Wire mesh type diesel exhaust particulate filter and production method thereof

A technology of exhaust particles and wire mesh, applied in the field of air purification, can solve the problems of high fuel quality requirements, long matching cycle, complex regeneration control, etc., achieve continuous passive regeneration, reduce weight and back pressure, and improve capture efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as Figure 7 , Figure 9 As shown, the wire mesh type diesel engine exhaust particulate filter includes a stainless steel cylinder 1, and a stainless steel wire mesh 2 located in the stainless steel cylinder 1 with several layers of intertwined winding; the pin 4 passes through the stainless steel cylinder 1 and runs through the stainless steel wire Net 2; both ends of the pin 4 are fixed to the stainless steel cylinder 1; the stainless steel wire mesh 2 is coated with a catalyst coating 3.

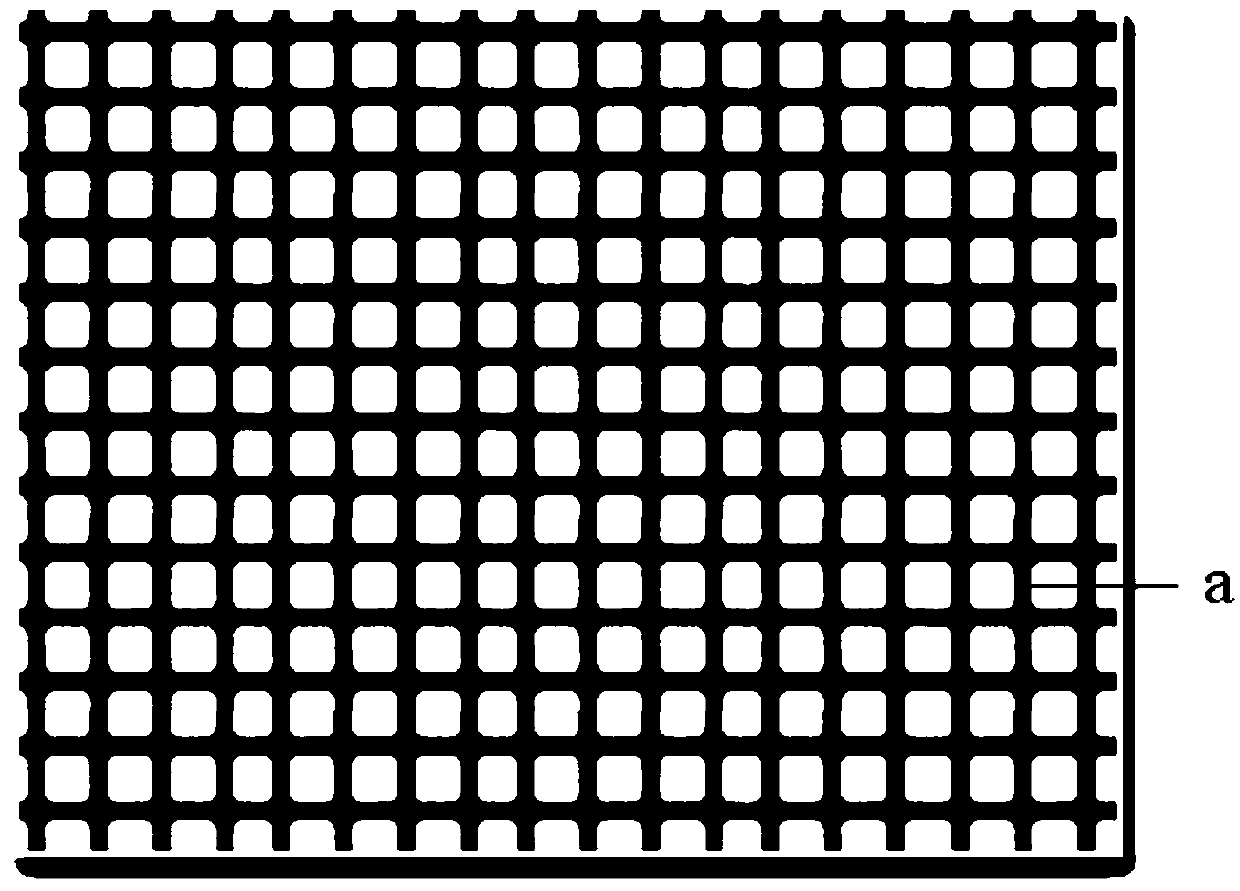

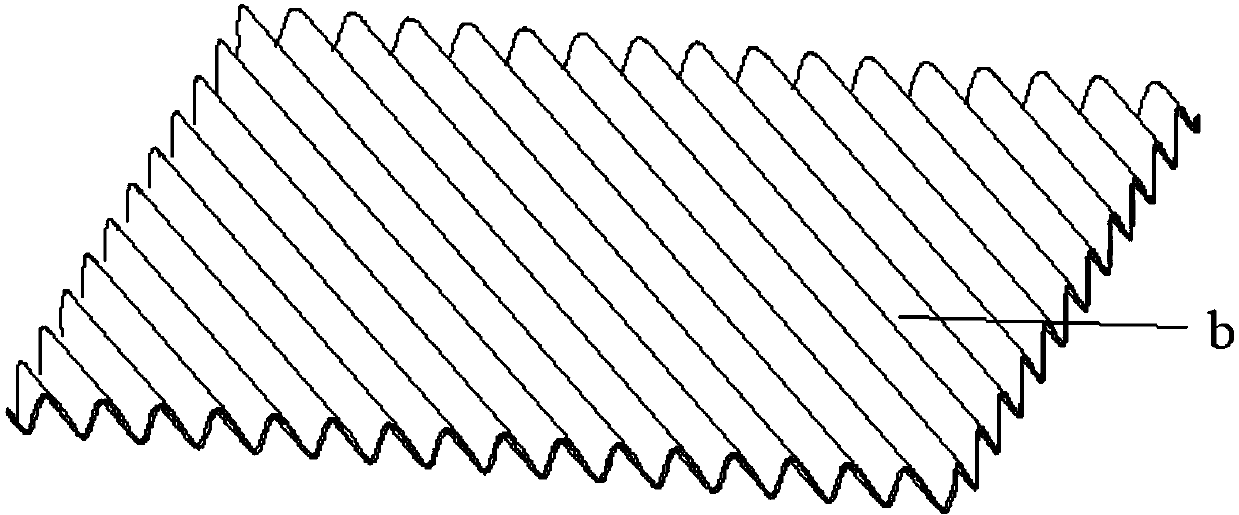

[0031] Such as Figure 4 As shown, the stainless steel wire mesh 2 includes several layers of positive corrugated mesh b and stainless steel flat mesh a that are interwoven and intertwined in sequence.

[0032] The corrugation height of the positive corrugated net b is 1.0 mm, the corrugation angle is 30°, and the corrugation pitch is 3.5 mm. Wire mesh corrugated net, width 150mm, filter cylinder: stainless steel tube Ø 151 x 170 (length); particulate filter specification: ...

Embodiment 2

[0041] Such as Figure 8 , Figure 9 As shown, the wire mesh type diesel engine exhaust particulate filter includes a stainless steel cylinder 1, and a stainless steel wire mesh 2 located in the stainless steel cylinder 1 with several layers of intertwined winding; the pin 4 passes through the stainless steel cylinder 1 and runs through the stainless steel wire Net 2; both ends of the pin 4 are fixed to the stainless steel cylinder 1; the stainless steel wire mesh 2 is coated with a catalyst coating 3.

