Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as voids, abnormal growth of materials, and reduced productivity, and achieve high film thickness uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

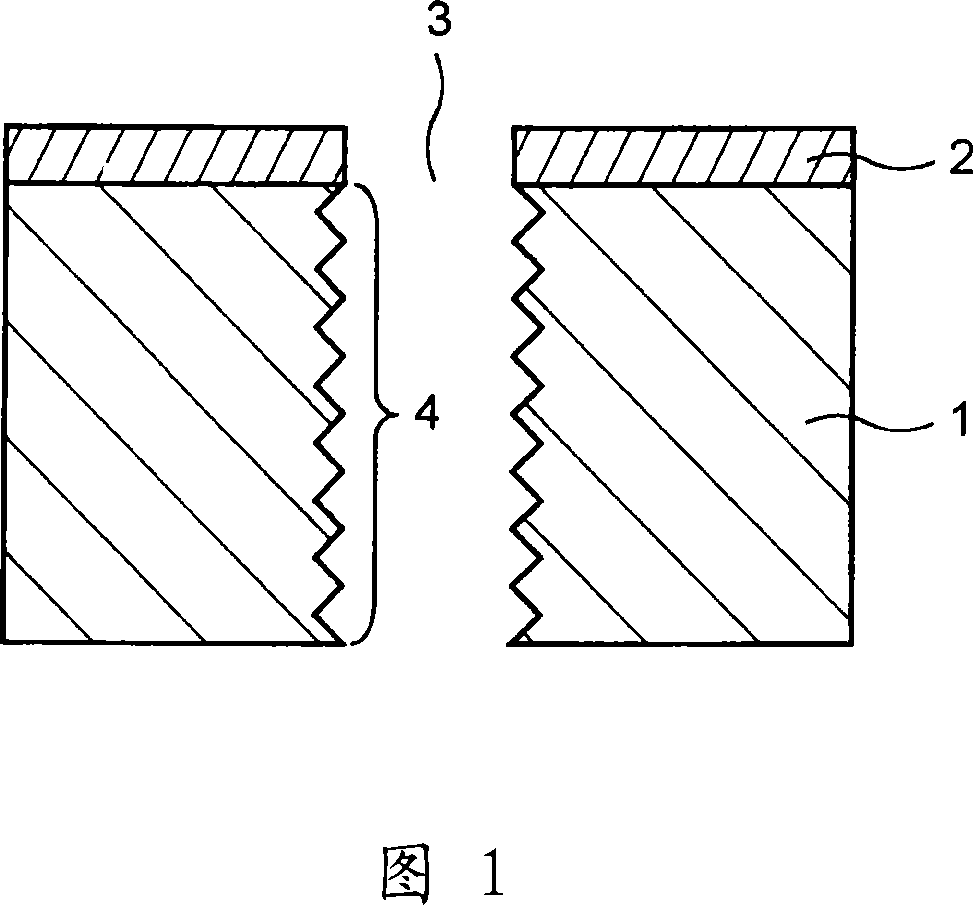

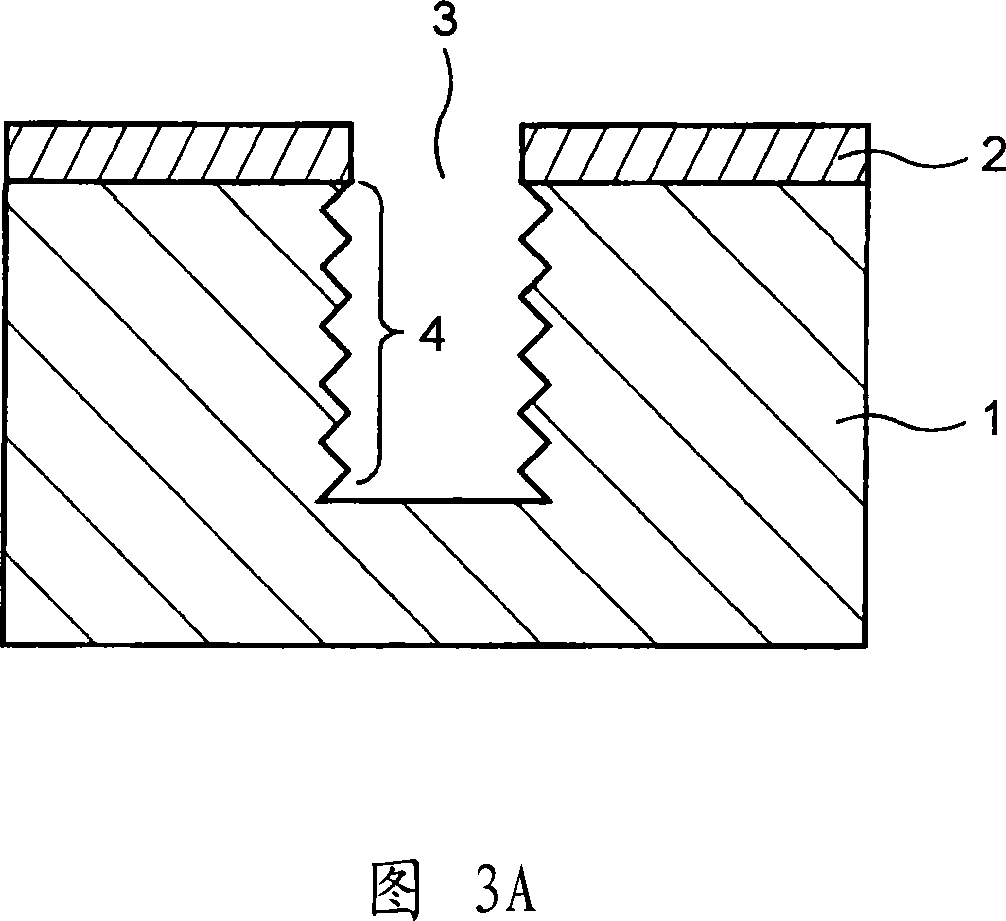

[0035] Next, embodiments of the present invention will be described with reference to the drawings. 1 to 3 are cross-sectional views illustrating a method of manufacturing a semiconductor device according to a first embodiment of the present invention.

[0036] First, as shown in FIG. 1 , a semiconductor substrate 1 on which an electronic device (not shown) is formed on the surface is prepared. Next, a mask layer 2 is selectively formed on the back surface of the semiconductor substrate 1 . The mask layer 2 is a layer used as a mask for forming the via hole 3, and its material is not particularly limited as long as it has this function. Therefore, the mask layer 2 may be an insulating film such as a silicon oxide film or a silicon nitride film, or may be a resist layer.

[0037] Next, a predetermined region of the semiconductor substrate 1 is etched by a Bosch process using the mask layer 2 as a mask. Specifically, for example, using an ICP (Inductively Coupled Plasma: Indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com