Three-fluidized-bed solid heat carrier coal pyrolysis, gasification and combustion cascade utilization method

A solid heat carrier and three-fluidized bed technology, which is applied to the gasification of granular/powdered fuels, the production of combustible gases, and direct heating and dry distillation, etc., can solve the problem of slowing down the reaction speed of fixed carbon, complex and large gasification systems, and increased costs and other issues to achieve the effect of solving pollutant control problems, reducing investment and operating costs, and improving efficiency and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

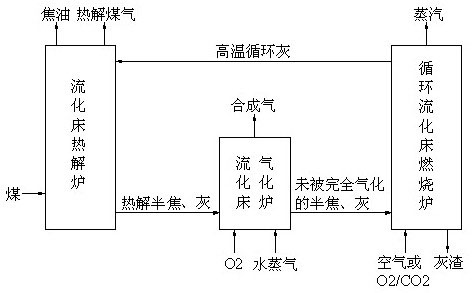

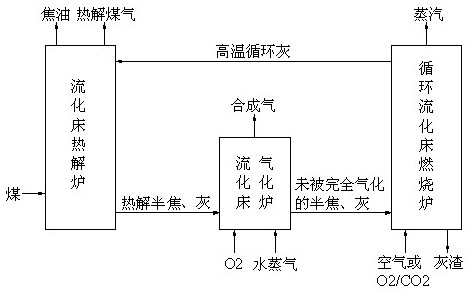

[0013] In conjunction with the accompanying drawings, the specific implementation of the technology introduced in the present invention will be described.

[0014] As shown in the figure, in the three-fluidized bed solid heat carrier coal pyrolysis gasification combustion cascade utilization process, the coal is first mixed in the fluidized bed pyrolysis furnace with the high-temperature circulating ash produced by the circulating fluidized bed combustion furnace , Coal is heated and pyrolyzed, volatile matter is precipitated, and pyrolytic semi-coke is produced. Then, the precipitated gaseous volatiles are dedusted and cooled in sequence. The condensable part obtained after cooling is liquid tar, and the non-condensable part is pyrolysis gas with medium and high calorific value, so that tar and pyrolysis gas can be separated. The tar obtained by pyrolysis is processed to extract high value-added chemicals such as aromatic hydrocarbons and phenols, and then hydrogenated to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com