Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Achieve stereotypes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Near-net forming method of 3D braided fiber reinforced metal-based composite material

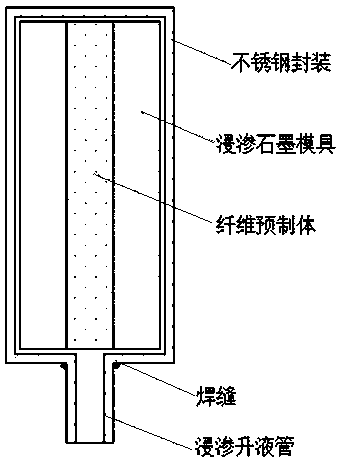

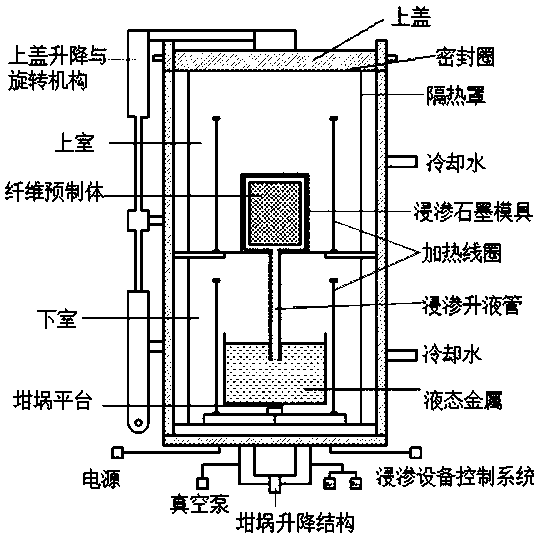

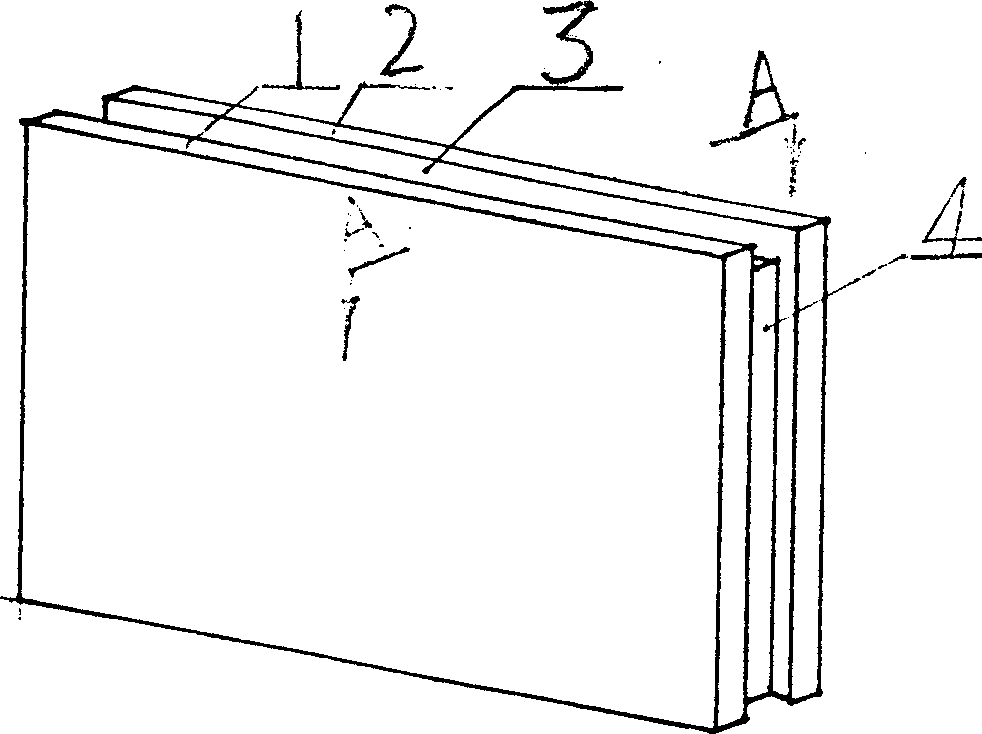

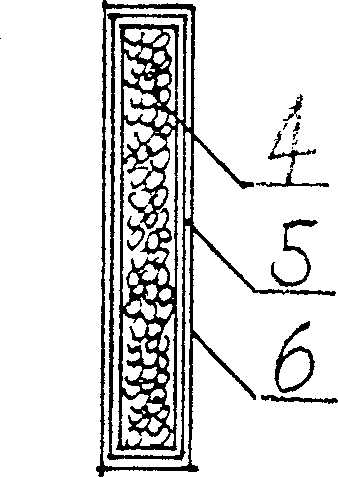

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

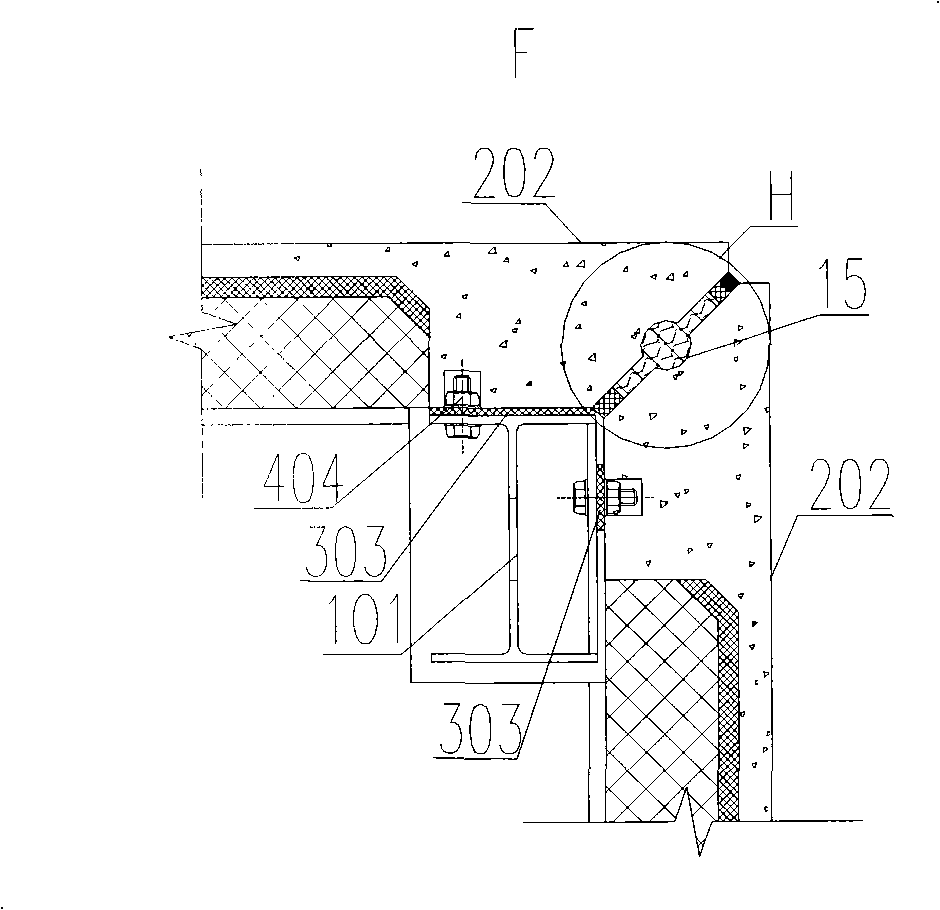

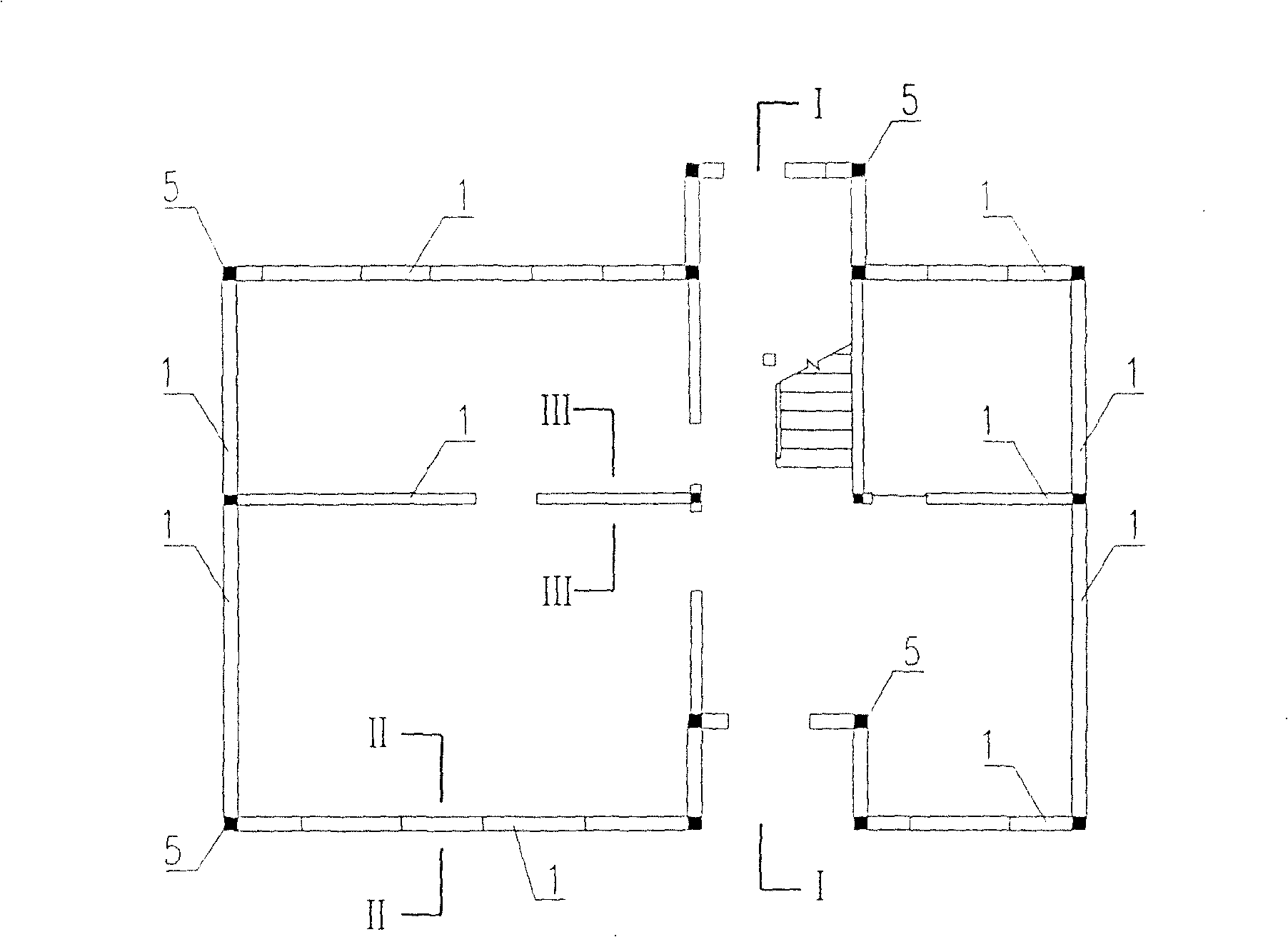

Concrete complex building of steel meshwork framework, and construction procedure

