Device and method for testing material creep under coupling action of tensile stress and environment

A testing device and tensile stress technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that it is difficult to use gravity or lever loading methods, limit the correlation of cement-based materials, and affect the spring stress, etc., to achieve Ensure effective delivery, reduce restrictions, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

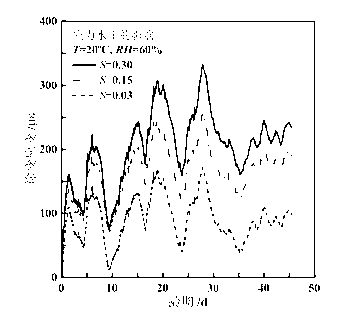

[0051] Mixing ratio of cement asphalt mortar (kg / m 3 ): dry powder 1000, emulsified asphalt 160, water 110, water reducer 1.4, defoamer 0.05. According to the above ratio, after using a forced mixer to mix well, pour the freshly mixed cement asphalt mortar into a dumbbell-shaped mold of a certain size, and then put the test piece into the standard curing room (temperature T =20±3℃, RH ≥95%) in the maintenance to the specified age and then taken out. Use the MTS810 testing machine to test the tensile strength of the cured specimens referring to GB / T 228.1-2010 "Metallic Materials Tensile Test Part One: Room Temperature Test Method". According to the measured tensile strength, using the testing device and testing method of the present invention, respectively apply 0.03, 0.15 and 0.30 stress levels (applied tensile stress / ultimate tensile stress) to the test piece, the control environment temperature is 20 ℃, relatively Humidity RH=60%. After the loading is completed, the st...

Embodiment 2

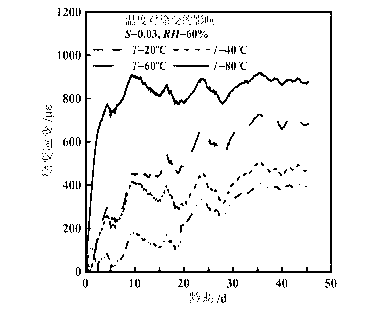

[0054] Mixing ratio of cement asphalt mortar (kg / m 3 ): dry powder 1000, emulsified asphalt 160, water 110, water reducer 1.4, defoamer 0.05. According to the above ratio, after using a forced mixer to mix well, pour the freshly mixed cement asphalt mortar into a dumbbell-shaped mold of a certain size, and then put the test piece into the standard curing room (temperature T= 20±3℃, RH≥95%) in the maintenance to the specified age and then taken out. Use the MTS810 testing machine to test the tensile strength of the cured specimens referring to GB / T 228.1-2010 "Metallic Materials Tensile Test Part One: Room Temperature Test Method". According to the measured tensile strength, adopt the test device and test method of the present invention to apply 0.030 stress level (applied tensile stress / ultimate tensile stress) to the test piece, and set the target temperature of the heating device to be 20°C, 40°C and 80°C, set relative humidity RH =60%. After the loading is completed,...

Embodiment 3

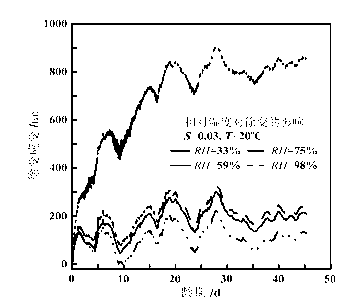

[0057] Mixing ratio of cement asphalt mortar (kg / m 3 ): dry powder 1000, emulsified asphalt 160, water 110, water reducer 1.4, defoamer 0.05. According to the above ratio, use a forced mixer to mix well, then pour the freshly mixed cement asphalt mortar into a dumbbell-shaped mold of a certain size, and then put the test piece into a standard curing room (temperature 20±3°C, RH≥95%) Maintain it to the specified age and then take it out. Use the MTS810 testing machine to test the tensile strength of the cured specimens referring to GB / T 228.1-2010 "Metallic Materials Tensile Test Part One: Room Temperature Test Method". According to the measured tensile strength, adopt the test device and test method of the present invention to apply 0.030 stress level (tensile stress / ultimate tensile stress) to the test piece, the setting temperature is 20 ℃, and the relative humidity of the preparation control is respectively 33%, 75%, 59% and 98% supersaturated inorganic salt solutions. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com