Medical devices having antimicrobial coatings thereon

a technology of antimicrobial coating and medical devices, which is applied in the direction of instruments, prostheses, catheters, etc., can solve the problems of hindering the use of antimicrobial coatings containing leachable antimicrobial agents, affecting the ocular health of the eye in which the lens is located, and affecting the use of antimicrobial coatings. to achieve the effect of low cytotoxicity and high antimicrobial efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

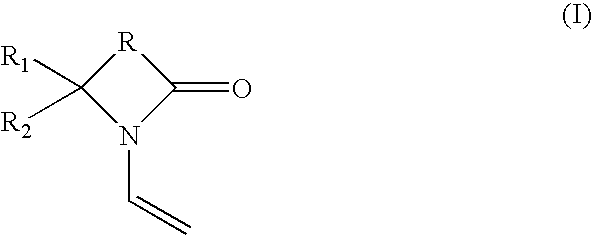

Image

Examples

example 1

The contact angle generally measures the surface hydrophilicity of a medical device, e.g., a contact lens. In particular, a low contact angle corresponds to more hydrophilic surface. Average contact angles (Sessile Drop) of contact lenses are measured using a VCA 2500 XE contact angle measurement device from AST, Inc., located in Boston, Mass.

Antimicrobial Activity Assay

Antimicrobial activity of a contact lens with or without a silver-containing antimicrobial LbL coating of the invention is assayed against Pseudomonas aeruginosa GSU # 3, which is isolated from a corneal ulcer. Bacterial cells of Pseudomonas aeruginosa GSU # 3 stored in a lyophilized state. Bacteria are grown on an tryptic soy agar slant for 18 hours at 37° C. The cells are harvested by centrifugation and washed twice with sterile, Delbeco's phosphate buffered saline. Bacterial cells are suspended in PBS and adjusted to Optical Density of 108 cfu. The cell suspension is serially diluted to 103 cfu...

example 2

Polyacrylic acid (PAA) solution: A solution of polyacrylic acid having a molecular weight of about 2,000, from PolyScience, is prepared by dissolving a suitable amount of the material in water to form a 4% PAA solution.

Poly(diallyldimethylammonium chloride) (PDDA) solution: A solution of PDDA having a molecular weight of about 400,000 to 500,00 from Aldrich, is prepared by dissolving a suitable amount of the material in water to form a 0.5% PDDA solution. The pH is adjusted by adding 0.1M NaOH solution until the pH is about 8.0.

A coating having multiple bilayers of PDDA / Ag—NP is formed on a glass slide. The glass slide is dipped in the PDDA solution for 10 min. The glass slide with a first layer of PDDA is then dipped in the PAA solution for 10 minutes. Then the glass slide is dipped again in PDDA for 10 min and then dipped in the Ag—NP solution for 10 minutes. Finally, the steps of dipping in the PDDA solution for 10 minutes followed by dipping in the Ag—NP solution for 10 min...

example 3

Polyacrylic acid (PAA) solution: A solution of polyacrylic acid having a molecular weight of about 90,000, from PolyScience, is prepared by dissolving a suitable amount of the material in water to form a 0.001M PM solution. The PM concentration is calculated based on the repeating unit in PM. Once dissolved, the pH of the polyanionic PM solution is adjusted by adding 1N hydrochloric acid until the pH is about 2.5.

Poly(diallyldimethylammonium chloride) (PDDA) solution: PDDA is a polyquat. A solution of PDDA having a molecular weight of about 400,000 to 500,00 from Aldrich, is prepared by dissolving a suitable amount of the material in water to form a 0.5% PDDA solution. The pH is adjusted by adding 0.1M NaOH solution until the pH is about 8.0.

A coating having multiple bilayers of PDDA / Ag—NP is formed on a soft contact lens made of a fluorosiloxane hydrogel material, lotrafilcon A (CIBA Vision). The contact lens is dipped in the PM solution (0.001M, pH 2.5) for 30 minutes to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com