The present invention discloses a kind of steel grid frame structure concrete composite building and its construction method. Said invention is characterized by that it can integrally assemble more than two floors of steel grid frame structure, and can utilize its self-body light weight, high-strength, positioning and loading construction property to integrally form concrete pouring unit and implement complete building structure including pipeline and wiring engineering. Said invention can raise construction speed and can raise construction quality.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

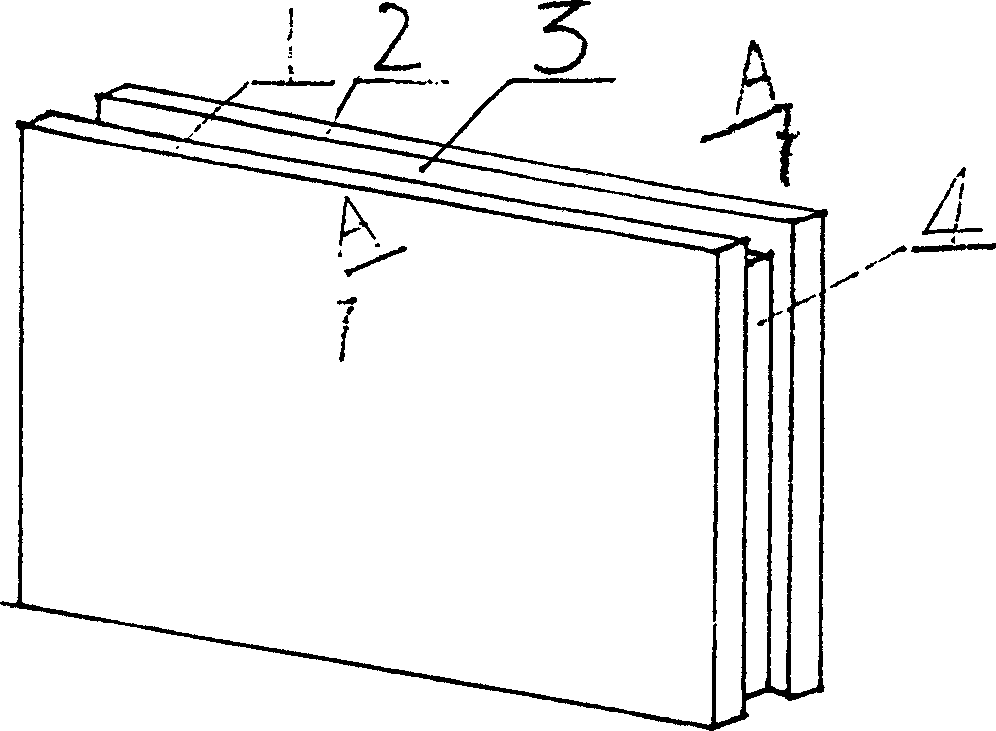

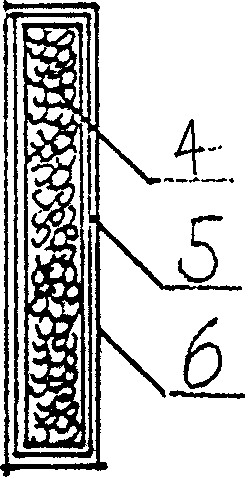

Light-weight small building block as sandwich of wall and its production method

InactiveCN1391017AFacilitate factory processing and productionSimple production processConstruction materialCeramic shaping apparatusRebarReinforced concrete

A light small building block with sandwich for wall is composed of rectangular sandwich board and two rectangular surface slabs made of concrete, and features that its each edge has a slot for casting the reinforced concrete. Its advantages are good insulation of heat and sound, and less possessed area.

Owner:李顺安 +2

High-phase-change thermoset phase change material and preparation method thereof

The invention discloses a high-phase-change thermoset phase change material. The high-phase-change thermoset phase change material is prepared form expandable graphite of which the expansion multiplying power is 100-500mL / g and erythritol which is adsorbed into gaps of the expandable graphite, wherein the weight of the expandable graphite accounts for 10-20 percent of the total weight, and the balance is erythritol. The method comprises the following steps of: heating erythritol in an oil bath of 125-135 DEG C according to a certain proportion till the erythritol is fully molten for later use; putting expandable graphite into a vacuum drying oven; drying at the temperature of 65-75 DEG C under the vacuum degree of -0.09MPa for 8-12 hours; taking out, and putting into a muffle furnace of which the temperature is 700-800 DEG C for calcining for 30-90 seconds to form expansion graphite with a microcellular structure for later use; stirring the two kinds of materials in the oil bath for 1-1.5 hours; and naturally cooling to obtain a product. The high-phase-change thermoset phase change material is simple in structure; and according to the porous adsorption characteristic of the expansion graphite and the high-phase-change potential heat value of the erythritol, the product has higher phase change potential heat value than a phase change material prepared in the prior art.

Owner:HENAN UNIV OF SCI & TECH

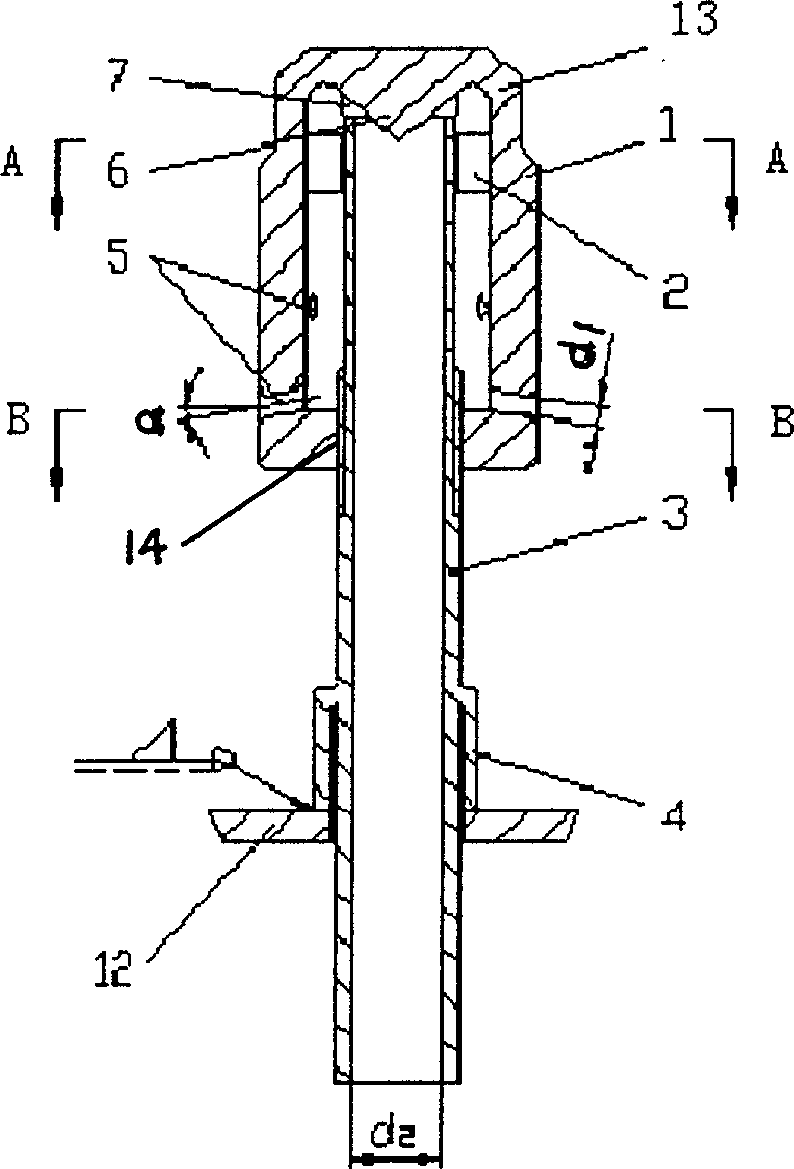

Resistance adjustable gas distributing device for fluid material

InactiveCN1412100AAdjustable resistance characteristicsAchieve stereotypesBulk conveyorsChemical/physical processesEngineeringNozzle

The resistance adjustable gas distribution equipment for fluidized material mainly includes gas intake pipe and gas nozzle, the upper portion of the gas intake pipe is equipped cap-like distribution head which is coaxially arranged with gas intake pipe and is screw-connected with it, between the inner wal of cap-like distribution head and outer wall of gas intake pipe a gas flowing cavity is formed, on the distribution head are opened gas nozzle orifices which use axis of the distribution head as centre and are radially distributed on the side wall of the cap-like distribution head, the upperpart of gas intake pipe is extended into the the interior of cap-like distribution head cavity, and between them a gas resistance adjustable cavity strucure is formed.

Owner:WUHAN KAIDI ELECTRIC POWER CO LTD

Industrialization energy-saving building house

ActiveCN101353929AAchieve aestheticsReduce consumptionFloorsDwelling buildingArchitectural engineeringShock resistance

The invention discloses an industrialized energy-saving building which comprises a load-carrying frame, an enclosing exterior wall, a floor cover slab and a roof cover plate; the enclosing exterior wall is formed by the assembly of entirely prefabricated composite exterior wall boards and fixed on the load-carrying frame of a main body by a shock-resistance and energy-dissipation connecting part. The building is an industrialized energy-saving building which lessens construction energy consumption, water consumption and work area, saves construction material, reduces construction noise and the influence of dust on the environment and the ecology, shortens the construction period, has function of shock resistance and energy dissipation and is capable of saving energy, material, water, land and protecting environment.

