Preparation of lanthanide series rare-earth doped bismuth titanate nano-tube

A technology of bismuth titanate nanotubes and lanthanide rare earths, which is applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of long preparation period, complicated equipment, complicated process, etc., and achieves short preparation period, simple equipment, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

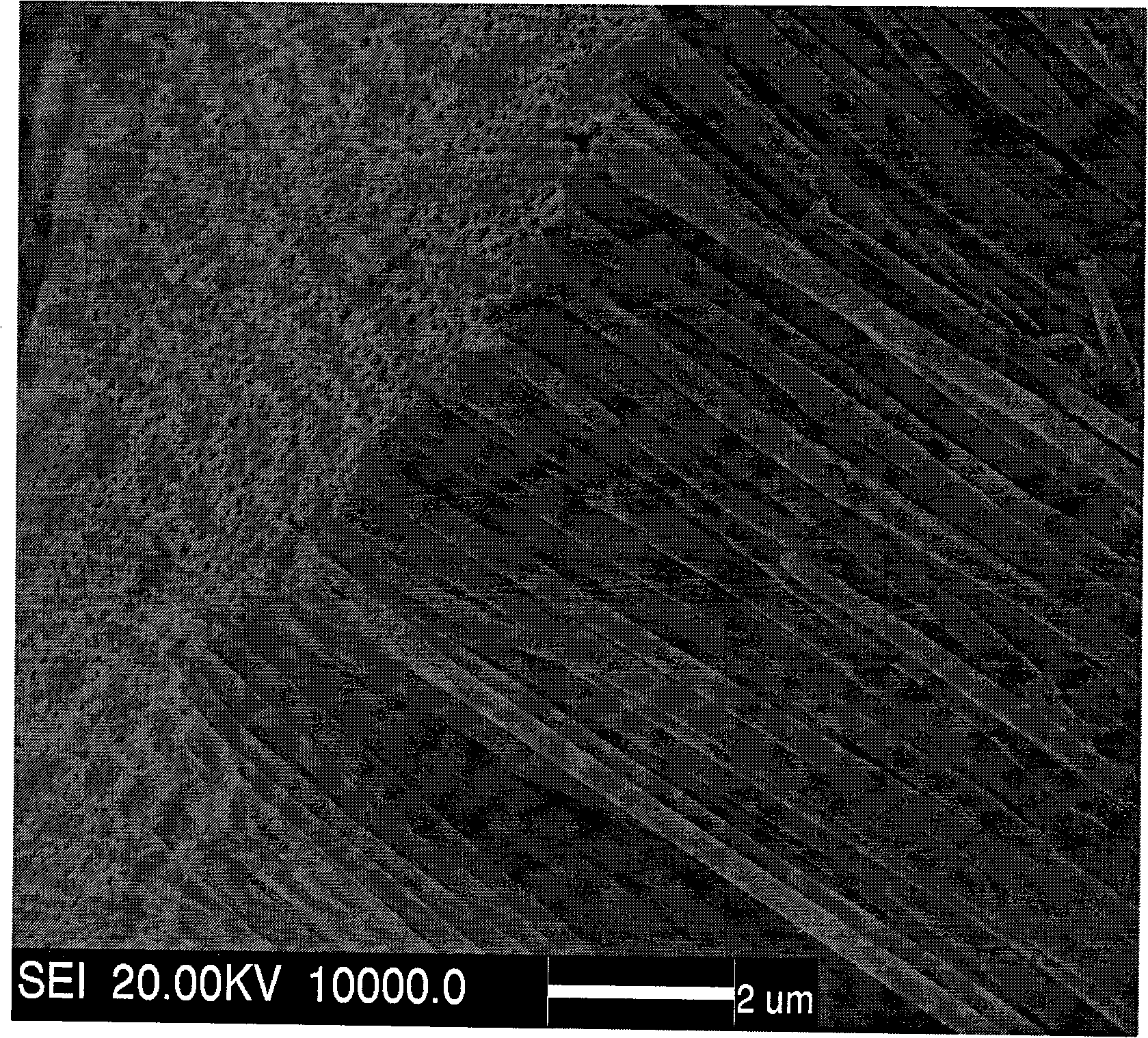

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of the lanthanide rare earth doped bismuth titanate nanotube in this embodiment is realized according to the following steps: 1. According to the chemical formula Bi 4-x R x Ti 3 o 12 , wherein R is a lanthanide rare earth element, 0<x<0.9, weigh the sub-bismuth salt, the nitrate of the lanthanide rare earth and tetrabutyl titanate according to the stoichiometric ratio, and then weigh it to make an excess of 0.1 to 10% (mass ) bismuth salt, the bismuth salt is bismuth subnitrate or bismuth acetate; 2. Dissolve the nitrate and bismuth salt of the lanthanide rare earth in the acetic acid mixture, then add tetrabutyl titanate, and stir to obtain the lanthanide rare earth doped titanium bismuth titanate sol; wherein the acetic acid mixture is a mixture of acetic acid and ethylene glycol, ethylene glycol methyl ether, and acetylacetone; third, drop the lanthanide rare earth-doped bismuth titanate sol on the surface of the alu...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment is different from Embodiment 1 in that the lanthanide rare earth element in step 1 is La, Sm, Nd, Eu, Yb, Dy, Tb, Ho or Lu. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the chemical formula Bi in step one 4-x R x Ti 3 o 12 Among them, x is preferably 0.1<x<0.9. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com