Method for evaluating creep performance of T/P92 steel

A creep performance and technology to be evaluated, applied in the field of creep performance evaluation, can solve the problems of T/P92 creep rupture life overestimation, strain prediction value deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

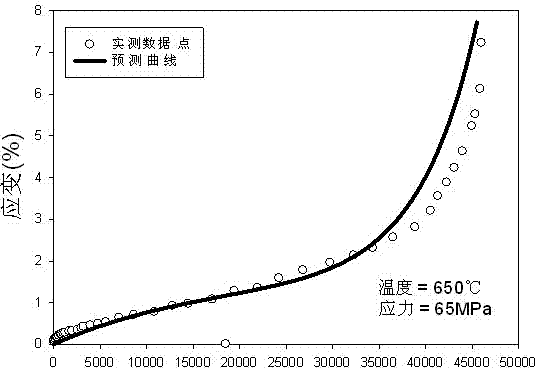

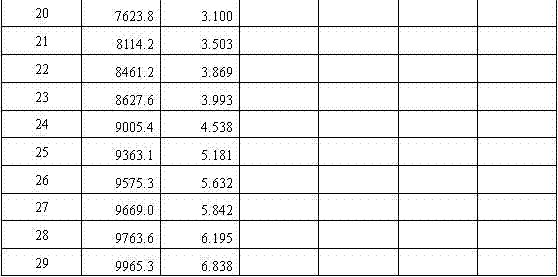

[0017] The creep curves of P92 steel at 650°C and 65MPa were extrapolated by using the deformation data of creep tests at 600°C (stress 135-190MPa) and 650°C (stress 87-125MPa). Table 1 shows the creep deformation data of P92 steel under the test conditions of 600°C (stress 135-190MPa) and 650°C (stress 87-125MPa). The high-temperature creep test lasts until the sample breaks. The table includes the test temperature ( T h / h), test stress ( σ k / MPa), test time ( t i,hk / h) and creep strain ( ε i,hk ); Table 2 is the creep deformation data table of P92 steel under the test conditions of 650 ° C and 65 MPa near the minimum creep rate in the test, including the test temperature ( T / h), test stress ( σ / MPa), the test time to reach the minimum creep rate ( t / h) and creep strain ( ε ). First of all, according to the specific implementation methods ①~② according to θ parametric formula and For each test condition of P92 steel in Table 1 ( T h , σ k ) to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com