Owner:黄涛 +1

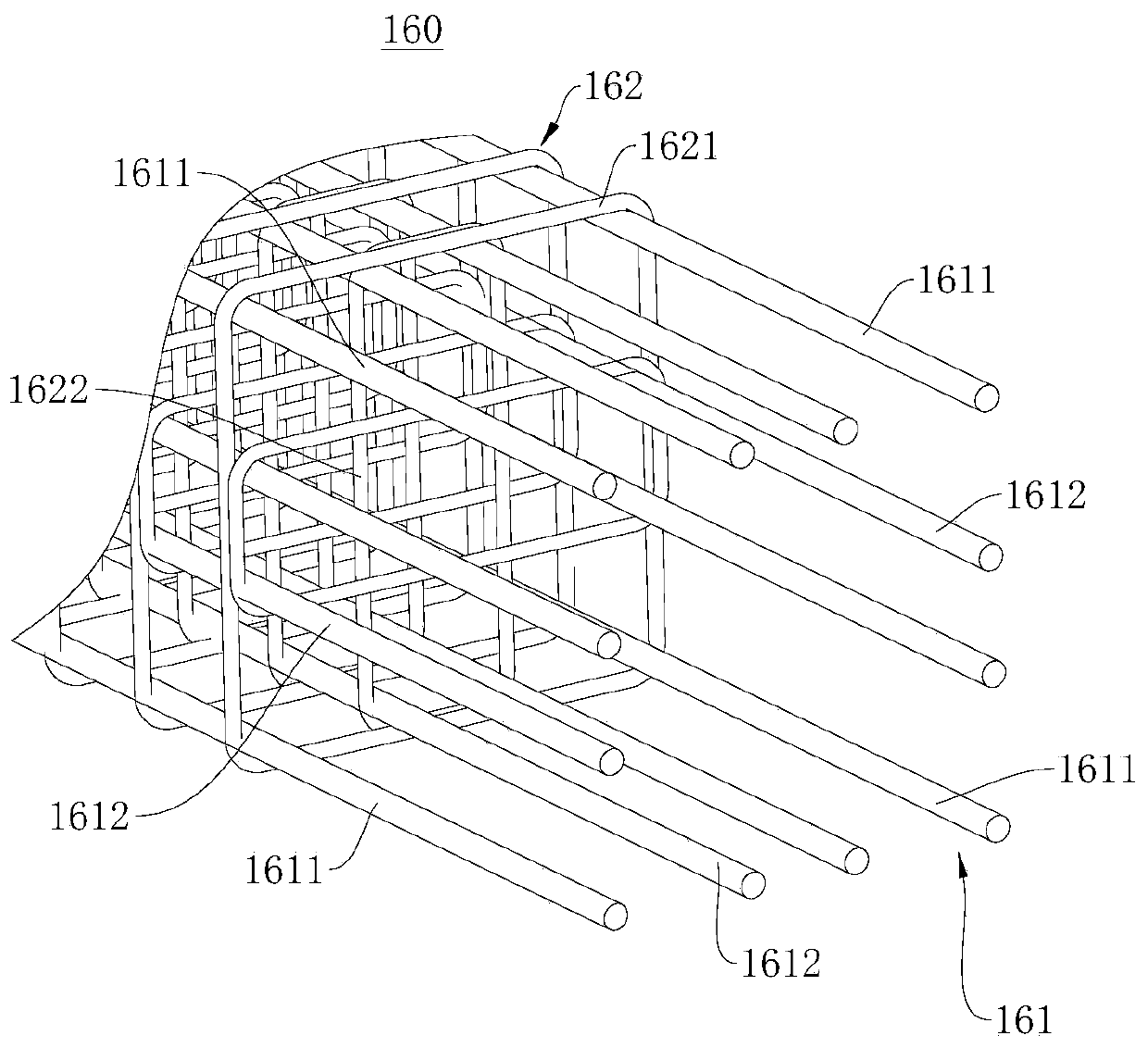

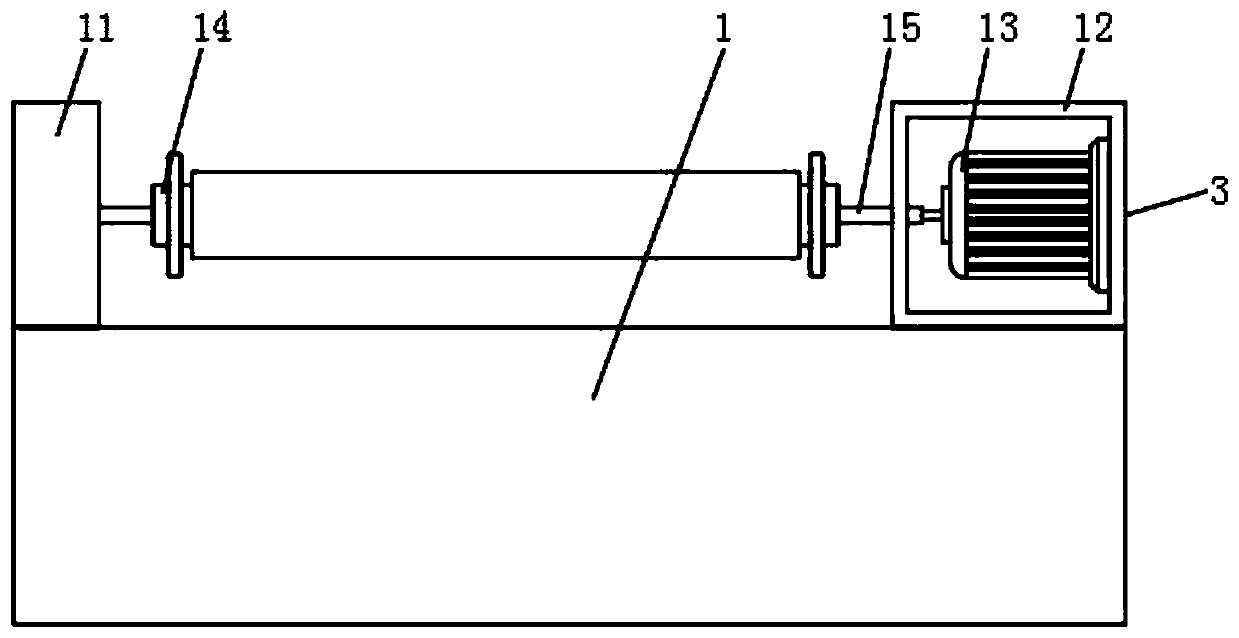

Cylindrical reinforcement cage production method and production system

InactiveCN110497110AAchieve stereotypesImprove structural stabilityWelding/cutting auxillary devicesAuxillary welding devicesWork in processRebar

The embodiment of the invention provides a cylindrical reinforcement cage production method and a cylindrical reinforcement cage production system and relates to the technical field of building components. The cylindrical reinforcement cage production method provided by the embodiment of the invention comprises the following steps of: arranging a first longitudinal bar inside a stirrup in a penetration manner, and welding and positioning the stirrup and the first longitudinal bar by adopting an automatic welding device to form a reinforcement cage semi-finished product; subsequently arranginga second longitudinal bar inside the reinforcement cage semi-finished product, and fixing the second longitudinal bar and the reinforcement cage semi-finished product to form a reinforcement cage finished product. According to the cylindrical reinforcement cage production method, the stirrup and a part of the longitudinal bar are welded to form the reinforcement cage semi-finished product in advance, the welding difficulty is reduced, so the machining step can be implemented by adopting the automatic welding device; moreover, the first longitudinal bar is inserted into the stirrup so that thefirst longitudinal bar makes contact with the inner sidewall surface of the stirrup, thus the first longitudinal bar and the stirrup can be fixed in a welding way; the shaping and consistency qualityof the manufactured reinforcement cage semi-finished product is high; and the common problem that a traditional tied reinforcement cage finished product is unstable in structure is solved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

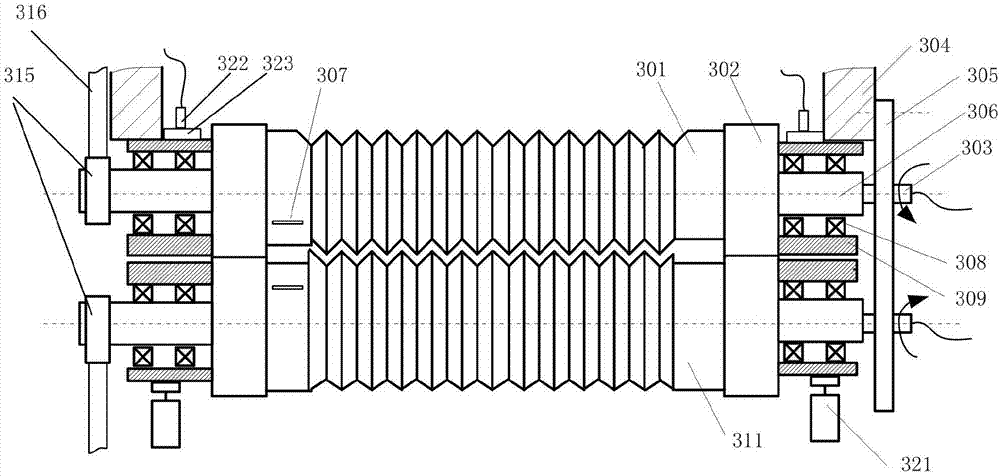

Method for producing air spring large capsule

The invention relates to a method for manufacturing a large capsule of an air spring. The method comprises a two-section molding procedure and a middle mold vulcanization procedure; the two-section molding procedure comprises the following steps: firstly, an inner layer rubber sheet, a cord fabric layer and an outer layer rubber sheet for forming the capsule are adhered and coiled to form a rubber fabric cylinder of which two ends are open; secondly, the rubber fabric cylinder is sleeved on a flared machine head; a small annular steel wire ring and a large annular steel wire ring of two sub-mouths are buttoned; thirdly, the cord fabric layer is folded along a mouth of the steel wire ring so as to wrap up and compact the steel wire ring by the cord fabric layer; and finally, a sealing rubber sheet is adhered to the sub-mouth part and is compacted; a capsule billet needed by the large capsule is formed after being detached from the machine head; the middle mold vulcanization procedure comprises the following steps: the capsule billet is put into a vulcanization mold and is charged and shaped; after the full mold matching, the capsule billet is filled with hot water and is vulcanized; after vulcanization, hot water inside the capsule billet is emptied; the mold is opened; and the vulcanized capsule is taken out. The method greatly improves the strength and fatigue service life of the air spring capsule of the steel ring with a nonsymmetrical structure and easily realizes the shaping of the extroversive shape of the upper sub-mouth in the vulcanization process.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Woolen knitwear steaming setting machine

InactiveCN104805666AAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

Light-weight small building block as sandwich of wall and its production method

InactiveCN1181250CHigh strengthImprove seismic performanceConstruction materialCeramic shaping apparatusReinforced concreteSandwich board

Owner:李顺安 +2

Preparation method of protein self-assembly artificial liver support

The invention provides a preparation method of a protein self-assembly artificial liver support. The method comprises the steps that a three-dimensional model of the liver of a patient is established according to the individual characteristics of the liver of the patient, and then a prepared fibroin solution with a certain concentration and liver cells, subjected to in-vitro subculturing, of the patient are evenly mixed to be a printing material; the mixed printing material is added into a biological forming machine; printing is conducted in an external ultraviolet irradiation environment finally, and preparation of the liver support is achieved. According to the method, the self-assembly characteristic of protein is utilized, an advanced biological printing technology is combined, and therefore preparation of the artificial liver support on the basis of the protein is achieved; the method can not only improve the preparation precision of the liver support, but also has higher biocompatibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Mud stacking device for producing ceramics

InactiveCN107160553AEffective stereotypesEffective stereotypingClay processing apparatusArchitectural engineeringCeramic

The invention discloses a mud stacking device for ceramic production, comprising a base plate, a groove is arranged in the center of the upper surface of the base plate, a bottom connecting plate is fixed on one side of the upper surface of the base plate by bolts, and the bottom connecting plate The upper surface of the upper surface is provided with a bottom threaded rod with an integrated structure, the body of the bottom threaded rod is connected to one end inside a threaded sleeve through a threaded structure, and the other end inside the threaded sleeve is connected to a top threaded rod through a threaded structure The rod body of the rod, and the thread direction of the threaded structure on the bottom threaded rod body is opposite to the thread direction of the threaded structure on the top threaded rod body, and a limiting device is arranged between the bottom threaded rod and the top threaded rod. The invention can effectively shape the stored mud embryos, thereby making its storage more convenient. In addition, the device can realize the shaping of multiple columnar piles of mud at one time, and has the characteristics of high efficiency and fast speed, thus effectively solving the problem of slow working efficiency. shortcoming.

