Preparation method of metal nanostructure

A kind of metal nanostructure and nanostructure technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the lack of precision, roughness and uneven shape of metal nanostructure in controlling the shape and size of metal nanostructures. The uniformity of size and size cannot be guaranteed, so as to achieve the effect of improving light extraction efficiency and light absorption efficiency, simple preparation process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a metal nanostructure, comprising the steps of:

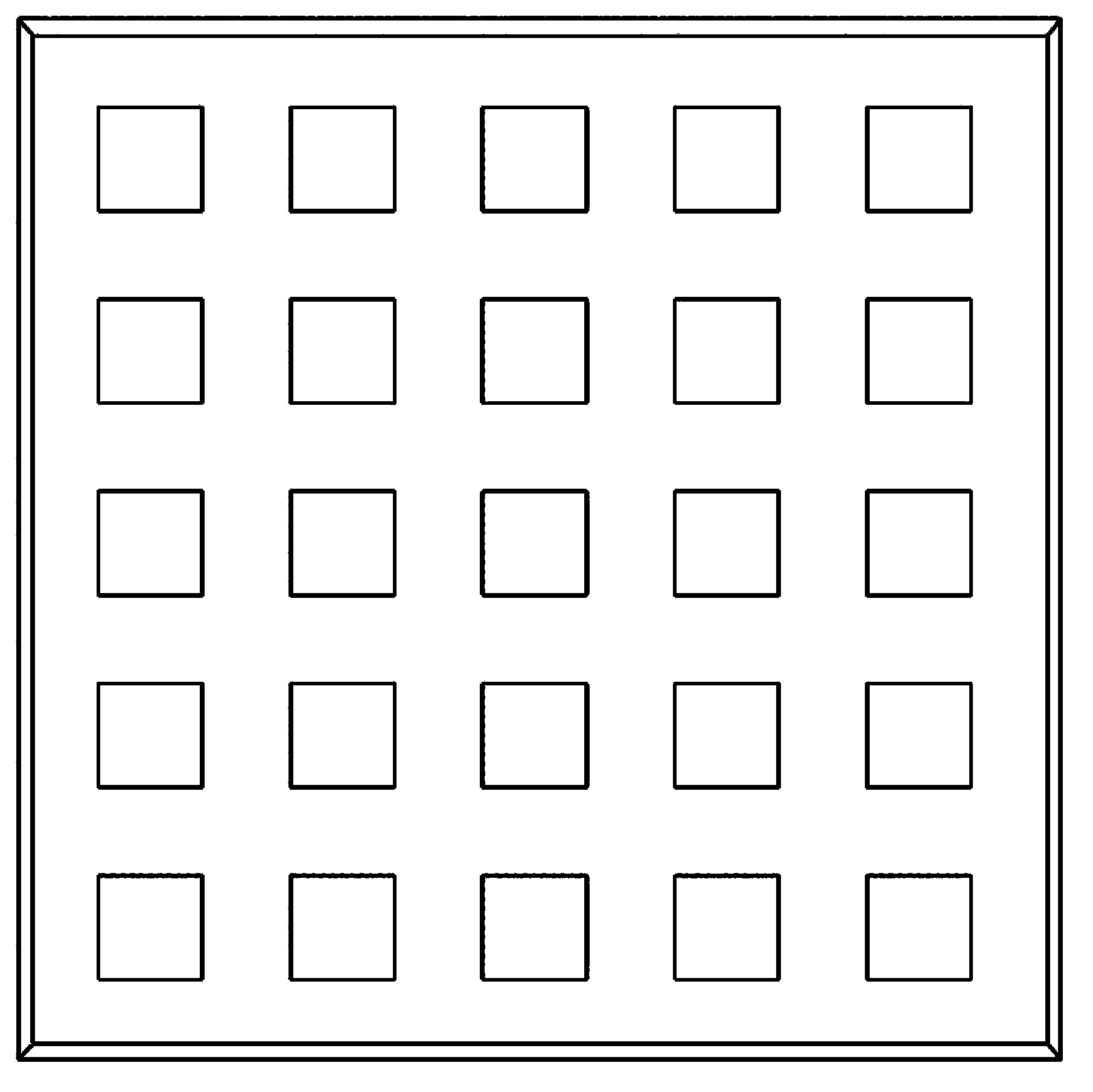

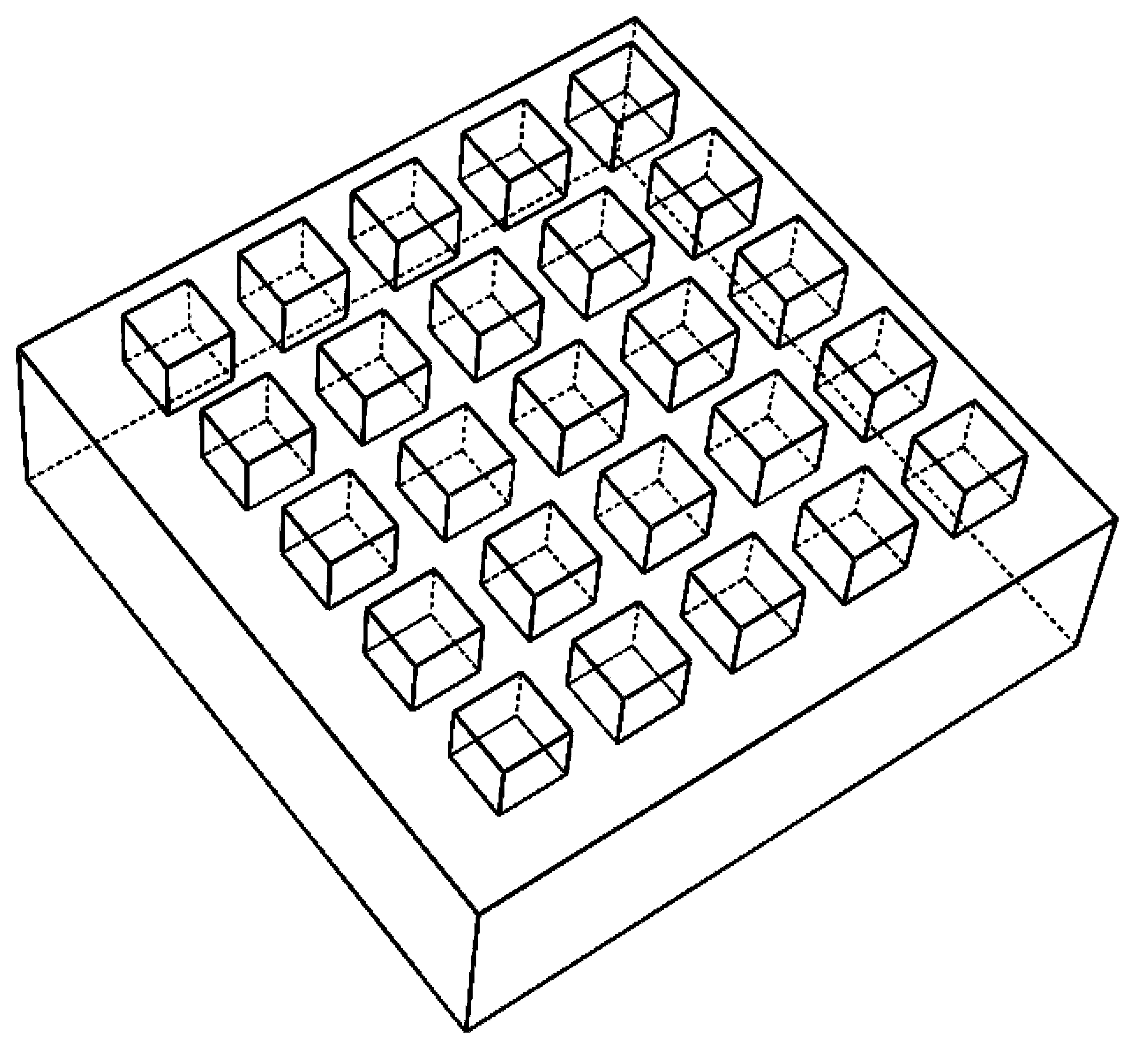

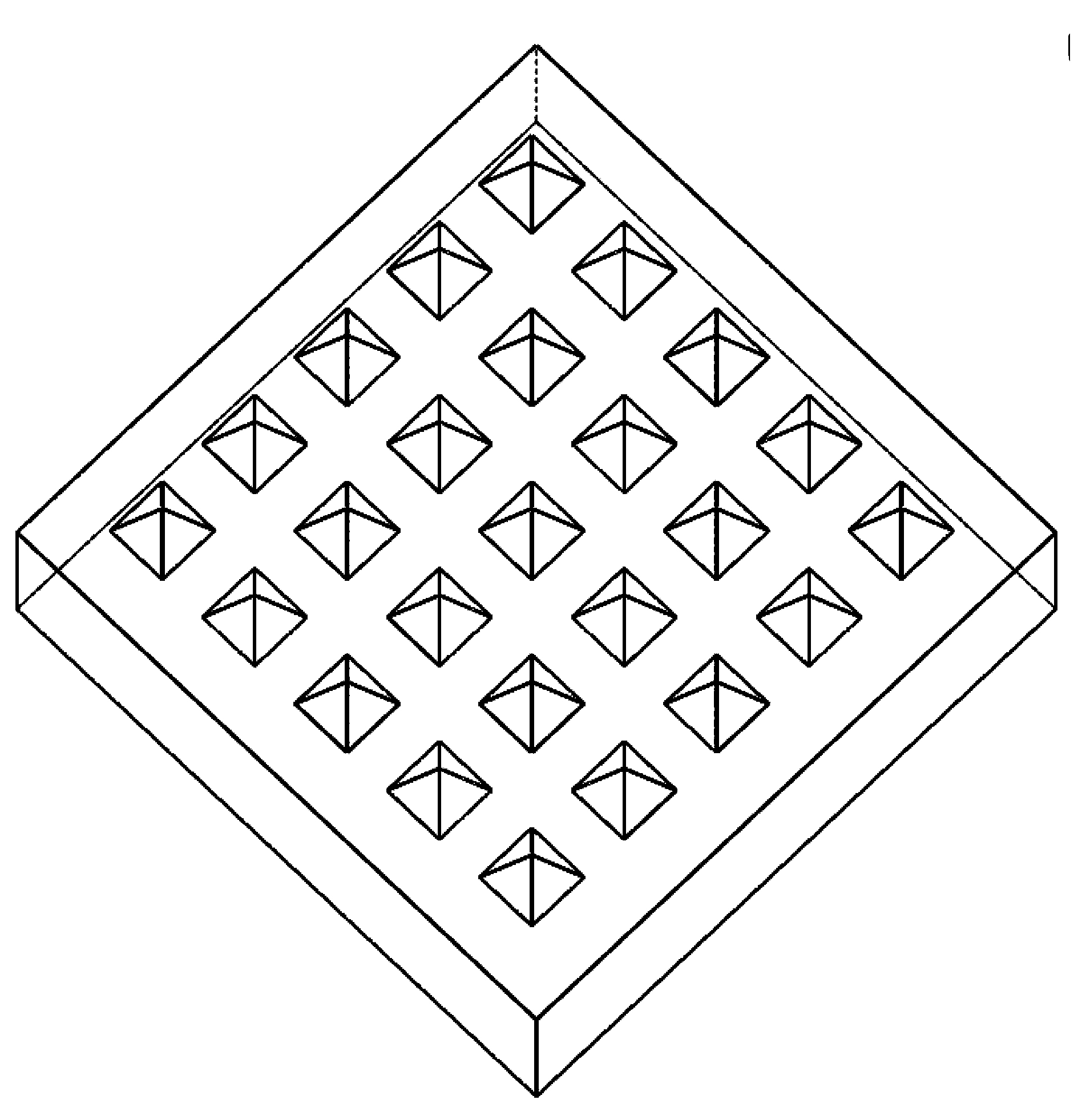

[0040] (1) Provide a clean substrate, and make the required nanostructure pattern on the substrate to form a mask, and the part with the pattern on the substrate is transparent to ultraviolet rays;

[0041] Select a tungsten steel substrate with a length of 12cm, a width of 12cm, and a thickness of 0.5cm, and clean it; draw a square array pattern with a side length of 40nm and a pitch of 20nm, and import it into a PC connected to an electron beam pattern generator, and control the electron beam through the PC. The beam pattern