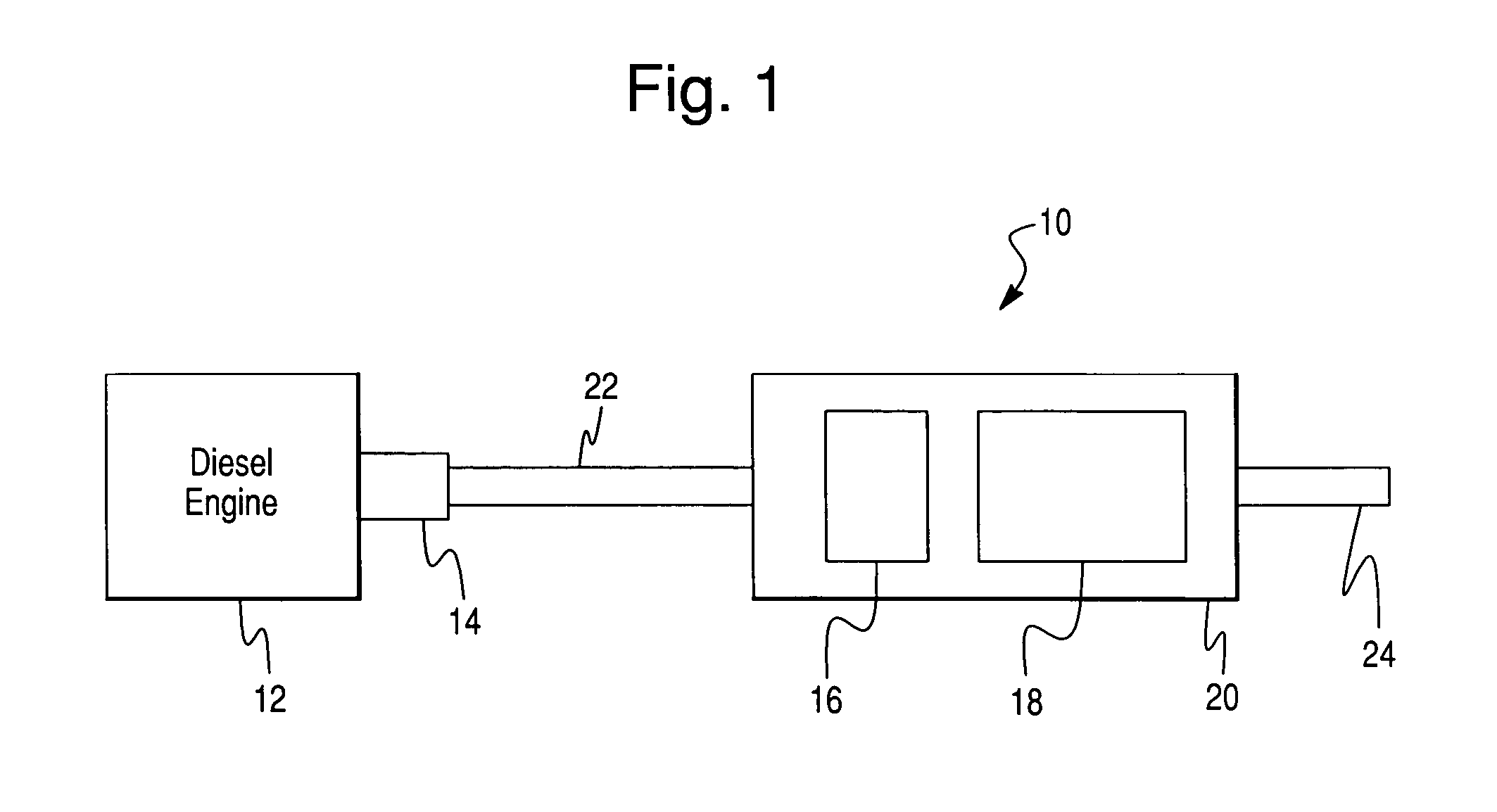

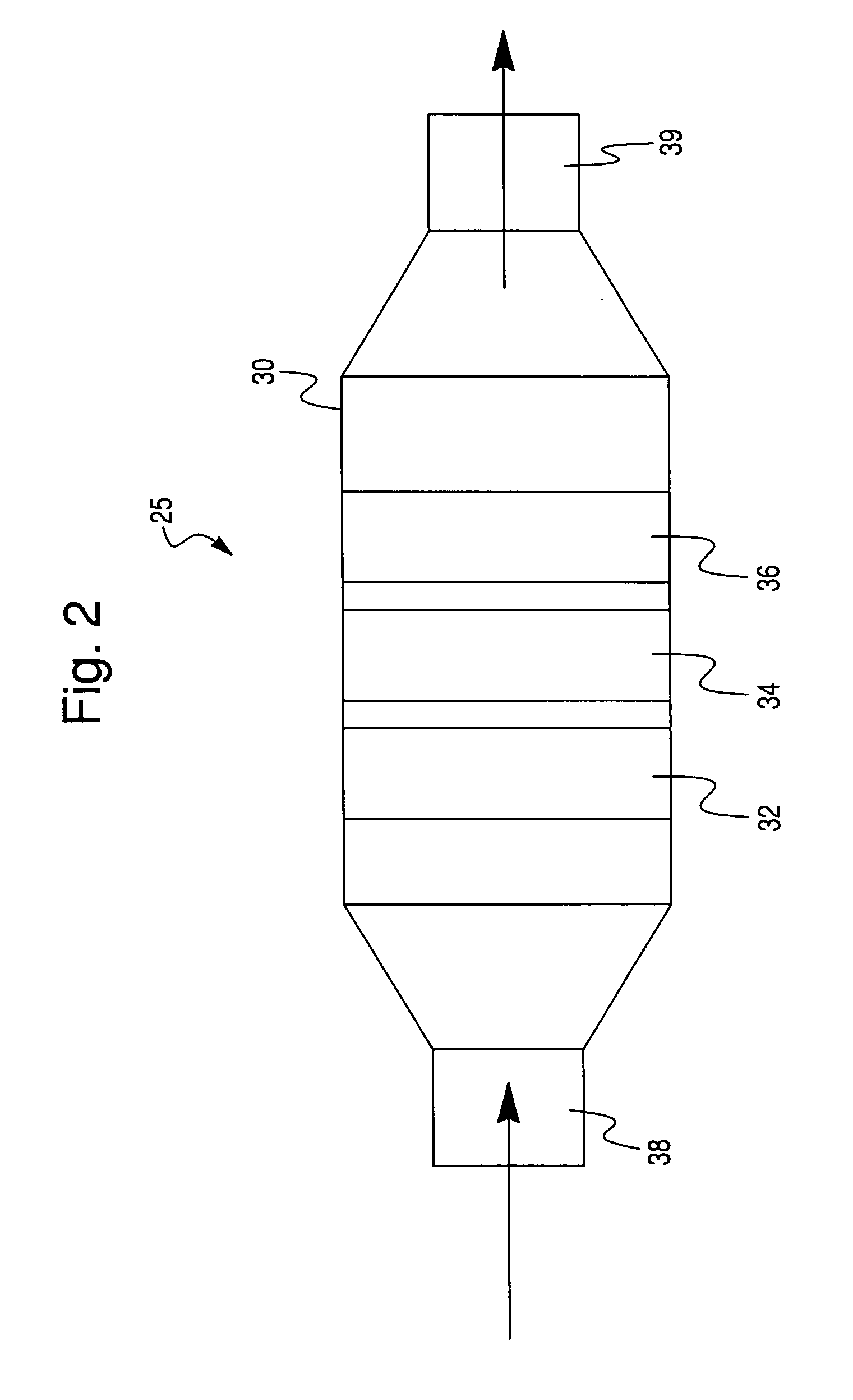

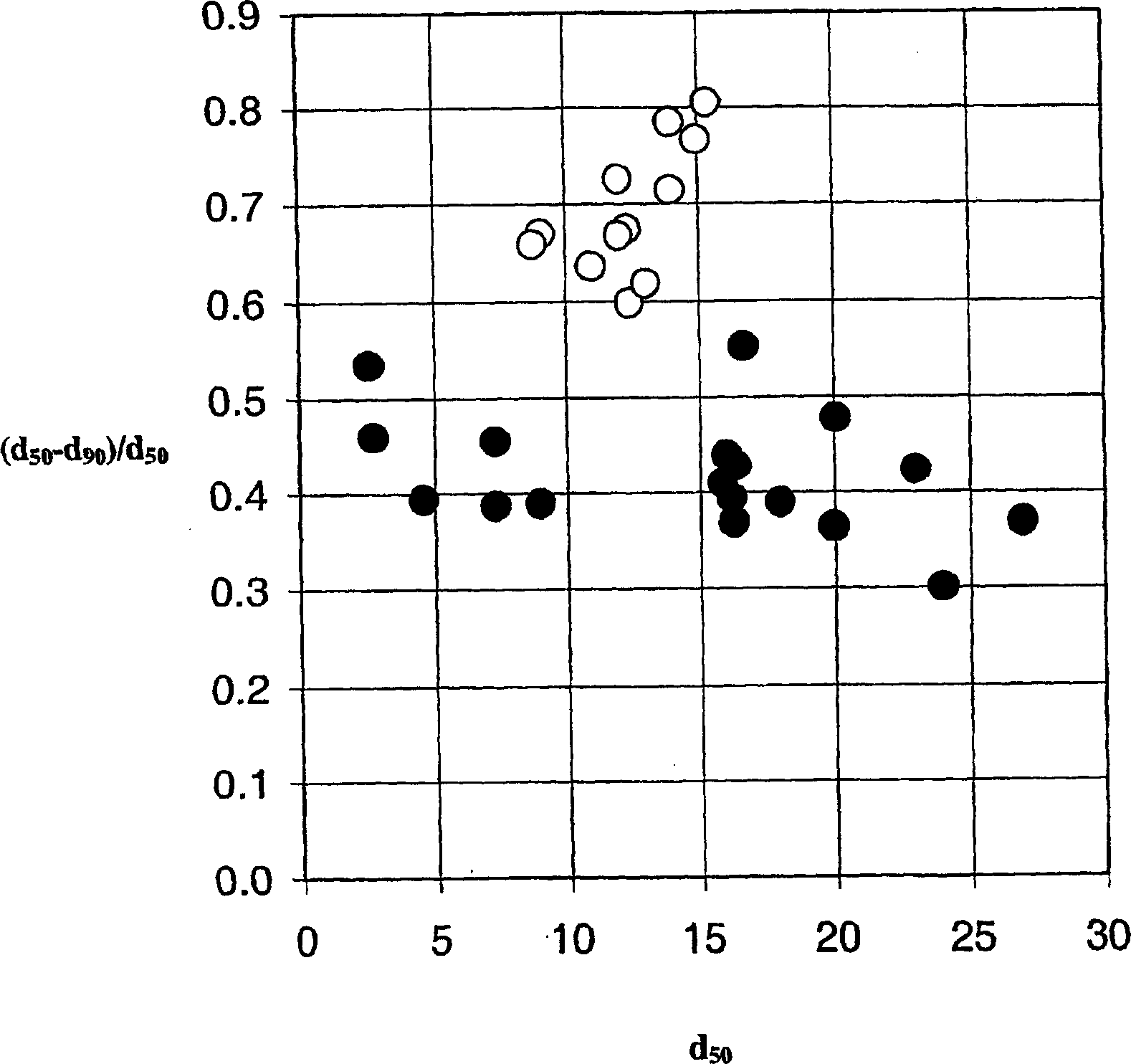

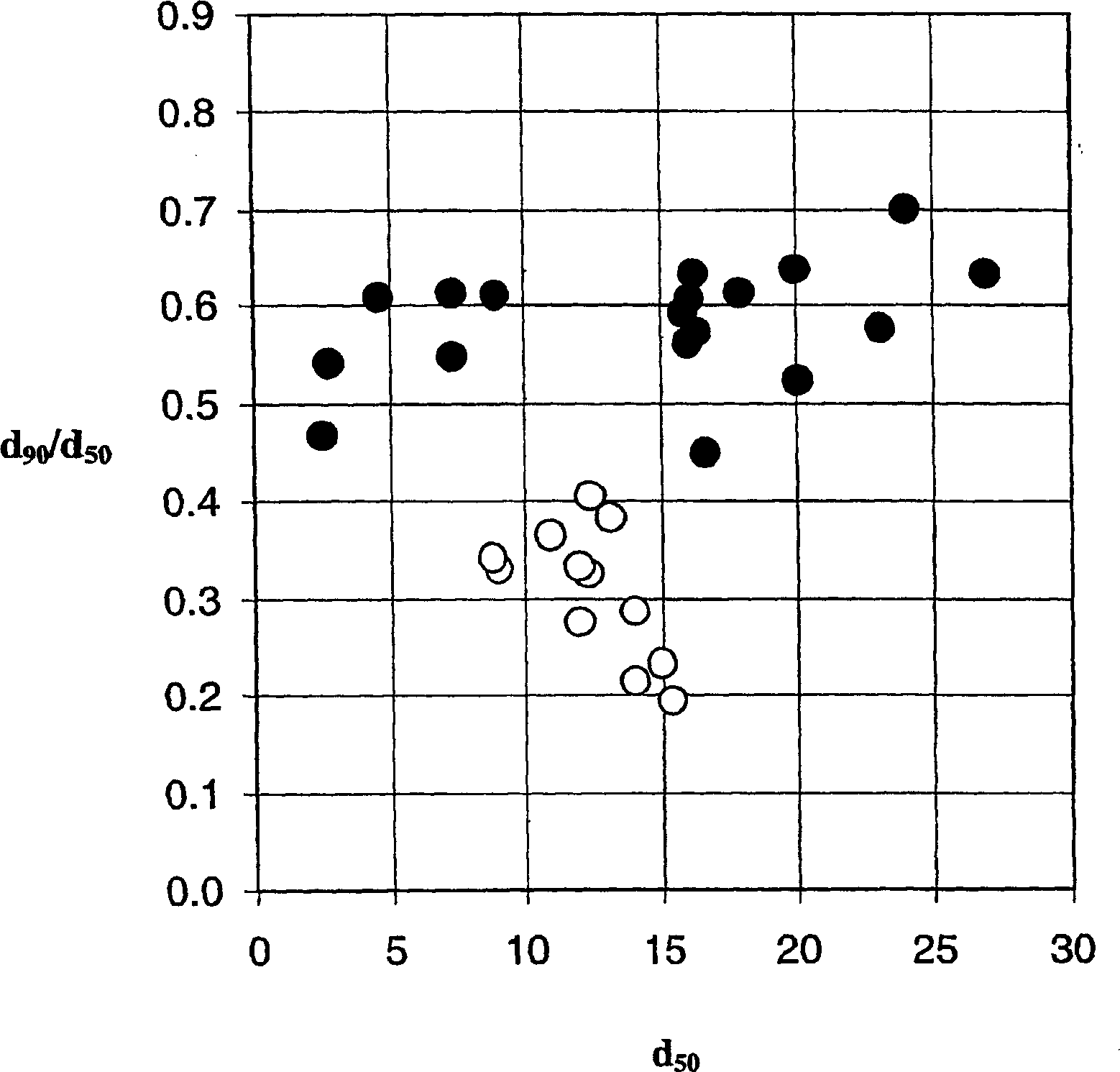

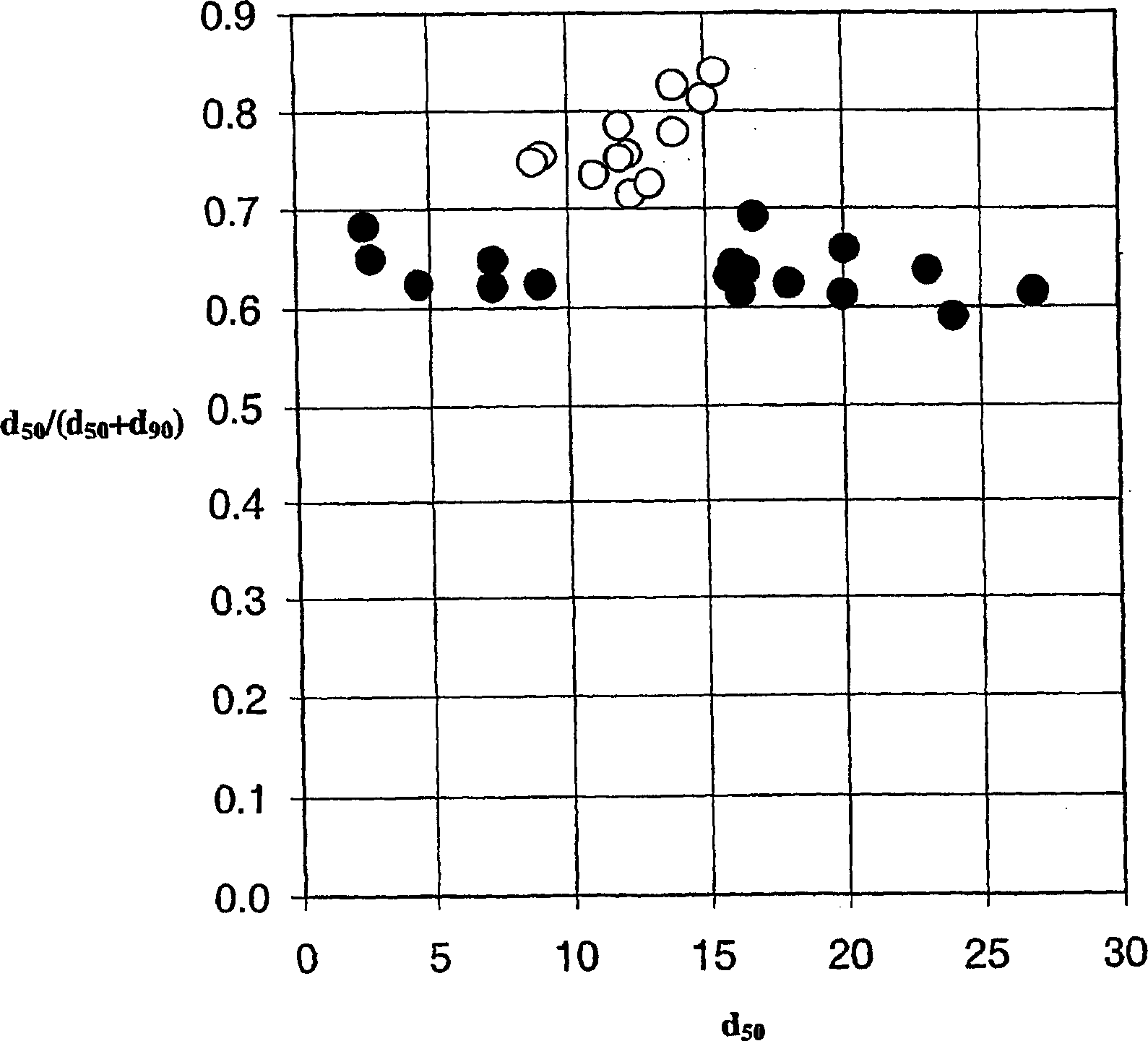

A ceramic filter for trapping and combusting diesel exhaust particulates composed of an end-plugged cordierite honeycomb structure exhibiting a pore size distribution as determined by mercury porosimetry in which the quantity d50 / (d50+d90) as related to pore size distribution is less than 0.70, a soot loaded permeability factor Sf, as defined by the equation [d50 / (d50+d90)] / [% porosity / 100], of less than 1.55, and, a coefficient of thermal expansion (25–800° C.) of no greater than 17×10−7 / ° C. The ceramic filter further exhibits a median pore diameter, d50, of at least 4 micrometers and up to 40 micrometers. A method of making the filter is provided.

Owner:CORNING INC

Diesel exhaust article and catalyst compositions therefor

A self-cleaning diesel exhaust particulate filter system is disclosed wherein burn-off of collected particulate matter is accomplished at normal exhaust gas temperatures, the filter system being provided with a catalyst mixture of a co-formed ceria-zirconia composite and, optionally, a base metal oxide, the presence of which allows regeneration of filters at temperatures that are readily achieved in diesel exhaust systems, including operating conditions that are at low load where lower exhaust temperatures exist.

Owner:BASF CATALYSTS LLC

Diesel exhaust article and catalyst compositions therefor

A self-cleaning diesel exhaust particulate filter system is disclosed wherein burn-off of collected particulate matter is accomplished at normal exhaust gas temperatures, the filter system being provided with a catalyst mixture of a co-formed ceria-zirconia composite and, optionally, a base metal oxide, the presence of which allows regeneration of filters at temperatures that are readily achieved in diesel exhaust systems, including operating conditions that are at low load where lower exhaust temperatures exist.

Owner:BASF CATALYSTS LLC

Oxygen-donor and catalytic coatings of metal oxides and metals

InactiveUS20070015002A1Reducing fuel penaltyReducing the fuel penaltyDispersed particle separationCatalyst activation/preparationCoated surfaceCarbonization

A method to fabricate thin, penetrating coatings of metal oxides with oxygen storage capability is disclosed. The application of these coating in diesel exhaust particulate oxidation, carbonization prevention in ethylene cracking pipes etc. is also disclosed. In this method, the use of thin, penetrating coatings of catalytic metals decreases the oxidation temperature of carbon in contact with or near the coated surfaces. Finally, the invention describes a method to prepare a better bonding surface for laying down catalysts through traditional calcification slurry methods, by pre-coating the surface with a thin, penetrating coating of metal oxide.