Owner:王 钦辉

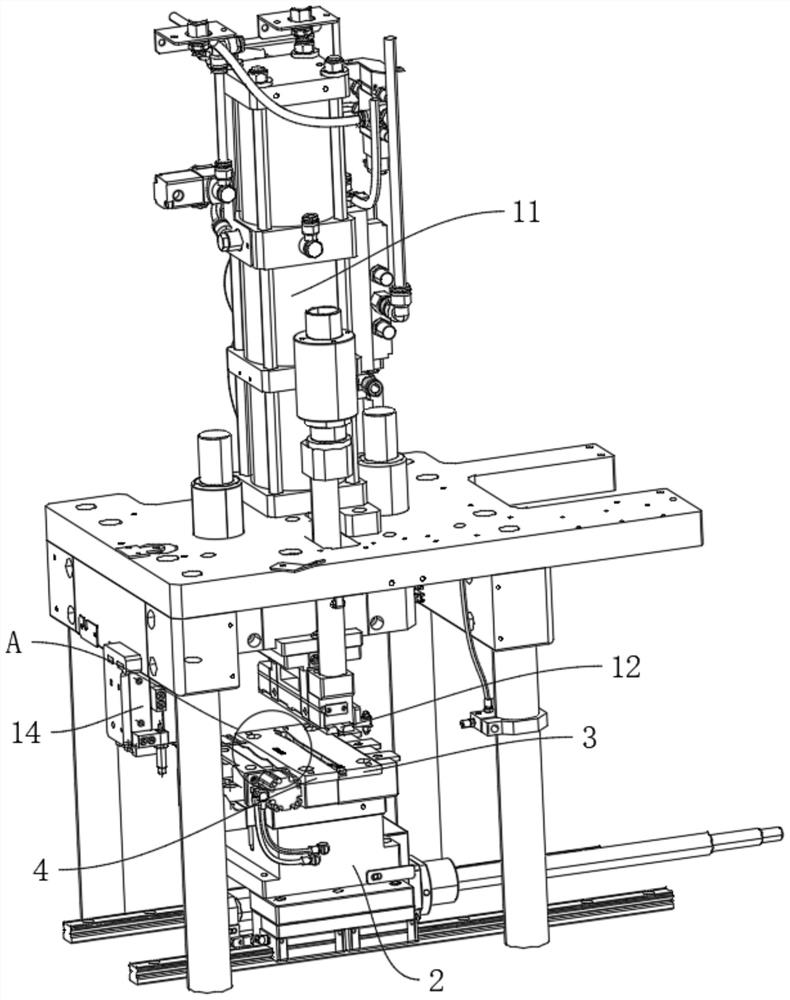

Integrated tool for air tightness detection and pipe orifice retaining ring installation of automobile pipeline

ActiveCN107253048AAchieve stereotypesEasy to operateMetal working apparatusFluid-tightness measurement using fluid/vacuumKeelEngineering

The invention discloses an integrated tool for air tightness detection and pipe orifice retaining ring installation of an automobile pipeline. The integrated tool comprises a base plate; and a fixing mechanism used for fixing the pipeline and an air tightness detection and retaining ring installation integrated mechanism matched with a pipe orifice are arranged on the base plate. The fixing mechanism comprises a clamping mechanism body used for clamping the pipe body portion close to the pipe orifice and a pressure-holding mechanism body arranged on a fin keel outside a pipe body in a pressure-holding mode; the air tightness detection and retaining ring installation integrated mechanism comprises a retaining ring installation mechanism body used for placing a retaining ring into the pipe orifice and an air tightness detection mechanism body used for pipe orifice closing and ventilating and further comprises a switching mechanism body used for switching the positions of the retaining ring installation mechanism body and the air tightness detection mechanism body relative to the pipe orifice; and the switching mechanism body comprises a switching plate and a first drive part driving the switching plate to move left and right relative to the pipe orifice. Inlaid placing and air tightness detection for the retaining ring of the pipeline can be completed only by manually placing the pipeline on the tool, so that operation is convenient, and efficiency is high.

Owner:十堰市倍力汽车管业有限公司

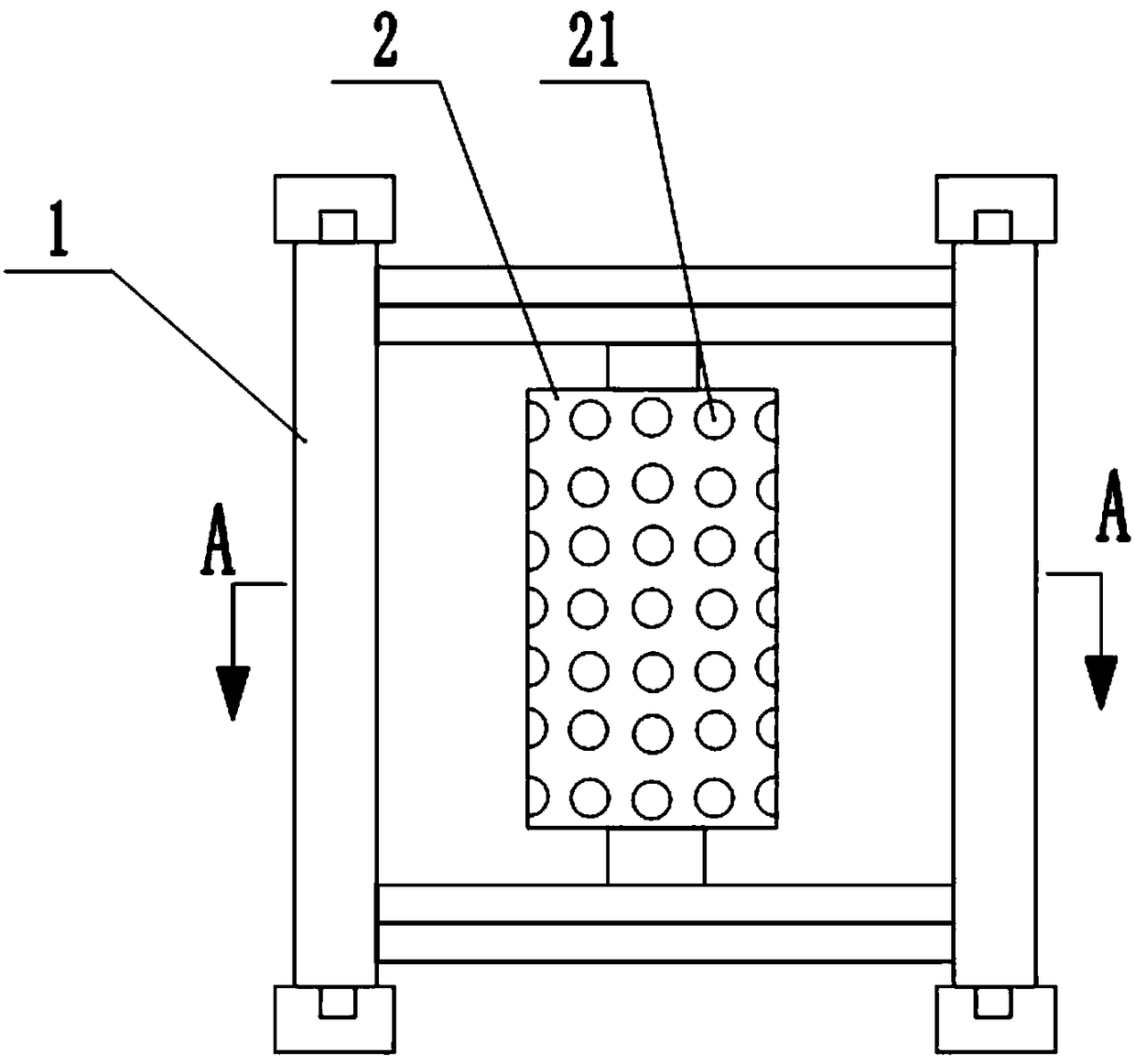

Integral forming device for convex points at surface of cloth

The invention relates to the technical field of textile machinery, and discloses an integral forming device for convex points at surface of cloth. The integral forming device comprises a machine frame, wherein an upper feed roll and a lower feed roll are assembled on the machine frame; semispherical bulges are densely distributed at the surface of the upper feed roll, and semicircular grooves arearranged at the surface of the lower feed roll; a first guide roll is arranged in the machine frame, a second guide roll and a third guide roll are arranged at one side of the first guide roll, the first guide roll is connected with a reciprocating movement device, and a conveying belt is arranged in the machine frame; an extruding device is arranged above the tail end of the conveying belt; a swinging device is arranged in the machine frame and is matched with the reciprocating movement device and the extruding device. The integral forming device has the advantages that the structure is novel; by utilizing the mutual matching of the upper feed roll and the lower feed roll, the convex points are formed at the surface of the cloth; by utilizing the mutual linkage and matching of the first guide roll, the reciprocating movement device, the swinging device and the extruding device, the condensed wax blocks in the convex points of the cloth can be separated from the cloth.

