Method and system for processing oil field wastes

A technology of oilfield waste and treatment method, which is applied in the field of oilfield waste treatment method and system, and achieves good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The first core of the present invention is to disclose an oilfield waste treatment method to achieve the purpose of improving the versatility of the oilfield waste treatment process; the second core of the present invention is to disclose an oilfield waste treatment system. Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

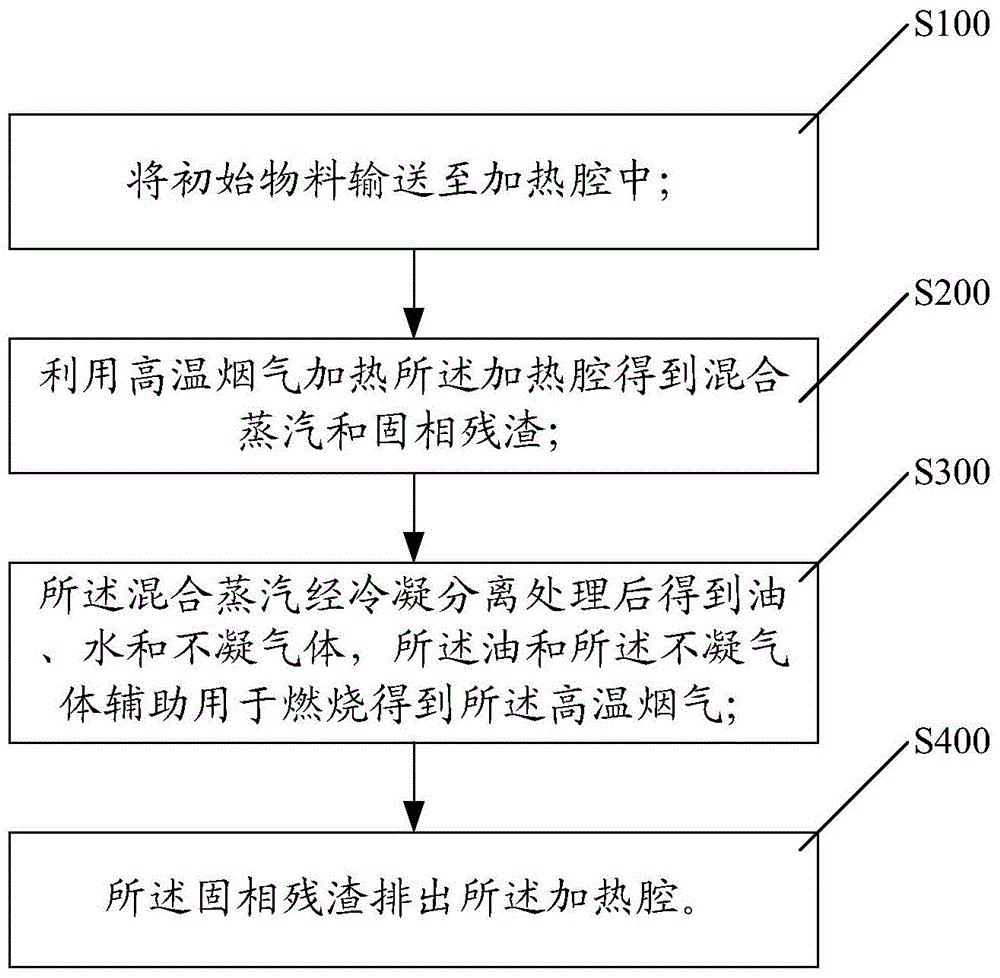

[0051] Such as figure 1 As shown, the oilfield waste treatment method, the method includes:

[0052] Step S100: Transporting the initial material into the heating chamber; wherein, in this step, the initial material is oilfield waste, and there are many ways to transport the initial material to the heating chamber, such as conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com