Ferrite magnet material of manganese-zinc, and Method for preparing high conductive ferrite of manganese-zinc from material

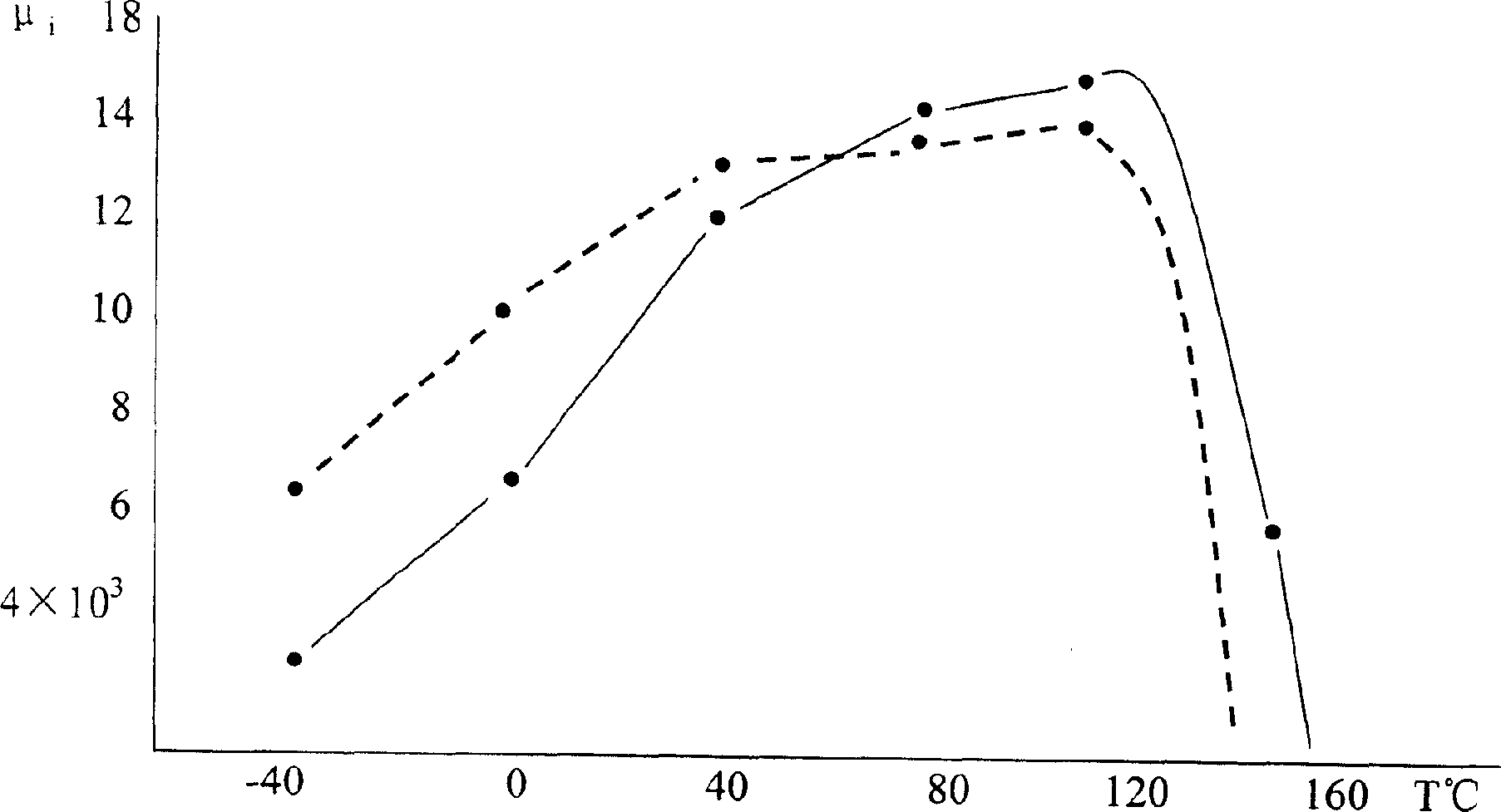

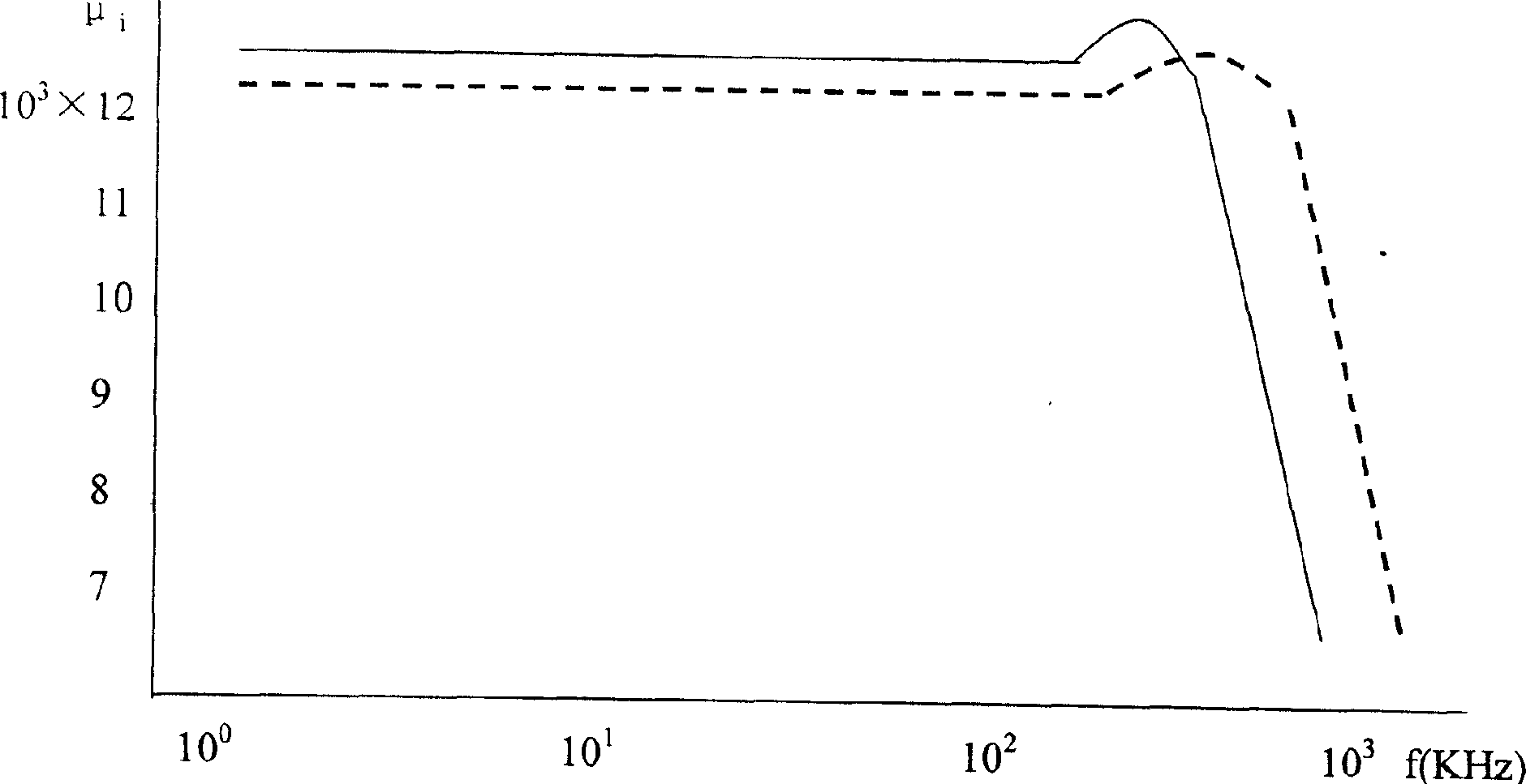

A technology of zinc ferrite and high conductivity, which is applied in the field of manganese-zinc ferrite magnet materials and the preparation of high-conductivity manganese-zinc ferrite and soft magnetic manganese-zinc ferrite products, which can solve the problem of It is difficult to solve the problems of high magnetic permeability and small specific loss coefficient, so as to achieve the effect of reasonable ratio, increased resistivity, and improved magnetic permeability-temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

