Wide-temperature, high-frequency and low-power-consumption manganese zinc iron oxidation material and method for manufacturing same

A ferrite material, manganese-zinc power consumption technology, applied in the field of manganese-zinc ferrite material and its preparation, can solve the problems of insufficient product grade, low process technology, backward equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

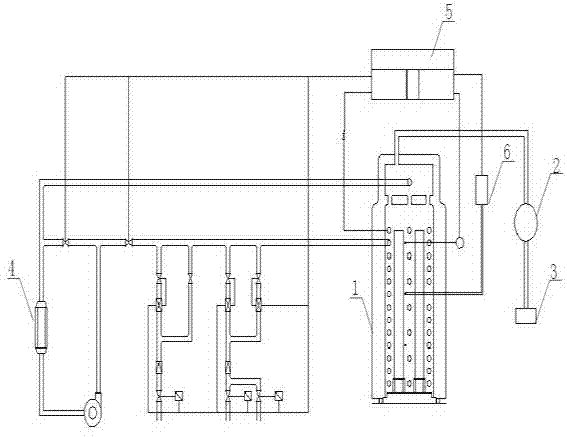

[0046] The controllable atmosphere bell jar sintering furnace is connected with the heat exchanger through pipelines, and the control system is respectively connected with the bell jar furnace and the heat exchanger. The temperature in the furnace can be well controlled by using a heat exchanger. The control system can detect the temperature in the furnace, and control the heat exchanger, the content of pure nitrogen, the content of air, etc. The bell furnace is connected to the heat exchanger through a pipe, and a regulating valve is set in the middle of the pipe, and the heat can be better transferred through the regulating valve. The pure nitrogen device is connected to the bell furnace through pipes, and the air inlet is connected to the bell furnace through pipes.

[0047] When the control system detects that the oxygen content is high, the vacuum pump is used to extract the vacuum, so that the furnace body is in a negative pressure state, and nitrogen is filled to reduc...

Embodiment 2

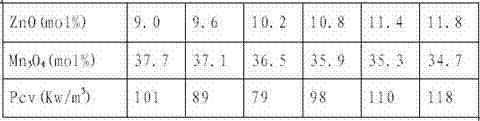

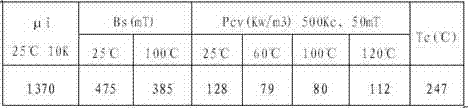

[0057] First select the Fe produced by Baosteel 2 o 3 53.3 mol%, and then fix the ZnO10.2mol% produced by Jinghua, the Mn of Hunan 3 o 4 36.5mol%; adopt dry strong mixing, the time is 45min, and then pre-fire in the rotary kiln, the control temperature is 950 ℃, the time is 3 hours; after 2.0 hours of sand grinding, the particle size of the powder is controlled at the average particle size Diameter 1.0-1.2μm; then add pure water 35wt%, dioctyl phosphate 0.2wt%, ZrO 2 0.025wt%, TiO 2 0.015wt%, 0.025wt%, Nb 2 o 5 0.055wt%. Then the spray particles are pressed into 25*15*10 rings. The controllable atmosphere bell jar sintering furnace is adopted, the sintering temperature is 1320°C, and the temperature is kept for 4 hours. The temperature used in the debinding section of the controlled atmosphere bell jar sintering furnace used in the sintering step is 500°C, and the temperature is slowly raised during the debinding process. The speed is 2°C / min, the volume percentage ...

Embodiment 3

[0061] First select the Fe produced by Baosteel 2 o 3 The molar percentage is 55.0%, and then the ZnO produced by Jinghua is fixed, and the molar percentage is 10.2%, and the Mn in Hunan 3 o 4, Its molar percentage is 36.5%; use dry strong mixing, the time is 45min, and then pre-fire in the rotary kiln, the control temperature is 950 ℃, the time is 3 hours; after 2.0 hours of sand grinding, the particle size of the powder is Control the average particle size at 1.0 μm; then add 38wt% pure water, 0.2wt% dioctyl phosphate, ZrO 2 0.025wt%, TiO 2 200ppm, HfO 2 0.0148wt%, Nb 2 o 5 0.055wt%. Then the spray particles are pressed into 25*15*10 rings. The controllable atmosphere bell jar sintering furnace is adopted, the sintering temperature is 1320°C, and the temperature is kept for 4 hours. The temperature used in the debinding section of the controlled atmosphere bell jar sintering furnace used in the sintering step is 500°C, and the temperature is slowly raised during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com