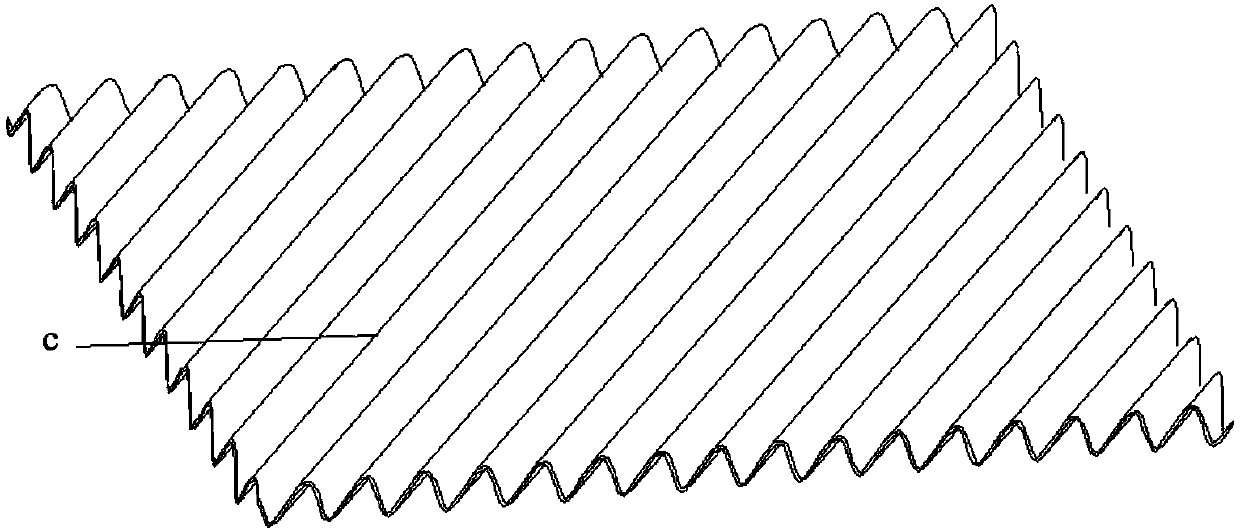

[0042] Such as Figure 5 As shown, the stainless steel wire mesh 2 includes several layers of regular corrugated net b and reverse corrugated net c interwoven and interwoven in sequence.

[0043] The corrugation height of the positive corrugated net b and the reverse corrugated net c is 3.0 mm, the corrugation angle is 60°, and the corrugation pitch is 5.5 mm. Particle collection filter specification: Ø150x150; wire mesh corrugated net, width 150mm; filter cylinder: stainle...

Embodiment 3

[0052] Such as Figure 9 As shown, the wire mesh type diesel engine exhaust particulate filter, the wire mesh type diesel engine exhaust particulate filter includes a stainless steel cylinder 1, and a stainless steel wire mesh 2 with several layers interwoven and wound inside the stainless steel cylinder 1; pins 4 passes through the stainless steel cylinder 1 and runs through the stainless steel wire mesh 2; both ends of the pin 4 are fixed to the stainless steel cylinder 1; the stainless steel wire mesh 2 is coated with a catalyst coating 3.

[0053] Such as Image 6 As shown, the stainless steel wire mesh 2 includes a positive corrugated mesh b, a stainless steel flat mesh a, and a stainless steel flat mesh a, which are intertwined in several layers at intervals.

[0054] The corrugation height of the positive corrugated net b and the reverse corrugated net c is 2 mm, the corrugation angle is 45°, and the corrugation pitch is 4.5 mm. Particle collection filter specificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ripple height | aaaaa | aaaaa |

| Ripple height | aaaaa | aaaaa |

| Ripple height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com