Owner:C 3 INTL +1

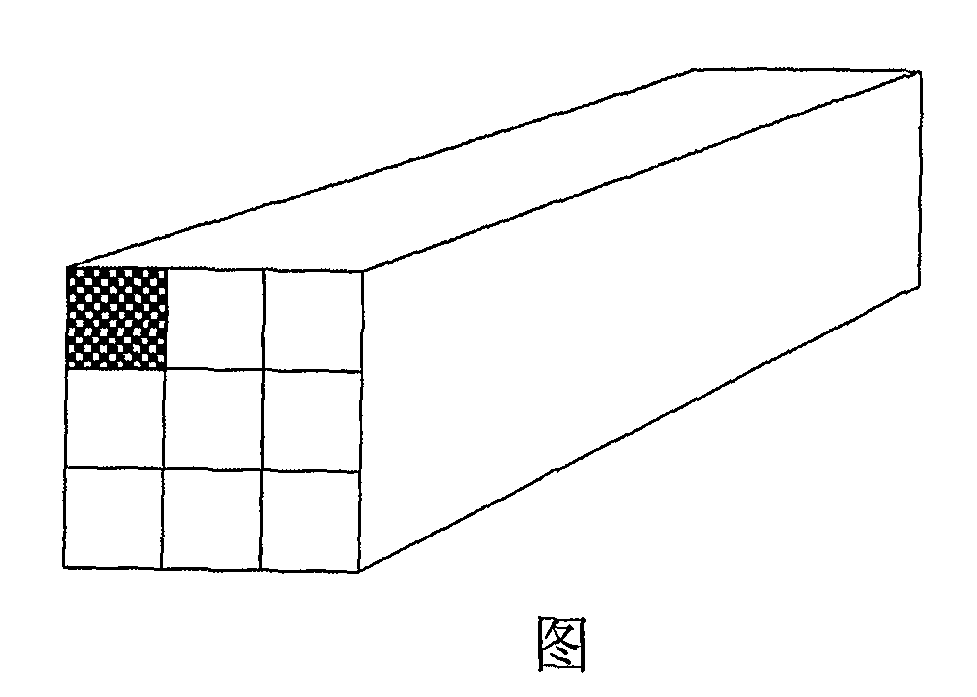

Honeycomb Ceramic Particulate Filtration Substrate, a Particulate Filter and a Filtration System as Well as Production Methods Thereof

ActiveUS20080236123A1Easy to sinterKeep a certain refractoryCeramic shaping apparatusLoose filtering material filtersPorosityParticulates

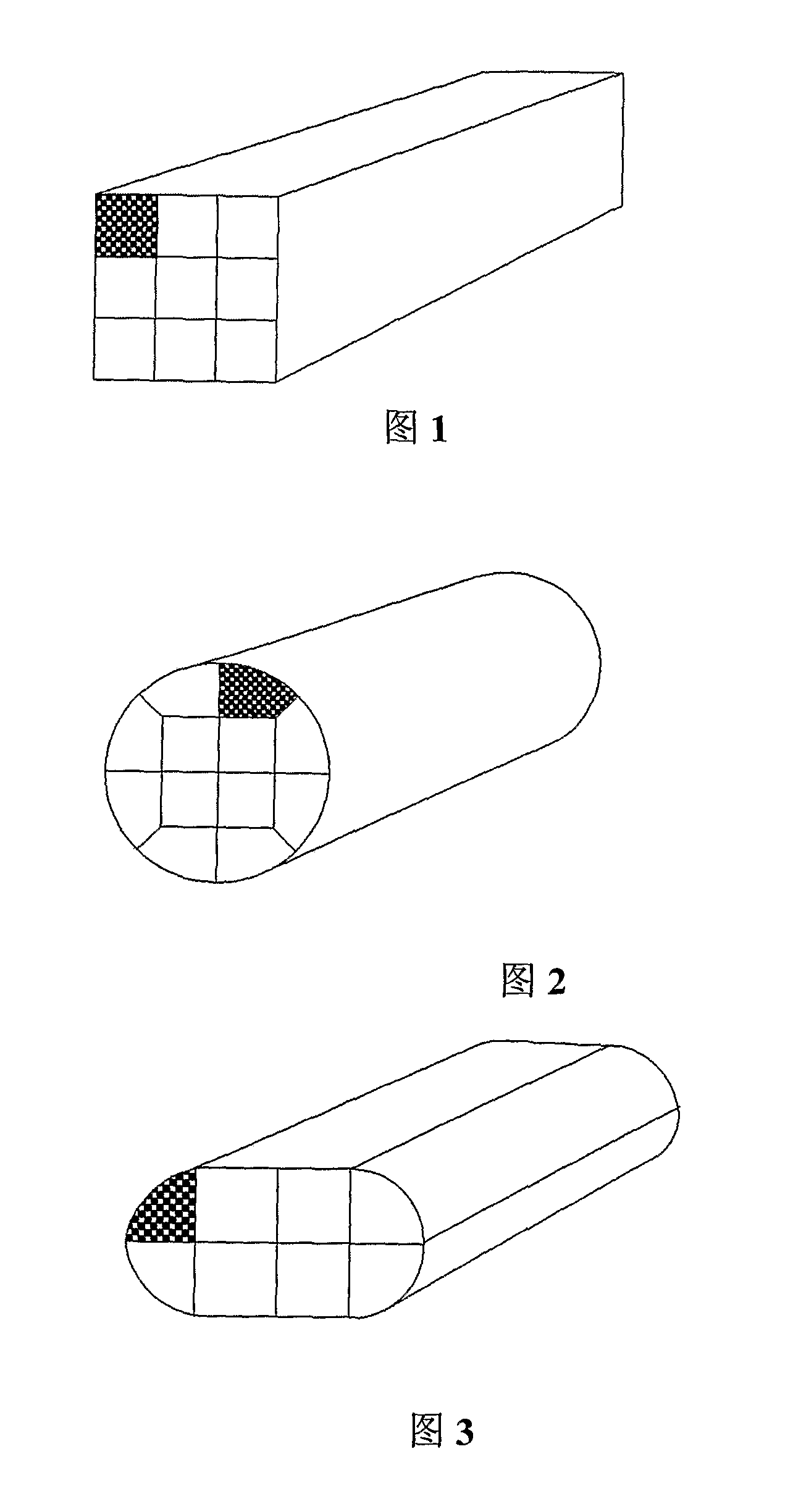

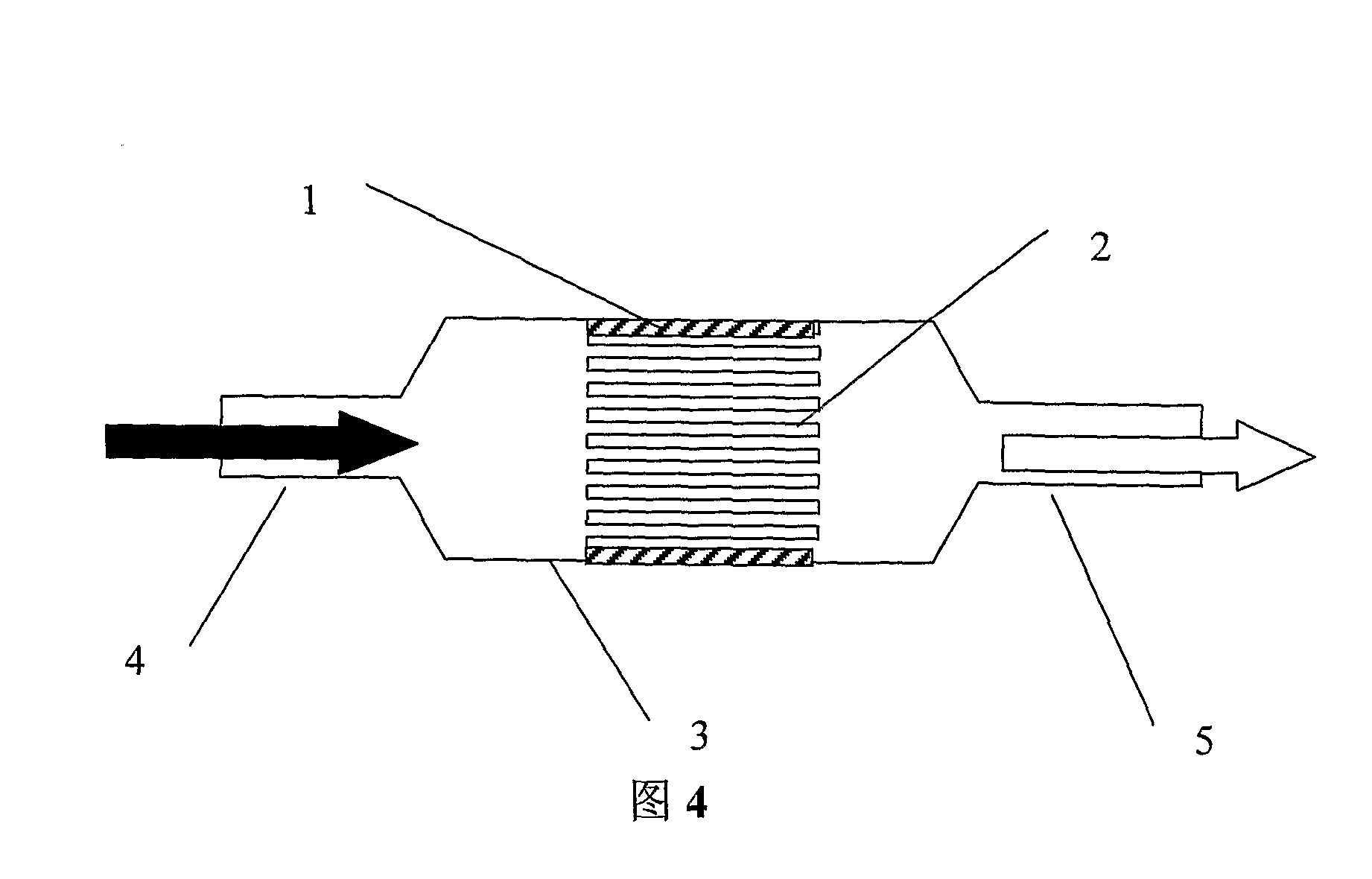

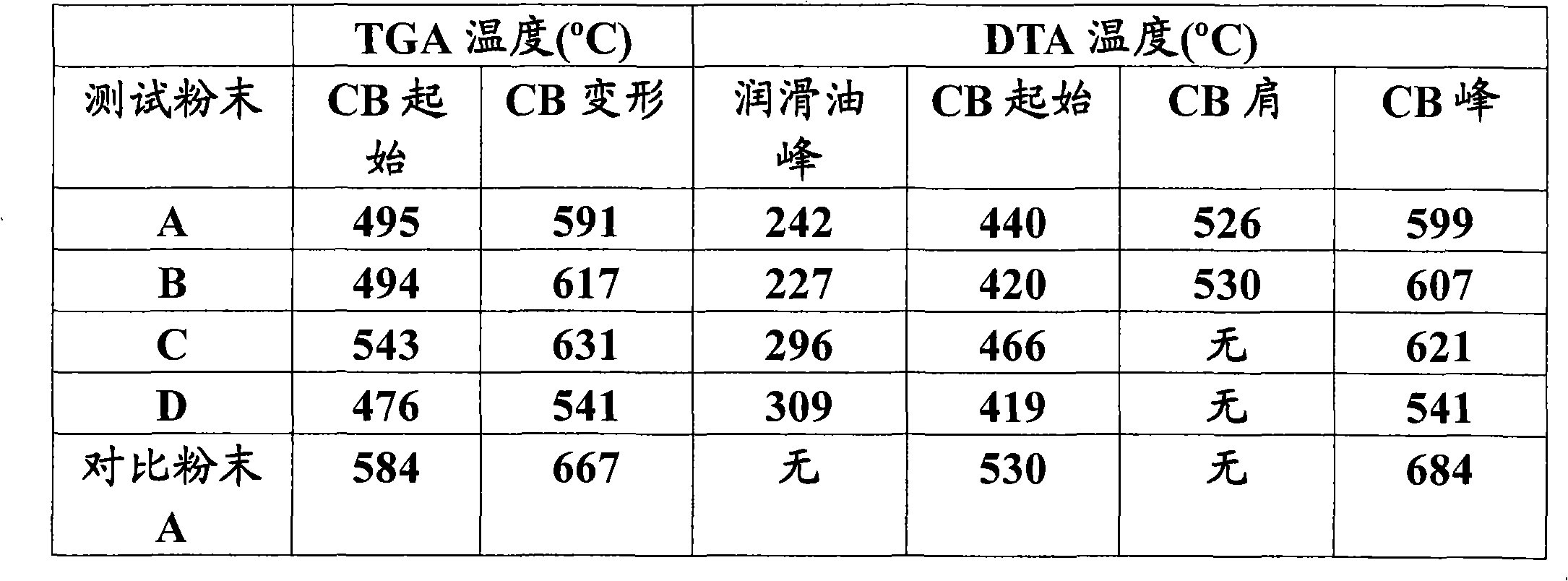

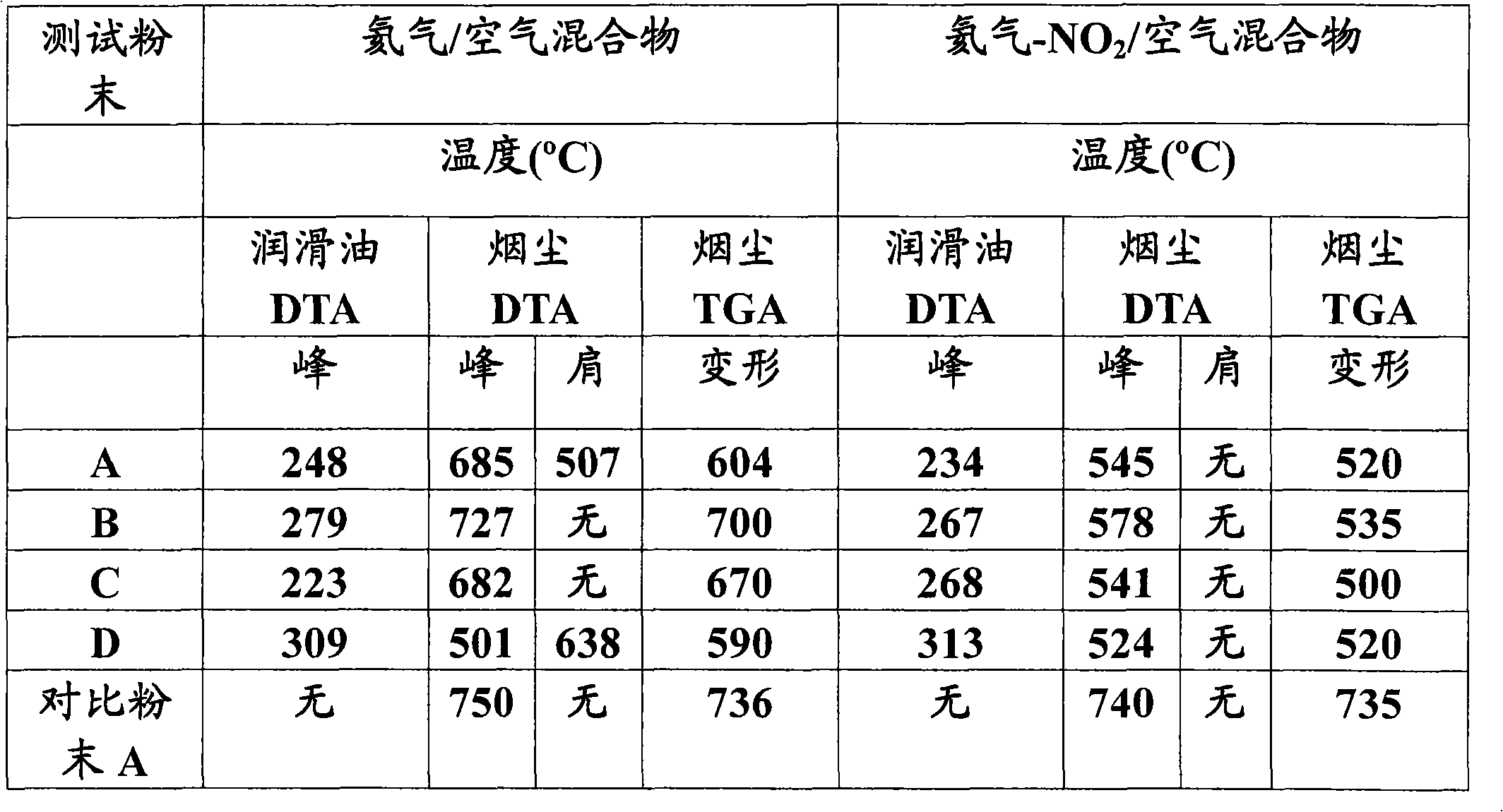

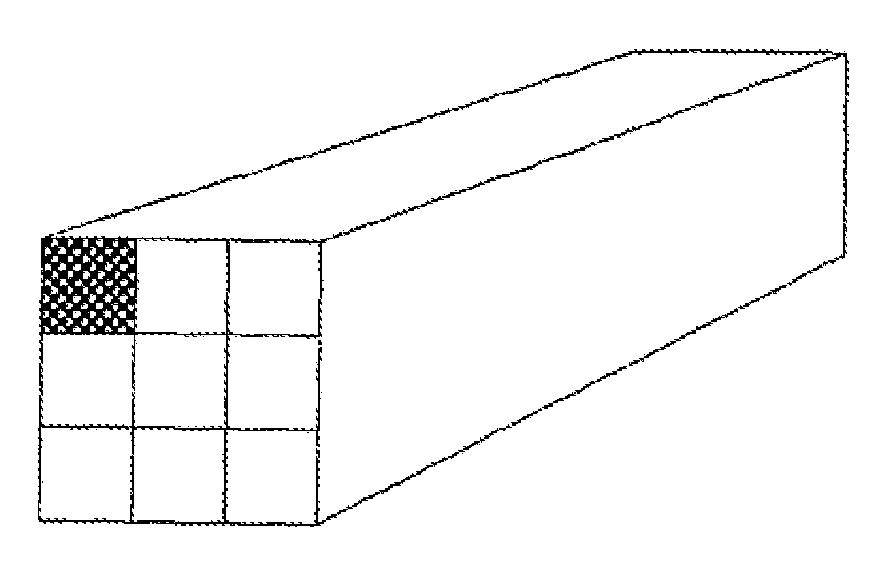

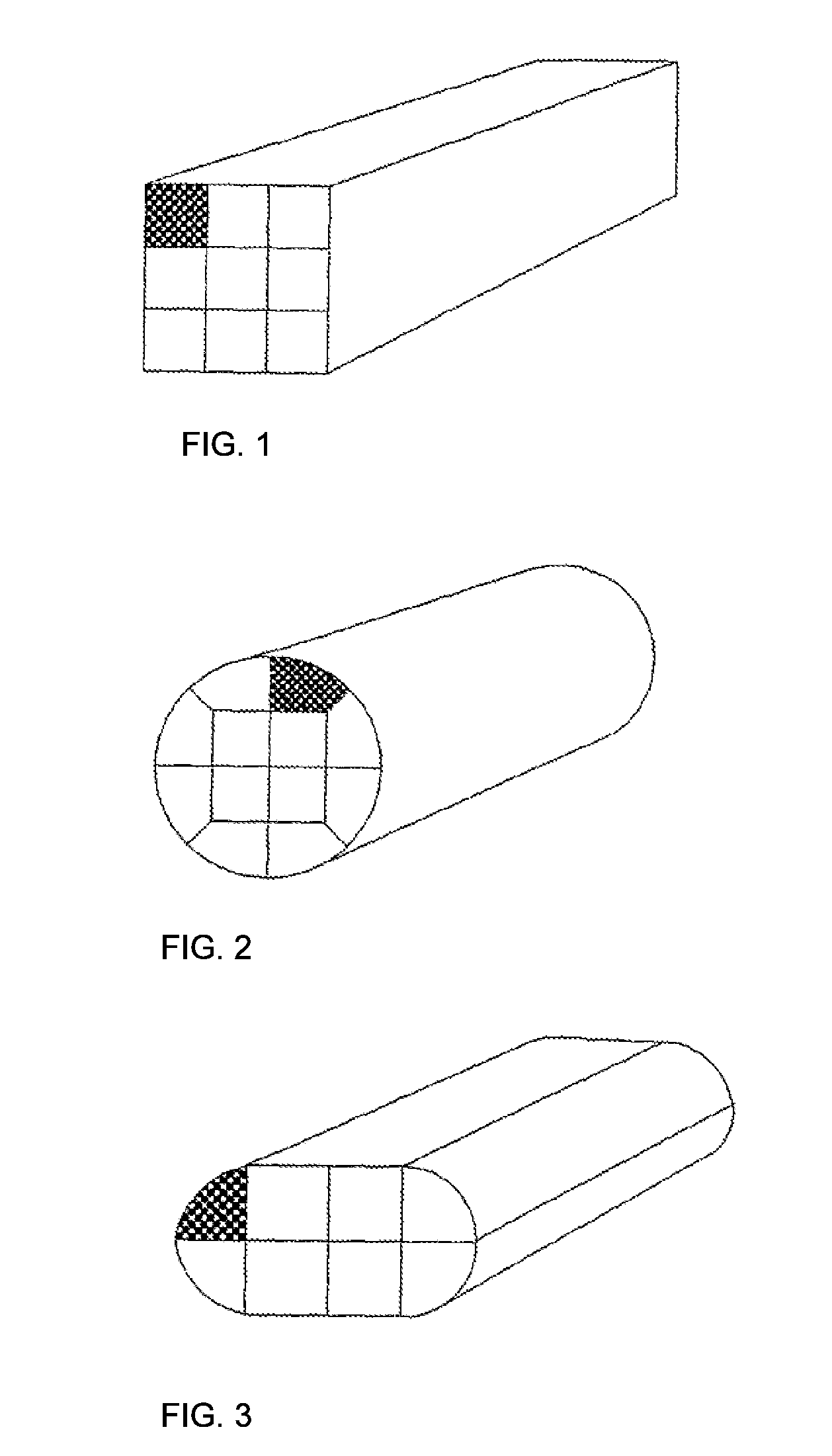

A honeycomb ceramic filtration substrate, a filter made of the said substrate and a filter system made of the said filter and their production methods are published in the present invention. The said substrates are extruded with a paste comprising (by portion): SiC: 1; Clay: 0.05-0.5; Flour: 0.1-0.35; grease: 0.025-0.05; Water: 0.2-0.35. The said sintered substrate has a honeycomb structure with cells density ranging from 4˜62 cells / cm2; The cell wall thickness is: 0.2-1.2 mm; The porosity of the cell wall: 40-70%. The cell wall through pore rate is more than 30%; The average diameter distribution of the cell wall micro-pores is in the ranging of 1-50 μm. The said substrate can be designed in different cylinders whose cross section are in form of square, one border curved square and one border curved triangle etc., After adhering the substrates, the filter can be used as vehicle particulates filter. After the canning of the filter, the filter system is produced. The problem of particulates pollutant from the vehicles can be resolved via the present invention, and it is especially efficient to treat the diesel exhaust particulates which are harmful to the human health.

