Nanoparticle reinforced creep-resistant magnesium alloy and preparation method thereof

A nanoparticle and magnesium alloy technology, applied in the field of magnesium alloy materials, can solve the problem of high alloy cost and achieve high mechanical properties, high temperature creep resistance, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

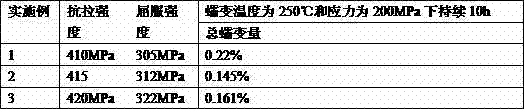

Examples

Embodiment 1

[0020] A nanoparticle-reinforced creep-resistant magnesium alloy, containing: Gd: 0.17%, Al: 0.66%, Zn: 1.24%, Ca: 0.37%, Sr: 0.185%, Nd: 0.235%, Zr: 0.47% by weight %, Sn: 0.865%, Be: 0.135%, Mn: 0.565%, Sb: 0.378%, Cu: 0.79%, SiC nanoparticles: 6.2%, the balance is Mg, the diameter of SiC nanoparticles is less than 50nm, and its preparation method Include the following steps:

[0021] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Ca master alloy, Al-Sr master alloy, Mg-Nd Master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy;

[0022] Pretreatment of nano-SiC particles: a. Pour an appropriate amount of analytical pure ethanol into the container, put a certain amount of dry SiC nanoparticles into the container, stir, and fully wet. The ratio of SiC particles to etha...

Embodiment 2

[0031] A nanoparticle-reinforced creep-resistant magnesium alloy, containing: Gd: 0.17%, Al: 0.66%, Zn: 1.18%, Ca: 0.36%, Sr: 0.125%, Nd: 0.46%, Zr: 0.435 %, Sn: 0.87%, Be: 0.10%, Mn: 0.555%, Sb: 0.38%, Cu: 0.78%, SiC nanoparticles: 5%, the balance is Mg, and the diameter of SiC nanoparticles is less than 80nm. The preparation method of the described nano-particle reinforced creep-resistant magnesium alloy comprises the following steps:

[0032] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Ca master alloy, Al-Sr master alloy, Mg-Nd Master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy;

[0033] Pretreatment of nano-SiC particles: a. Pour an appropriate amount of analytical pure ethanol into the container, put a certain amount of dry SiC nanoparticles into the contai...

Embodiment 3

[0042] A nanoparticle-reinforced creep-resistant magnesium alloy, containing: Gd: 0.16%, Al: 0.79%, Zn: 1.25%, Ca: 0.37%, Sr: 0.12%, Nd: 0.43%, Zr: 0.545 %, Sn: 0.86%, Be: 0.125%, Mn: 0.565%, Sb: 0.38%, Cu: 0.725%, SiC nanoparticles: 8%, the balance is Mg, and the diameter of SiC nanoparticles is less than 20nm. . The preparation method of the described nano-particle reinforced creep-resistant magnesium alloy comprises the following steps:

[0043] (1) Raw material preparation: raw material preparation is carried out according to weight percentage content, and described raw material is pure Mg ingot, Mg-Gd master alloy, pure Al ingot, pure Zn, Al-Ca master alloy, Al-Sr master alloy, Mg-Nd Master alloy, Mg-Zr master alloy, pure Sn, Al-Be master alloy, Al-Mn master alloy, pure Sb, Al-Cu master alloy;

[0044] Pretreatment of nano-SiC particles: a. Pour an appropriate amount of analytical pure ethanol into the container, put a certain amount of dry SiC nanoparticles into the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com