Vacuum resistive brazing method for lap piece

A resistance brazing and vacuum brazing furnace technology, which is used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the air cannot be discharged from the lap joint and the sheet brazing material, the quality of the brazing seam is reduced, and the small pores in the brazing seam can be solved. and other problems, to achieve the effect of excellent vacuum welding process method, uniform thickness of brazing layer and thermal stress distribution, and elimination of air conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

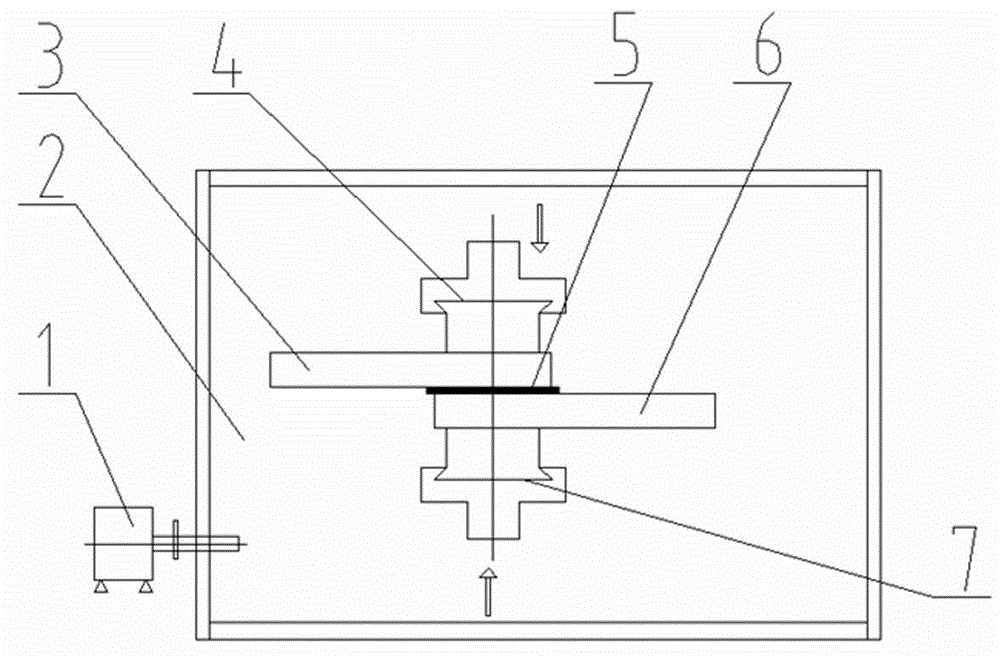

[0017] Embodiment 1, with reference to accompanying drawing, a kind of vacuum resistance brazing method of lap joint, the material of its lap joint is red copper, and it comprises the following steps:

[0018] Step 1. To clean the lap joints, remove the oil and oxides on the surface of the upper lap joint 3, the lower lap joint 6 and the solder 5 to ensure the cleanliness of the upper lap joint 3, the lower lap joint 6 and the solder 5 and dry;

[0019] Step 2, to fix the brazing material and the brazing material, use the upper electrode 4 and the lower electrode 7 to fix the brazing material 5 in the middle of the contact surface of the upper lapping part 3 and the lower lapping part 6;

[0020] Step 3: Vacuumize the brazing furnace, put the parts to be bonded with solder 5 into the vacuum brazing furnace 2, and use the compressor 1 to evacuate the vacuum brazing furnace 2 so that the vacuum degree in the vacuum brazing furnace 2 is 1.0×10 -2 Pa~1.0×10 -4 Pa;

[0021] Ste...

Embodiment 2

[0023] Embodiment 2, with reference to the accompanying drawings, a vacuum resistance brazing method for lap joints, the material of the lap joints is aluminum alloy, except that the vacuum degree in the vacuum brazing furnace 2 in step 3 is 1.0×10 -1 Pa~1.0×10 -3 Except Pa, all the other are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com