Owner:YUNNAN FILTER ENVIRONMENT PROTECTION S &T

Diesel exhaust article and catalyst compositions therefor

InactiveCN101287550AImprove oxidation efficiencyDispersed particle separationSilencing apparatusParticulatesLow load

A self-cleaning diesel exhaust particulate filter system is disclosed wherein burn-off of collected particulate matter is accomplished at normal exhaust gas temperatures, the filter system being provided with a catalyst mixture of a co-formed ceria-zirconia composite and, optionally, a base metal oxide, the presence of which allows regeneration of filters at temperatures that are readily achieved in diesel exhaust systems, including operating conditions that are at low load where lower exhaust temperatures exist.

Owner:BASF CATALYSTS LLC

Strontium feldspar aluminum titanate for high temperature applications

InactiveCN1642872ARelieve pressureInternal combustion piston enginesDispersed particle filtrationThermal expansionDiesel Exhaust Particulate

Owner:CORNING INC

Magnesium aluminum silicate structures for DPF applications

InactiveCN1674972ARelieve pressureIncrease resistanceInternal combustion piston enginesOther chemical processesThermal dilatationParticulates

A ceramic filter for trapping and combusting diesel exhaust particulates composed of an end-plugged cordierite honeycomb structure exhibiting a pore size distribution as determined by mercury porosimetry in which the quantity d50 / (d50+d90) as related to pore size distribution is less than 0.70, a soot loaded permeability factor Sf, as defined by the equation [d50 / (d50+d90)] / [% porosity / 100], of less than 1.55, and, a coefficient of thermal expansion (25-800° C.) of no greater than 17x10-7 / ° C. The ceramic filter further exhibits a median pore diameter, d50, of at least 4 micrometers and up to 40 micrometers. A method of making the filter is provided.

Owner:CORNING INC

Honeycomb ceramic particulate filtration substrate, a particulate filter and a filtration system as well as production methods thereof

ActiveUS8114184B2Easy to sinterKeep a certain refractoryDispersed particle filtrationCeramic shaping apparatusPorosityParticulates

A honeycomb ceramic filtration substrate, a filter made of the said substrate and a filter system made of the said filter and their production methods are published in the present invention. The said substrates are extruded with a paste comprising (by portion): SiC: 1; Clay: 0.05-0.5; Flour: 0.1-0.35; grease: 0.025-0.05; Water: 0.2-0.35. The said sintered substrate has a honeycomb structure with cells density ranging from 4˜62 cells / cm2; The cell wall thickness is: 0.2-1.2 mm; The porosity of the cell wall: 40-70%. The cell wall through pore rate is more than 30%; The average diameter distribution of the cell wall micro-pores is in the ranging of 1-50 μm. The said substrate can be designed in different cylinders whose cross section are in form of square, one border curved square and one border curved triangle etc., After adhering the substrates, the filter can be used as vehicle particulates filter. After the canning of the filter, the filter system is produced. The problem of particulates pollutant from the vehicles can be resolved via the present invention, and it is especially efficient to treat the diesel exhaust particulates which are harmful to the human health.

Owner:YUNNAN FILTER ENVIRONMENT PROTECTION S &T

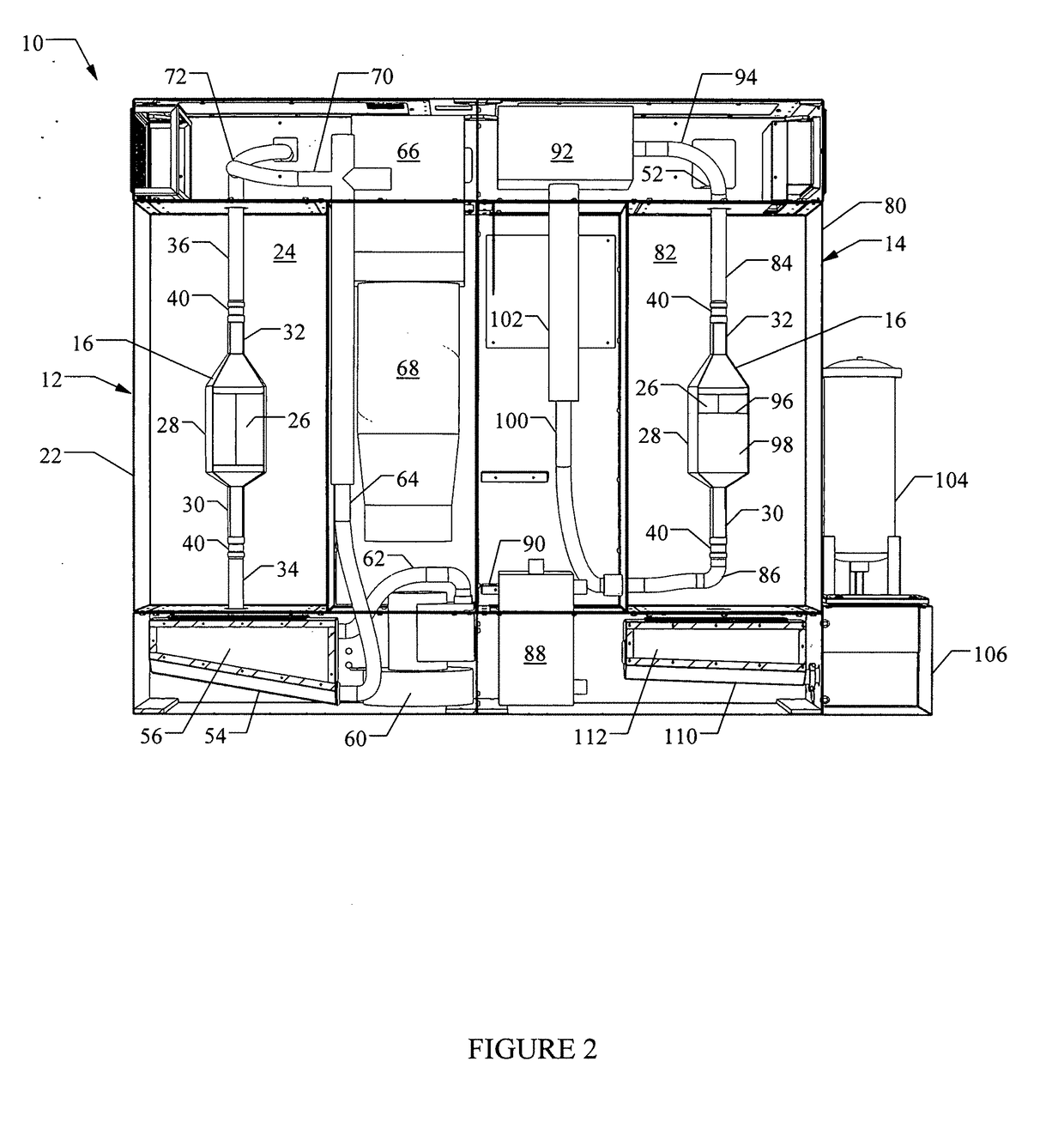

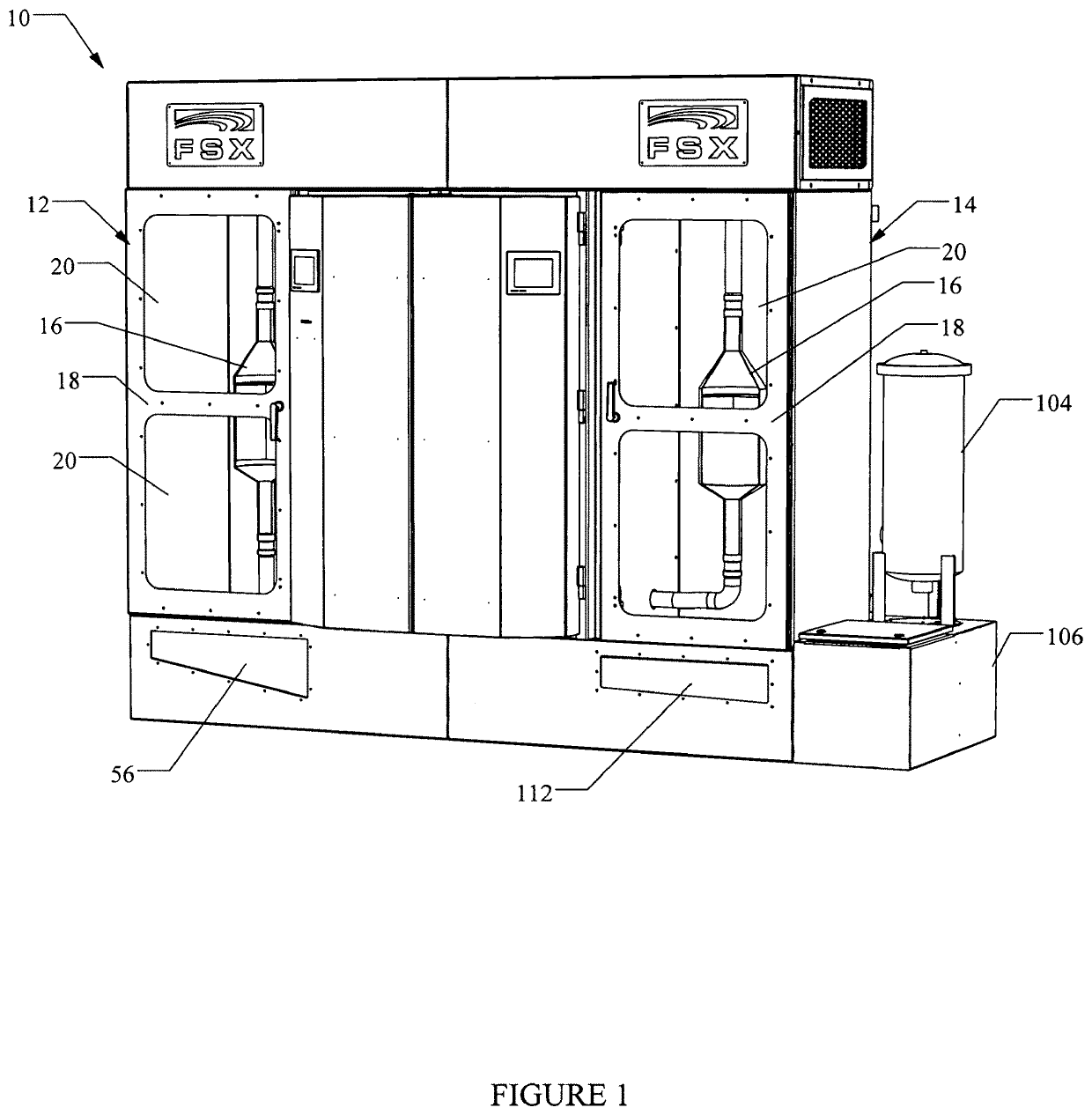

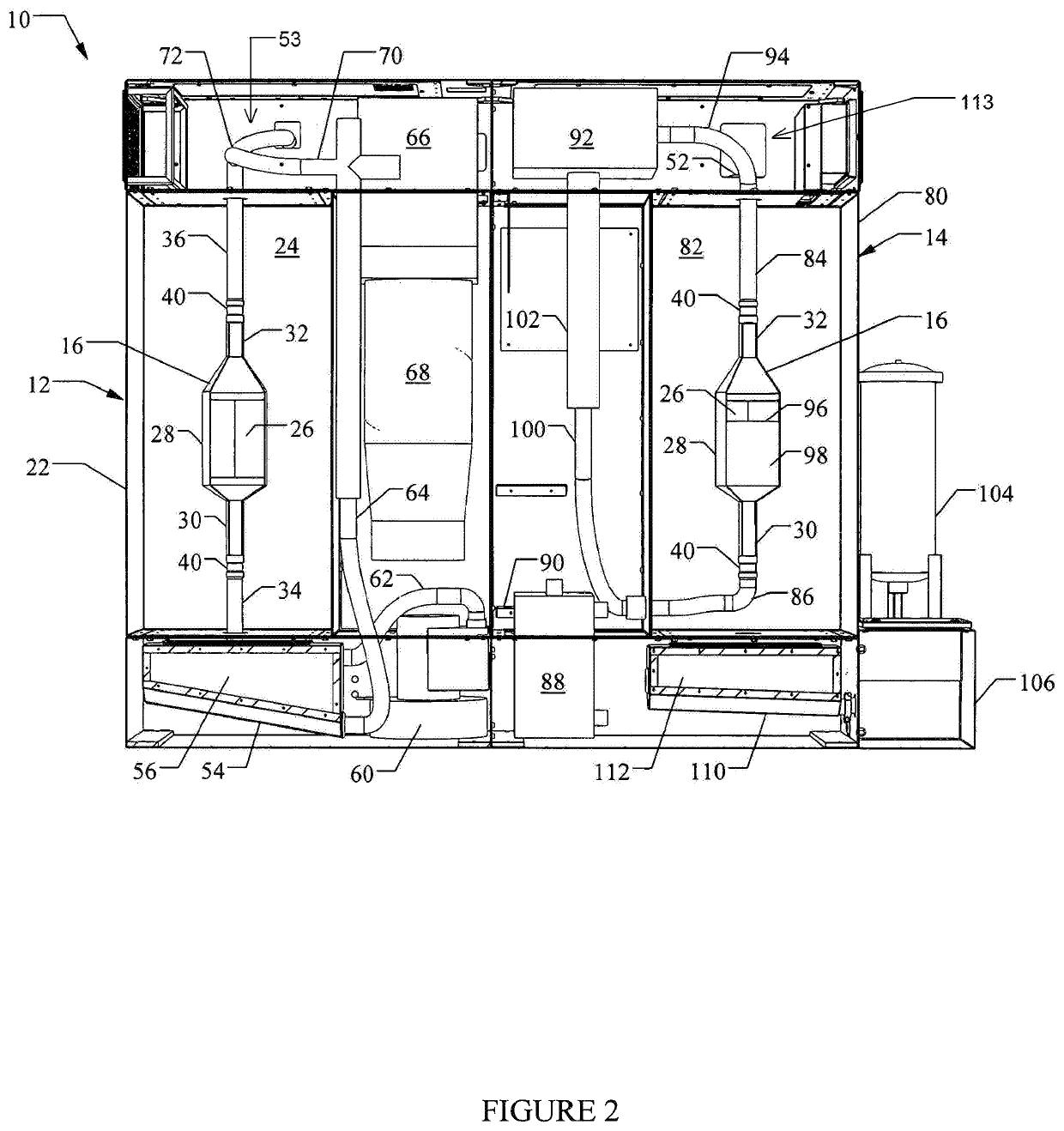

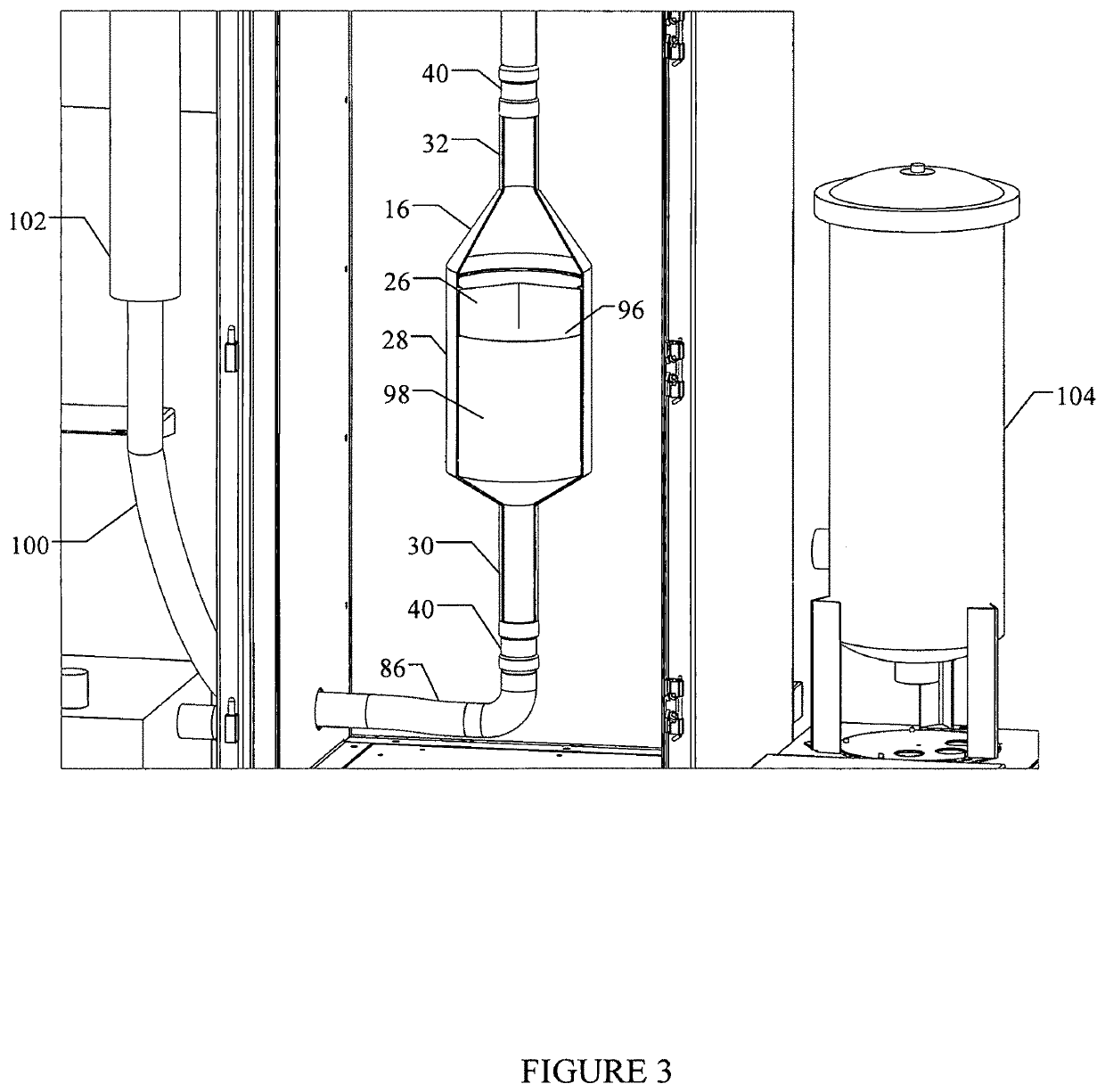

Diesel exhaust particulate collectors

ActiveUS20170211440A1Easy to cleanExhaust apparatusCombustion enginesExhaust fumesDiesel Exhaust Particulate

