Alkali and chlorine-free liquid setting accelerator based on industrial polyaluminium sulfate and its preparation method

A technology of polyaluminum sulfate and accelerator, applied in the field of building material admixtures, can solve the problems of high alkali content of liquid accelerator, large loss of 28d strength, short stability period, etc. Good effect without loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0056] Example 1-5, preparation of alkali-free and chlorine-free liquid quick-setting agent based on industrial polyaluminum sulfate

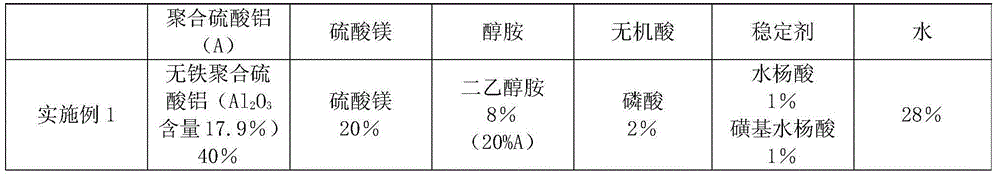

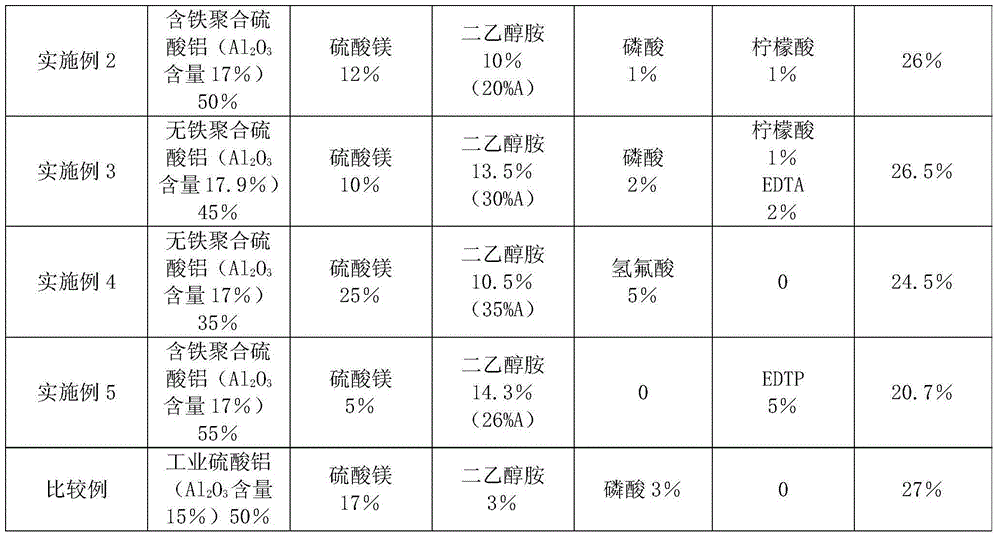

[0057] Embodiment 1-5 is based on the raw material formula of the non-alkali and chlorine-free liquid quick-setting agent of industrial polyaluminum sulfate and comparative example as shown in table 1:

[0058] Table 1 Example 1-5 The raw material formula of the alkali-free and chlorine-free liquid quick-setting agent based on industrial polyaluminum sulfate (the data listed in the table is the percentage of the total weight, and the total weight is 100kg)

[0059]

[0060]

[0061] Prepare the alkali-free and chlorine-free liquid quick-setting agent according to the aforementioned method according to the ingredients listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com