Preparation method of tungsten carbide embedment sample

A technology of tungsten carbide and tungsten carbide powder, which is applied in the field of preparation of tungsten carbide inlaid samples, can solve the problems that it is difficult to reflect the actual performance of tungsten carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

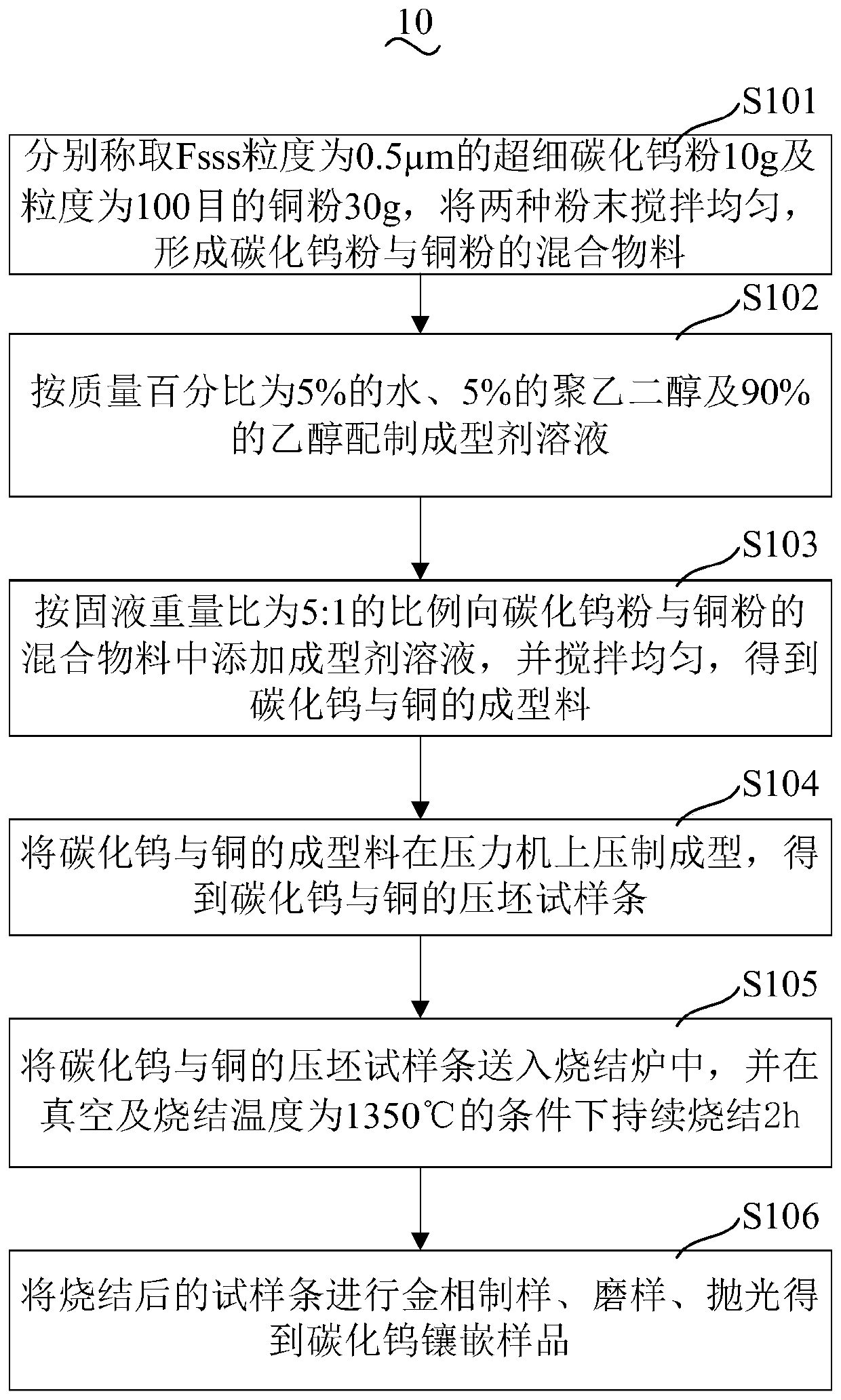

[0021] see figure 1 , the present invention provides a preparation method 10 of a tungsten carbide mosaic sample, the preparation method 10 of the tungsten carbide mosaic sample comprises the following steps:

[0022] S101: Weigh 10 g of ultrafine tungsten carbide powder with a particle size of Fsss of 0.5 μm and 30 g of copper powder with a particle size of 100 mesh, and stir the two powders evenly to form a mixture of tungsten carbide powder and copper powder.

[0023] Specifically, fully mixing the tungsten carbide powder and the copper powder can increase the contact area between the tungsten carbide powder and the copper powder. The gaps between the tungsten carbide powders are filled, and the cooled copper can firmly wrap the tungsten carbide powders, thereby improving the stability of the tungsten carbide powder inlays and facilitating the grinding and polishing of the tungsten carbide inlay samples.

[0024] S102: Prepare a forming agent solution with 5% water, 5% pol...

Embodiment 2

[0038] see figure 2 , the present invention provides a preparation method 20 of a tungsten carbide mosaic sample, the preparation method 20 of the tungsten carbide mosaic sample comprises the following steps:

[0039] S201: Weighing 20 g of tungsten carbide powder with a Fsss particle size of 5 μm and 20 g of copper powder with a particle size of 200 mesh respectively, and stirring the two powders evenly to form a mixture of tungsten carbide powder and copper powder.

[0040] S202: Prepare a forming agent solution with 10% water, 10% polyethylene glycol and 80% ethanol in mass percentage.

[0041] S203: Add a molding agent solution to the mixture of tungsten carbide powder and copper powder at a solid-to-liquid weight ratio of 6:1, and stir evenly to obtain a molding material of tungsten carbide and copper.

[0042] Specifically, add 6.7g of molding solvent to the mixture of tungsten carbide powder and copper powder, and stir the mixture of tungsten carbide powder and copper p...

Embodiment 3

[0048] see image 3 , the present invention provides a preparation method 30 of a tungsten carbide mosaic sample, the preparation method 30 of the tungsten carbide mosaic sample comprises the following steps:

[0049] S301: Weighing 30 g of ultrafine tungsten carbide powder with a particle size of Fsss of 40 μm and 10 g of copper powder with a particle size of 300 mesh, and stirring the two powders evenly to form a mixture of tungsten carbide powder and copper powder.

[0050] Since copper powder is only used to melt and fill the gaps between tungsten carbide powders under heating conditions, its particle size has no effect on the quality of tungsten carbide powders. That is to say, the particle size of the copper powder is not limited to the sizes listed in the embodiments of the present invention, and can be any size on the basis of satisfying the stability of the compacted sample bar of tungsten carbide and copper after drying, and the copper powder The size of the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com