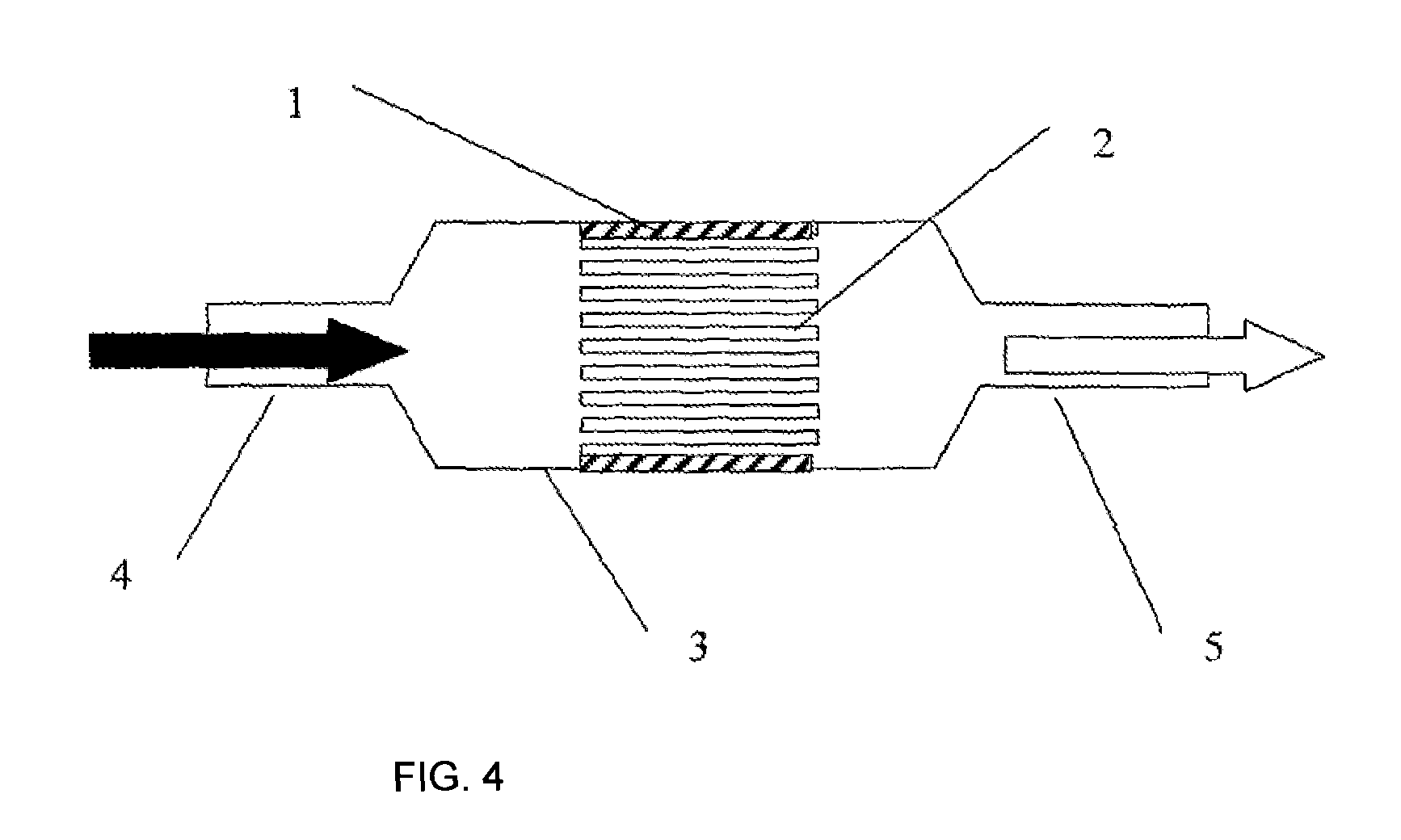

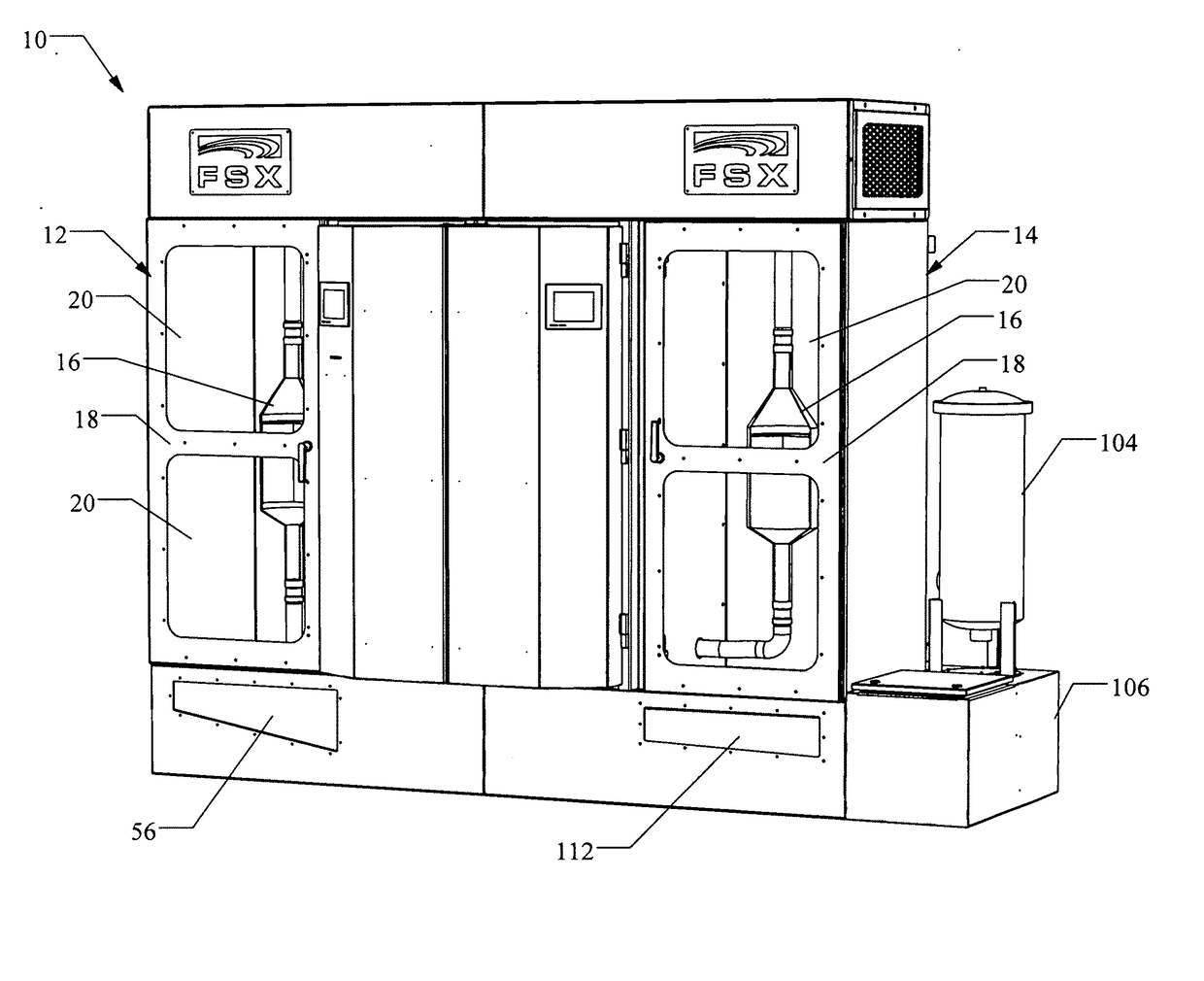

An apparatus and method for cleaning ash / soot and other particulates from diesel particulate filters (DPF), including diesel oxidative catalysts (DOC) and similar exhaust components. Section for dry and wet cleaning include conduits that connect to the filters. For dry cleaning, a filter is mounted clean side up and air pressure is applied in opposite directions so that the particulate is dislodged and falls out. For wet cleaning, the filter is floated with a slug of liquid cleaning solution which is surged back-and-forth through the filter to dislodge and remove the particulate. The dry and wet cleaning sections may be combined or collocated, or may be located separately or used one without the other.

Owner:FSX EQUIP

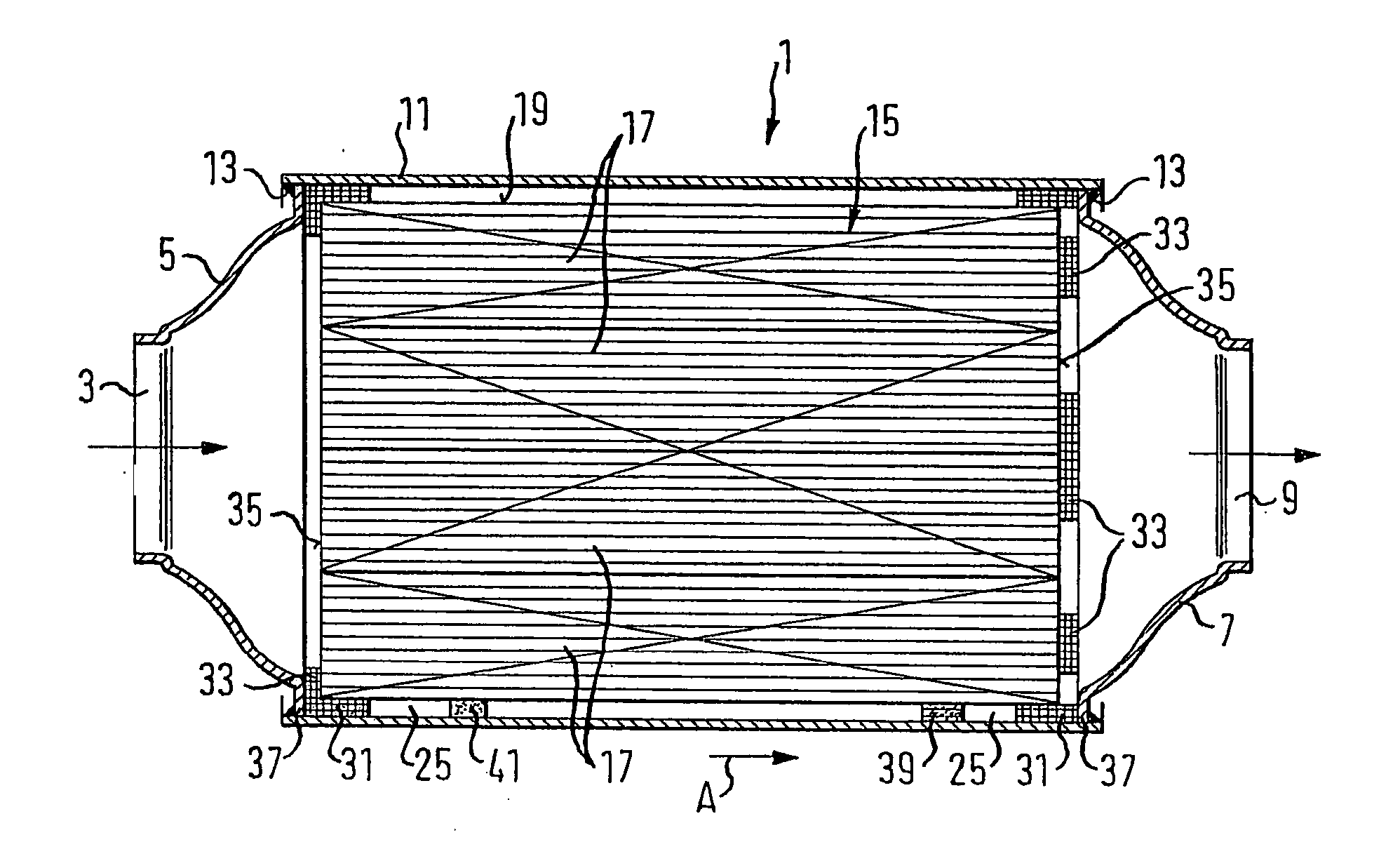

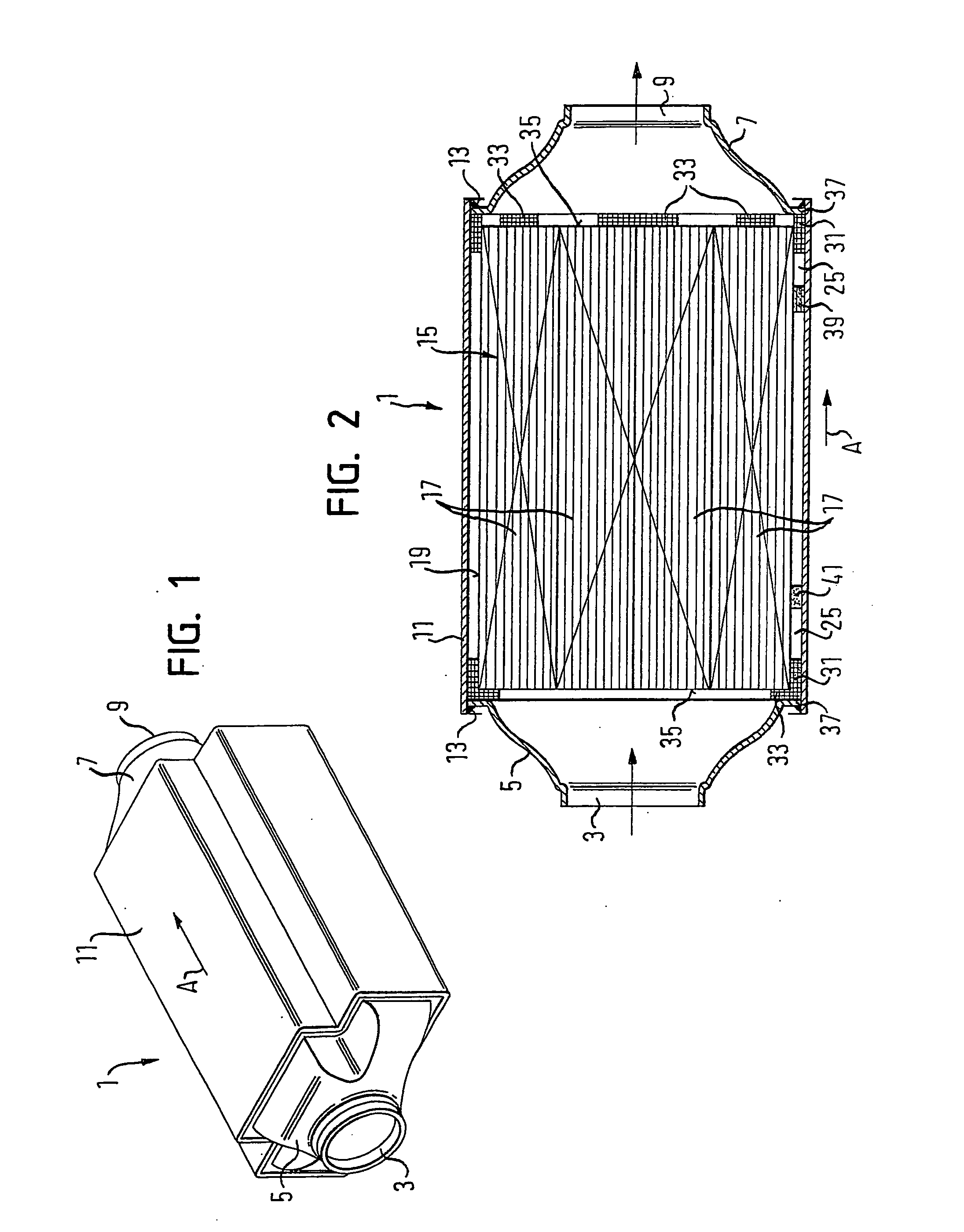

Device for cleaning vehicle exhaust gas

InactiveUS20050183408A1Reduce the numberEvenly distributedInternal combustion piston enginesDispersed particle filtrationParticulatesExhaust fumes

A device for cleaning vehicle exhaust gas, especially a filter for diesel exhaust particulates or a catalytic converter, comprises a filter body including a plurality of individual cuboid bodies through which gas flows. The filter body has, at least in sections, an angular outer contour, as seen in a main direction of flow. The filter body also has an unmachined outer surface at the angular outer contour.

Owner:ET US HLDG

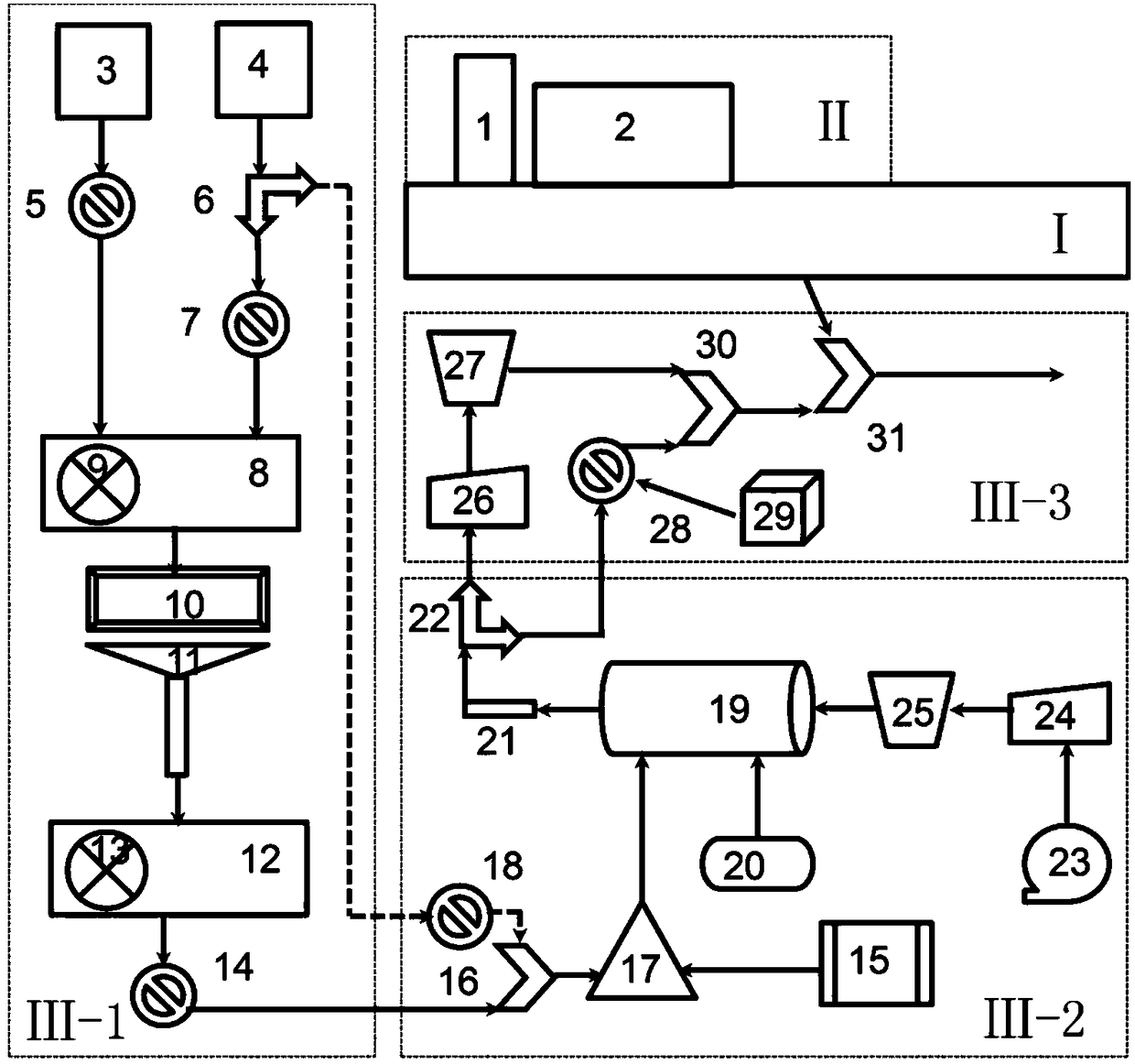

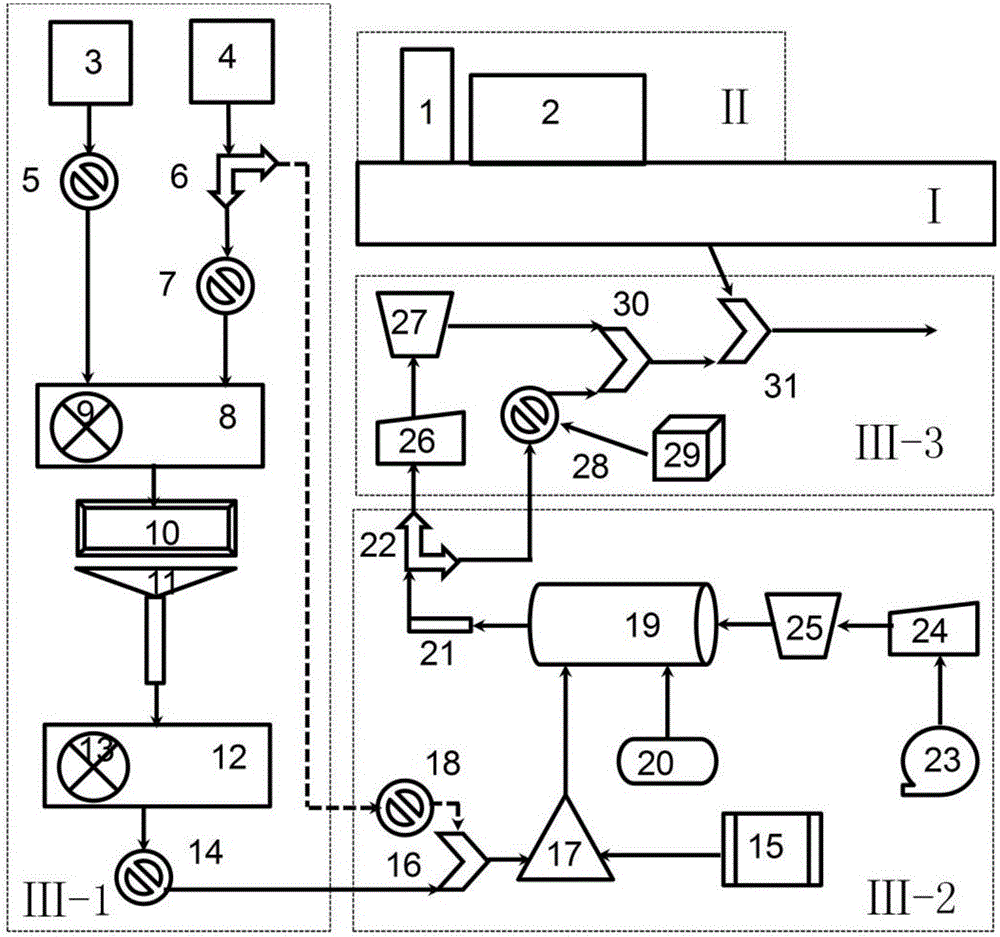

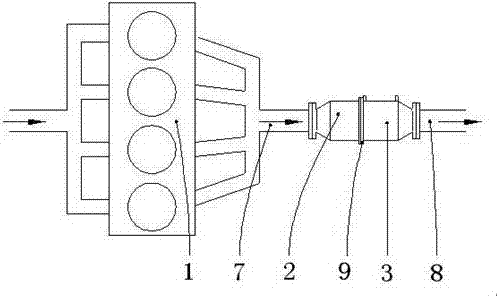

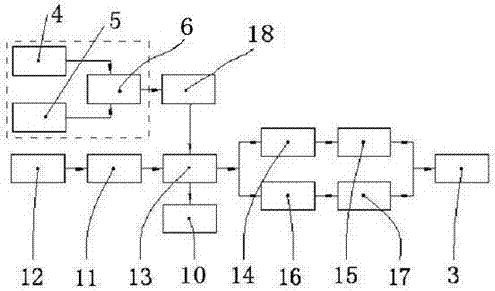

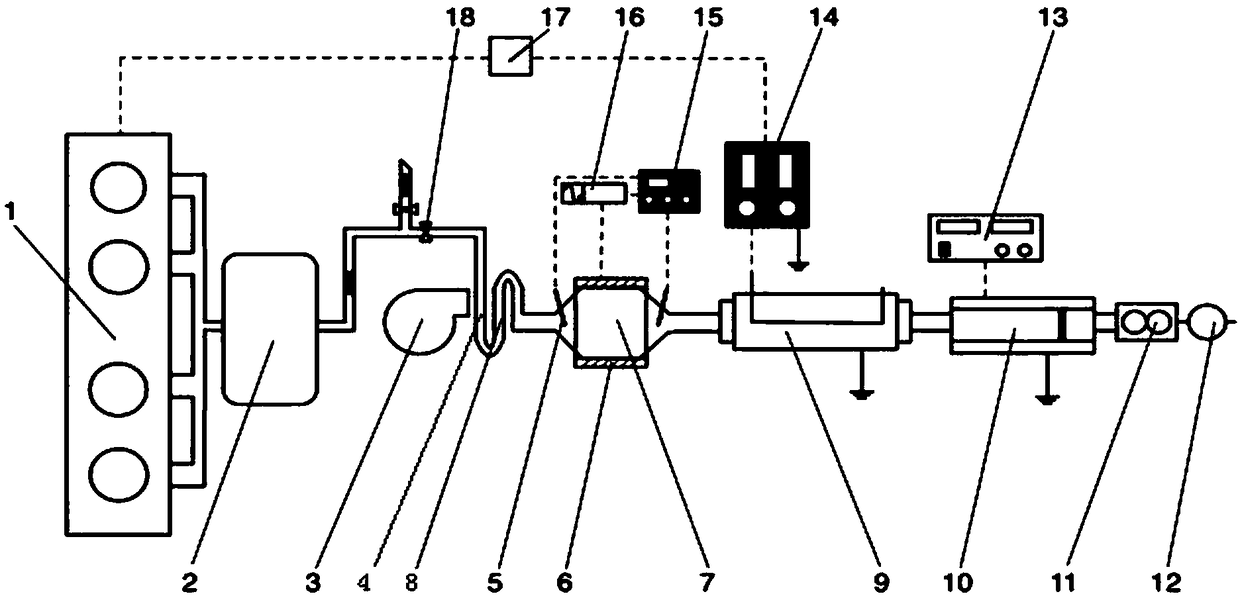

A mixed aerosol generator for simulating diesel engine exhaust particle flow

ActiveCN105833807BStable concentrationWide concentration rangeAerogel preparationColloidal chemistry detailsAir filterDistilled water

