Multiple-angle scissor blade

a scissor blade and multi-angle technology, applied in the field of laparoscopic scissors, can solve the problem of no heat-treatment step afterwards, and achieve the effect of increasing tension and giving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following description refers to the accompanying drawings that illustrate the embodiments of the invention. Other embodiments are possible and modifications may be made to the embodiments without departing from the spirit and scope of the invention. Thus, the following description is not meant to limit the invention.

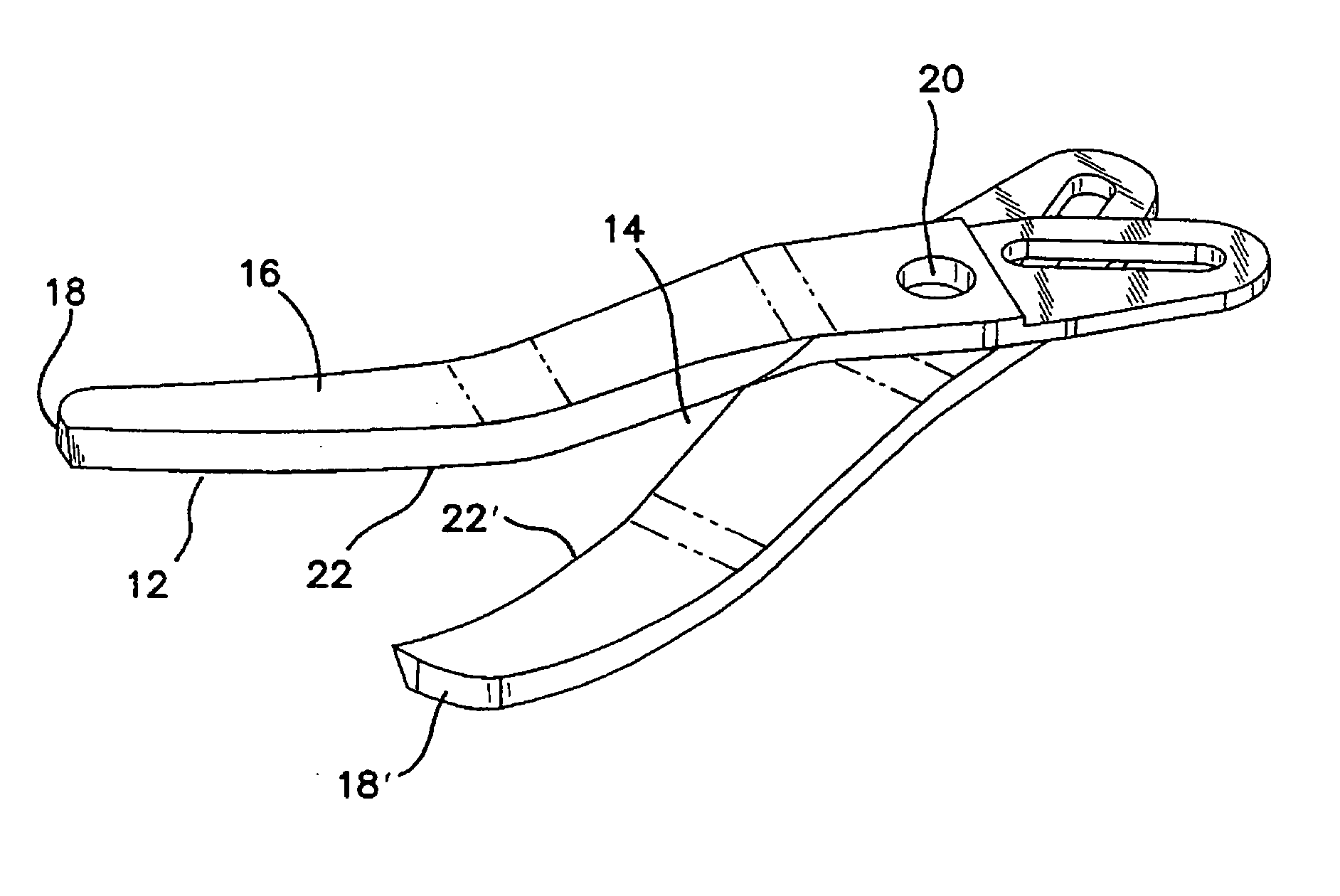

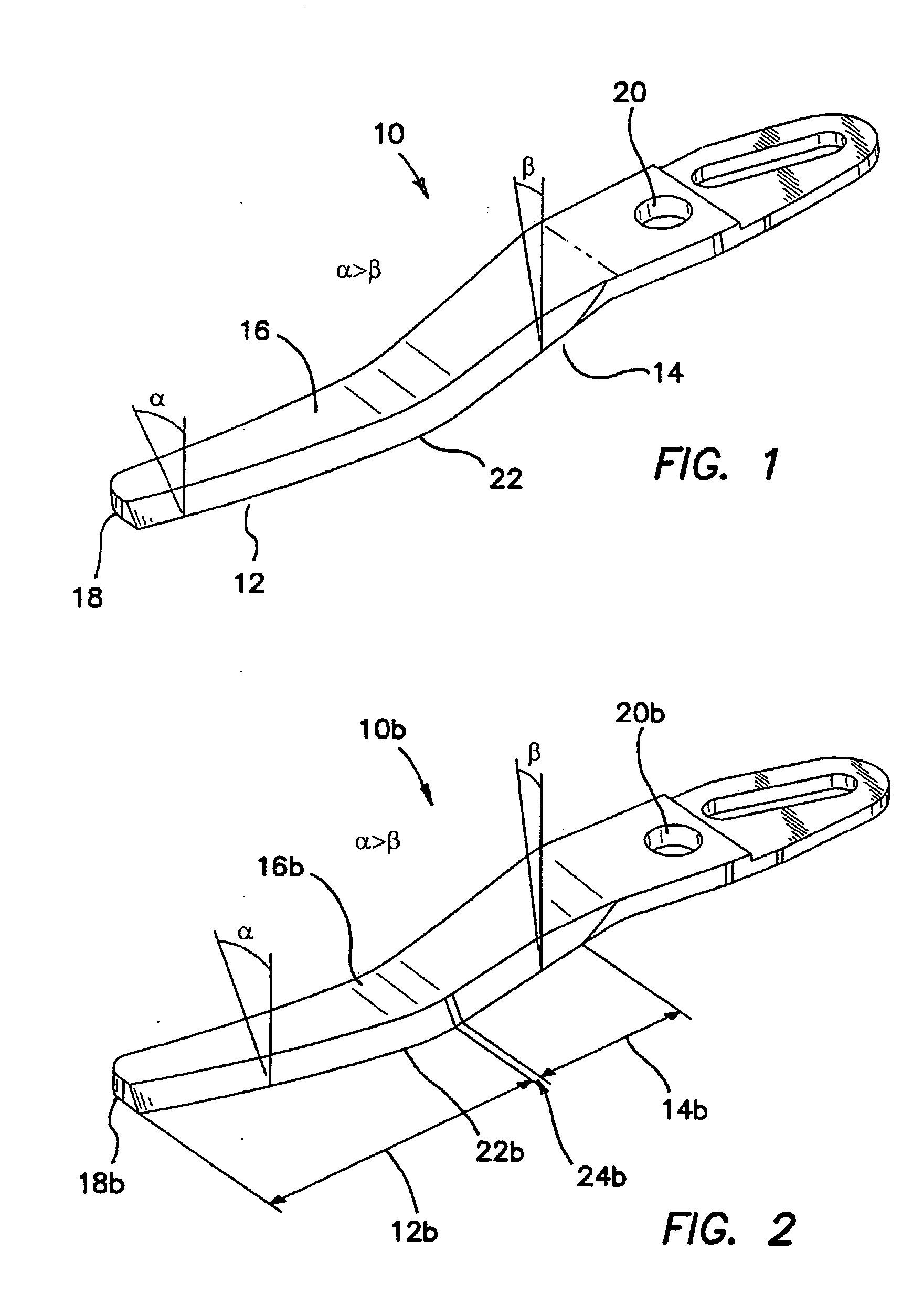

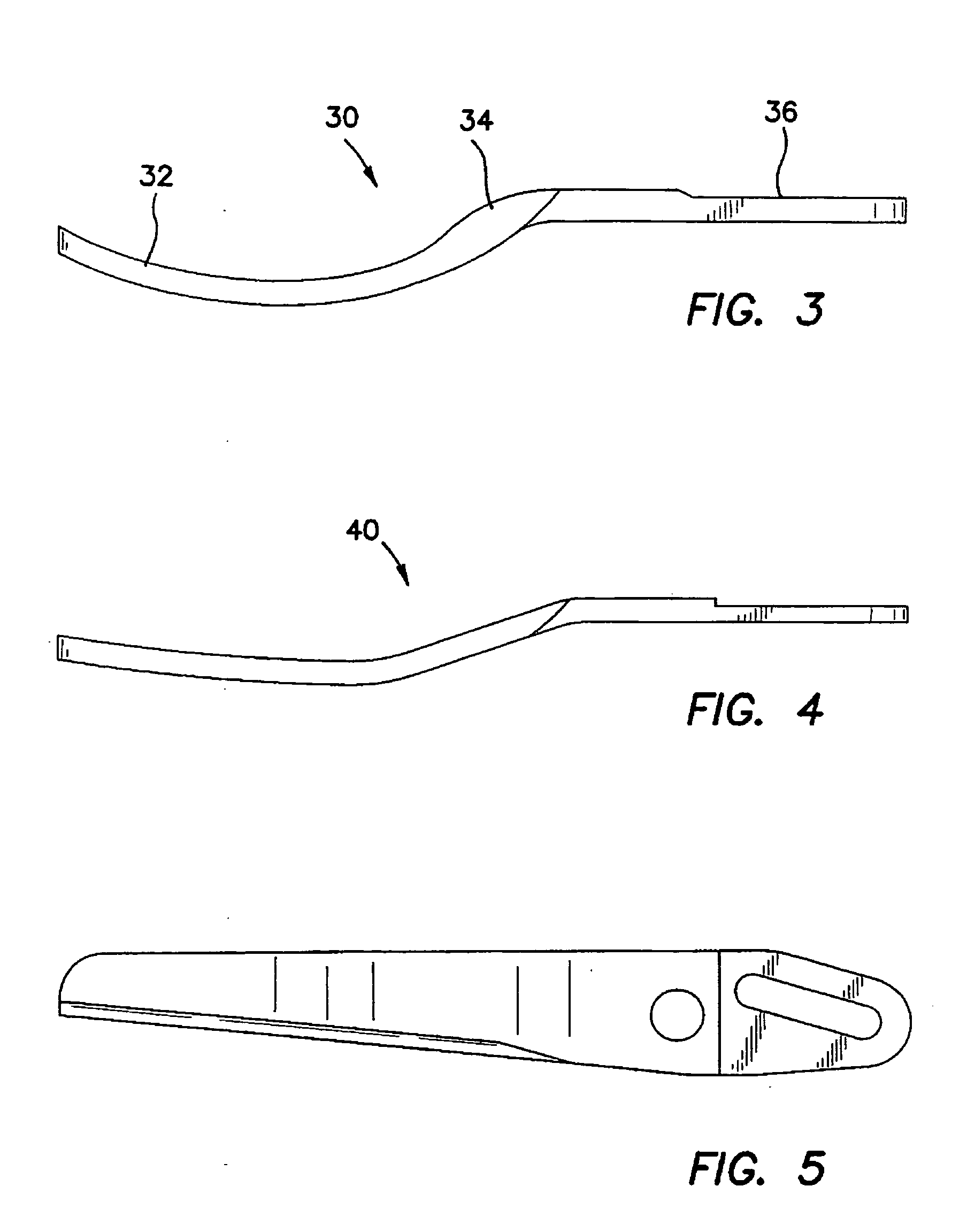

[0019] Referring now to the drawings, and in particular to FIG. 1, there is shown an exemplary blade 10 of a scissors in accordance with the first embodiment of the invention. The blade 10 includes a tip portion 12, a body or throat portion 14, an outer surface 16, an inner surface 18, a cutting edge 22 and a pivot area 20. The cutting edge 22 forms an angle with the outer surface 16 along the length of the blade 10 such that tension at the tip portion 12 is about the same as tension at the body or throat portion 14. The function and effectiveness of the scissor blades depend heavily on the tension and angle the cutting surfaces are to each other. The blades ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com