Cr-containing creep-resisting extruded zinc alloy and preparation method thereof

A zinc alloy and anti-creep technology, which is applied in the field of creep-resistant extruded zinc alloy and its preparation, zinc alloy and its preparation, can solve the problems of not being obvious enough, narrow research content, not systematic enough and in-depth research, etc., and achieve improvement Effect of recrystallization temperature, high melting point, excellent creep resistance and comprehensive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

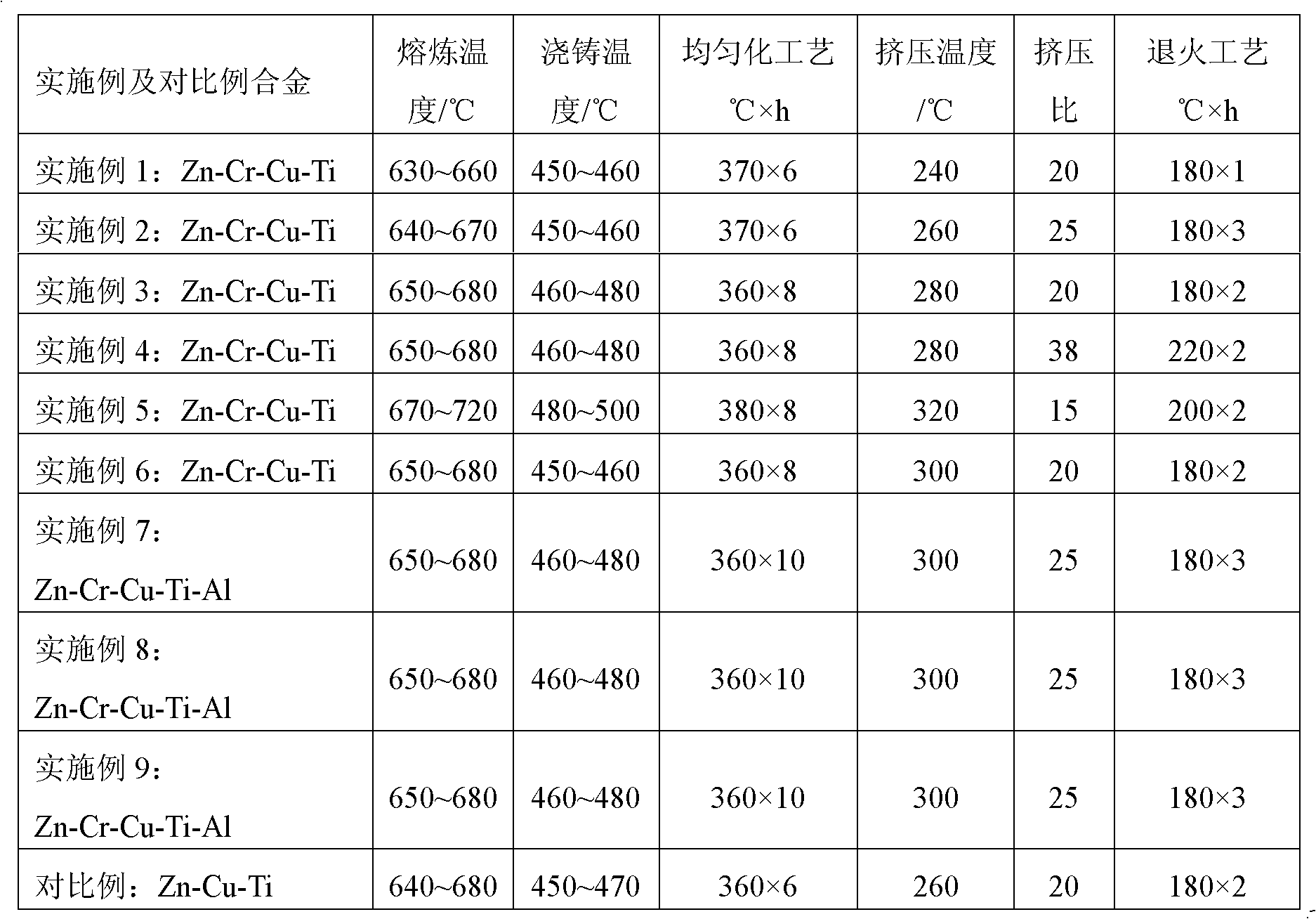

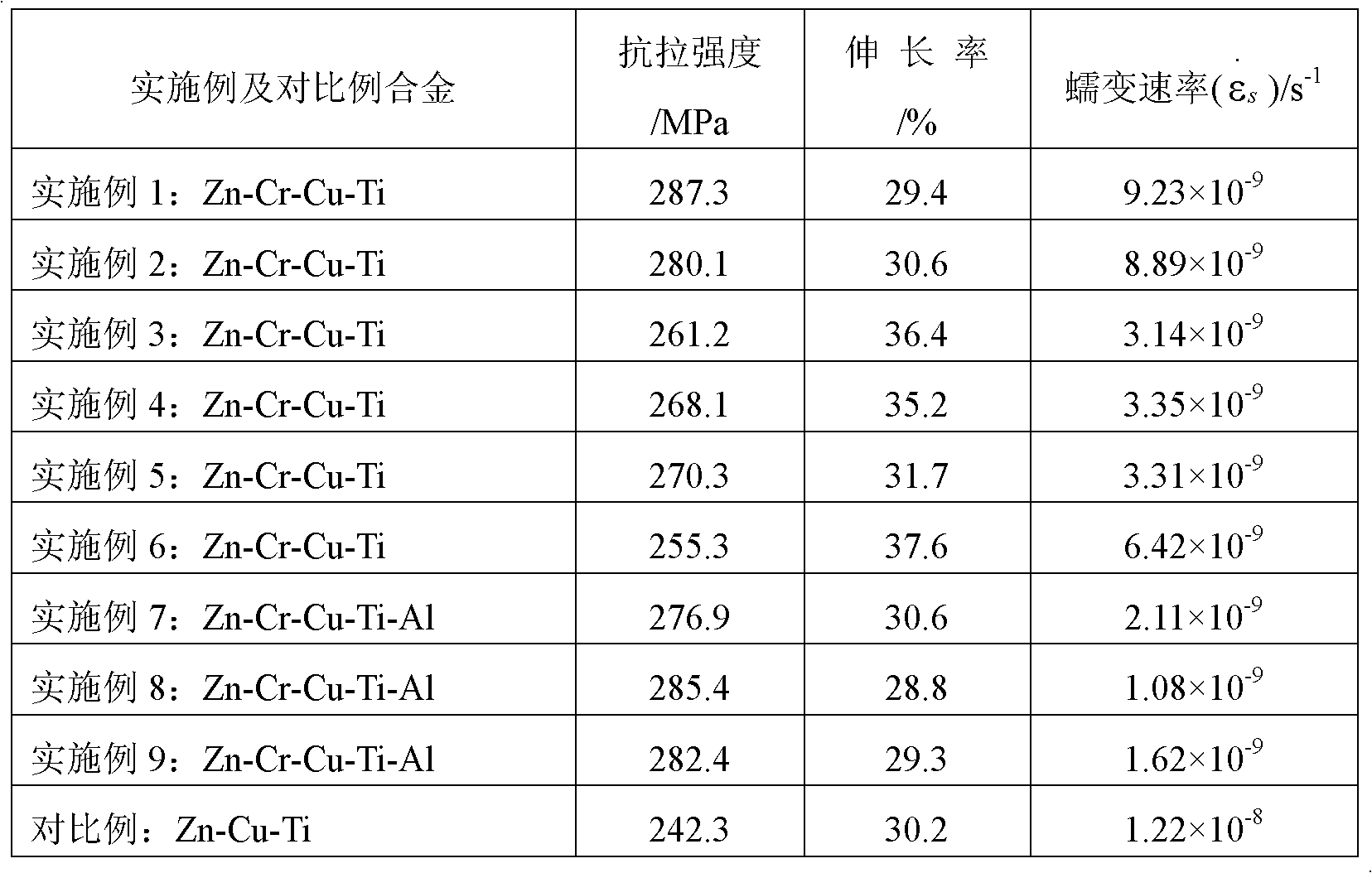

[0043] The present invention will be described in further detail below in conjunction with specific examples 1-9.

[0044] The production process flow of Cr-containing anti-creep extruded zinc alloy in the embodiment of the present invention is as follows:

[0045] Raw material preparation and batching-------preparation of master alloy------alloy casting------homogenization treatment------ingot extrusion------annealing-- ----Inspect the finished product.

[0046]Specifically, it can be expressed as follows: the creep-resistant zinc alloy is smelted in an intermediate frequency induction furnace using the covering protection method, and chromium, copper, and titanium are added in the form of Cu-Cr, Zn-Cu, and Zn-Ti master alloys respectively, while zinc and aluminum are respectively added. It is added in the form of simple substance, and the melting temperature is 630-720°C, so that chromium, copper, titanium and aluminum are quickly melted and mixed uniformly in the zinc melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com