Owner:宁波隆锐机械制造有限公司

Bonding shaping device for plywood

ActiveCN109176765AIncrease the shaping rateThoroughly stereotypedPlywood pressesVeneer pressesFixed framePneumatic pressure

The invention belongs to the technical field of plywood production, and particularly relates to a bonding shaping device for plywood. The bonding shaping device comprises a frame. A motor rotates to drive an extruding rod to rotate, the extruding rod can extrude and loosen a first airbag for two times every time rotating a circle, and the shaping speed can be increased; when the first airbag is extruded and loosened, the driving end of a first air cylinder communicating with the first airbag stretches out and draws back, thus a brake block is pushed to move up and down, and the brake block moves up and down to drive a first rack to move up and down, so that a first gear is driven to rotate forwards and reversely; a thread formed on a fixing frame is engaged with the first gear, thus the fixing frame drives an extruding roller to move left and right, and when moving left and right, the extruding roller is matched with a conveying roller to shape the plywood for the second time; and theextruding roller is arranged perpendicular to a driving roller, and the extruding roller shapes the plywood comprehensively mainly aiming at the positions, where the driving roller cannot conduct press fitting, at the two edges of the plywood.

Owner:安徽省赛旺劳务分包有限公司

Embossing machine for cigarette filter stick fiber paper

ActiveCN107471749AAvoid damageImprove adsorption capacityMechanical working/deformationFiberCellulose acetate

The invention discloses an embossing machine for cigarette filter stick fiber paper. The embossing machine comprises a control unit, an unrolling unit, an embossing unit, a rolling unit and multiple rotary rollers supporting the paper, wherein the unrolling unit, the embossing unit, the rolling unit and the multiple rotary rollers are sequentially arranged in the paper moving direction. The embossing unit is of a rotary male and female roller pressing structure and includes a female roller and a paired male roller, wherein the female roller and the male roller are independently driven and rotate oppositely. Multiple triangular grooves perpendicular to a rotating axis are machined on the outer circle of the female roller and the outer circle of the male roller, the triangular grooves of the female roller and the triangular grooves of the male roller are paired in a concave-convex manner, and clearances for containing paper are reserved. The rolling unit comprises a rolling wheel and a power driving device. By means of the embossing machine for the cigarette filter stick fiber paper, due to an embossing device with the male roller and the female roller, part of longitudinal and transverse paper fibers are quantitatively cut off, long fibered paper subjected to extruding finalized production is used for replacing existing cellulose acetate fiber used for cigarette nozzle bars, the draw resistance performance for manufacturing the cigarette nozzle bars is the same with that in the past, the adsorption performance to harmful substances of cigarette is improved, and harm to cigarettes is greatly lowered.

Owner:陕西浩合机械有限责任公司

Drying, finishing and shaping device for functional fabric

InactiveCN110470123AAchieve finishingAchieve stereotypesDrying gas arrangementsHeating/cooling textile fabricsEngineeringAir blower

The invention relates to the technical field of fabric production, and discloses a drying, finishing and shaping device for functional fabric. The drying, finishing and shaping device comprises a baseand a fabric body. The two sides of the top of the base are fixedly connected with a drying box and a winding mechanism correspondingly. Pressing mechanisms located on the top of the base are arranged on each of the two sides of the drying box. The two sides of the top of the drying box are fixedly connected with an air blower and a heating box correspondingly. An air feeding port of the air lower fixedly communicates with one side of the heating box. The other side of the heating box fixedly communicates with an air feeding pipe. The other end of the air feeding pipe extends to the top of aninner cavity of the drying box and is fixedly connected with a rack pipe transversely distributed. According to the drying, finishing and shaping device, by means of the combinational design of the pressing mechanisms and the winding mechanism, elastic pressing in the winding process of the fabric body is achieved, the finishing and shaping effect of the fabric body is improved, it is avoided that folds or the inclined winding phenomenon is caused to the fabric body in the drying process, and practicability and use convenience of the device are improved.

Owner:CHANGXING BAOFU WEAVING

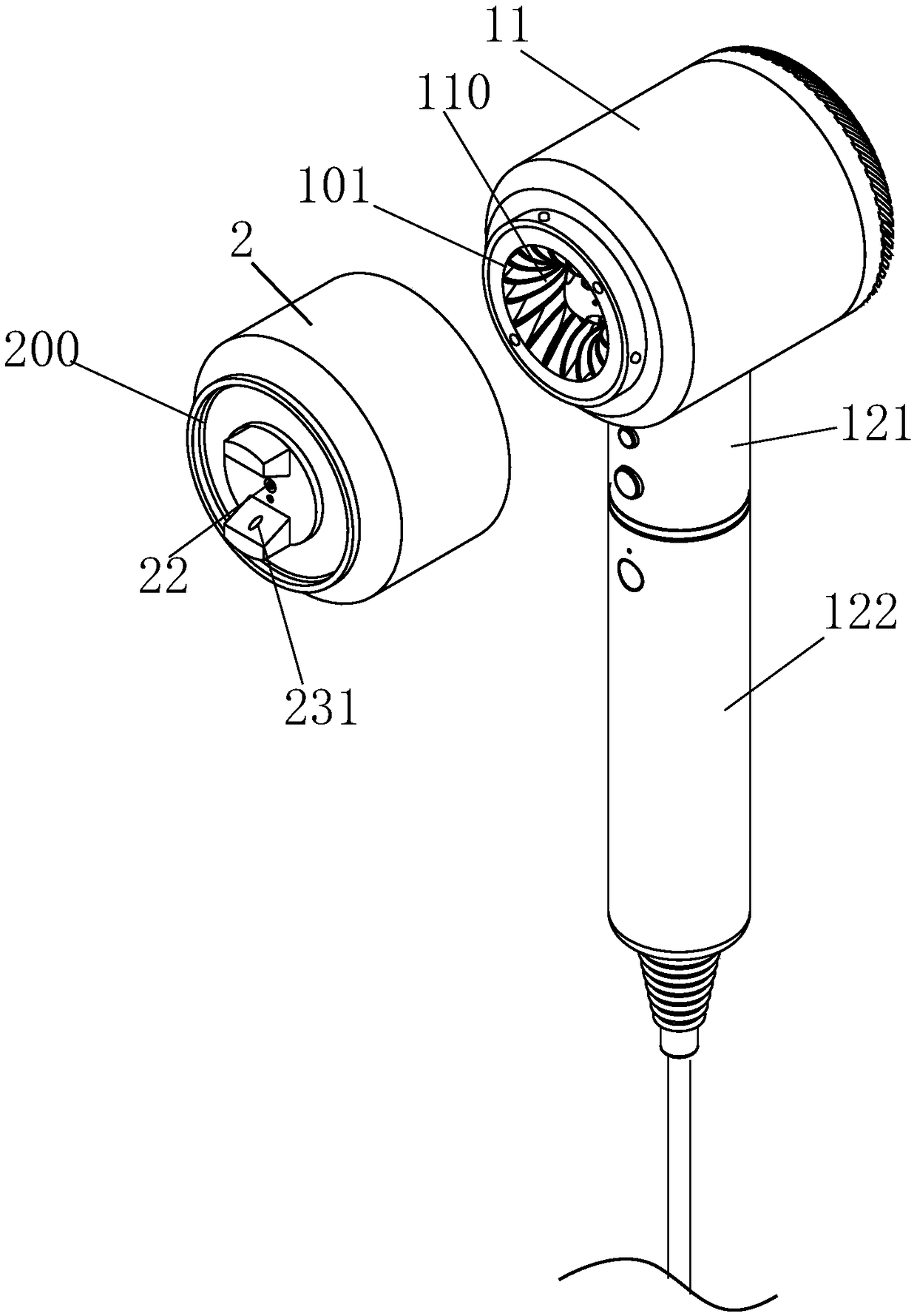

Hairdryer with shaping spraying function

The invention discloses a hairdryer with a shaping spraying function, comprising a hairdryer body; a spray module is releasably mounted at an air outlet of the hairdryer body; a liquid storage space is arranged in the spray module; the front end face of the spray module is provided with a liquid spray hole and air spray holes; an air flow generated by the hairdryer body enters the spray module viathe air outlet; the air flow passes through an air passage arranged in the spray module and is then sprayed out of the air spray holes; negative pressure formed by spraying of the air spray holes enables the liquid in the storage space to be sprayed out of the liquid spray hole. The negative pressure formed by spraying of the air spray holes beside the liquid spray hole is used to suck out glue in the storage space, the glue is then sprayed to a user's hair with the air flow, and spray shaping of the air is completed. Glue spraying and air blowing are combined herein; spray shaping is achieved during air blowing, hairstyling time is saved, and hairstyling is more effective.

