Electrical machine

A technology of electric motors and laminations, applied in the field of electric motors, can solve problems such as uneven shafts and unsatisfactory coaxiality, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

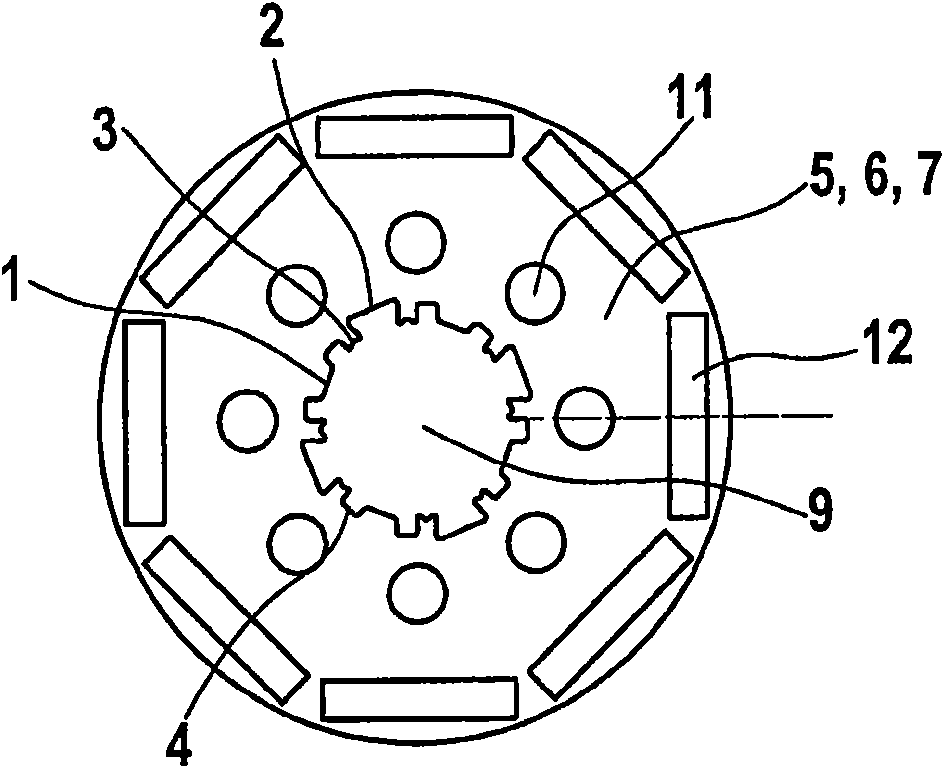

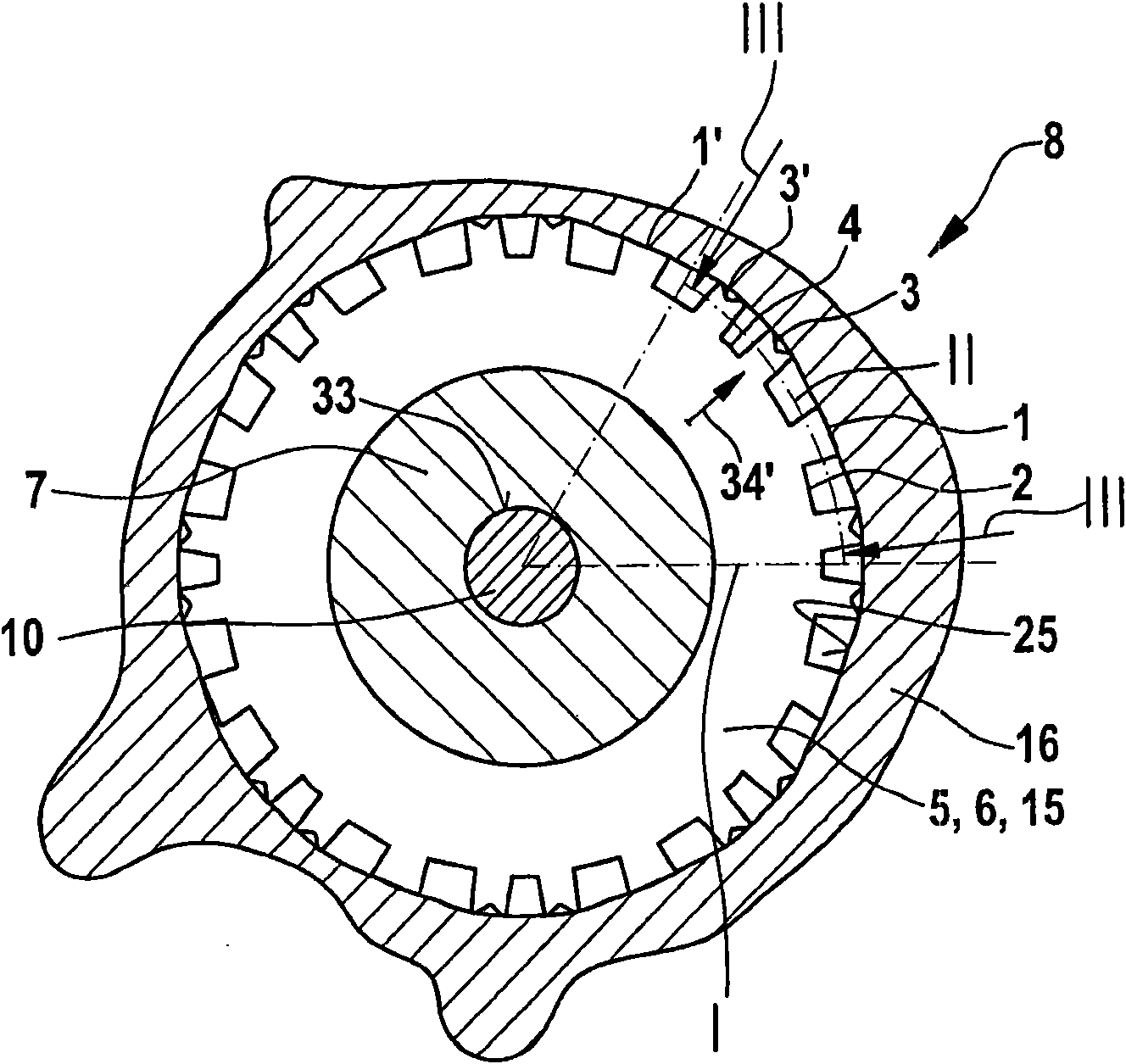

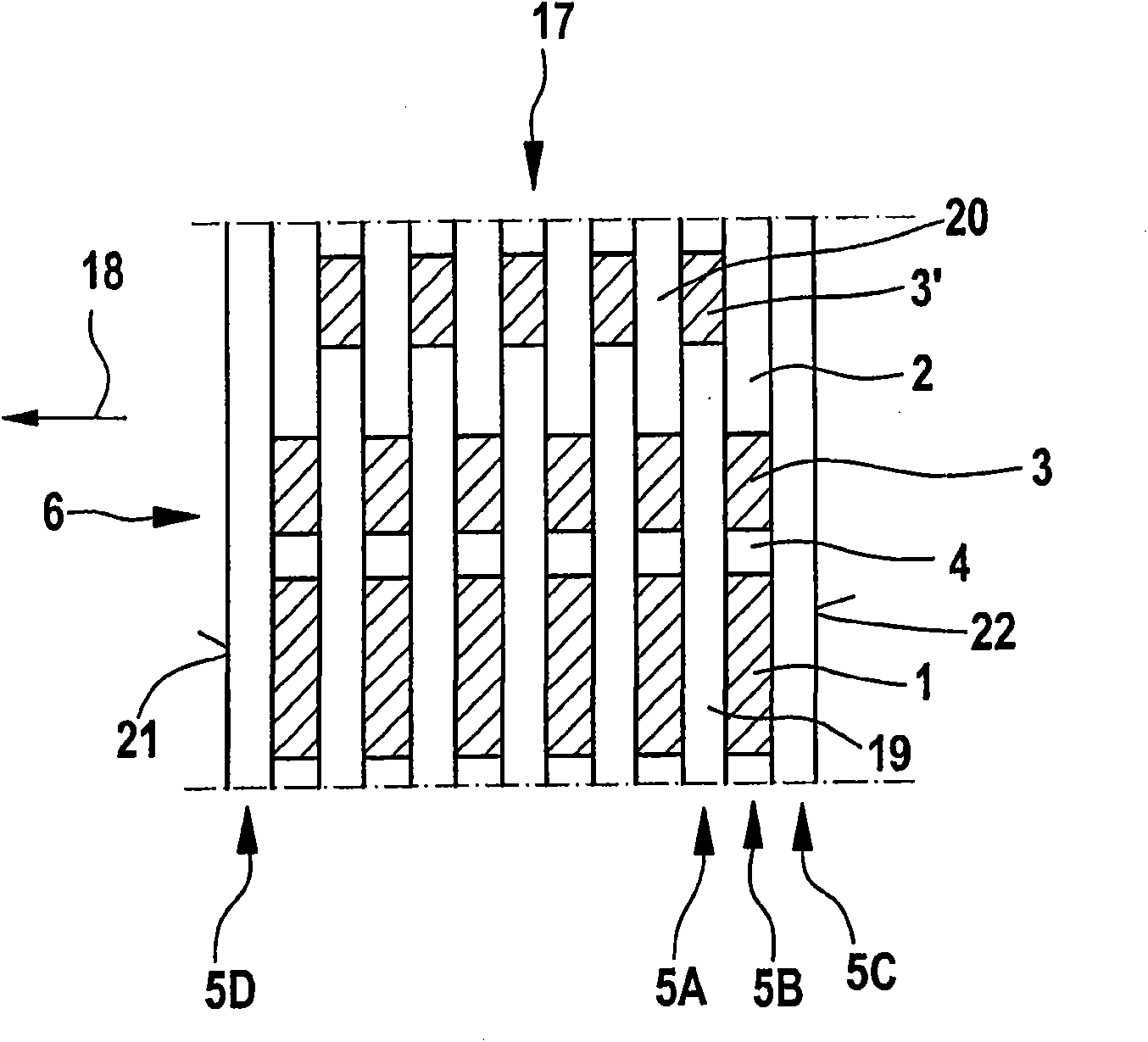

[0030] figure 1 Indicates a motor 8 ( figure 2 ) of a lamination 5 of the lamination pack 6 of the rotor 7 . The electric machine 8 can in particular be designed in the form of an electric motor for a motor vehicle. The electric motor 8 itself is especially suitable for adjusting vehicle components, such as a retractable top, windows or seats, by means of external force. Also, the motor 8 can be used as a power steering motor. However, the electric machine 8 according to the invention is also suitable for other applications.

[0031] The laminations 5 of the lamination stack 6 of the rotor 7 have centering projections 1 which enable concentric accommodation of a shaft which can be inserted into central recesses 9 of the laminations 5 . Furthermore, the lamination 5 has a resilient protrusion 3 in the shape of a nose. The elastic protrusion 3 realizes the fixing of a plurality of laminations 5 on the shaft 10 or the fixing of the lamination group 6 on the shaft 10 by mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com