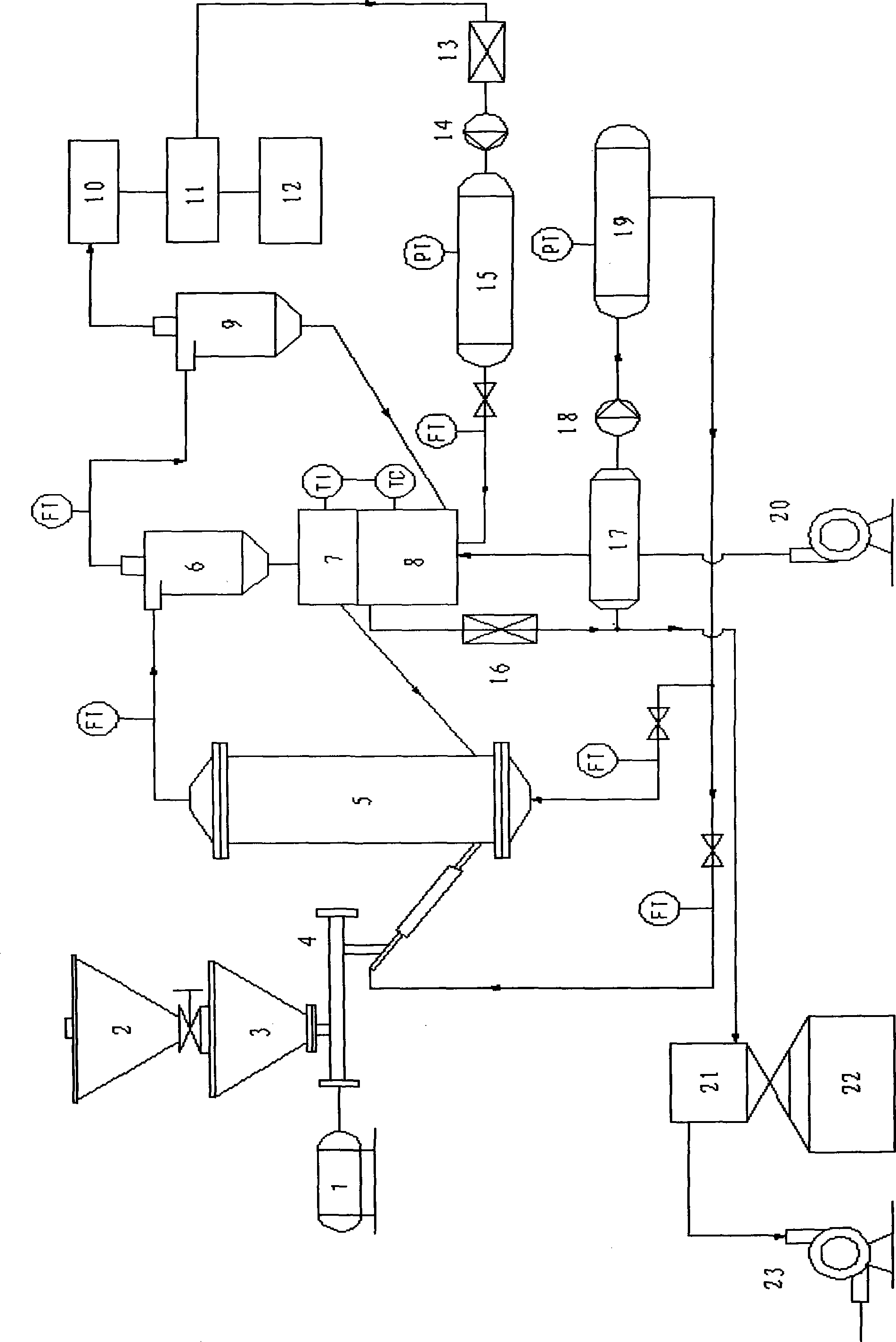

Method and device for preparing biological oil by biomass cracking

A biomass thermal cracking and bio-oil technology, which is applied in the field of biomass regeneration and energy utilization, can solve the problems of low energy utilization rate and poor production continuity, solve the problem of flue gas emission, reduce the total cost, system simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The implementation scheme of this embodiment is as follows:

[0028] (1) Raw material pretreatment: In this embodiment, corn stalks are used as biomass materials. In order to increase the yield of bio-oil, a high heating rate is necessary, so the materials are required to have a small enough particle size, and the biomass powder is crushed to Particle size 1-2mm. In order to avoid excessive moisture in the raw material being brought into the bio-oil, the raw material should be dried. According to the actual production situation, the high-temperature flue gas discharged from the lower layer 8 of the heat carrier heating device in the device system is used to provide heat energy for the raw material drying chamber 21, and dry the biomass powder to a moisture content of less than 8%.

[0029] (2) Heating heat carrier: heat the heat carrier (the fuel is coal gas when used for the first time, and the pyrolysis product charcoal and non-condensable gas after circulation), so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com