Two-fluid jet system

An injection system and two-fluid technology, applied in liquid injection devices, injection devices, etc., can solve the problems of increasing the wear of the injection needle and valve body, reducing the dispensing accuracy and service life of the equipment, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

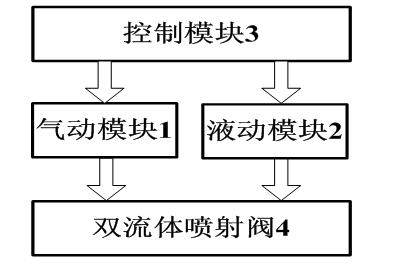

[0060] Embodiment one: refer to figure 1 , the dual-fluid injection system includes a pneumatic module (1), a hydraulic module (2), a control module (3), and a dual-fluid injection valve (4). The control signal input / output ports of the pneumatic module (1) and the hydraulic module (2) are respectively connected to the control module (3), and the flow and pressure of the output gas and liquid are controlled by the control module (3), and the pneumatic module (1) and the working medium output ports of the hydraulic module (2) are respectively connected to the gas and liquid inlets of the dual-fluid injection valve (4), and this system realizes the injection of liquid materials.

Embodiment 2

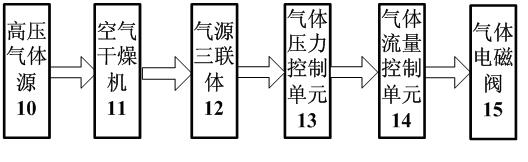

[0061] Embodiment two: refer to figure 1 and figure 2 , this embodiment is basically the same as Embodiment 1, and the special feature is that the pneumatic module (1) is a subsystem of the dual-fluid injection system, which is provided with a high-pressure gas source (10), an air dryer (11), and a gas source in sequence. Triple body (12), gas pressure control unit (13), gas flow control unit (14), gas solenoid valve (15), there are φ6-M5 push-in connectors and φ6 hose connections between each component, This subsystem realizes the supply of working medium—gas.

Embodiment 3

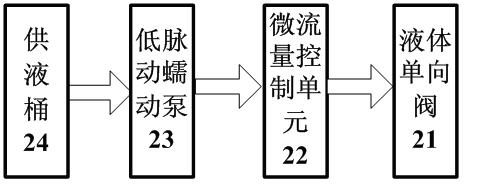

[0062] Embodiment three: refer to figure 1 and image 3 , this embodiment is basically the same as Embodiment 1, and the special feature is that the hydraulic module (2) is a subsystem of a dual-fluid injection system, which is sequentially provided with a liquid supply barrel (24), a low-pulsation peristaltic pump (23), The micro-flow control unit (22), the liquid solenoid valve (21), and the components are connected with φ6-M5 quick-plug connectors and φ6 hoses, and this subsystem realizes the supply of the working medium—liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com