Owner:DONGGUAN RUIDI THREE DIMENSIONAL ELECTRONICS TECH

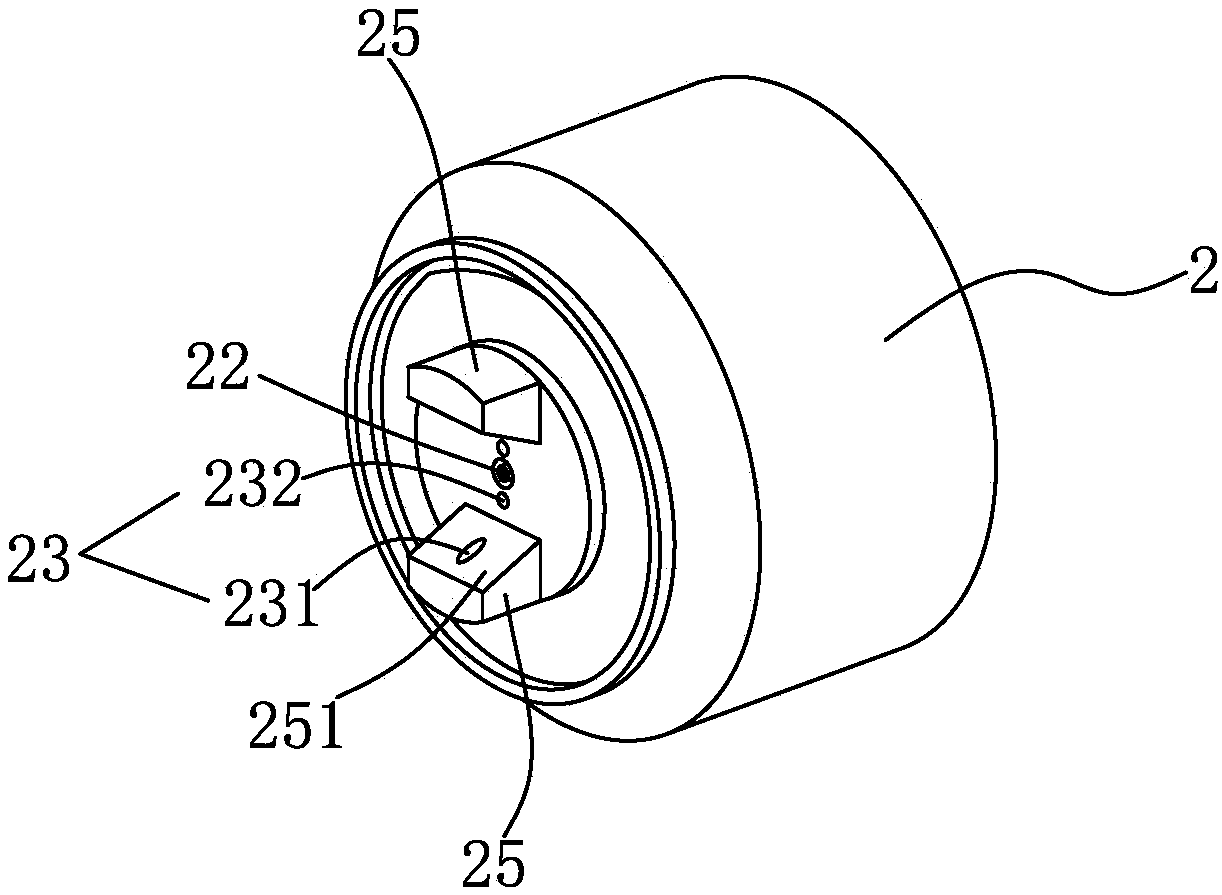

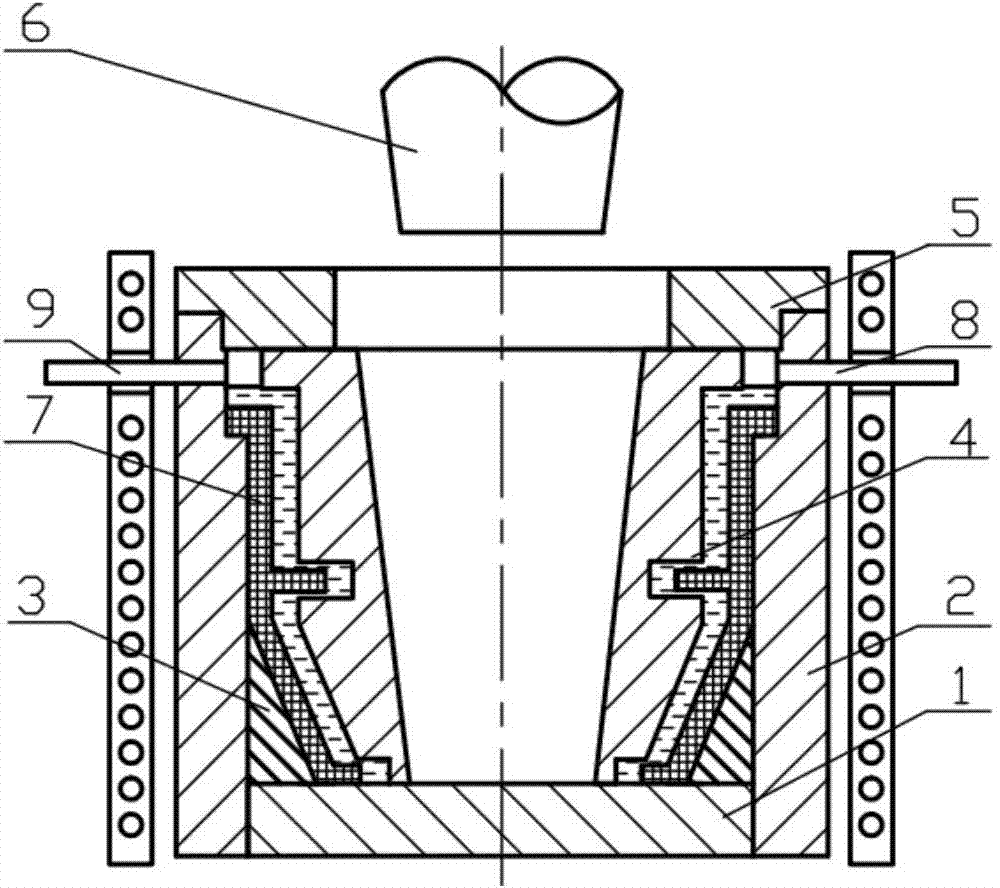

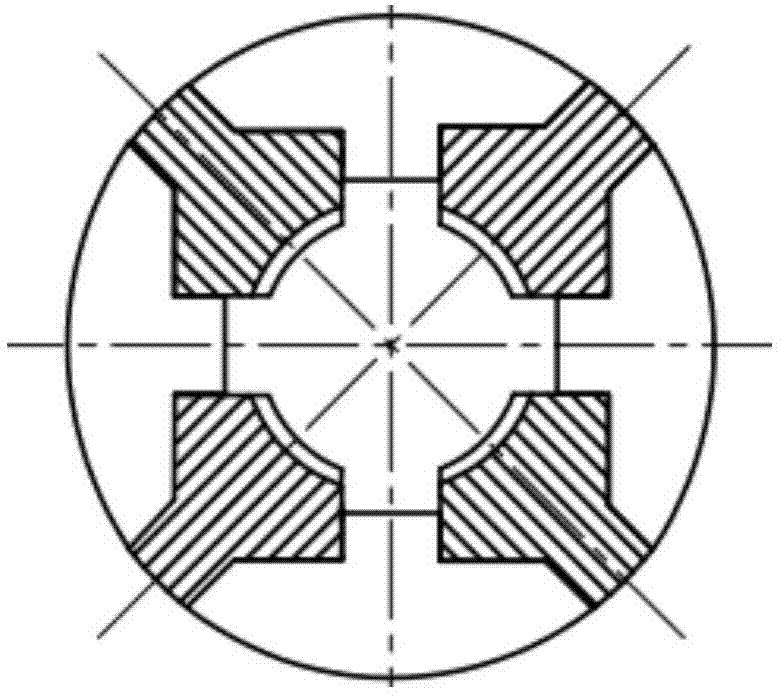

Liquid-solid pressure formation device and method for thin-wall special-shaped parts made of Cf-Mg composite materials

The invention discloses a liquid-solid pressure formation device and method for thin-wall special-shaped parts made of Cf-Mg composite materials. The liquid-solid pressure formation device and method for the thin-wall special-shaped parts made of the Cf-Mg composite materials are used for solving the technical problem that prefabricated parts with complex inner wall structures are difficult to form by an existing fiber-reinforced intermetallic compound composite part manufacturing device. According to the technical scheme, a split insert structure replaces an integrated mandrel to shape the prefabricated parts. Compared with the integrated mandrel, the inner side of an insert set is hollow, a male mould is small, and the overall weight of a formation device can be reduced; magnesium alloy fluid is prompted to permeate the prefabricated parts evenly through the radial movement generated by stress on inserts; the surfaces of the inserts are tightly attached to the inner walls of the prefabricated parts, and the sizing effect is remarkable; near-net forming of the different-shape thin-wall special-shaped parts made of the Cf-Mg composite materials can be achieved by changing the shapes of sections of the inserts; the inserts are separated after extrusion is completed to achieve demoulding, and the technical problems that the prefabricated parts with the complex inner wall structures are high in sizing difficulty, and demoulding is difficult are effectively solved, and forming of the thin-wall special-shaped parts made of the Cf-Mg composite materials is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Light homogenizing type processing technology for color steel plate

InactiveCN113426650AQuality improvementImprove uniformityPretreated surfacesCoatingsLight irradiationMaterials science

The invention discloses a light homogenizing type processing technology for a color steel plate, and belongs to the technical field of color steel plate processing. After a color steel plate is subjected to corona treatment and painting, multiple light homogenizing capsules are taken and placed in paint, then the paint is subjected to strong light irradiation, the thickness of a paint film is sensed through the light homogenizing capsules, and once the thickness is insufficient, the light homogenizing capsules can guide external light into the light homogenizing capsules, then a light-heat conversion phenomenon is triggered, converted heat heats gas in the light homogenizing capsules, gas expansion is promoted, and then the light homogenizing capsules are forced to bulge upwards in the designated direction, so that paint at the position is forced to be lifted upwards for filling-in; and when the thickness of the paint just covers the light homogenizing capsules, photo-thermal conversion is stopped, and then self-shaping is realized, so that an area with insufficient thickness on the surface of the paint is filled in, the uniformity of the thickness of the paint film is effectively improved, and the quality of the paint film is improved.

Owner:刘青

Special device for down ball preparation and down ball preparation method thereof

The invention discloses a special device for down ball preparation and a down ball preparation method thereof. The special device for down ball preparation comprises a rack, a compressing unit, a wrapping unit, and a drying unit, the compressing unit, the wrapping unit and the drying unit are all fixedly mounted on the rack, the compressing unit is fixedly mounted on the upper end of the wrappingunit, and the drying unit is fixedly mounted at the lower end of the wrapping unit. Down balls are prepared by the steps of down preprocessing, down compression, water-soluble adhesive preparation, down wrapping, down ball shaping and drying. According to the invention, by mounting baffle plates at the upper end of a passage, compressed down in an outlet a can conveniently pass through the baffleplates on both sides, so that position is limited, consequently, by means of the passage, the wrapping of an adhesive is carried out, and the adhesive which is placed in a solvent tank can wrap the down by means of the baffle plate sides. According to the invention, by adopting the special device for down ball preparation, down balls can be directly prepared, the preparation method is simple, anddown is more convenient to fill.

Owner:IANGSU COLLEGE OF ENG & TECH

Concrete complex building of steel meshwork framework, and construction procedure

The present invention discloses a kind of steel grid frame structure concrete composite building and its construction method. Said invention is characterized by that it can integrally assemble more than two floors of steel grid frame structure, and can utilize its self-body light weight, high-strength, positioning and loading construction property to integrally form concrete pouring unit and implement complete building structure including pipeline and wiring engineering. Said invention can raise construction speed and can raise construction quality.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +2

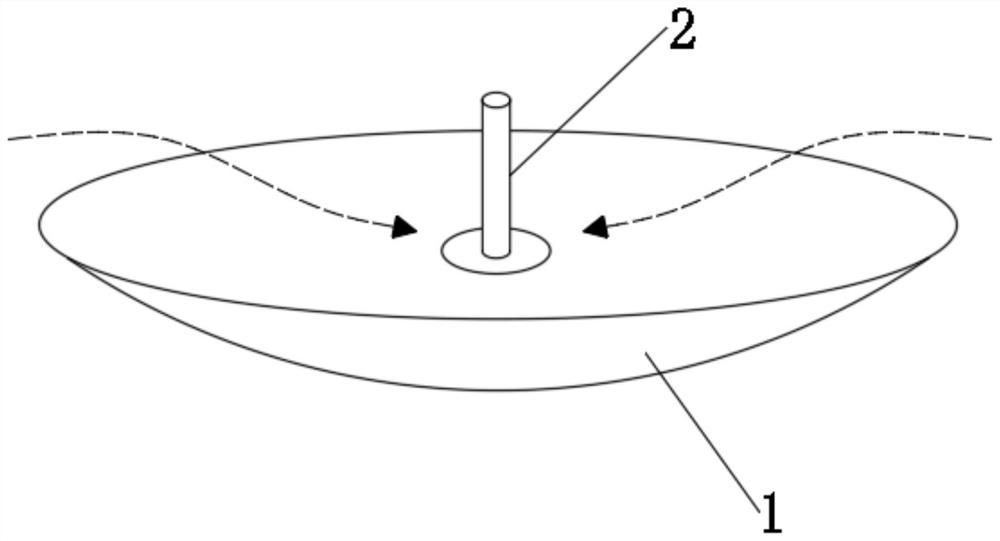

Automobile airbag shaped through reinforcing material

InactiveCN105196958AUniform strengthAchieve stereotypesPedestrian/occupant safety arrangementEngineeringUltimate tensile strength

