A mixed aerosol generator for simulating diesel engine exhaust particle flow

An aerosol generation and generation device technology, applied in aerogel preparation, colloid chemistry, colloid chemistry and other directions, can solve the problems of easy precipitation, can not achieve ash suspension effect, etc., achieve a wide concentration range, simple and reliable structure, design unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

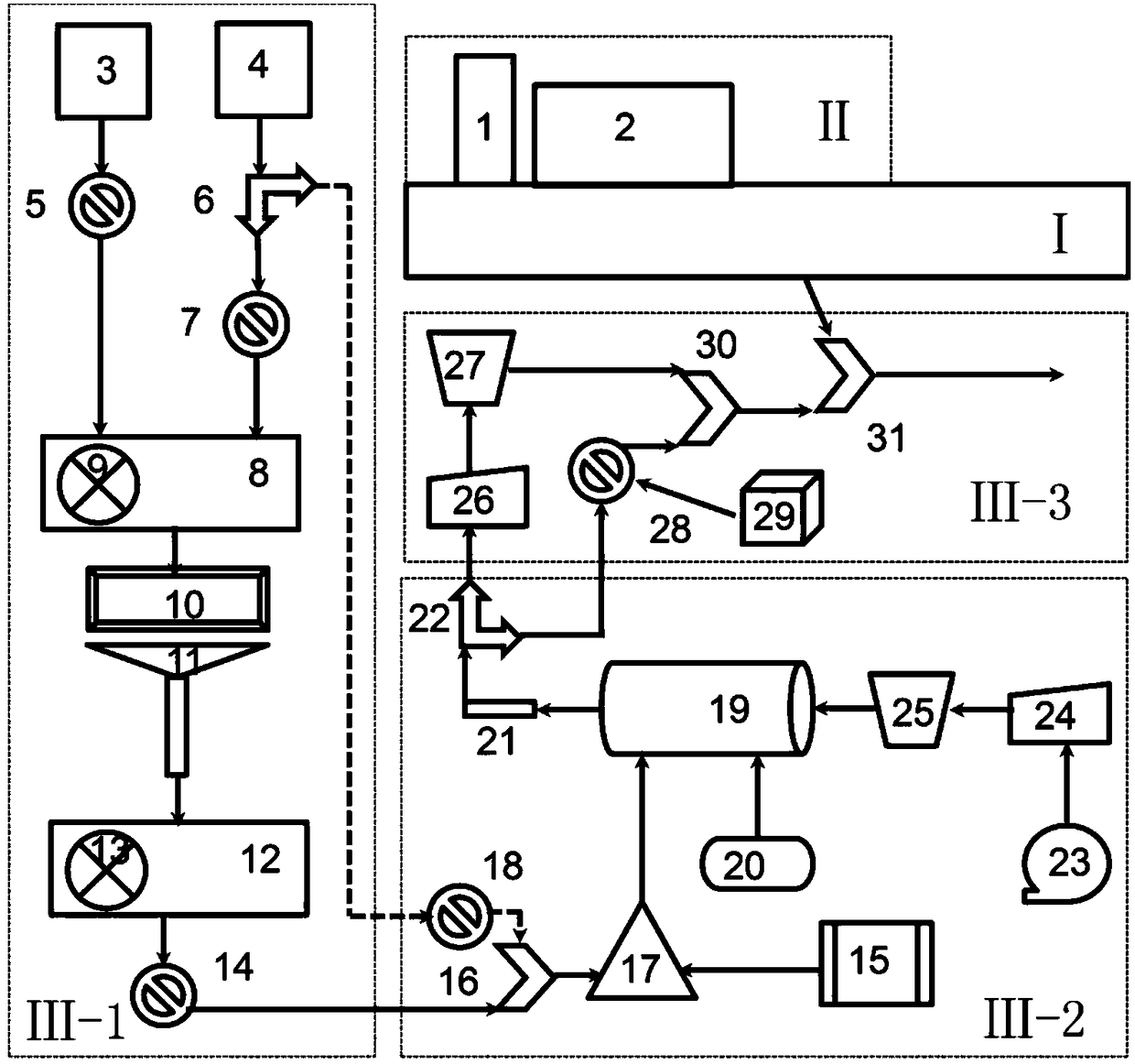

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1As shown, in the mixed aerosol generating device for simulating diesel engine exhaust particle flow provided by the present invention, the flow direction of the whole passage is: soluble organic matter generating device II fuel injector 1 produces diesel oil and lubricating oil mixed liquid spray and carbon black aerosol phase Combining to form the initial mixed aerosol, and based on the pipeline of the carbon black aerosol generating device I (such as the device described in Chinese patent CN201410289789.7), it reaches the sampling interface; the ash holding cup 3 is connected to the ash holding cup valve 5, and the distilled water holds After the cup 4 is connected to the pneumatic tube tee 6, the distilled water holding cup valve 7 and the injector cleaning valve 18 are respectively connected. The ash holding cup valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com