High-power quick soft-restoring diode and mfg technology thereof

A production process and soft recovery technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of hard reverse recovery characteristics, no high-power fast soft-recovery diode manufacturing process, and it is difficult to solve high-power fast recovery diodes. Soft recovery diode forward voltage drop, reverse recovery characteristics and high power problems, to achieve the effect of soft reverse recovery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

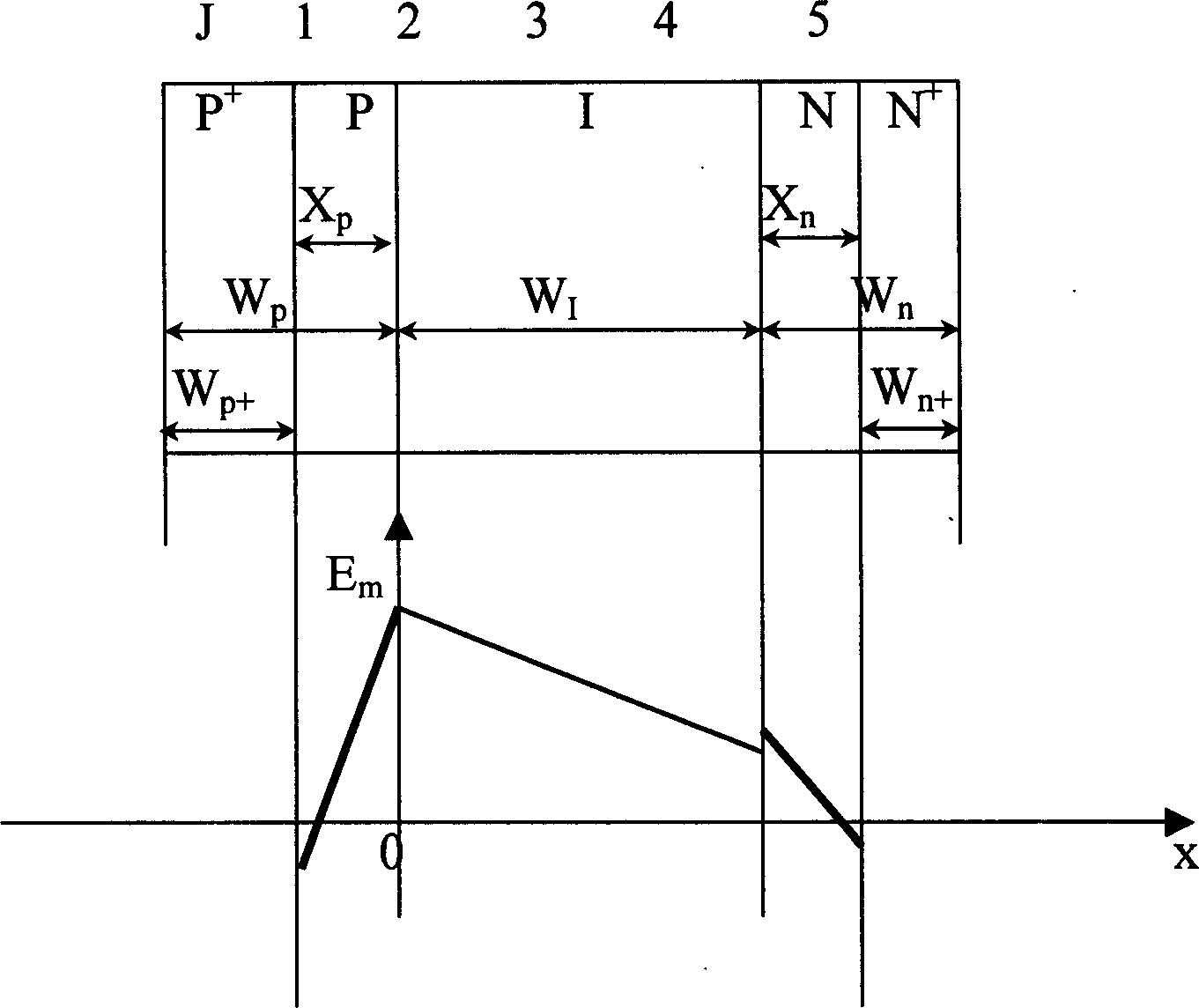

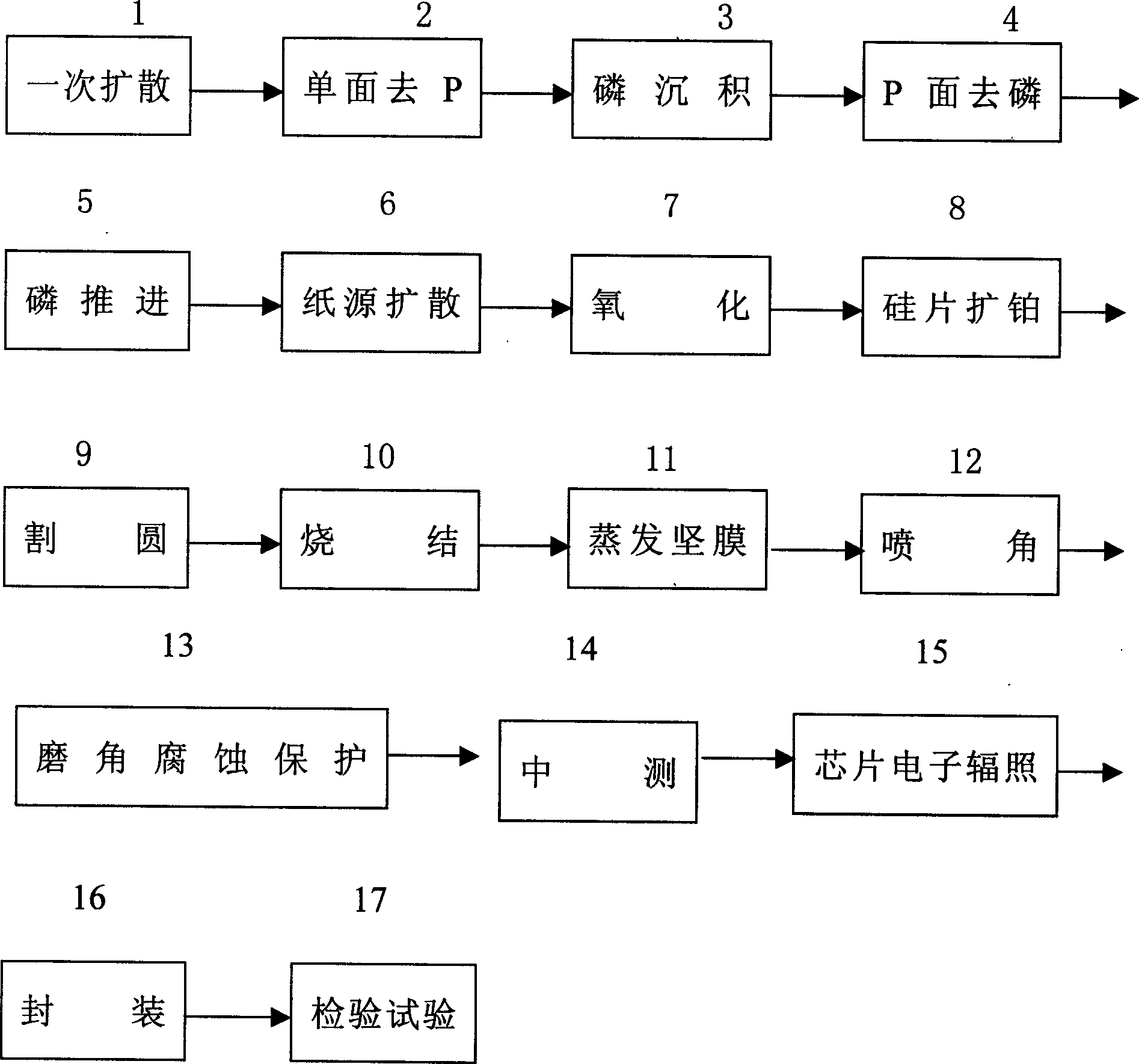

[0048] Preparation of P + PINN + Type high power fast soft recovery diode:

[0049] 1).Primary diffusion (closed expansion): clean the original silicon wafer, 1200 ℃ diffusion furnace constant temperature diffusion, using 99.9999% pure home source diffusion, the surface concentration is 10 17 / cm 3 ;

[0050] 2). Remove P-type on one side: Use a grinder to grind off one side of the P-type diffuser;

[0051] 3). Phosphorus deposition: clean and remove the diffusion sheet on one side, diffuse at a constant temperature in a 1000°C diffusion furnace, and use a liquid source of phosphorus oxychloride (POCl 3 ) diffusion, the surface concentration is ≥1×10 19 / cm 3 ;

[0052] 4). Dephosphorization of P surface: use a screen printing machine to print the P-shaped surface, and corrode the phosphorus on the P-shaped surface;

[0053] 5). Phosphorus propulsion: clean the diffusion sheet, and propel it at a constant temperature in a 1200°C diffusion furnace;

[0054] 6). Diffusi...

Embodiment 2