The invention discloses an automobile airbag shaped through a reinforcing material. The automobile airbag comprises an airbag body and a gas generator, wherein the airbag body is communicated with the gas generator; the airbag body is made of an elastic plastic material; a reinforcing piece is arranged on the outer surface of the top end of the airbag body; the periphery of the reinforcing piece is fixedly connected with the bottom end of the airbag body through reinforcing bands; the reinforcing piece and the reinforcing bands are fixed on the surface of the airbag body in a sticking manner. According to the invention, the unfolded airbag can be shaped, and the rigidity in the airbag unfolding process is distributed more uniformly, so that the contact action area of the airbag and a passenger in the inflation unfolding process is increased, the impact of the airbag to the passenger is reduced, and a safety protection effect of the airbag directly facing a driver on the passenger is promoted. The reinforcing material further has the effect of reinforcing the whole strength of the airbag and the fact that the manufacturing process is simple, convenient and rapid is guaranteed since the reinforcing piece and the reinforcing bands are fixed in a sticking manner.

Owner:WUHU JINPENG AUTO PARTS

Convex surface forming device for cloth

The invention relates to the technical field of textile machinery, and discloses a convex surface forming device for cloth. The convex surface forming device for the cloth comprises a machine frame, an upper feeding roller and a lower feeding roller are assembled on the machine frame, melted wax liquid is injected into the upper feeding roller, hemispheric protrusions are arranged on the surface of the upper feeding roller, convex parts of the hemispherical protrusions are provided with openings, clamping blocks used for sealing the openings are connected to the openings, springs are connectedbetween the clamping blocks and the inner wall of the upper feeding roller, and hemispheric grooves are densely distributed in the surface of the lower feeding roller. According to the convex surfaceforming device for the cloth, the cloth to be processed penetrates between the upper feeding roller and the lower feeding roller, the protrusions at the lower end of the upper feeding roller push thecloth into the grooves in the upper part of the lower feeding roller, meanwhile, the clamping blocks are ejected into the protrusions, and the melted wax flows out of the openings, flows to the clothand is solidified so as to enable the convex surfaces on the cloth to be completely formed. The convex surface forming device for the cloth has the advantages that the concept is novel, and the problems that in the prior art, the forming effect of the convex surfaces processed and formed on the cloth by an existing convex point forming multi-roll stretching device for cloth is poor, and deformation is easy can be solved.

Owner:宁波隆锐机械制造有限公司

Novel efficient shutter forming die

ActiveCN107824685AImprove work efficiencyAchieve stereotypesShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention provides a novel efficient shutter forming die. The novel efficient shutter forming die comprises a lower die holder, and an upper template connected with the lower die holder in a sliding manner through symmetrically arranged guide rods, wherein a feeding device is arranged on the lower die holder; the feeding device is arranged at the outer part of the upper template; a reversing correction device is arranged in the position, close to the feeding device, between the lower die holder and the upper template; a circle winding device is arranged on one side of the reversing correction device; a pulling-down forming device is arranged at the side end of the circle winding device; the reversing correction device, the circle winding device and the pulling-down forming device are sequentially arranged between the lower die holder and the upper template, and are positioned on the same straight line; and an ejector mechanism is arranged at the end, away from the feeding device, of the lower die holder. According to the novel efficient shutter forming die, a traditional stamping design concept is changed through the precise die, circle winding and forming can be achieved in batches in one device, the die is relatively small, processing and manufacturing cost is obviously reduced, the circle winding effect is relatively good, and the forming requirement of shutters can be well met.

Owner:秦皇岛圣标门窗有限公司

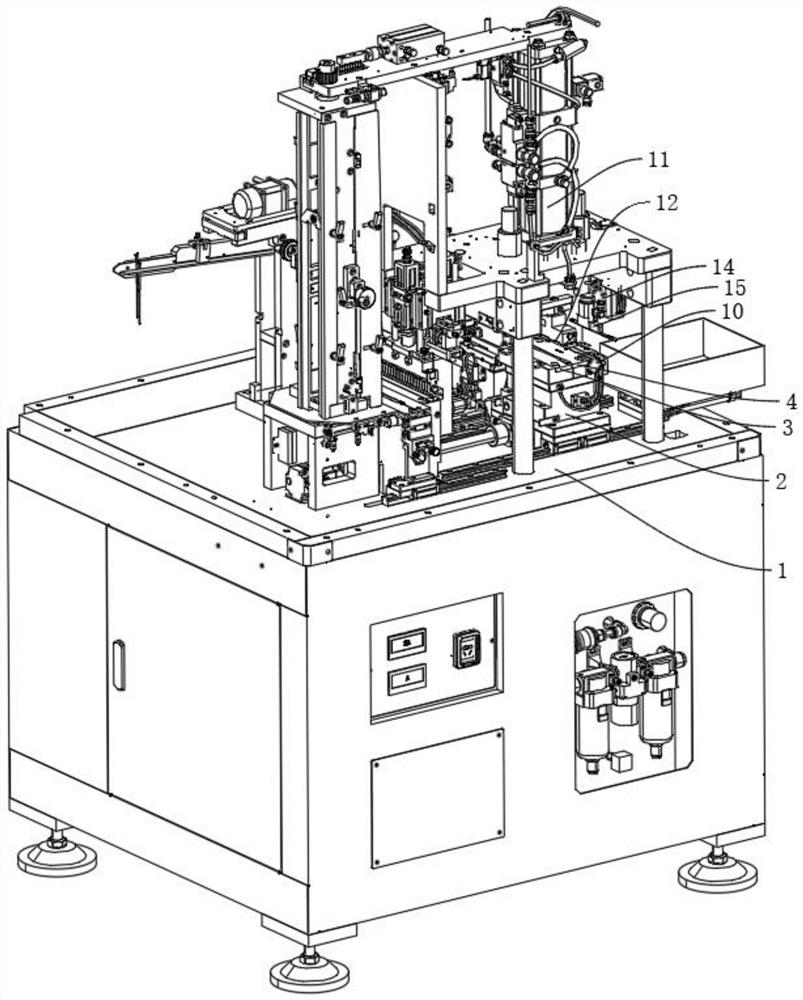

Device for fixing earpiece and inserting hinge support rod in glasses pin inserting machine

PendingCN113589555AEasy accessAchieve stereotypesSpectales/gogglesNon-optical partsEyewearEngineering

The invention discloses a device for fixing an earpiece and inserting hinge support rod in a glasses pin inserting machine, which is characterized in that the device for fixing the earpiece and inserting the hinge support rod in the glasses pin inserting machine comprises a rack, the rack is provided with a material receiving mechanism used for receiving the heated earpieces, an abutting assembly used for abutting against the upper end faces of the earpieces, and a material taking assembly used for taking out the machined earpieces. The material receiving mechanism comprises a material receiving seat slidably connected to the rack, a moving structure driving the material receiving seat to horizontally move, and a clamping assembly arranged on the material receiving seat and used for containing and fixing the earpieces. According to the invention, earpieces can be conveniently mounted, and deformation of the earpieces can be avoided when the earpieces are inserted into the hinge support rods.

Owner:浙江日科自动化设备有限公司

Manufacture method of sauced pork elbows

The present invention provides a manufacture method of sauced pork elbows. A technical scheme is based on a current situation in the prior art that in a sauce cooking process, wire and rope binding isgenerally used, and aims at technical problems that raw pork elbows are not easy to be bound after bones are removed. Before washing, open fire is firstly used to burn the pork elbows. Based on not causing denaturation of pork proteins, surface skin of the burnt elbows is shrunk, tightening and shaping of the whole pork elbows are realized, and a subsequent binding technology is favored. At the same time, the open fire burning can also realize remove of pig hairs and improves mouthfeel. Based on the open fire burning, the manufacture method solves a problem that high-temperature heating destroys nutrients. Low-temperature stewing is combined with subsequent soaking technology. At the same time, a soup stock formula is optimized and the manufacture method ensures flavoring of sauce juice,effectively reduces operation temperature, and enables the nutrients to be effectively restored. The manufacture method achieves good technical effects with innovative technological improvements and has a good promotion prospect.

