Method for surface treatment of a die-casting die

a die-casting die and surface treatment technology, applied in the direction of manufacturing tools, foundry patterns, moulding apparatus, etc., can solve the problems of shallow depth of nitrogen diffusion layer, degrade the dimensional accuracy of cast products, etc., and achieve excellent abrasion resistance, high hardness, and high residual stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

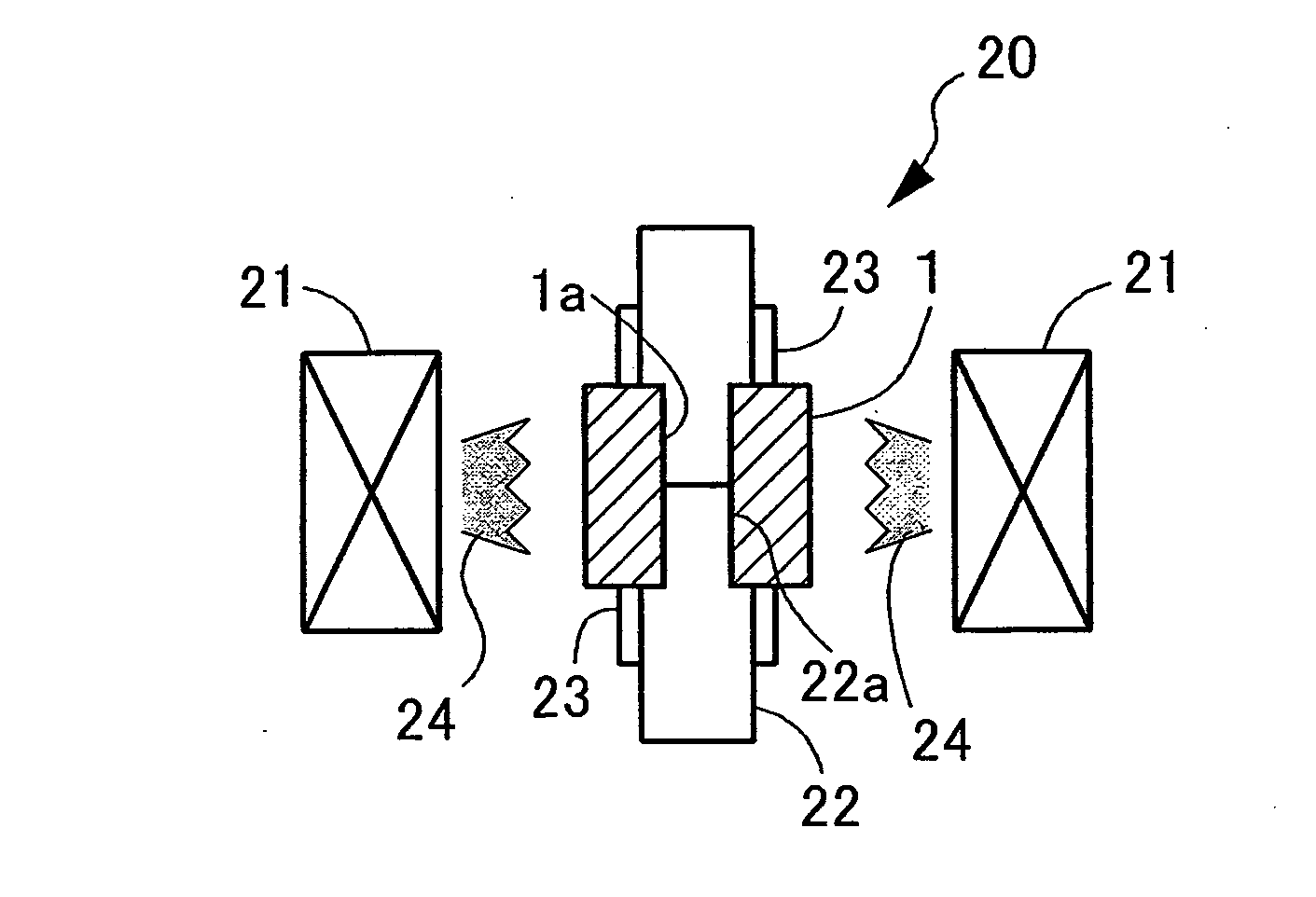

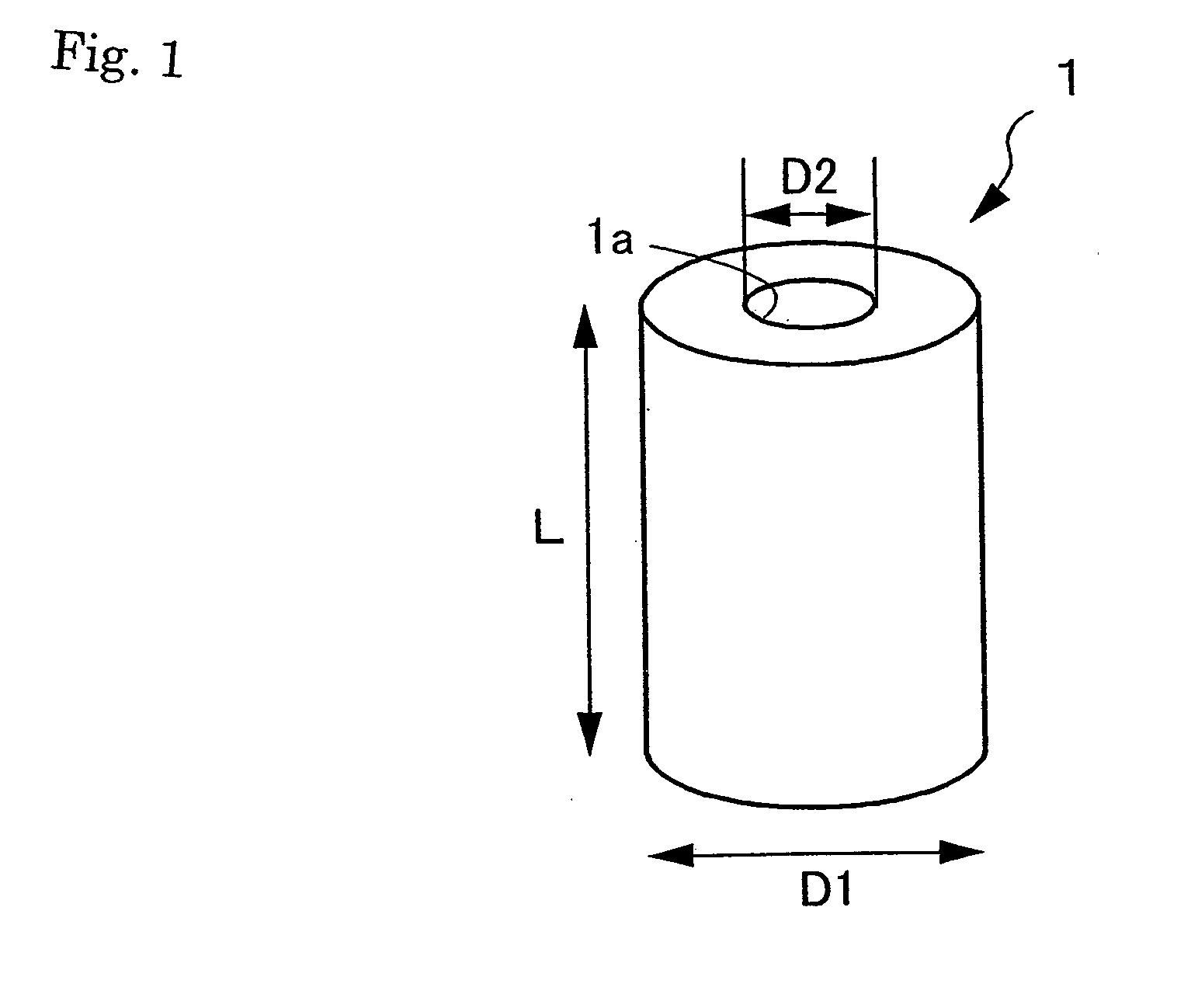

[0027]On the method for surface treatment of the die-casting die of the present invention, the details will be explained with reference to the result of the verification test as indicated in FIGS. 1 to 8. In the verification tests, cylindrical specimens 1 (see FIG. 1) each corresponding to a die-casting die are prepared and various surface treatments are then carried out on them to evaluate them.