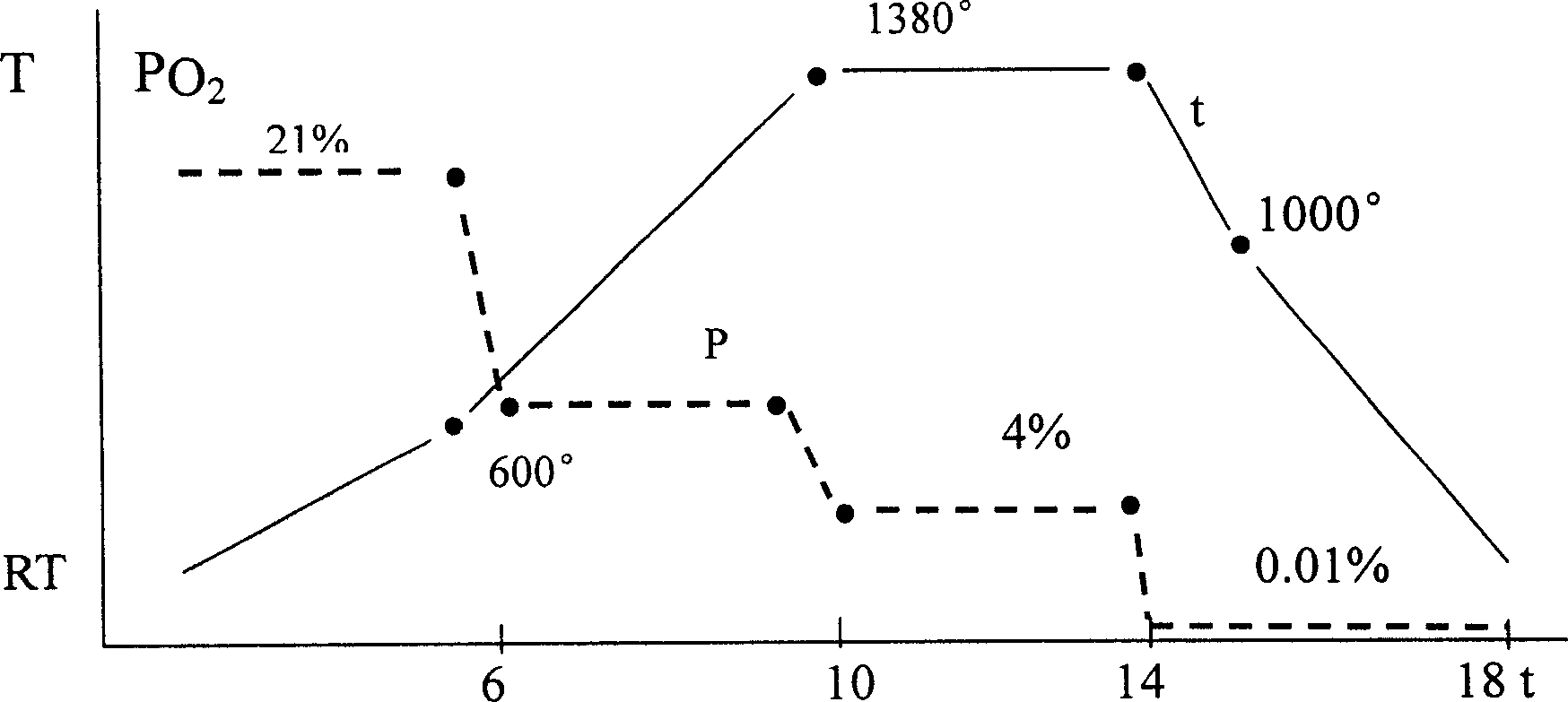

[0029] First, the selected components are 52.2mol% of iron oxide, 25mol% of manganese oxide, and 22.8mol% of zinc oxide. Vibrate the ball mill for 0.6h to obtain fine powder, send the vibrated fine powder to the electric rotary kiln for pre-calcination, the pre-fire temperature is 950°C, the time is 2h, after cooling, add the preferred component of CaO 0.05WT% 、TiO 2 0.06wt%, Bi 2 o 3 0.03wt% auxiliary raw material after weighing, send into sand mill sand mill 2h, in sand mill process, control material: ball: the ratio of water is 1: 1: 0.6, the grain size of the material after sand mill is below 1 μm , and then use spray drying equipment to make the slurry obtained by sand grinding into granules, that is, spray granulation, and add 10% of the amount of PVA aqueous solution before spraying. The requirements for the particles are: water content 0.15-0.25%, particle size distribution 100- 200μm accounts for 75%, flow angle is 26-35°, bulk specific gravity is 1.35~1.45g / cm 3 ...

Embodiment 2

[0032] Only the iron oxide, manganese oxide, and zinc oxide of the main raw material components were changed to Fe 2 o 3 52.2mol%, MnO24.6mol%, ZnO23.2mol%, the initial magnetic permeability of the obtained finished ferrite i =13400, specific loss coefficient tgδ / μ i =3×10 -6 (f: 10kHZ), all the other are the same as embodiment 1.

Embodiment 3

[0034] Only the iron oxide, manganese oxide, and zinc oxide of the main raw material components were changed to Fe 2 o 3 52.8mol%, MnO24.0mol%, ZnO23.2mol%, the initial magnetic permeability of the obtained finished ferrite i =12800, specific loss coefficient tgδ / μ i =2.8×10 -6 (f: 10kHZ), all the other are the same as embodiment 1.

[0035] The ideal physical properties shown by the test of the ferrite products obtained in the foregoing embodiments are shown in the following table:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com