Owner:罗英海

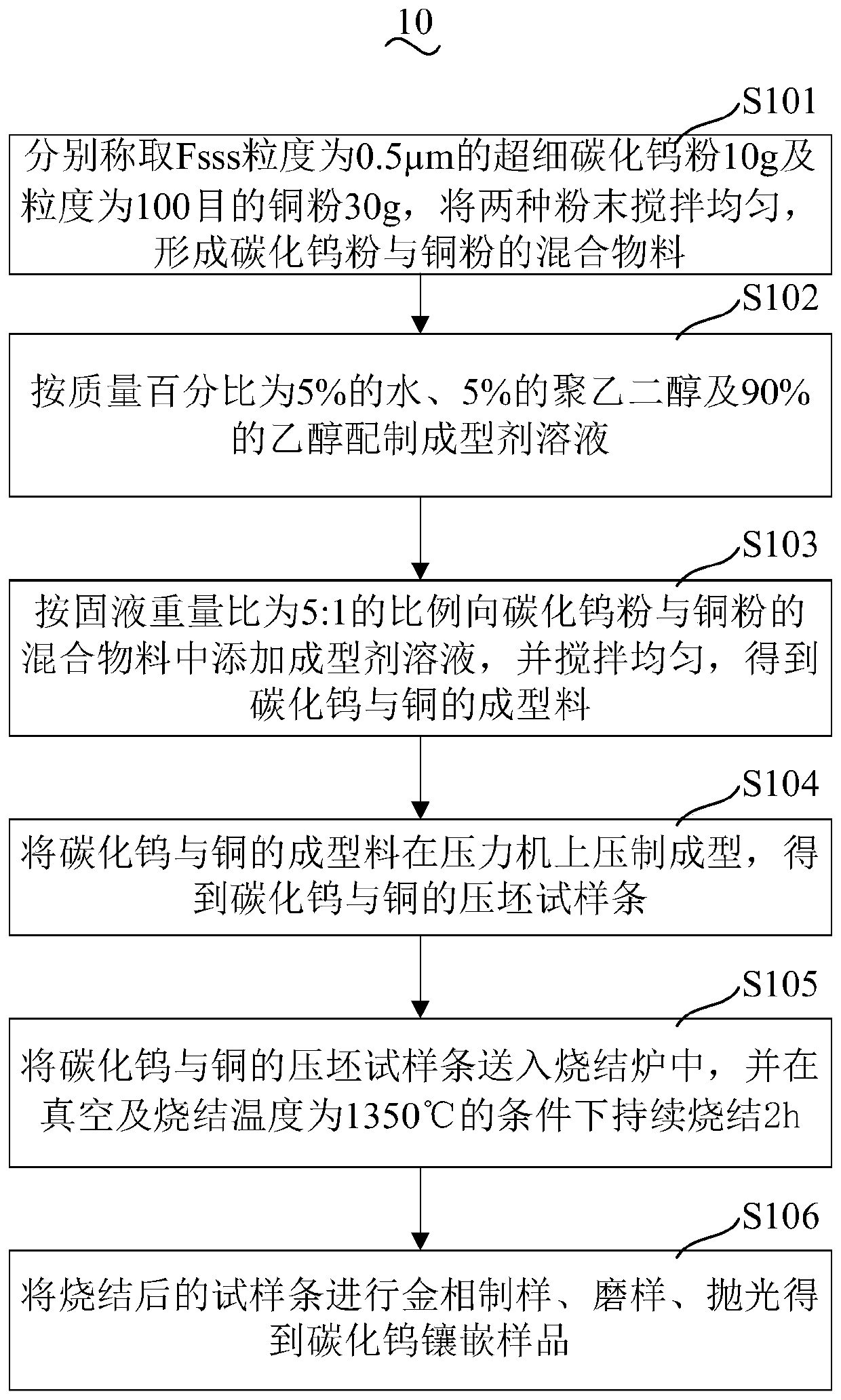

Preparation method of tungsten carbide embedment sample

InactiveCN110823656AReduce the difficulty of cuttingFacilitate effective assessment of qualityPreparing sample for investigationCompression moldingAlcohol

The invention discloses a preparation method of a tungsten carbide embedment sample. The preparation method comprises the following steps of respectively weighing an appropriate amount of tungsten carbide powder and an appropriate amount of copper powder, and uniformly mixing the tungsten carbide powder and the copper powder; preparing a formation agent solution comprising 5-10wt% of water, 5-10wt% of polyethylene glycol and 80-90wt% of ethyl alcohol; adding the formation agent solution into a mixed material, and performing uniform stirring to obtain a formation material; performing compression molding on the formation material to obtain a press blank sample strip; performing anaerobic sintering on the press blank sample strip in a sintering furnace; and performing gold-phase sample preparation, sample grinding and polishing on the sintered sample strip to obtain the tungsten carbide embedment sample. According to the preparation method of the tungsten carbide embedment sample, the copper powder and the tungsten carbide powder are mixed and sintered, the tungsten carbide powder is shaped, thus, the cutting difficulty of tungsten carbide is reduced, and single-crystal grain is favorably detected; copper is not fused with tungsten carbide during sintering, the performance reliability of the single-crystal grain is ensured; and the tungsten carbide is embedded and fixed by cooledcopper, poly-crystal grain is difficult to fall off during grinding and polishing, and effective proceeding of tungsten carbide detection operation is ensured.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

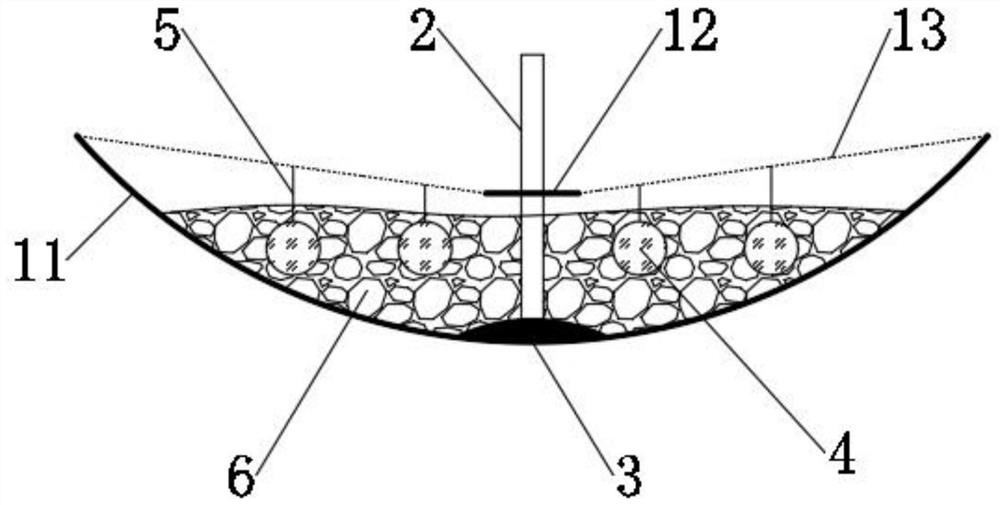

Net cage for breeding tilapia

InactiveCN103563804AAchieve stereotypesAchieve positioningClimate change adaptationPisciculture and aquariaTilapiaEconomic benefits

The invention discloses a net cage for breeding tilapia. The net cage comprises a net cage body and a shaping and positioning structure, wherein the net cage body is cuboid and consists of side nets and a bottom net, the long side nets and the bottom net are made of polyethylene net pieces with the fineness smaller than 20-40 meshes, and the short side nets are made of polyethylene net pieces with hole diameters of 1-4cm; and the shaping and positioning structure comprises piles, cross beams, steel wires and sand weights. The net cage has the advantages that the water quality inside the net cage is fresh, tilapia breeding is facilitated, the roe yield is increased, the production controllability is improved, and meanwhile, the cost and the work intensity of production of roes are reduced, so that the good economic benefit can be realized.

Owner:GUANGXI ACADEMY OF FISHERY SCI

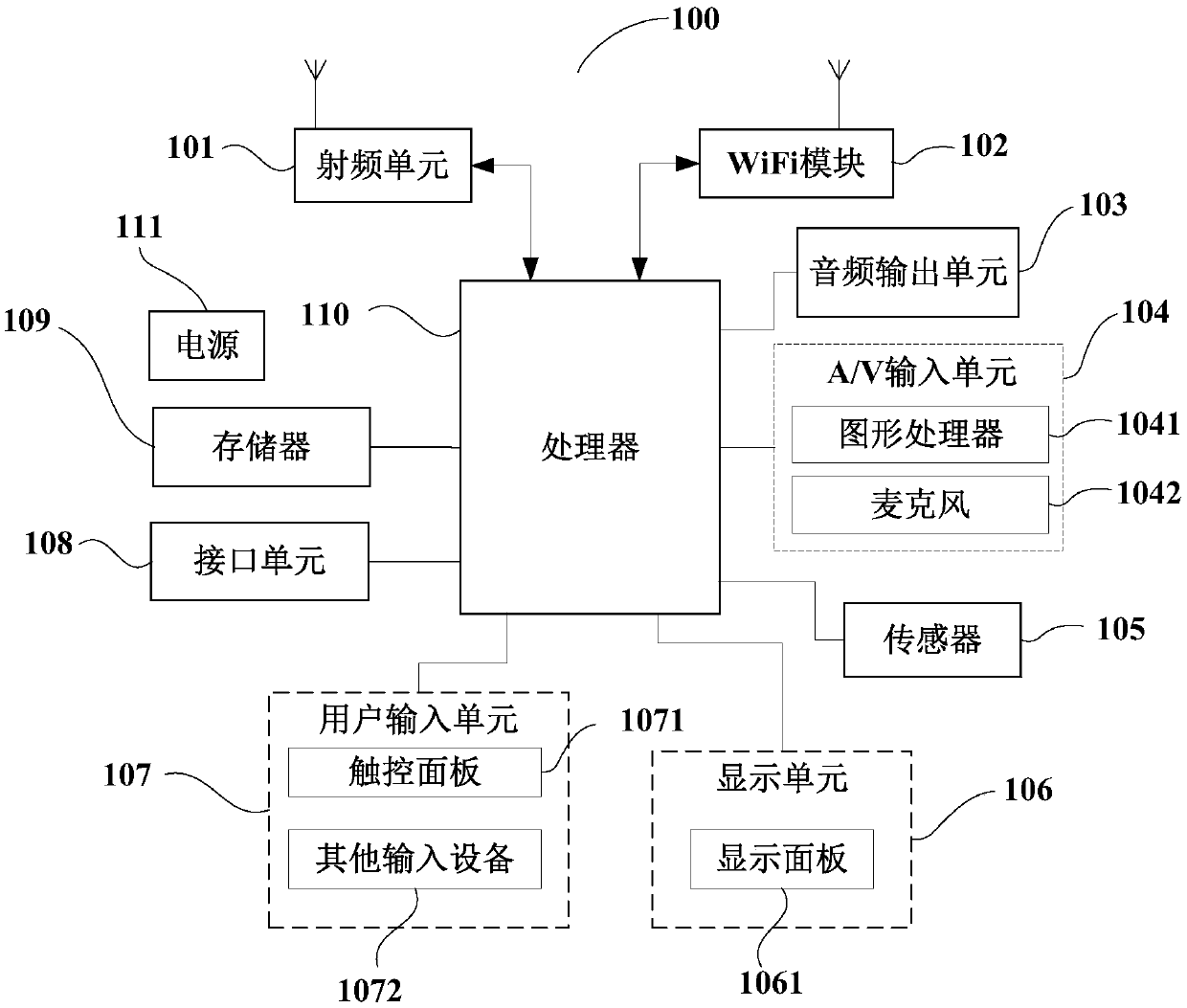

Connecting structure and terminal

InactiveCN110547568AAchieve stereotypesImprove wearing convenienceBraceletsWrist-watch strapsSimple modeElectrical and Electronics engineering

The invention provides a connecting structure and a terminal. By aiming at the problems that in the prior art, wearable equipment has an inconvenient wearing mode and cannot realize self shaping, theinvention provides the connecting structure for terminal wearing connection and the terminal. The connecting structure comprises a flexible outer case and a power steel sheet, wherein the power steelsheet is arranged in the flexible outer case; at least one end in the length direction of the power steel sheet is movably connected with the flexible outer case; and a smooth guide layer is arrangedon the surface of at least one inner side wall of the inner side walls, corresponding to the top surface and the bottom surface of the power steel sheet, of the flexible outer case. Therefore, automatic wearing of the terminal is realized through the power steel sheet, a user can wear the terminal through bending and folding generation by changing the elastic balance of the power steel sheet in simple modes such as flapping, so that the wearing convenience is improved, and the wearing speed is accelerated; and after the power steel sheet is bent and folded, the shape is fixed, so that the terminal wearing shaping is realized.

Owner:NUBIA TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com