Multi-element composite rare earth tungsten electrode material and preparation method thereof

A kind of electrode material and multi-component composite technology, which is applied in the direction of welding/cutting media/materials, manufacturing tools, welding equipment, etc., can solve the problems of polluting the environment, slow heating and cooling speed, poor electrode arcing and retention, etc., to achieve durability Good arc ablation performance, good welding performance, good arc starting and arc maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

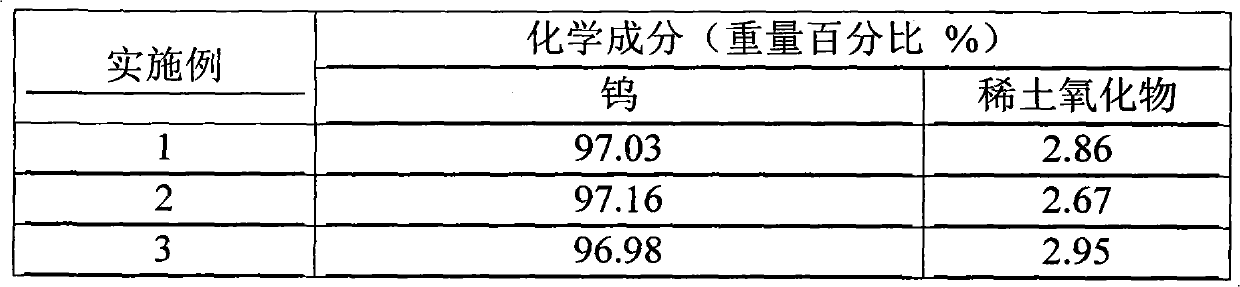

[0029] A multi-component composite rare-earth tungsten electrode material is made by adding rare-earth oxides to a tungsten metal matrix (ammonia paratungstate APT powder) with an average particle size of 20-50 μm. Rare earth oxides are composed of four oxides: lanthanum oxide, cerium oxide, rhenium oxide and erbium oxide. Wherein, the weight percentage of the tungsten metal matrix is 95-98%, and the weight percentage of the rare earth oxide is 2.0-5.0%.

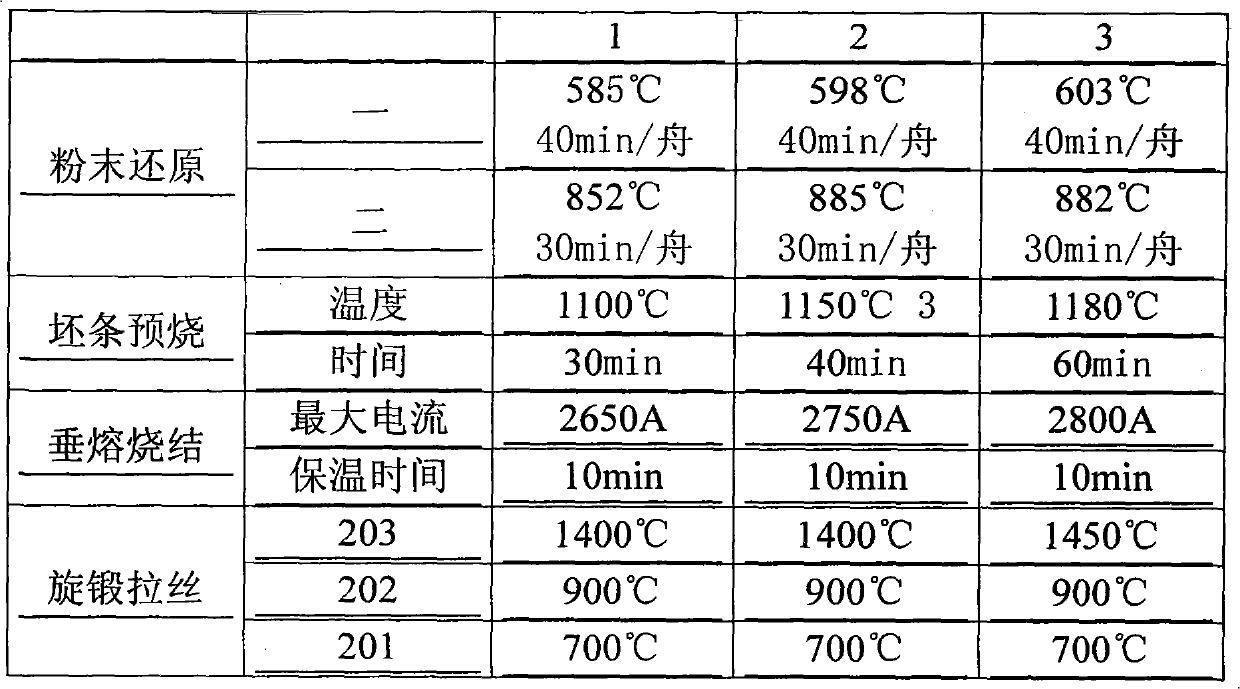

[0030] The preparation method of the above multi-component composite rare earth tungsten electrode material is completed according to the following steps:

[0031] 1. Material preparation: Weigh the ammonium paratungstate APT powder with an average particle size of 20-50 μm and pour it into the doping pot according to the proportioning weight, and add deionized water to stir to obtain a uniform suspension; add lanthanum nitrate, cerium nitrate, The rhenium nitrate and erbium nitrate are weighed to form a solution, added t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com