The invention discloses a mixed aerosol generating device simulating diesel exhaust particulate flow. A dissolved organic matter generating device is arranged based on a carbon black aerosol generating device, and an ash aerosol generating device has three sections, namely the mixed solution generating section, the mixed solution evaporating section and the ash aerosol dilution and deposition section; in the mixed solution generating section, an ash containing cup, a distilled water containing cup and a mixed solution containing cup are connected, and an outlet of a mixed solution stirrer is connected with a mixed solution filter net, a hopper, a filtered solution containing cup, a filtered solution stirrer, a stirrer valve, an ejector T-joint and a solution ejector in sequence; in the mixed solution evaporating section, the ejector T-joint is connected to the solution ejector, and the solution ejector is connected with a mixing pipe, a heating wire pipe and a heating wire pipe T-joint in sequence; in the ash aerosol dilution and deposition section, the heating wire pipe T-joint is connected with an air filter, a second float flowmeter and one inlet of a dilution section T-joint in sequence. The mixed aerosol generating device is simple in structure, and mixed aerosol generating concentration is controlled in multiple regulating ways so as to better simulate diesel exhaust particulate flow.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

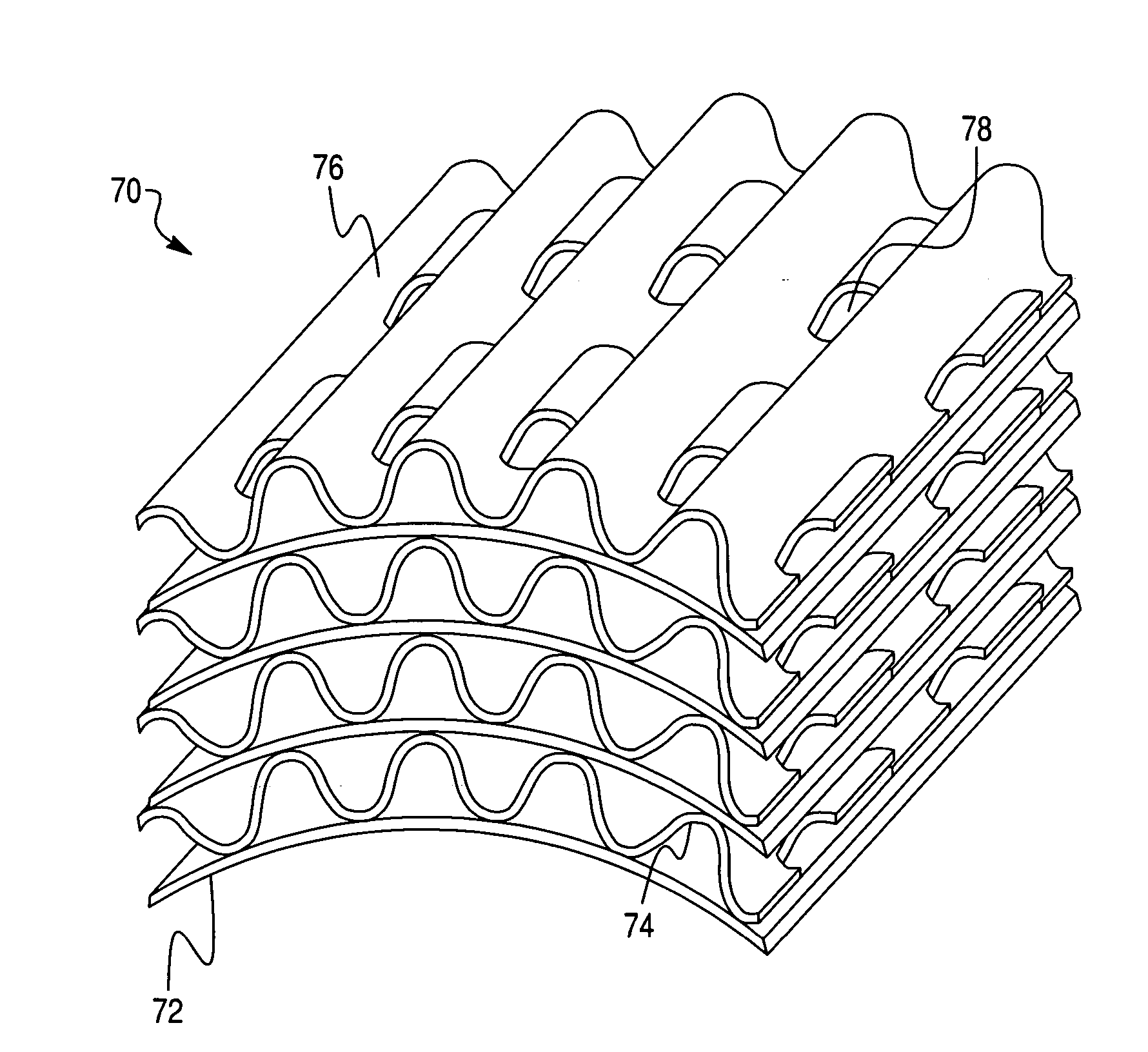

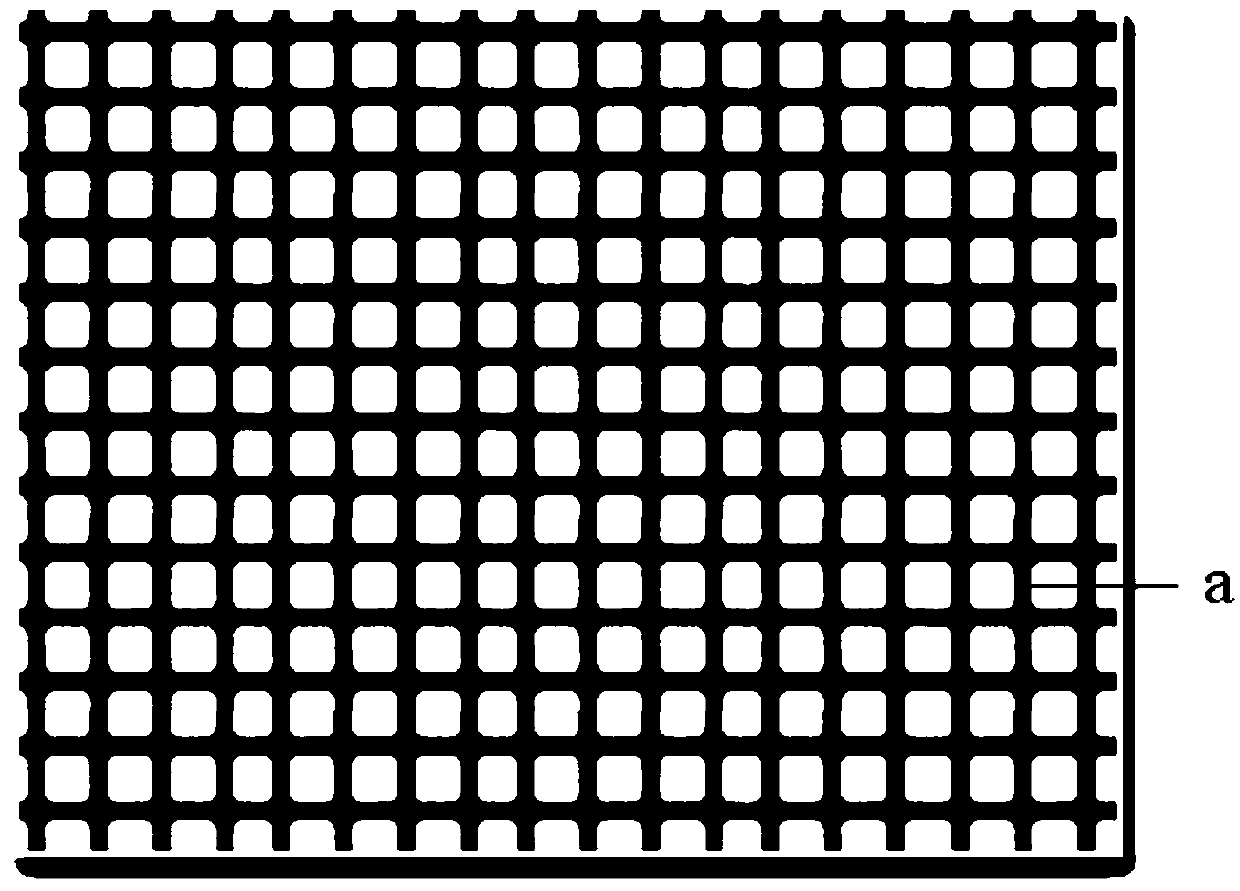

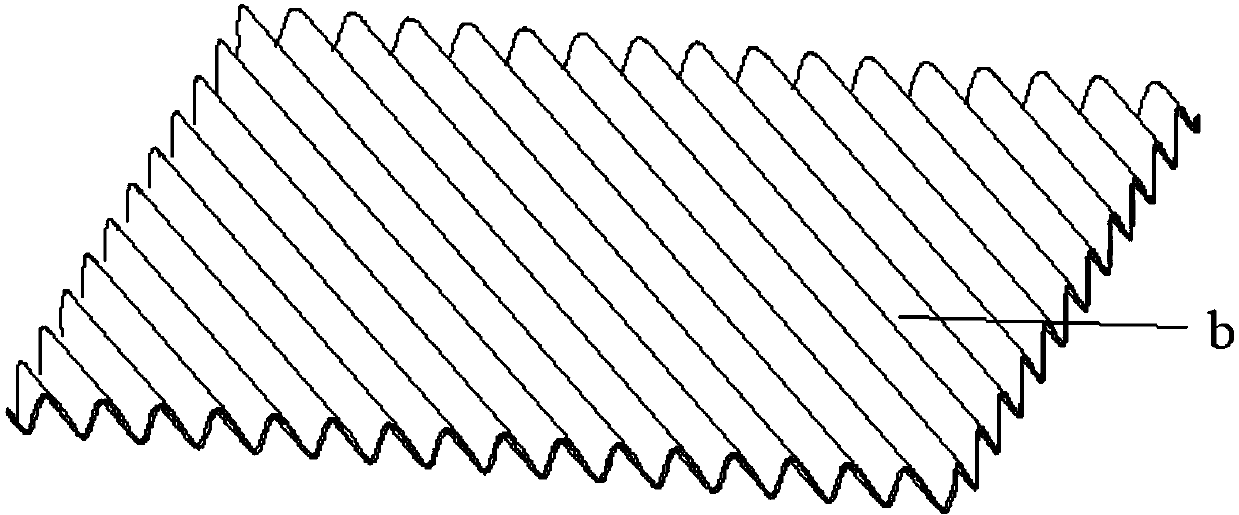

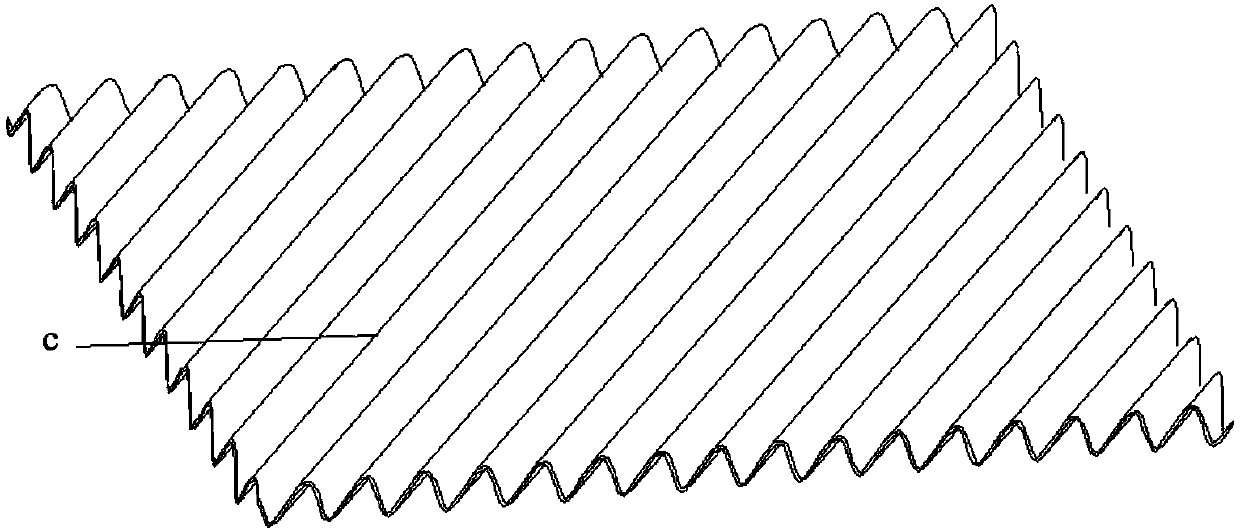

Wire mesh type diesel exhaust particulate filter and production method thereof

InactiveCN103742232AReduce weightReduce back pressureExhaust apparatusSilencing apparatusPtru catalystAir decontamination

The invention relates to a wire mesh type diesel exhaust particulate filter and a production method thereof, and belongs to the technical field of air purification. The wire mesh type diesel exhaust particulate filter comprises a stainless steel barrel, a pin playing a role in fixation and a plurality of layers of interwoven and intertwined stainless steel wire meshes located in the stainless steel barrel, and each stainless steel wire mesh is coated with a catalyst coating. Wavy wire meshes and plain meshes are combined and intertwined differently, so that weight and back pressure of the particulate filter an be reduced effectively; filtration efficiency and back pressure can be regulated by different combining and intertwining modes; complexity of the section of the particulate filter can be ensured by the angle of the wavy meshes, particulate interception effect is better, and filtration efficiency is improved; by the catalyst coatings, temperature of soot particulate regeneration can be reduced effectively, necessary NO2 gas for regeneration is provided, and continuous passive particulate regeneration of the filter is realized.

