Heat-resistant conductive polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of heat-resistant conductive polypropylene composite material and its preparation, can solve the problems of reduced conductive synergistic effect, poor mechanical properties of the composite system, poor compatibility, etc., to improve the conductive effect, surface The effect of resistance reduction and workability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

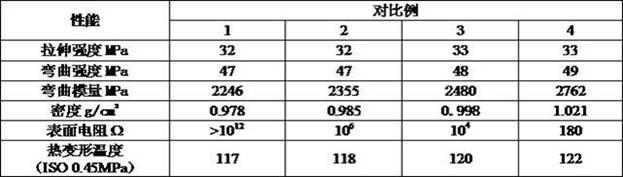

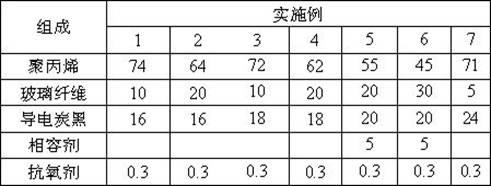

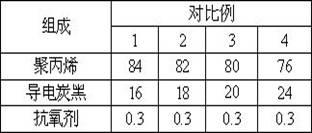

[0025] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

[0026] In the formulas of the examples and comparative examples shown in Table 1 and Table 3: the selected polypropylene is PP HJ4045 produced by Korea Petrochemical Company; the compatibilizer is the maleic anhydride grafted polypropylene PC-1 produced by Guangzhou Baichen Company , the grafting rate is 0.5%; the carbon black is Cabot conductive carbon black VXC-500; the glass fiber is the alkali-free chopped glass fiber ESC13-4.5-508A produced by Jushi Group Co., Ltd.; the antioxidant is produced by Ciba The compound of hindered phenol antioxidant Irganox 1010 and organic phosphite Irganox 168, the ratio is 1:2.

[0027] Its preparation method: in parts by weight, take polypropylene, antioxidant and lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com