Wear-resistant steel with 400-level Brinell hardness and manufacturing method thereof

A technology of Brinell hardness and manufacturing method, which is applied in the field of steel manufacturing, can solve problems such as large residual stress, poor uniformity, and cracking of steel plates, and achieve the effects of full dissolution, reduced cracking tendency, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A wear-resistant steel of Brinell hardness 400 grade with a thickness of 30mm, its chemical composition by mass percentage is: C 0.18%, Si 0.25%, Mn 1.05%, P 0.014%, S≤0.005%, Cr 0.78%, Ni 0.07 %, Mo 0.31%, Als 0.038%, Ti 0.024%, V 0.013%, B 0.002, and the rest are iron and unavoidable impurities.

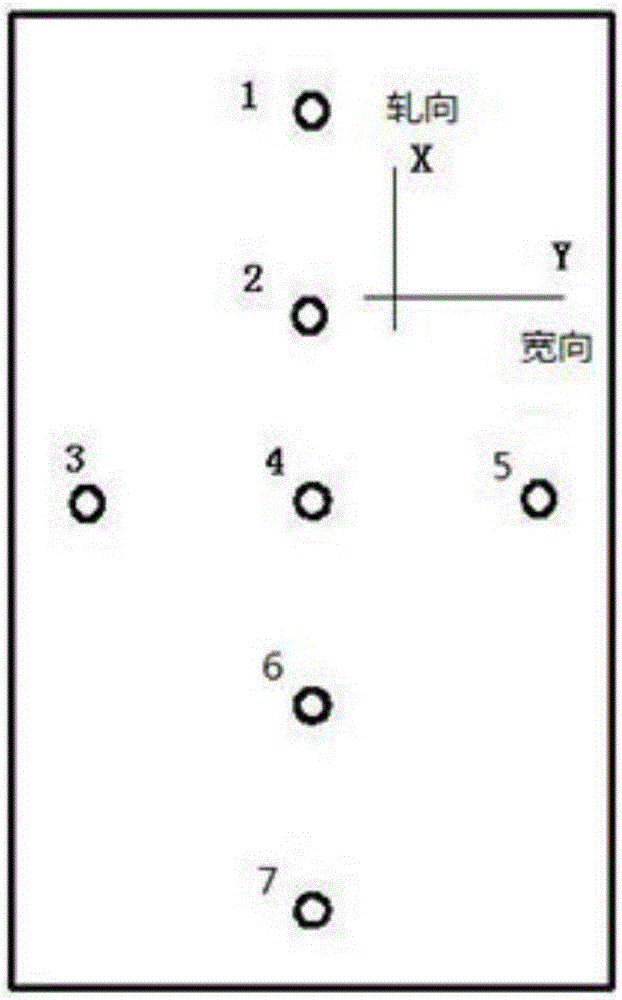

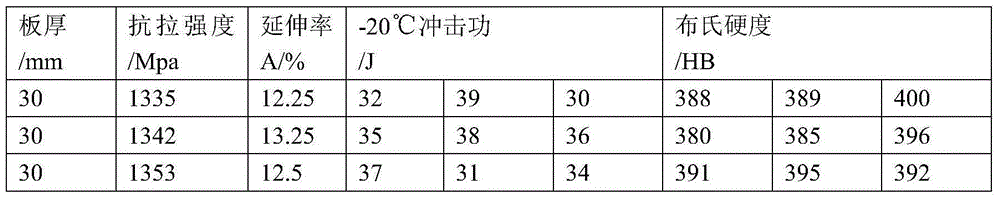

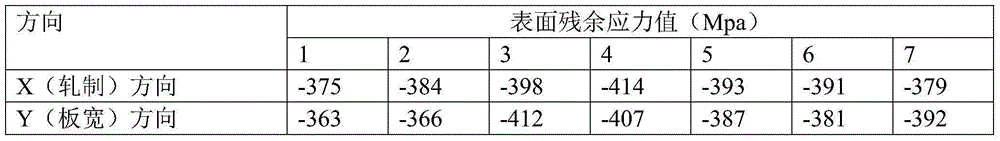

[0035] Carry out vacuum smelting and casting into slabs according to the proportioned chemical composition, heat the slab at a high temperature of 1200°C for 240 minutes; Roll the slab with a reduction rate greater than 20%; then cool it; quench the cooled plate at a high temperature of 870°C and keep it for 30 minutes; temper the quenched plate at a low temperature of 190°C and keep it for 100 minutes to complete the wear-resistant steel. make. Table 1 and Table 2 are respectively the mechanical properties and surface residual stress analysis table of the wear-resistant steel with a Brinell hardness of 400 and a thickness of 30 mm prepared by the above method.

[0036] Ta...

Embodiment 2

[0041] A wear-resistant steel of Brinell hardness 400 grade with a thickness of 20mm, its chemical composition by mass percentage is: C 0.19%, Si 0.31%, Mn 1.2%, P 0.013%, S≤0.005%, Cr 0.68%, Ni 0.07 %, Mo 0.29%, Als 0.032%, Ti 0.026%, V 0.017%, B 0.002, and the rest are iron and unavoidable impurities.

[0042] Carry out vacuum smelting and casting into slabs according to the chemical composition of the ratio, and soak the slab at 1200°C for 160 minutes; roll the heated slab at a starting temperature of 1060°C and a final rolling temperature of 980°C , the single-pass reduction rate is greater than 20%; cooling; quenching the cooled plate at a high temperature of 870°C and holding it for 20 minutes; tempering the quenched plate at a low temperature of 190°C and holding it for 70 minutes to complete the production of wear-resistant steel.

[0043] Table 3 and Table 4 are respectively the mechanical properties table and the surface residual stress analysis table of the 20 mm th...

Embodiment 3

[0049] A wear-resistant steel of Brinell hardness 400 grade with a thickness of 25mm, its chemical composition by mass percentage is: C 0.17%, Si 0.31%, Mn 0.9%, P 0.013%, S≤0.008%, Cr 0.68%, Ni 0.07 %, Mo 0.29%, Als 0.032%, Ti 0.026%, V 0.017%, B 0.002, and the rest are iron and unavoidable impurities.

[0050] Carry out vacuum smelting and casting into slabs according to the chemical composition according to the ratio. The slab is soaked at 1250°C for 200 minutes; the heated slab is rolled with a starting temperature of 1200°C and a final rolling temperature of 980°C. , the single-pass reduction rate is greater than 30%; cooling; quenching the cooled plate at a high temperature of 870°C and holding it for 50 minutes; tempering the quenched plate at a low temperature of 190°C and holding it for 100 minutes to complete the production of wear-resistant steel.

[0051] Table 5 and Table 6 are the mechanical properties table and surface residual stress analysis table of the wear-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com