A kind of post-treatment method of diesel engine exhaust particulates

A diesel engine and particulate technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of low filtration efficiency, easy damage to the filter body, and large flow resistance, and achieve enhanced filtration efficiency, efficient and rapid regeneration, and flow resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

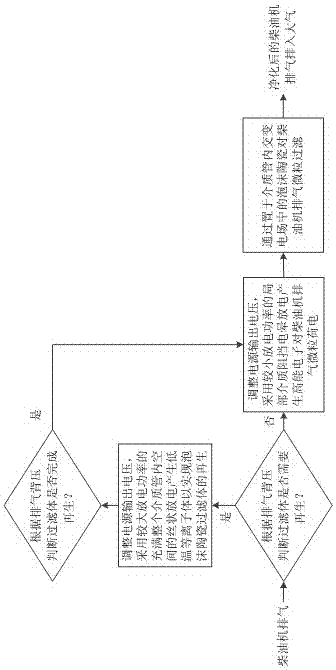

Method used

Image

Examples

Embodiment 1

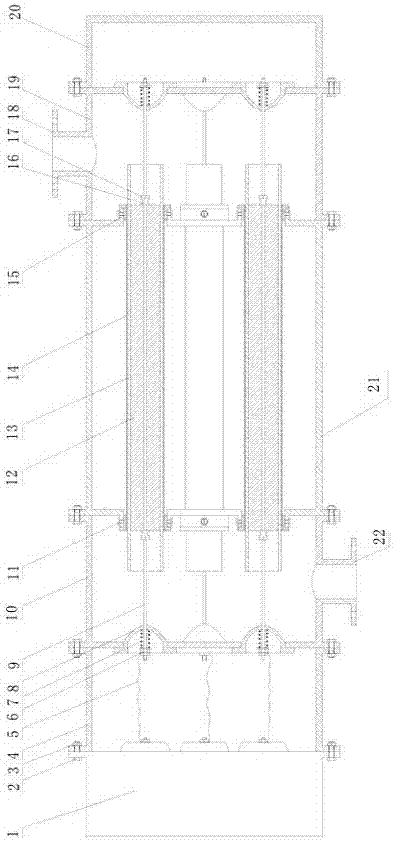

[0026] Taking the 186F single-cylinder air-cooled diesel engine produced by a certain factory as the experimental prototype, the figure 2 The shown device, which includes a filter regeneration unit, aftertreatment of exhaust gas from a diesel engine using the method according to the invention. During the experiment, the operating condition of the engine was 1800r / min, 16N.m, and when the device of the present invention was not installed for post-treatment, the exhaust smoke of the original machine was 1.9BSU, and the exhaust back pressure was about 740Pa.

[0027] Step 1, using a partial dielectric barrier corona discharge with a discharge power of 12 watts to charge the particles flowing through the foam ceramics, and filter the diesel engine exhaust particles through the foam ceramics;

[0028] Step 2, when the amount of diesel engine exhaust particles accumulated in the foam ceramics causes the diesel exhaust back pressure to rise to 2.5kPa, use a 150W discharge power to f...

Embodiment 2

[0031] Experiments were carried out using the engine and aftertreatment device described in Example 1, and the engine operating conditions were as described in Example 1.

[0032] Step 1, using a partial dielectric barrier corona discharge with a discharge power of 20 watts to charge the particles flowing through the foam ceramics, and filter the diesel engine exhaust particles through the foam ceramics;

[0033] Step 2, when the amount of diesel exhaust particles accumulated in the foam ceramics causes the diesel exhaust back pressure to rise to 2.8kPa, use a 240W discharge power to fill the entire dielectric tube space with a filamentary discharge to decompose the accumulated particles to achieve foam Regeneration of ceramic filters.

[0034] It is found through experiments that after the post-treatment by the method of the present invention, the engine exhaust wave smoke degree is 0.2BSU, and the filtration efficiency is 89.4%; adopt 240W discharge power to carry out filter...

Embodiment 3

[0036] Experiments were carried out using the engine and aftertreatment device described in Example 1, and the engine operating conditions were as described in Example 1.

[0037] Step 1, using a partial dielectric barrier corona discharge with a discharge power of 30 watts to charge the particles flowing through the foam ceramics, and filter the diesel engine exhaust particles through the foam ceramics;

[0038] Step 2, when the amount of diesel engine exhaust particles accumulated in the foam ceramics causes the diesel engine exhaust back pressure to rise to 2.94kPa, use a 330W discharge power to fill the entire dielectric tube space with a filamentary discharge to decompose the accumulated particles to achieve foam Regeneration of ceramic filters.

[0039] It is found by experiments that after the post-treatment through the method of the present invention, the engine exhaust smoke level is 0.1BSU, and the filtration efficiency is 94.7%; adopt 330W discharge power to regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com