High-heat-conductivity corrosion-resistant die-cast aluminum alloy and preparing technique thereof

A technology of corrosion-resistant aluminum alloy and cast aluminum alloy, which is applied in the field of metal materials, can solve the problems of corrosion resistance decline and anodic oxidation difficulty, and achieve the effect of superior thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

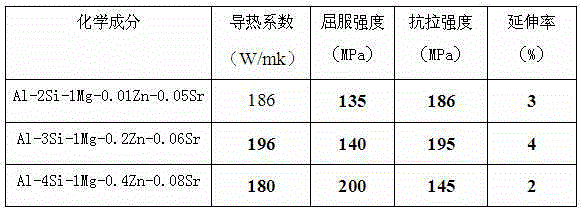

Embodiment 1

[0029] 1:50kgAl-2Si-1Mg-0.01Zn-0.05Sr high thermal conductivity die-casting aluminum alloy, that is, the composition content of the aluminum alloy is: 1.5wt.%Si, 1%wt.%Mg, 0.1%Zn, 0.05wt.%Sr, The rest is aluminum, and the content of other impurity elements is less than 0.005%.

[0030] 1. Ingredients and cleaning of the crucible: According to the amount of alloy to be smelted, the mass of the added alloy is calculated after considering the burning loss rate. If the surface is greasy, it needs to be cleaned, and the alloy ingot needs to be dried in an oven. The crucible should be cleaned and dried to prevent the influence of the residual material from the last smelting on the ratio of alloying elements.

[0031] 2. Melting of aluminum ingots: put pure aluminum ingots into the crucible of the pit furnace, heat the crucible for melting, and control the temperature of the molten aluminum between 700-730°C

[0032] 3. Add the master alloy: when the temperature of the aluminum liqu...

Embodiment 2

[0038] 50kgAl-3Si-2Mg-0.3Zn-0.07Sr high thermal conductivity die-casting aluminum alloy, that is, the composition content of the aluminum alloy is: 3wt.%Si, 2.5%wt.%Mg, 0.3%Zn, 0.07wt.%Sr, and the rest is aluminum , the content of other impurity elements is less than 0.005%.

[0039] 1. Ingredients and cleaning of the crucible: According to the amount of alloy to be smelted, the mass of the added alloy is calculated after considering the burning loss rate. If the surface is greasy, it needs to be cleaned, and the alloy ingot needs to be dried in an oven. The crucible should be cleaned and dried to prevent the influence of the residual material from the last smelting on the ratio of alloying elements.

[0040] 2. Melting of aluminum ingots: put pure aluminum ingots into the crucible of the pit furnace, heat the crucible for melting, and control the temperature of the molten aluminum between 710-730°C

[0041] 3. Add the master alloy: when the temperature of the aluminum liquid...

Embodiment 3

[0047] 50kgAl-4Si-2.5Mg-0.4Zn-0.08Sr high thermal conductivity die-casting aluminum alloy, that is, the composition content of the aluminum alloy is: 5wt.%Si, 3%wt.%Mg, 0.5%Zn, 0.1wt.%Sr, and the rest is Aluminum and other impurity elements are less than 0.005%.

[0048] 1. Ingredients and cleaning of the crucible: According to the amount of alloy to be smelted, the mass of the added alloy is calculated after considering the burning loss rate. If the surface is greasy, it needs to be cleaned, and the alloy ingot needs to be dried in an oven. The crucible should be cleaned and dried to prevent the influence of the residual material from the last smelting on the ratio of alloying elements.

[0049] 2. Melting of aluminum ingots: put pure aluminum ingots into the crucible of the pit furnace, heat the crucible for melting, and control the temperature of the molten aluminum between 710-730°C

[0050] 3. Add the master alloy: when the temperature of the aluminum liquid reaches 710°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com