Owner:WUXI WEIFU LIDA CATALYTIC CONVERTER

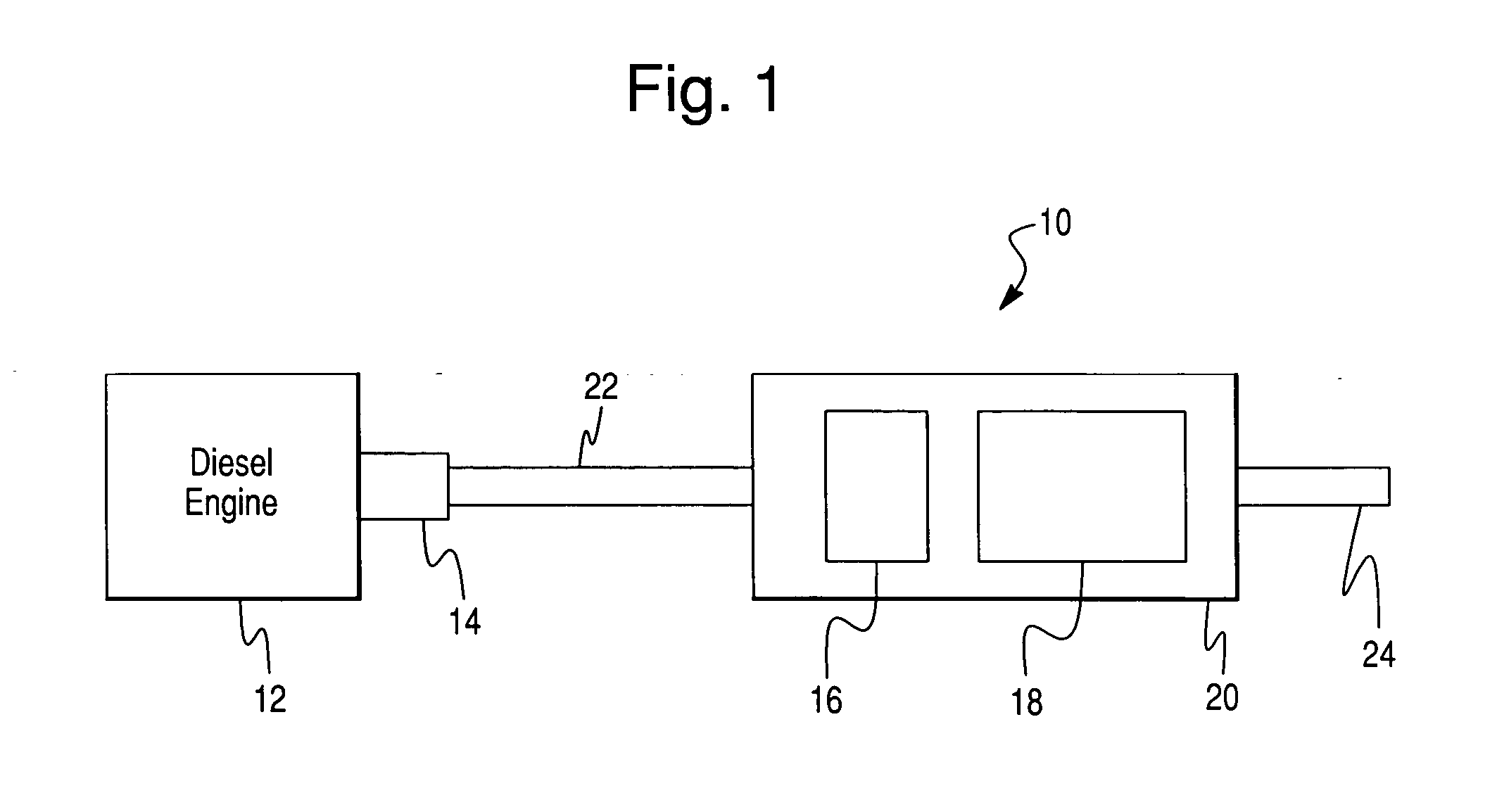

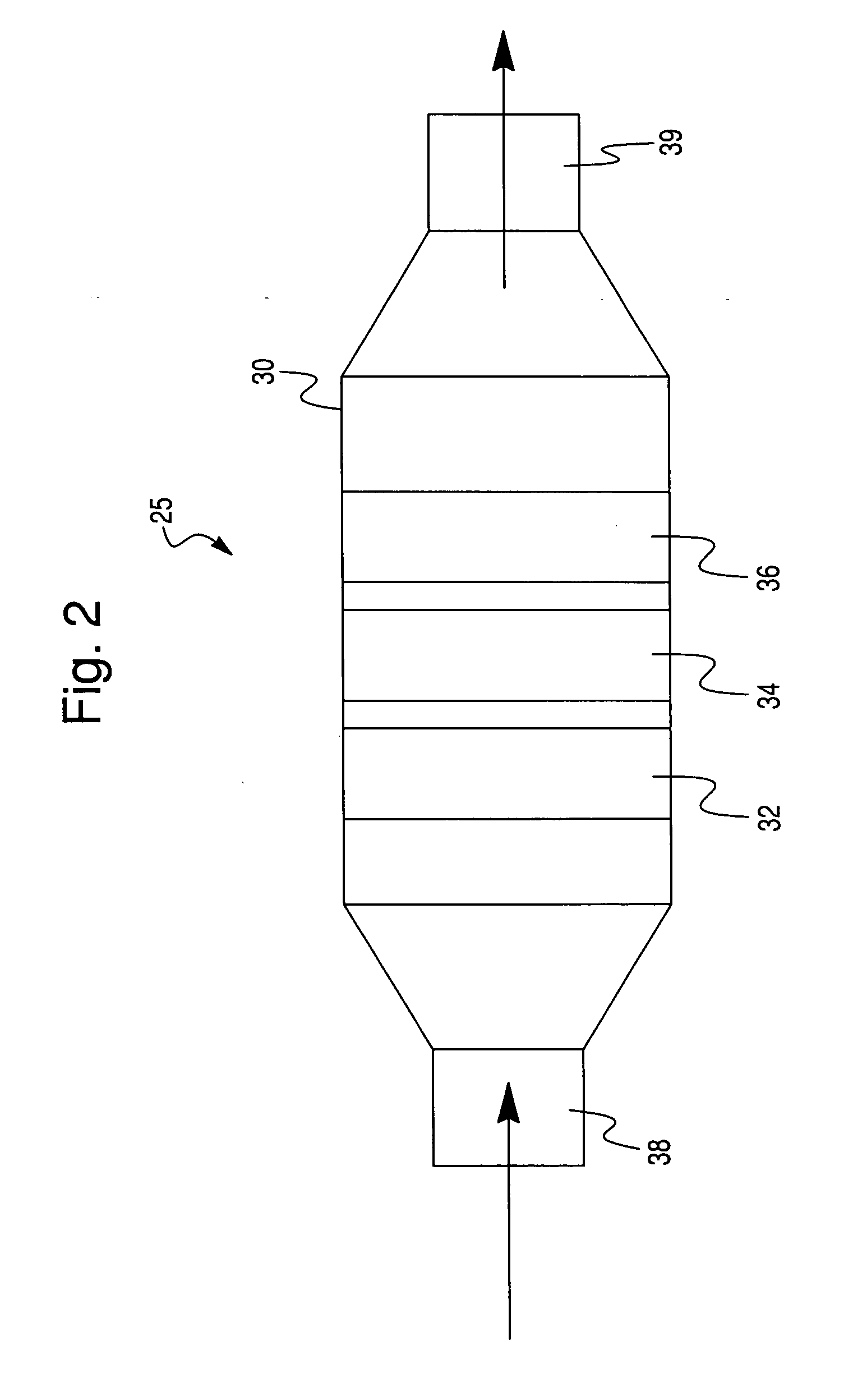

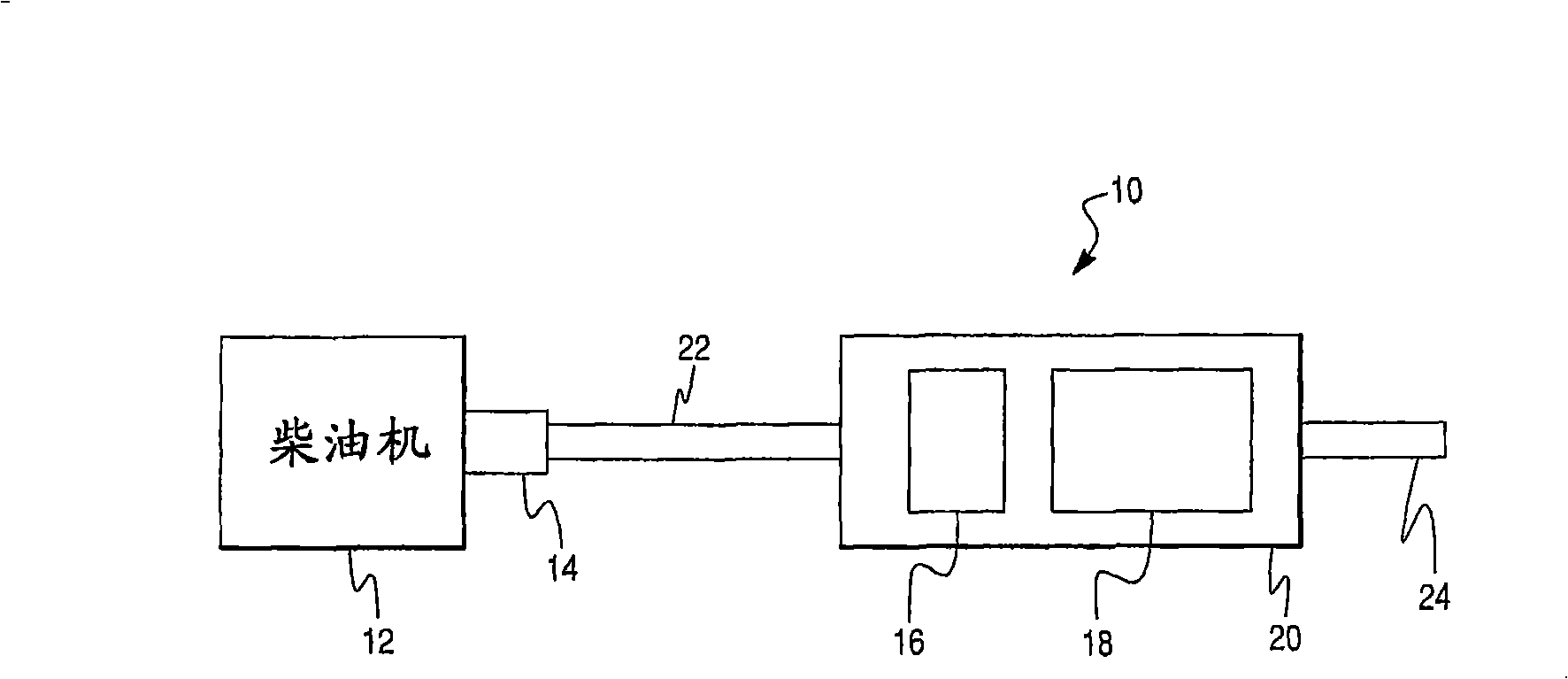

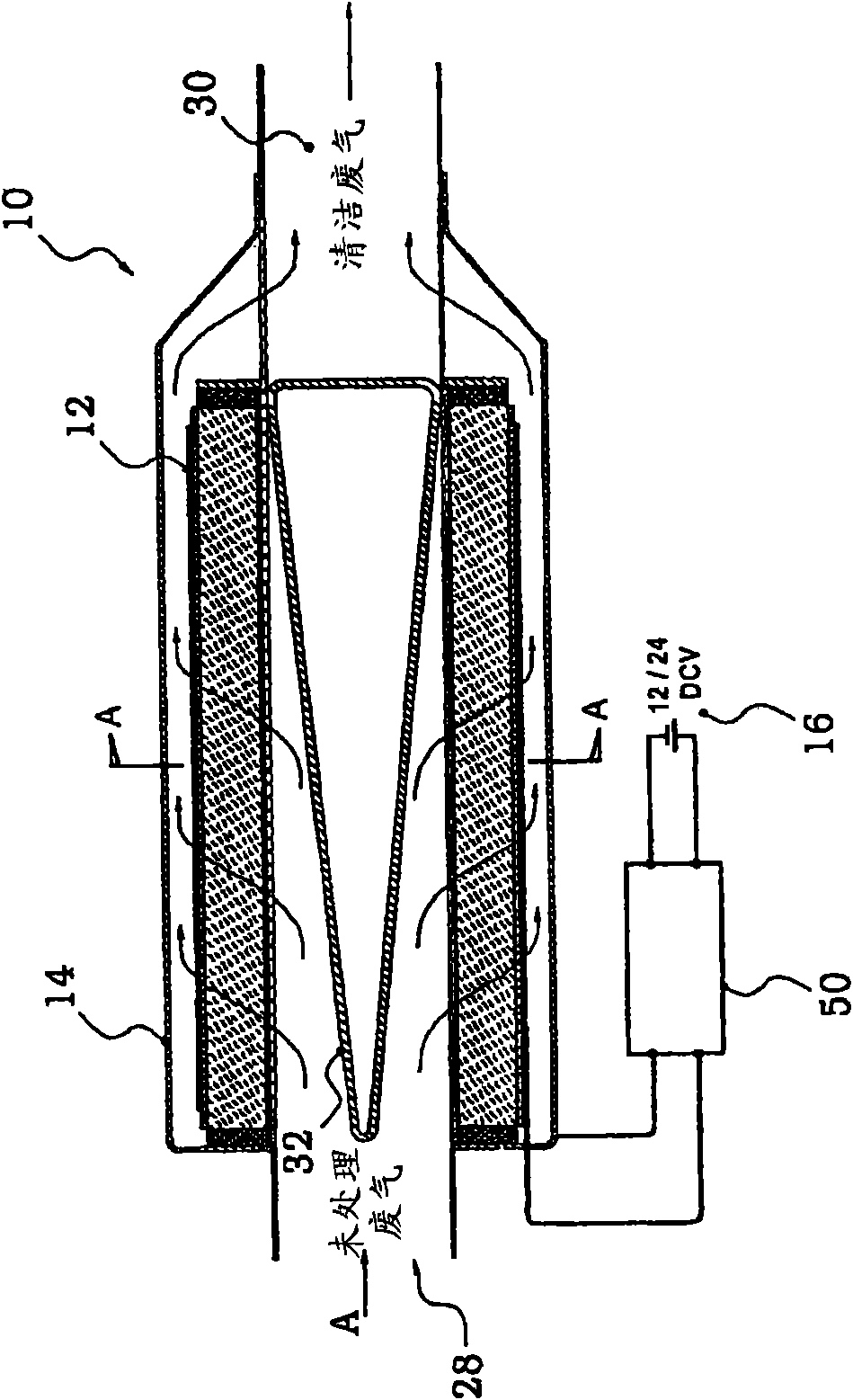

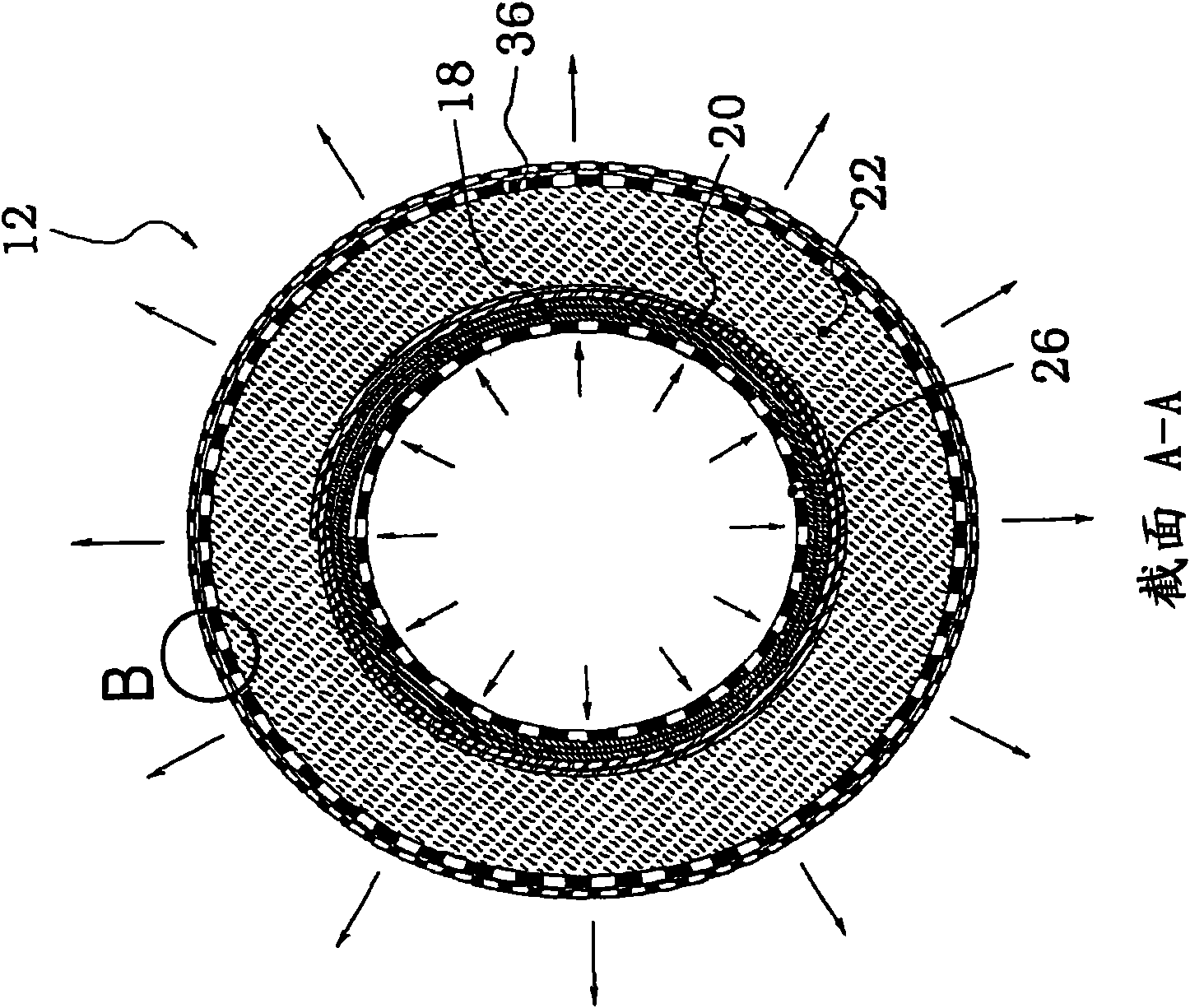

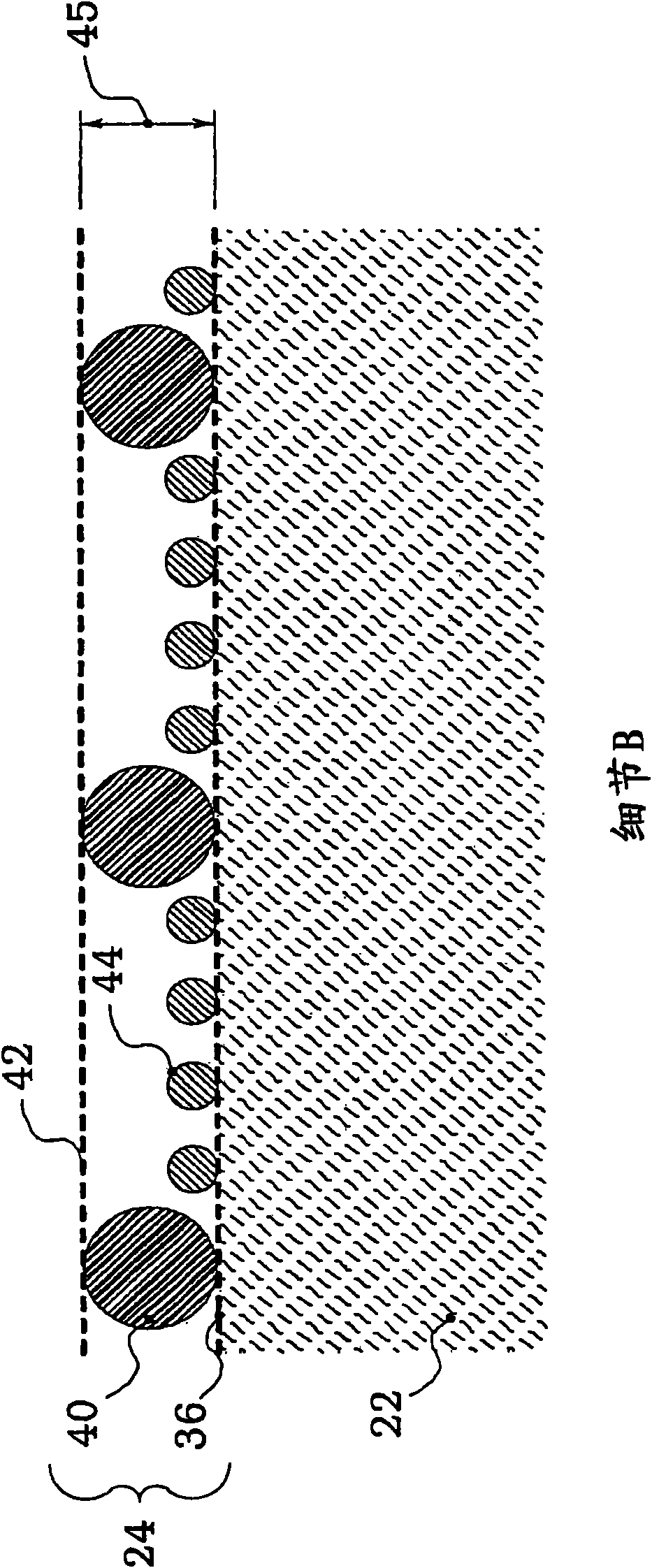

System and method for the treatment of diesel exhaust particulate matter

A particulate converter for the collection and the incineration of particulate matters from diesel engine exhaust includes an exhaust path extending from the diesel engine through the particulate converter. The particulate converter further includes a housing and at least one candle located in the housing. An electrical incineration system may be electrically connected to a pulsed power supply forincinerating soot collected within the candle. A diesel oxidation catalyst (DOC) may be disposed in the exhaust path to generate sufficient amount of NO2 to assist in incineration. At least one exhaust cooling device may be provided for the control of exhaust temperature. A feedback control system may control exhaust gas temperatures based on pressure drop across the DPC, temperature ahead of theDPC and engine RPM.

Owner:里法特·卡梅尔

Method for preparing silicon-boron-carbon-nitrogen porous ceramic with nano pore structure

Owner:HARBIN INST OF TECH AT WEIHAI

Method for preparing silicon-boron-carbon-nitrogen porous ceramic with nano pore structure

The invention relates to a method for preparing silicon-boron-carbon-nitrogen porous ceramic with a nano pore structure. The method comprises the following steps: uniformly mixing boron trichloride, aniline and simethicone according to a ratio of 1:1:2.5, and heating to react to prepare an organic precursor; then dipping nano polyacrylonitrile fibers in the organic precursor and performing heat preservation at a certain temperature; finally sintering the mixture in a high-purity nitrogen atmosphere, and cooling the mixture to room temperature with the furnace after the heat preservation is finished, wherein after the high temperature nitrogen treatment, the nano polyacrylonitrile fibers are corroded to form silicon-boron-carbon-nitrogen (Si-B-C-N) porous ceramic with the nano pore structure. The aperture of the obtained silicon-boron-carbon-nitrogen (Si-B-C-N) porous ceramic is 150-300 nm, the porosity is up to 78-90%, the silicon-boron-carbon-nitrogen (Si-B-C-N) porous ceramic is high temperature resistant, oxidation resistant, free of obvious oxidation at 950 DEG C in an air atmosphere, and free of obvious loss of mechanical property at 1100 DEG C. The silicon-boron-carbon-nitrogen (Si-B-C-N) porous ceramic can be applied to a diesel exhaust particulate filter (DPF) carrier.

Owner:HARBIN INST OF TECH AT WEIHAI

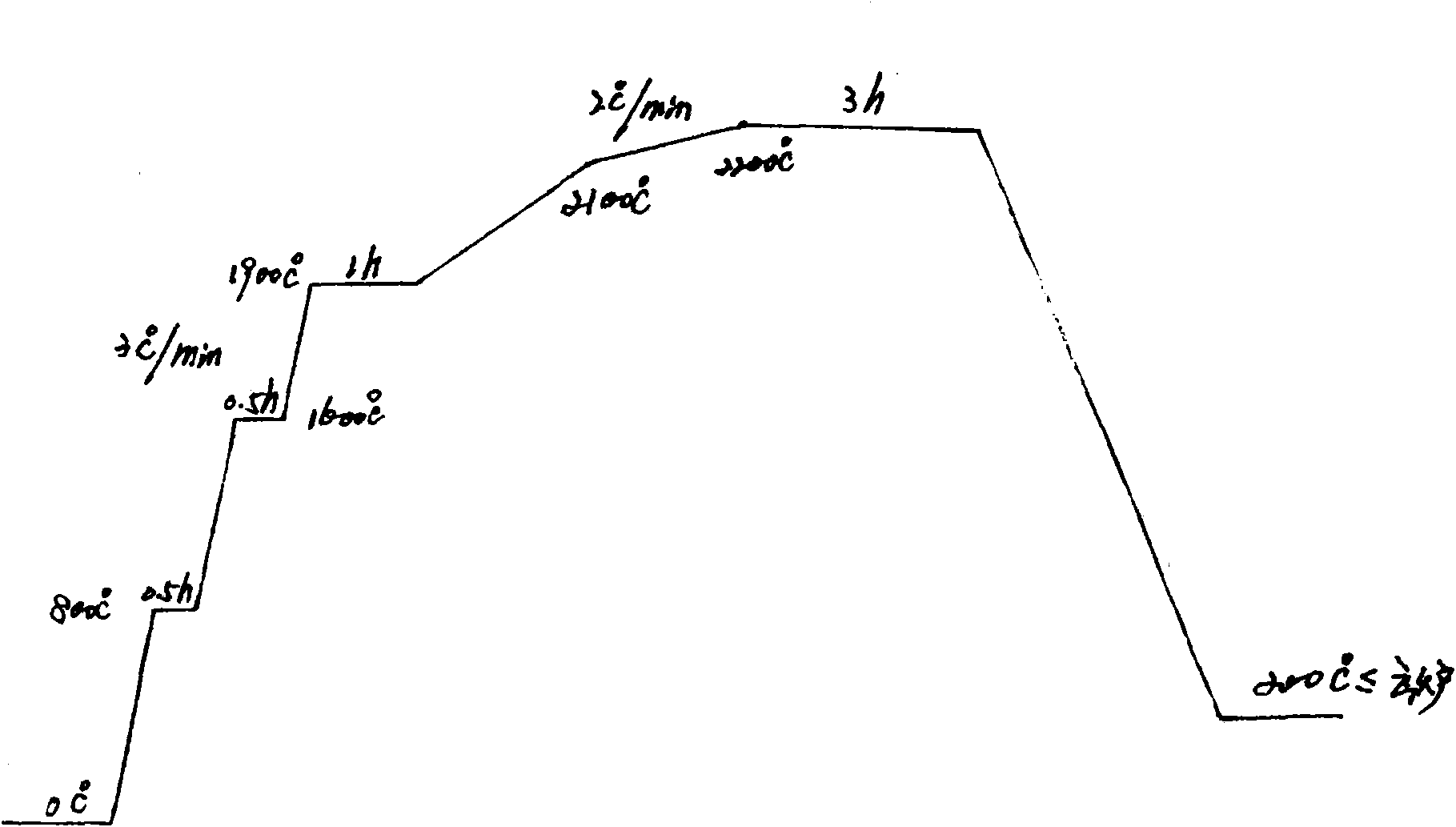

Sintering method of wall-flow type honeycomb ceramic carrier

ActiveCN100515999CHigh strengthMeet the melting temperatureCatalyst carriersExhaust apparatusMolten stateParticulates

The invention relates to a method for sintering a wall-flow honeycomb ceramic carrier, which is mainly used for trapping diesel engine exhaust particles. The wall-flow honeycomb ceramic carrier body is put into a kiln and vacuumized. When the temperature of the kiln rises to the set Keep warm after the value, fill the kiln with protective gas for sintering, keep warm after sintering, continue to raise the furnace temperature and sinter to the set value, then keep warm, continue to raise the furnace temperature to the set value, keep warm, cool down, and come out of the furnace. Advantages: First, the combination of furnace heating and heat preservation not only ensures the sintering quality of the honeycomb green body, but also ensures the ceramic strength after sintering; second, the furnace adopts protective gas protection firing process, which not only meets the The melting temperature required for silicon carbide recrystallization can also keep the silicon carbide recrystallization in a molten state for heat preservation and smelting, and finally form a high-strength recrystallized silicon carbide honeycomb ceramic collector.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

Mixed aerosol generating device simulating diesel exhaust particulate flow

ActiveCN105833807AStable concentrationWide concentration rangeAerogel preparationColloidal chemistry detailsAir filterDistilled water

The invention discloses a mixed aerosol generating device simulating diesel exhaust particulate flow. A dissolved organic matter generating device is arranged based on a carbon black aerosol generating device, and an ash aerosol generating device has three sections, namely the mixed solution generating section, the mixed solution evaporating section and the ash aerosol dilution and deposition section; in the mixed solution generating section, an ash containing cup, a distilled water containing cup and a mixed solution containing cup are connected, and an outlet of a mixed solution stirrer is connected with a mixed solution filter net, a hopper, a filtered solution containing cup, a filtered solution stirrer, a stirrer valve, an ejector T-joint and a solution ejector in sequence; in the mixed solution evaporating section, the ejector T-joint is connected to the solution ejector, and the solution ejector is connected with a mixing pipe, a heating wire pipe and a heating wire pipe T-joint in sequence; in the ash aerosol dilution and deposition section, the heating wire pipe T-joint is connected with an air filter, a second float flowmeter and one inlet of a dilution section T-joint in sequence. The mixed aerosol generating device is simple in structure, and mixed aerosol generating concentration is controlled in multiple regulating ways so as to better simulate diesel exhaust particulate flow.

