Numerical control plate shearing and stacking production line

A production line and stacking technology, applied in shearing devices, shearing machines, stacking of objects, etc., can solve problems such as the inability to separate waste from qualified workpieces, the inability to accurately control the size of the material plate, and the increase of operator labor intensity. , to achieve the effect of improving product qualification rate, precise size control, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

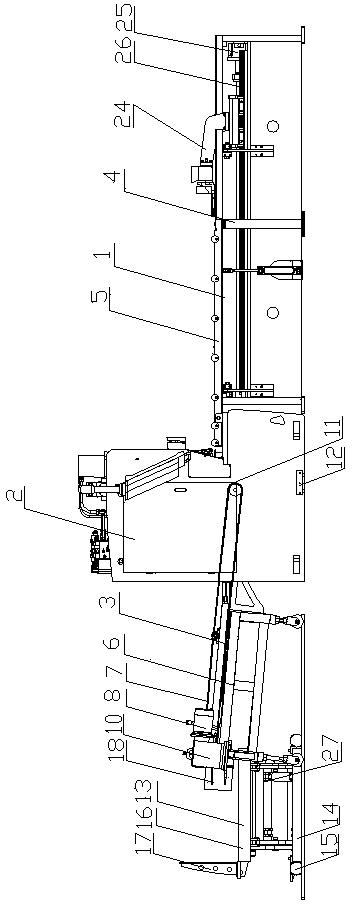

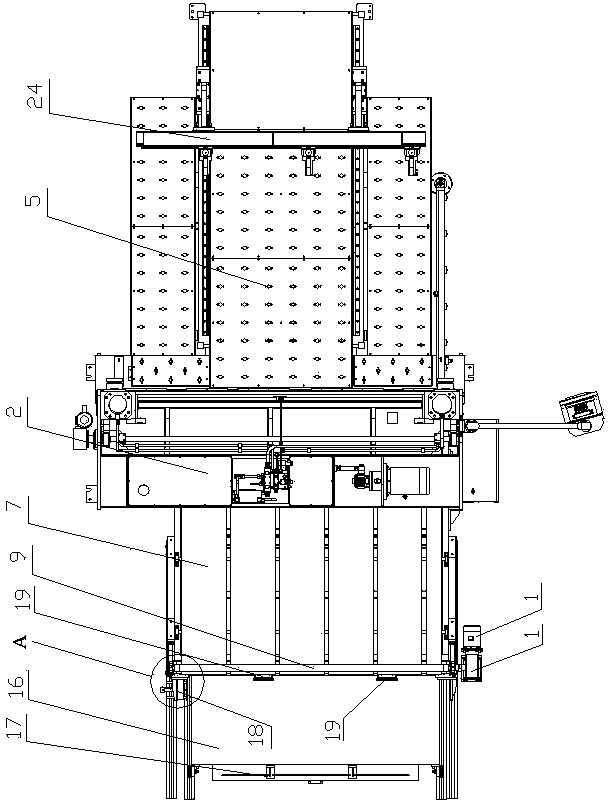

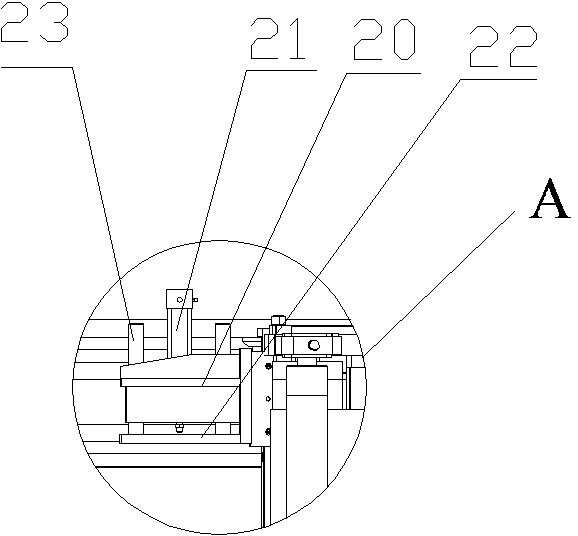

[0015] like figure 1 , 2 , 3, 4, and 5, the CNC shearing and palletizing production line includes a front feeding mechanism 1, a shearing machine host 2, a rear discharging mechanism 3, a front feeding mechanism 1, and a rear discharging mechanism 3 respectively. Cooperate with the front and rear ends of the shearing machine host 2; the front feeding mechanism 1 includes a bottom bracket 4, and a delivery platform 5 is arranged on the bottom bracket 4, and a feeding clamp 24 is arranged on the top of the delivery platform 5, and the front of the delivery platform 5 Servo motors 25 and ball screws 26 are respectively provided on both sides of the bottom bracket, and one end of each ball screw 26 is respectively connected to the output ends of two servo motors 25, and the other end of the ball screws 26 is connected to the feeding clamp respectively. 24 connection; the rear discharge mechanism 3 includes a bottom bracket 6, a conveyor belt 7 is set on the bottom bracket 6, a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com