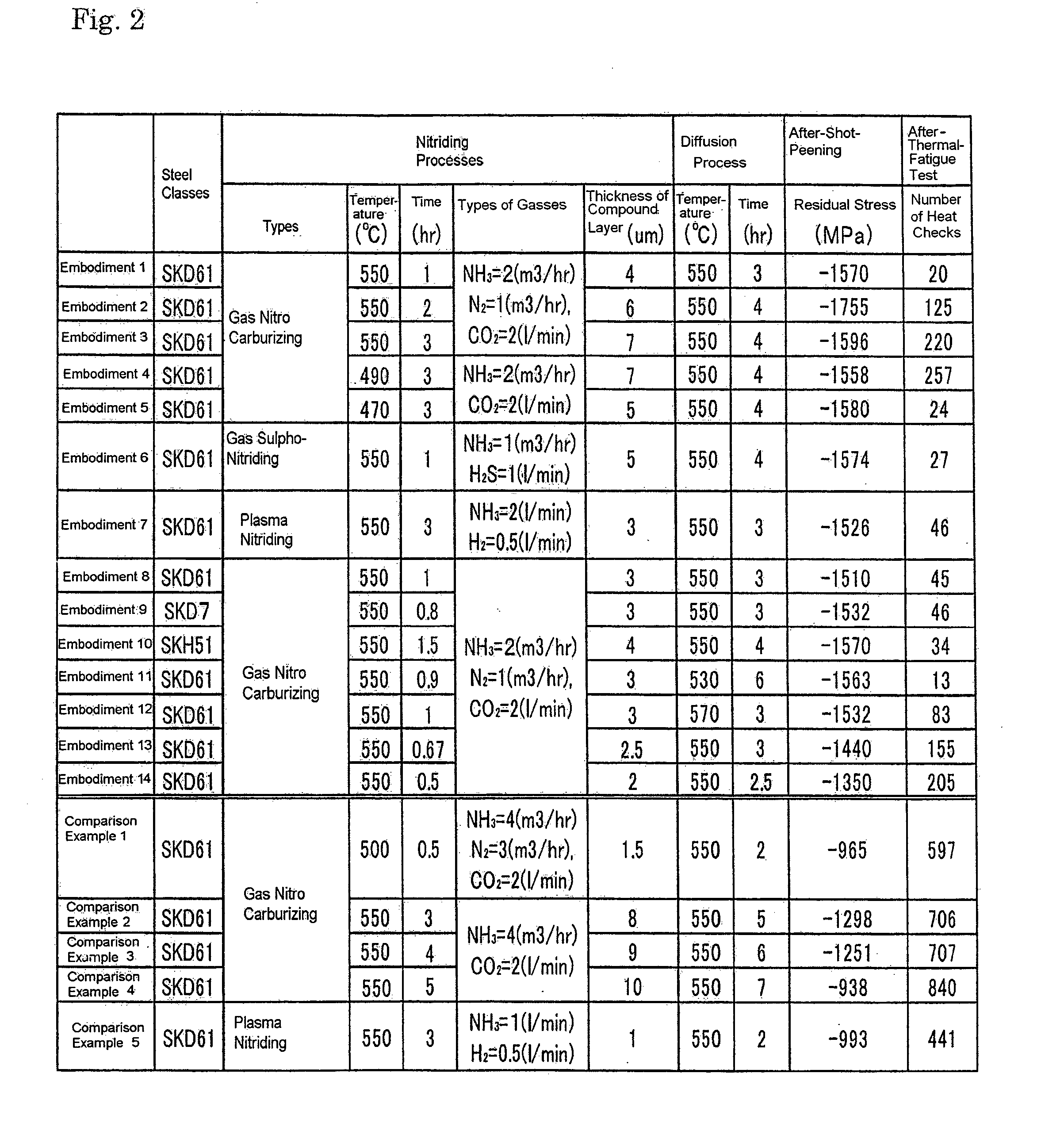

[0028]Cylindrical specimens 1 having an outer diameter D1=15 mm, an inner diameter D2=3 mm, and a length L=20 mm are prepared. Each specimen 1 is machined from a round bar stock of Japanese Industrial Standards (JIS), the steel material of an alloy toll SKD 61 equivalency. Instead of the SKD 61 equivalency, the specimens 1 in the ninth embodiment and the tenth embodiment are machined from round bar stocks of JIS SKD 7 equivalency and a steel material of an alloy toll SKH51 equivalency. The steel classes of the embodiments and comparison examples are described and compiled in FIG. 2.

[0029]Eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com