Owner:CHENGDU AERONAUTIC POLYTECHNIC

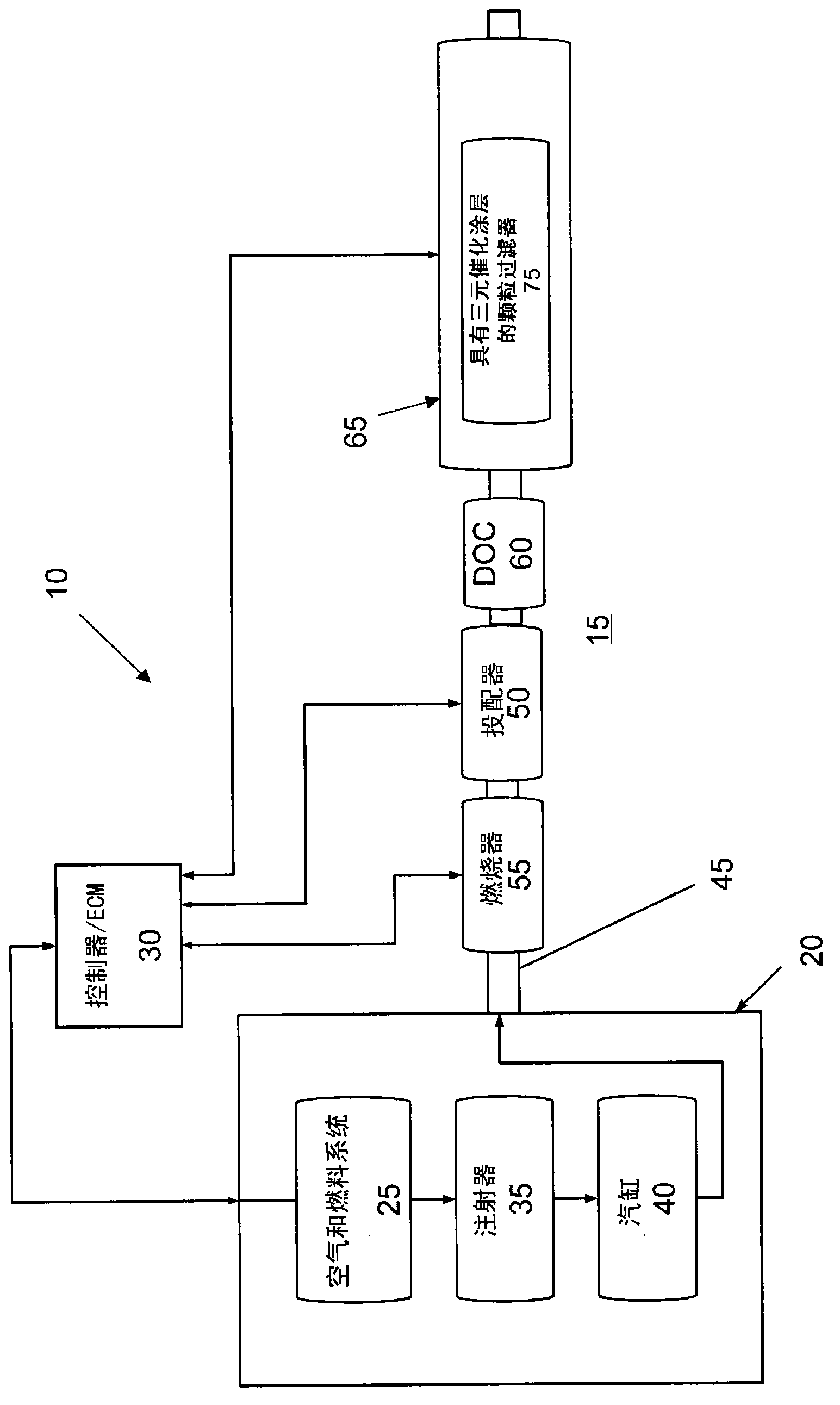

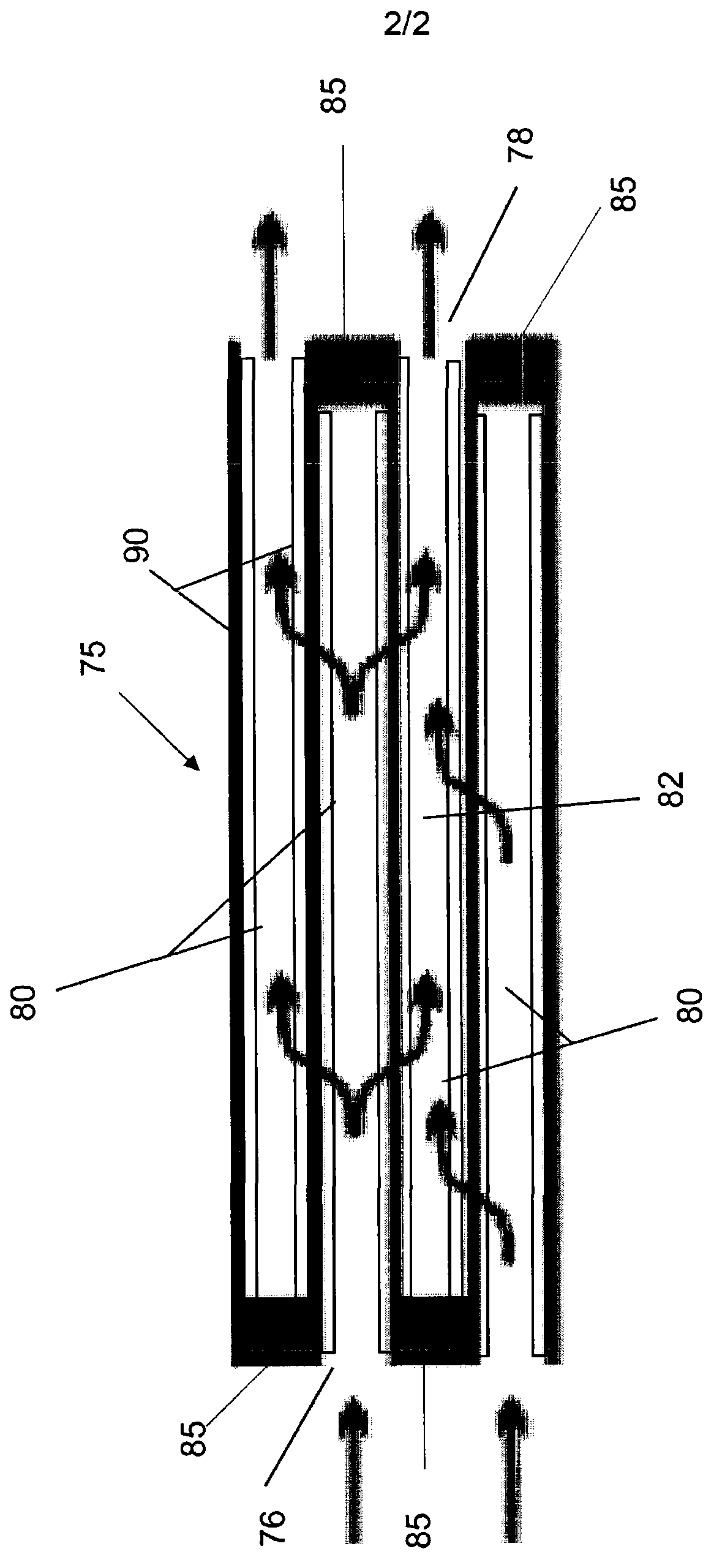

Diesel particulate filter provided with three-way catalytic coatings

InactiveCN103806987AIncrease the air-fuel ratioResponse to transient stateElectrical controlInternal combustion piston enginesExhaust fumesEngineering

The invention relates to a diesel particulate filter provided with three-way catalytic coatings, and relates to a diesel particulate filter used for a diesel exhaust system. The diesel particulate filter comprises a plurality of filter flow channels which are used for removing diesel exhaust particulates from diesel exhaust flow, wherein the plurality of filter flow channels are contacted with the diesel exhaust flow and coated with the three-way catalytic coatings; and the three-way catalytic coatings can be configured to promote soot oxidation during occurrence of a regeneration event, and promotes reduction of NOx in the exhaust flow simultaneously. The three-way catalytic coatings can be used as replacement or supplementation of a three-way catalyst of a diesel oxidation catalyst.

Owner:INT ENGINE INTPROP CO LLC

Particle capturing and regenerating system of mining explosion-proof diesel engine

InactiveCN107178405AMinor changesEasy to transformExhaust apparatusSilencing apparatusExhaust fumesEnvironmental engineering

The invention discloses a particle collection and regeneration system for a mine-used explosion-proof diesel engine, comprising a trap installed at the exhaust end of the explosion-proof diesel engine for processing the exhaust gas of the diesel engine, and a trap installed on the ground for regenerating the trap The regeneration device, the trap includes a DOC that is installed on the exhaust manifold of the mine explosion-proof diesel engine to convert CO and HC in the engine exhaust into harmless water and carbon dioxide through an oxidation reaction, and is equipped with a filter element inside for DPF for filtering exhaust gas and reducing PM content in exhaust gas. The DPF is fixedly connected to the exhaust end of the DOC through a clamp, and the outlet end of the DPF is connected to the exhaust pipe. The invention can safely and effectively realize the particle trapping work of the exhaust gas of the explosion-proof diesel engine, and can effectively reduce the content of CO, HC and PM in the exhaust pollutants.

Owner:WUXI LONGSHENG TECH

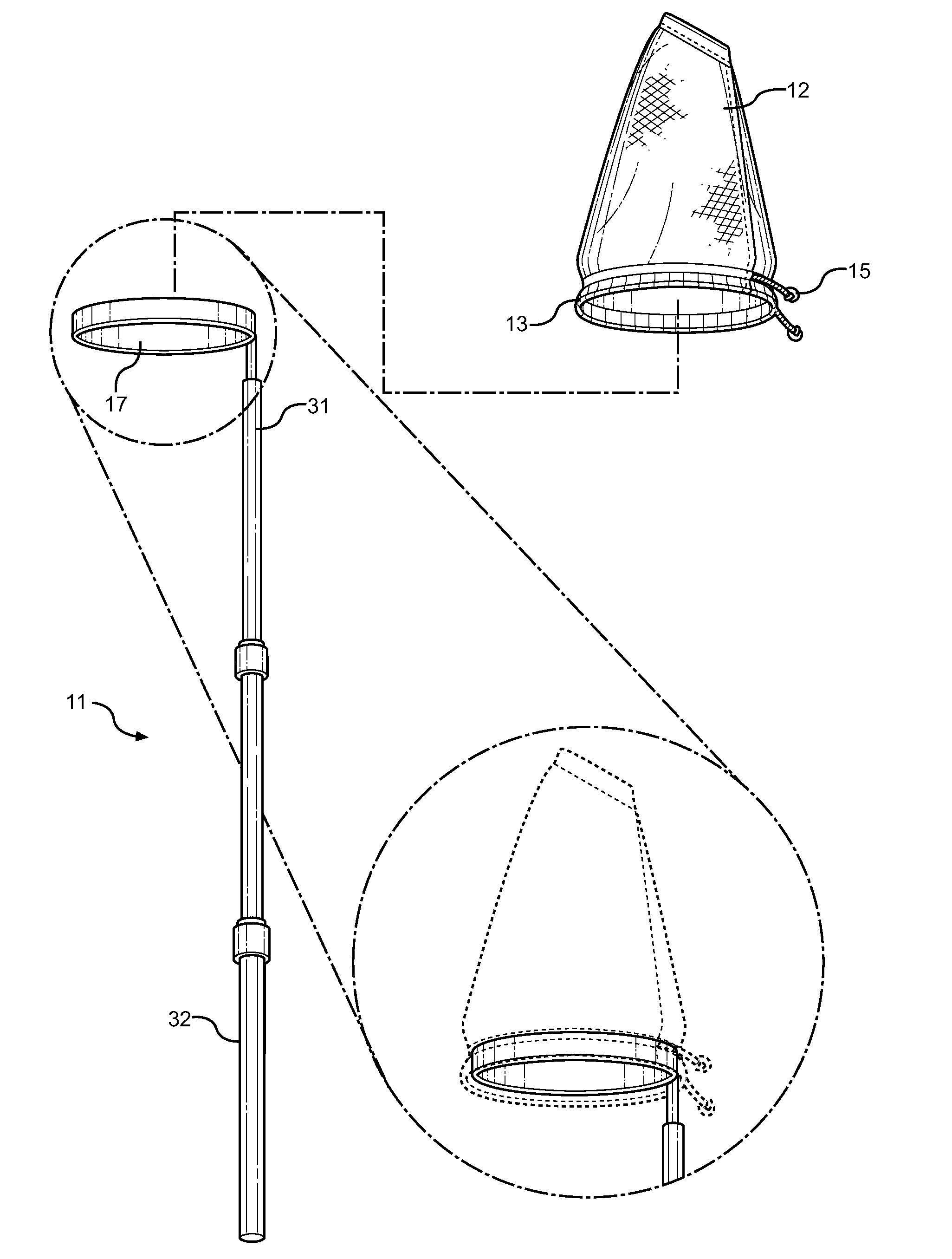

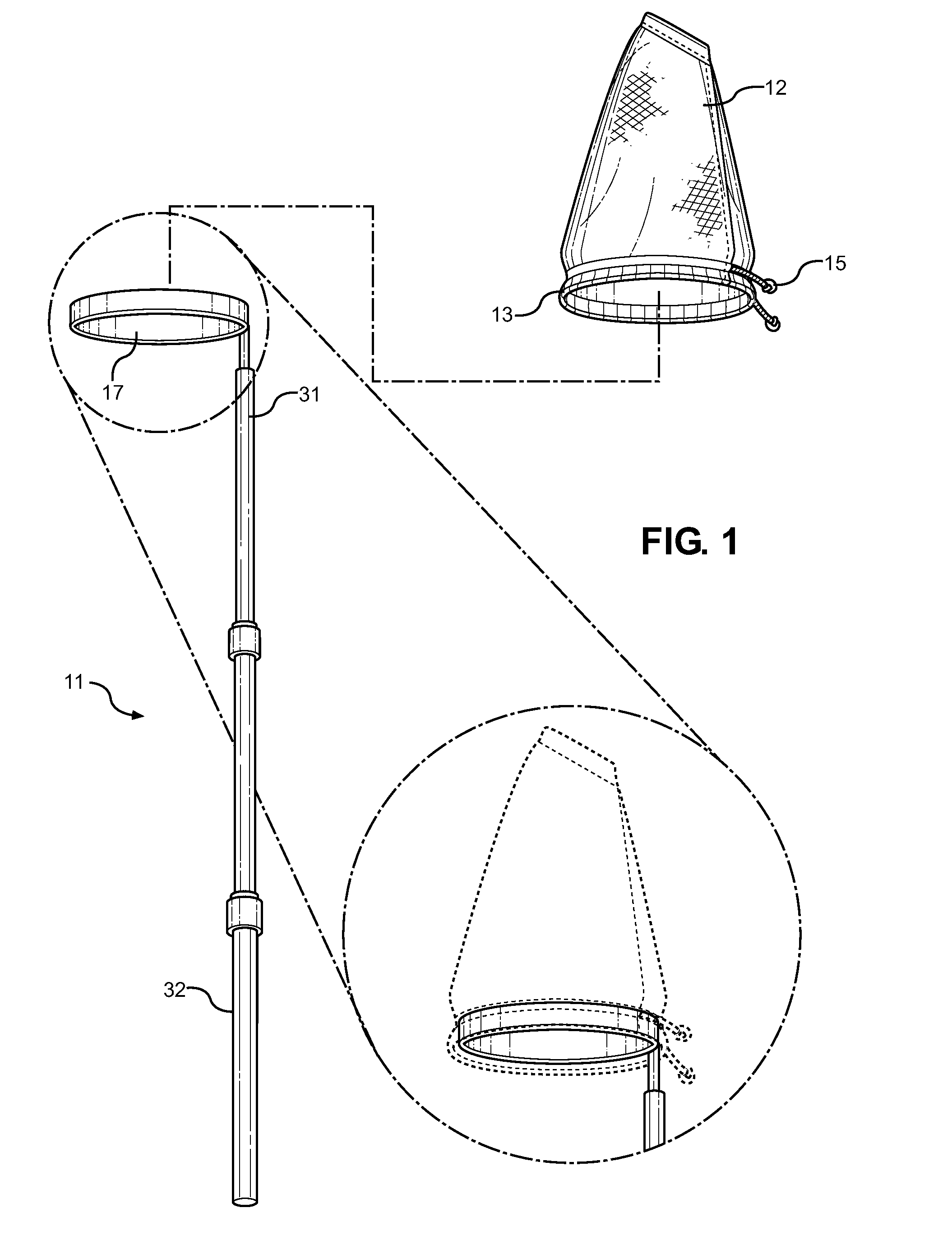

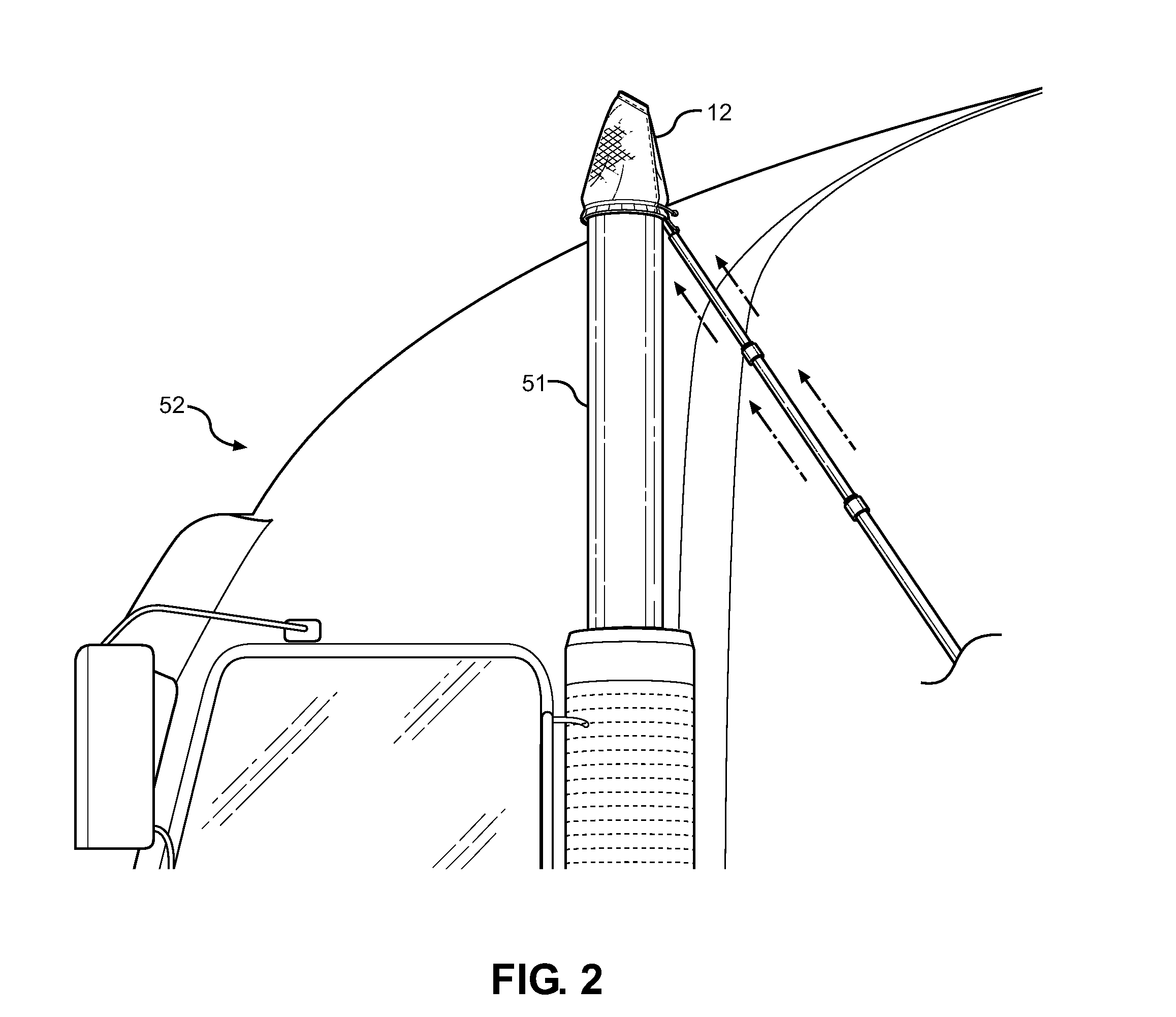

Diesel Exhaust Particulate Filter

InactiveUS20140237992A1Internal combustion piston enginesDispersed particle filtrationFiltrationDiesel Exhaust Particulate

A method and device for testing a diesel engine to determine whether the engine's diesel particulate filter is functioning properly is provided. The device comprises an elongated pole with a service ring disposed at one end. The service ring is designed to removably support a filtration means, which is composed of porous cloth material. The device is removably affixed over the outlet of a diesel engine exhaust pipe, allowing the filtration means to trap any particulates that may be contained within the engine exhaust. If the diesel engine particulate filter is functioning properly, there will be no particulates collected by the filtration means; if the diesel engine particulate filter is not functioning properly, the present invention allows the user to collect physical evidence of such.

Owner:WALLACE CLAUDE LEE

Diesel exhaust particulate collectors

An apparatus and method for cleaning ash / soot and other particulates from diesel particulate filters (DPF), including diesel oxidative catalysts (DOC) and similar exhaust components. Section for dry and wet cleaning include conduits that connect to the filters. For dry cleaning, a filter is mounted clean side up and air pressure is applied in opposite directions so that the particulate is dislodged and falls out. For wet cleaning, the filter is floated with a slug of liquid cleaning solution which is surged back-and-forth through the filter to dislodge and remove the particulate. The dry and wet cleaning sections may be combined or collocated, or may be located separately or used one without the other.

