Alloy creep resistant heat resistant steel submerged arc welding stick

A technology of submerged arc welding wire and creep resistance, which is applied in the field of alloy creep-resistant and heat-resistant steel submerged arc welding wire, can solve the welding requirements that cannot meet the high temperature resistance, creep resistance and high tensile strength, and the welding seam deposited metal High temperature creep resistance restriction, heat resistance temperature, creep resistance and other performance degradation problems, to achieve the effect of simple chemical composition design, good mechanical properties and welding process performance, and preventing creep rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

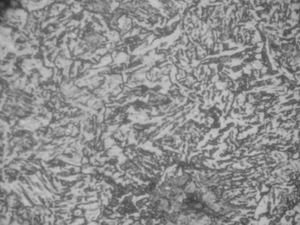

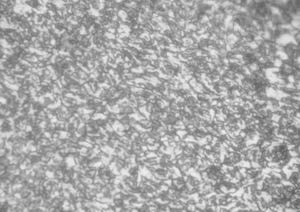

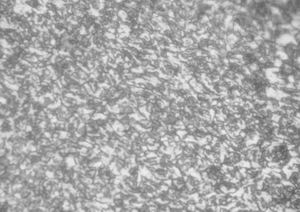

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the examples and accompanying drawings, but the implementation of the present invention is not limited thereto.

[0035] The alloy creep-resistant heat-resistant steel submerged arc welding wire of this embodiment has the following components and mass percentages:

[0036] C 0.05~0.18

[0037] Mn 0.80~1.20

[0038] Si 0.40~0.80

[0039] S≤0.010

[0040] P≤0.010

[0041] Cu≤0.35

[0042] Cr 1.80~4.00

[0043] Ni 0.20~1.00

[0044] Mo 0.80~1.40

[0045] W 0.20~1.00

[0046] V 0.20~0.50

[0047] Ti 0.05~0.20

[0048] B 0.0035~0.005

[0049] Al≤0.05

[0050] The balance is Fe.

[0051] Among them, the preferred range of Cr is 2.20 to 3.80%. The preferred range of Ni is 0.40 to 0.80%. The preferred range of Mo is 0.90-1.30%。 The preferable range of W is 0.30-0.80%. The preferred range of Ti is 0.08-0.16%.

[0052] The embodiment of the present invention is based on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com