Method for manufacturing uniform-heating plate with foam copper as liquid absorption core

A manufacturing method and technology of foamed copper, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of difficult control of the overall uniformity and flatness of the sintering effect, poor capillary suction effect, etc., and achieve obvious reflux effect, Improve heat dissipation effect, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

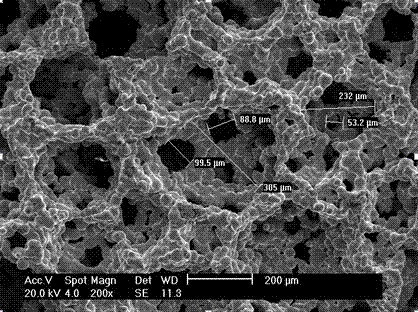

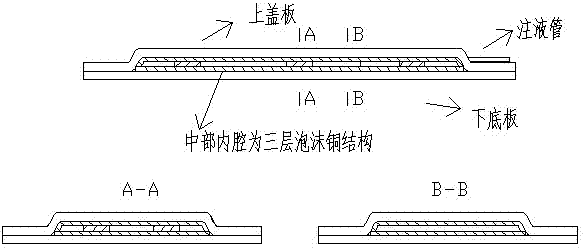

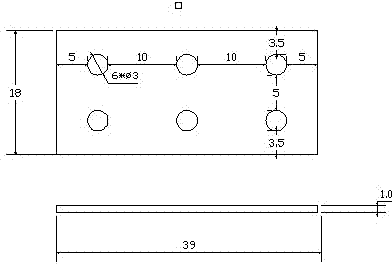

[0026] Example 1, the manufacture of a soaking plate with a thickness of 2.6 mm: both the upper cover plate and the lower bottom plate are made of copper plates with a thickness of 0.6 mm, which are molded into Figure 4 As shown, the height of the formed chamber is 1.4mm, and the copper injection capillary is welded, and the foam copper with a thickness of 0.3mm produced by Jiangsu Geye New Material Technology Co., Ltd. is used to diffuse the surface of the upper cover plate and the lower plate respectively. Method of sintering and combining, and then select the graded porous copper with a thickness of 0.8mm produced by Jiangsu Geye New Material Technology Co., Ltd. to form a Φ5mm cylinder (such as Figure 4 Shown), press (as Figure 4 As shown), as for the diffusion bonding between the upper cover and the lower bottom plate, the heat-resistant steel mold is used to compress the upper cover and the lower bottom plate, so that the edge joint part is in good surface contact. In the...

example 2

[0027] Example 2, the manufacture of a soaking plate with a thickness of 3.6mm: a copper plate with a thickness of 1mm in the lower base plate is used, and a copper plate with a thickness of 0.6mm in the upper cover plate is molded into Figure 5 As shown, the height of the formed steam chamber is 2mm, and the copper injection pipe is welded, and the 0.5mm thick foamed copper produced by Jiangsu Geye New Material Technology Co., Ltd. is used on the inner surface of the upper and lower cover plates through diffusion mode. After sintering, the porous copper with a thickness of 1.0mm produced by Jiangsu Geye New Material Technology Co., Ltd. is cut into 3x8mm 3 x 5 strips (such as Image 6 Shown), press (as Image 6 As shown), as for the upper and lower cover plates, by diffusion welding, graphite is used as a mold to compress the upper and lower cover plates, and the upper and lower covers (including the sintered copper foam) and The support columns (foamed copper) are combined t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com