Owner:FSX EQUIP

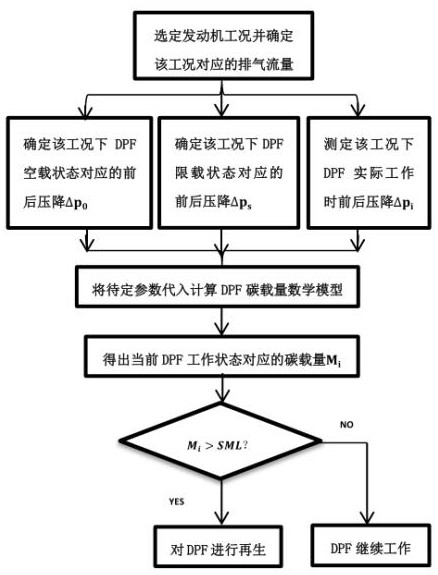

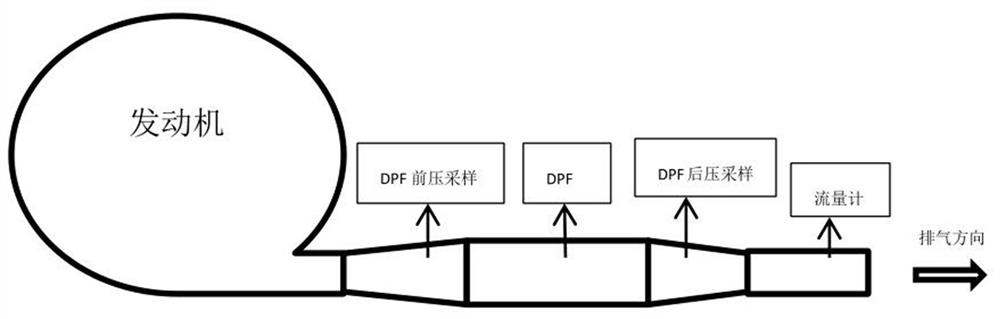

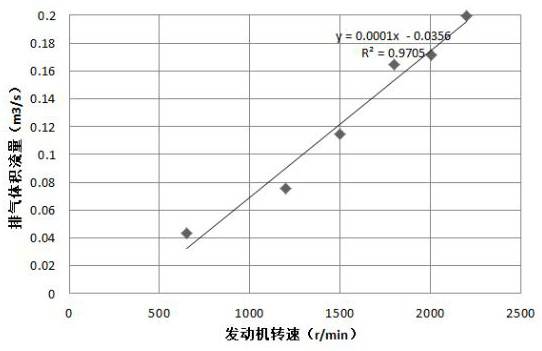

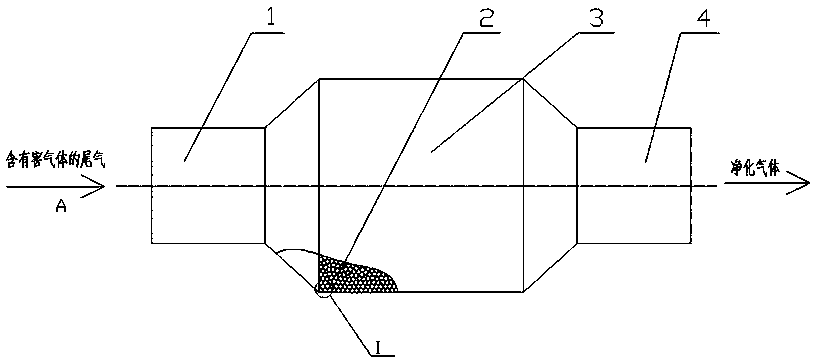

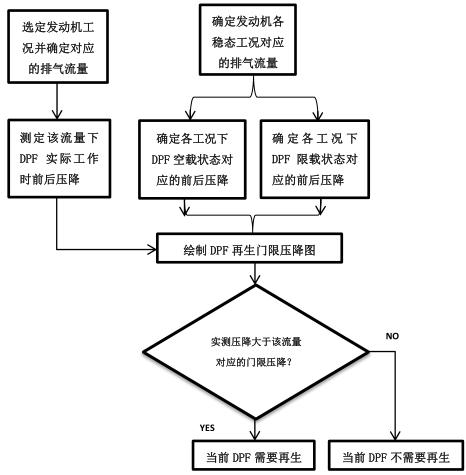

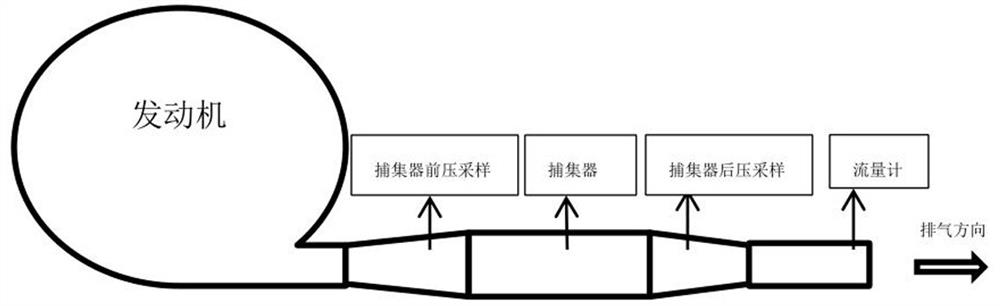

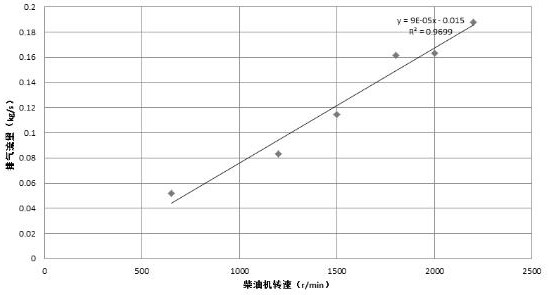

Carbon Load Estimation Method for Diesel Particulate Filter

ActiveCN109404107BPromote timely regenerationAccurate estimateInternal combustion piston enginesExhaust treatment electric controlMathematical modelDieseling

The invention is a method for estimating the carbon load of a diesel engine exhaust particulate filter, comprising the following steps: 1) selecting a diesel engine steady-state working condition and determining the flow rate of exhaust gas passing through the diesel engine exhaust particulate filter under this working condition; 2) ) Determine the front and rear pressure drop corresponding to the exhaust flow in the no-load and load-limited states of the DPF; 3) Build and calculate the DPF carbon The mathematical model of the load; 4) Substitute the actually measured pressure drop before and after the DPF into the mathematical model under the exhaust flow rate, and calculate the carbon load value of the current DPF; 5) Substitute the carbon load value of the current DPF The load value is compared with the DPF carbon load limit value to determine whether the current state of the exhaust particulate filter of the diesel engine needs to be regenerated. The invention can accurately estimate the carbon load of the particle trap, has high reliability of the estimation result, and helps to promote the timely regeneration of the DPF.

Owner:GUANGDONG UNIV OF TECH

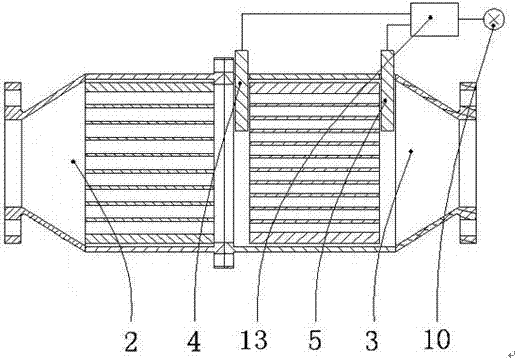

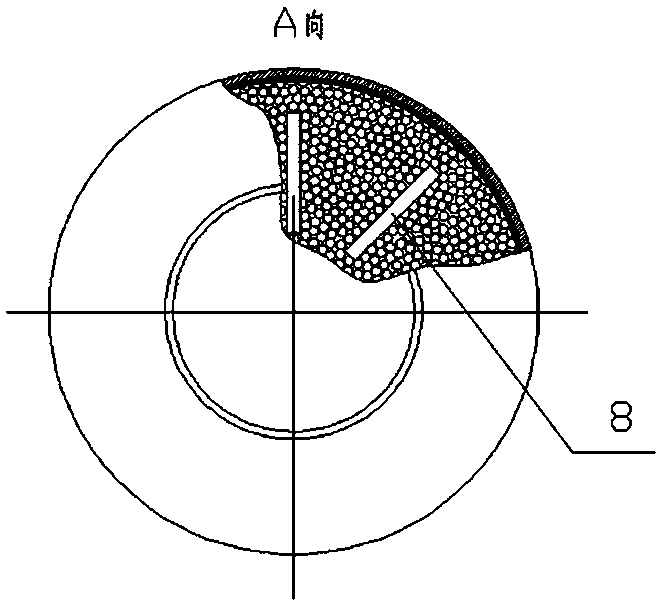

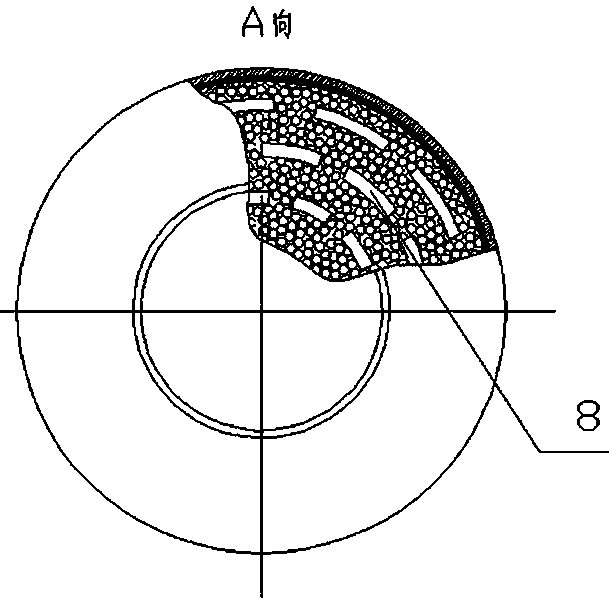

Catalyst for collecting particulate matter in diesel vehicle exhaust

InactiveCN105626207BImprove adsorption capacityDiffusion fastExhaust apparatusSilencing apparatusParticulatesEngineering

The invention provides a diesel vehicle exhaust particle capturing catalyst. The catalyst is composed of a metal shell and an inner core, wherein the inner core is a columnar body and formed by stacking inertia alumina porcelain balls coated with binding agents; the cross section of the inner core is round, square, oval or racetrack-shaped; multiple exhaust channels are evenly arranged inside the inner core and are arranged in the circumferential or radial direction; the sections of the channels are rectangular, round and fan-shaped; the sum of the sectional areas of the channels is not larger than 25% of the sectional area of the inner core; and the length of the channels in the axis direction is 60%-100% that of the columnar body. According to the diesel vehicle exhaust particle capturing catalyst, as the binding agents evenly coating the porcelain balls have a large number of pores, the specific area is large, and the adsorption effect of particles is high; and as the exhaust channels of the diesel vehicle exhaust particle capturing catalyst are each of a special-shaped structure, the capturing effect of the particles is very high.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

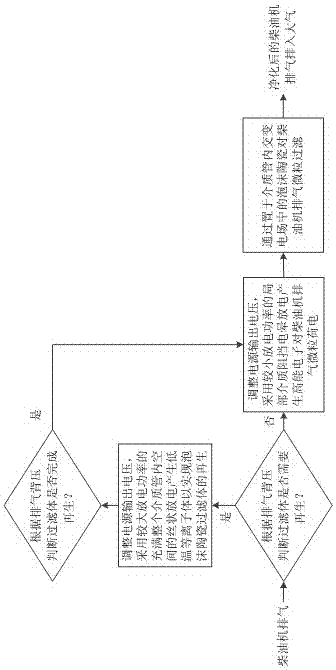

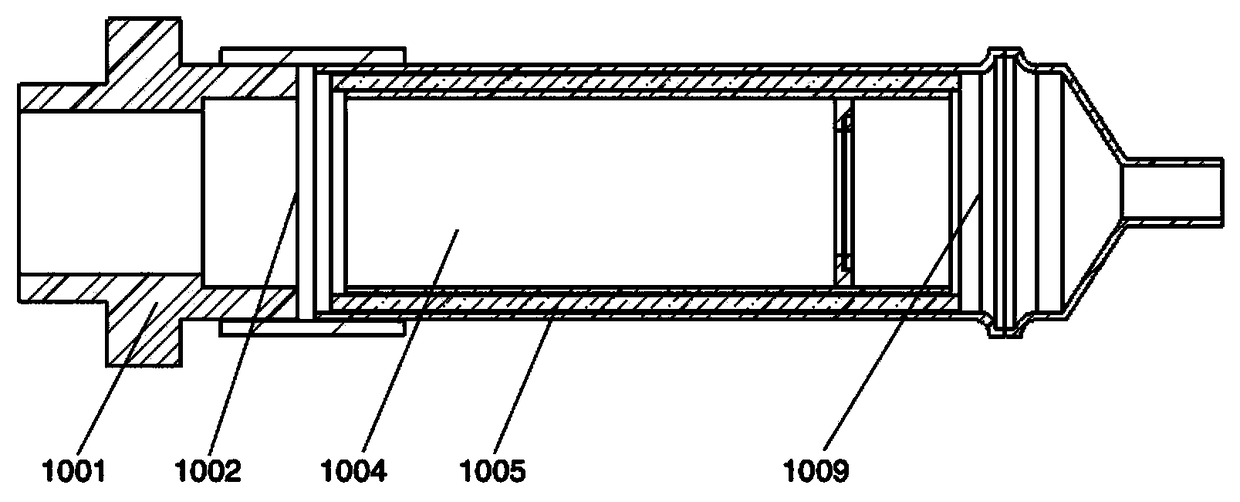

A kind of post-treatment method of diesel engine exhaust particulates

ActiveCN104747255BImprove filtering effectEffective oxidative decompositionExhaust apparatusSilencing apparatusAfter treatmentHigh energy

Owner:盐城市富源引擎科技有限公司

Judgment method for regeneration time of exhaust particulate filter of diesel engine

ActiveCN109538333BPromote timely regenerationSimple methodInternal combustion piston enginesExhaust apparatusDieselingExhaust fumes

The invention relates to a method for judging the regeneration time of a diesel engine exhaust particle trap. It includes the following steps: 1) Select the steady-state working conditions of the diesel engine series and measure the exhaust gas flow through the DPF under each working condition; 2) Determine the front-to-back pressure drop corresponding to the exhaust flow of the DPF under no-load and load-limiting conditions under different working conditions ; 3) Draw the DPF regeneration threshold pressure drop diagram according to the obtained DPF load-limited state corresponding pressure drop value, and correct the drawn threshold pressure drop diagram to obtain the final DPF regeneration threshold pressure drop diagram; 4) In the selected Under the steady-state working condition of the diesel engine, first determine the exhaust flow corresponding to the working condition, and compare the actual measured pressure drop before and after the DPF with the threshold pressure drop corresponding to the flow in the threshold pressure drop diagram; 5) judge the measured DPF Whether the front-to-back pressure drop is greater than the corresponding threshold pressure drop, and then determine whether the current DPF state needs to be regenerated. The invention can more accurately determine the regeneration timing of the DPF and promote the timely regeneration of the DPF.

Owner:GUANGDONG UNIV OF TECH

Wall-flow type honeycomb ceramic carrier batching and sludge mixing method

ActiveCN100509698CMeet stickinessMeet the bondCatalyst carriersExhaust apparatusMethylcellulose PowderAdditive ingredient

The invention relates to a method for batching and mud-mixing a wall-flow honeycomb ceramic carrier blank for capturing diesel engine exhaust particles. ① Mix the mixed powder of pure silicon carbide and methyl cellulose, pour the pure silicon carbide and methyl cellulose into the blender and stir, so that the silicon carbide powder and methyl cellulose powder can be mixed evenly; ② Stir the pure silicon carbide Mix the powder with methyl cellulose for a few minutes, mix the flour aqueous solution mixed with flour and water, and pour it into the mixer while stirring. After pouring all the flour aqueous solution into the mixer, stir and mix the mud fully; ③ After mixing Add tung oil to the mud. After stirring for a few minutes, when the mud is sticky and easy to stick together, mix the mud well, put the mud in a container and seal it up to ensure that the mud in the mud Moisture does not evaporate and stale time is several days.

Owner:GUIZHOU HUANGDI DIESEL ENGINE CLEANER

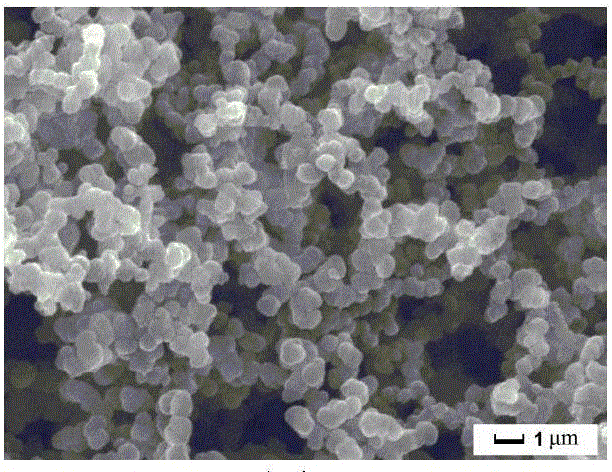

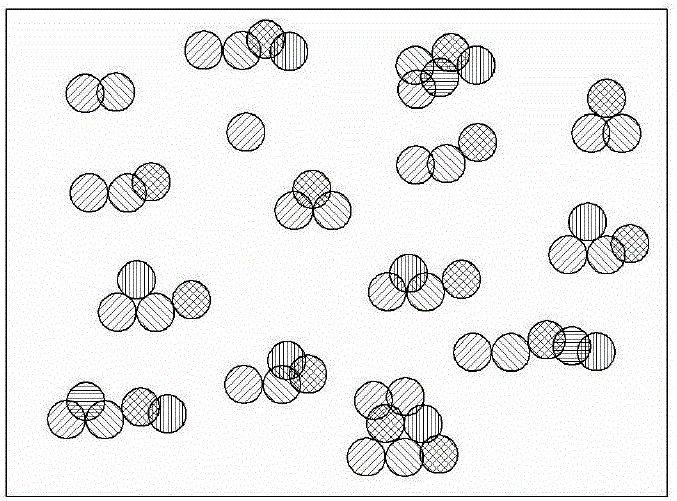

A method for measuring the median diameter of particles in diesel engine exhaust

ActiveCN103630471BHigh measurement accuracySimple measuring deviceParticle size analysisPower flowImaging processing

The invention relates to the technical field of measurement and provides a method for measuring and calculating the median particle diameter of particles in the exhaust gas of a compression ignition engine. A method for measuring the median particle diameter of the particles in the exhaust gas of a diesel engine mainly comprises the following steps: collecting particle samples to be measured; dispersing the particle samples to be measured; acquiring an electron microscope image of dispersed particles; judging the dispersion degree of agglomerated particles; and solving the diameter of a single particle in Mi to finally obtain the median particle diameter D50 of the particles in the exhaust gas of the diesel engine. Compared with the prior art, the method has the characteristics that the particle diameter can be obtained without conversion of the current and the particle diameter; and the particles with the particle diameter of 0.1 to 0.5 micron can be intuitively obtained. Through the particle electron microscope image processing, the single particle can be distinguished, and the particle diameter measurement accuracy of the particles is improved.

Owner:JIANGSU UNIV

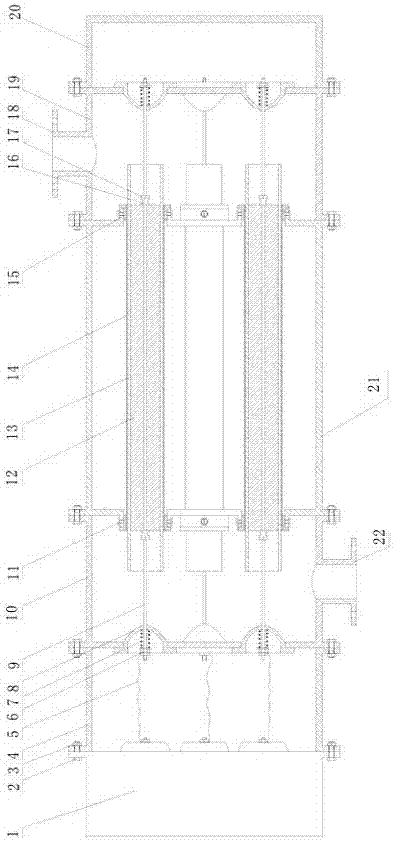

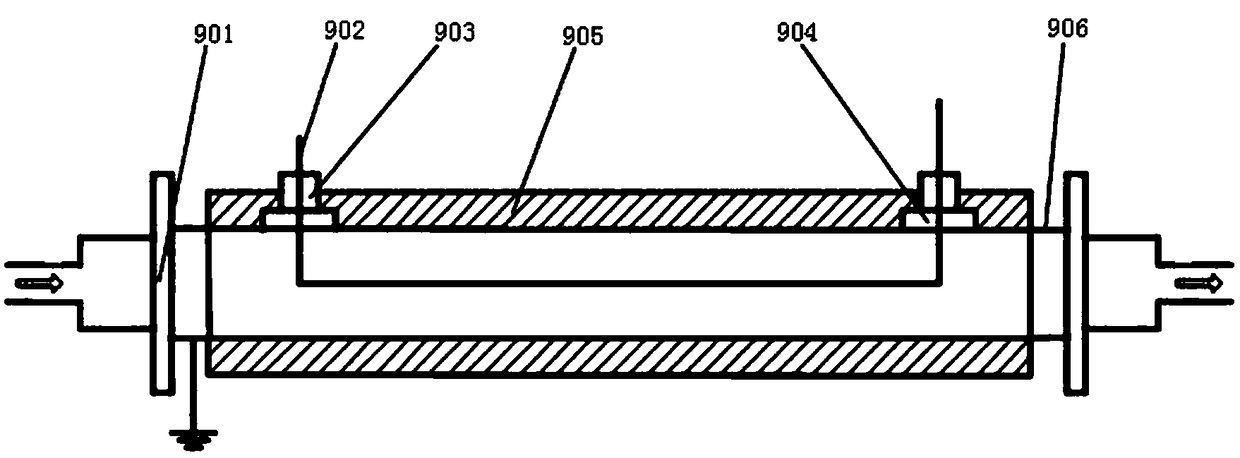

A diesel engine exhaust particulate matter charge and charge measurement device

ActiveCN105642441BImprove charging capacityLarge particle sizeMagnetic separationExternal electric electrostatic seperatorParticulatesBobbin

The invention discloses an exhaust particulate matter charging and charging capacity measuring device of a diesel engine. The exhaust particulate matter charging and charging capacity measuring device comprises a water removal device, a charging reactor and a Faraday cylinder of an improved structure. The water removal device comprises a cooling system and a heating system. The charging reactor comprises a bobbin type corona generator and a positive / negative high voltage power source. The Faraday cylinder of the improved structure comprises a PVC pipe, a first metal net, a second metal net, a rubber pipe, a filter paper bracket, a quick connector, a stainless steel inner barrel, a stainless steel outer barrel and a flow control system. Water in exhaust of the diesel engine is reduced through the cooling system, the exhaust is made to be constant at certain temperature through the heating system, the heated exhaust is then introduced into the charging reactor to react, and therefore particulate matter is charged. On-line measurement is adopted in the whole charging capacity measurement process, the charging capacity of the particulate matter is measured through the Faraday cylinder of the improved structure, and the charged particulate matter is captured through filter paper. By means of the positive / negative high voltage corona discharge technology, real-time capturing of the particulate matter of the diesel engine and measurement of the charging capacity are achieved.

Owner:JIANGSU UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com