generator draws the square array pattern in the middle of the substrate at a ratio of 1:1, puts it in an oven and dries it at 60°C for 30 minutes, so that the part with the pattern on the substrate is transparent to ultraviolet light, forming mask board.

[0042](2) Provide a clean and dry substrate, and uniformly coat positive UV photoresist on the substrate, pre-baking, so...

Embodiment 2

[0052] A method for preparing a metal nanostructure, comprising the steps of:

[0053] (1) Provide a clean substrate, and make the required nanostructure pattern on the substrate to form a mask, and the part with the pattern on the substrate is transparent to ultraviolet rays;

[0054] Select an iron oxide substrate with a length of 5cm, a width of 5cm, and a thickness of 0.5cm, and clean it for later use; draw a square array pattern with a side length of 30nm and a spacing of 30nm, and import it into a PC connected to a laser pattern generator, and control it through the PC The laser pattern generator draws the square array pattern to the middle of the substrate at a ratio of 1:1, puts it in an oven and dries it at 80°C for 20 minutes to prepare a mask.

[0055] (2) Provide a clean and dry substrate, and uniformly coat positive UV photoresist on the substrate, pre-baking, so that the positive UV photoresist is cured to form a photoresist substrate;

[0056] Select a gallium ...

Embodiment 3

[0064] A method for preparing a metal nanostructure, comprising the steps of:

[0065] (1) Provide a clean substrate, and make the required nanostructure pattern on the substrate to form a mask, and the part with the pattern on the substrate is transparent to ultraviolet rays;

[0066] Select a chromium substrate with a length of 2cm, a width of 2cm, and a thickness of 0.3cm, and clean it for later use; draw a square array diagram with a side length of 20nm and a spacing of 10nm, and import it into a PC connected to the copying device, and control the copying device through the PC. The square array image is copied to the middle of the chrome substrate at a ratio of 1:2, and placed in an oven to dry at 80°C for 20 minutes, so that the part with the pattern on the substrate is transparent to ultraviolet rays and forms a mask.

[0067] (2) Provide a clean and dry substrate, and uniformly coat positive UV photoresist on the substrate, pre-baking, so that the positive UV photoresis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com