[0079] Preparation of P + PINN + Type high power fast soft recovery diode:

[0080] 1).Primary diffusion (closed expansion): clean the original silicon wafer, 1250 ℃ diffusion furnace constant temperature diffusion, using 99.9999% pure home source diffusion, the surface concentration is 10 18 / cm 3 ;

[0081] 2). Remove P-type on one side: Use a grinder to grind off one side of the P-type diffuser;

[0082] 3). Phosphorus deposition: clean and remove the diffusion sheet on one side, diffuse at a constant temperature in a 1150°C diffusion furnace, and use a liquid source of phosphorus oxychloride (POCl 3 ) diffusion, the surface concentration is ≥9×10 19 / cm 3 ;

[0083] 4). Dephosphorization of P surface: use a screen printing machine to print the P-shaped surface, and corrode the phosphorus on the P-shaped surface;

[0084] 5). Phosphorus propulsion: clean the diffusion sheet, and propel it at a constant temperature in a 1250°C diffusion furnace;

[0085] 6). Diffusi...

Embodiment 3

[0110] Preparation of P + PINN + Type high power fast soft recovery diode:

[0111] 1).Primary diffusion (closed expansion): clean the original silicon wafer, 1230 ℃ diffusion furnace constant temperature diffusion, using 99.9999% pure home source diffusion, the surface concentration is 10 18 / cm 3 ;

[0112] 2). Remove P-type on one side: Use a grinder to grind off one side of the P-type diffuser;

[0113] 3). Phosphorus deposition: clean and remove the diffusion sheet on one side, diffuse at a constant temperature in a 1100°C diffusion furnace, and use a liquid source of phosphorus oxychloride (POCl 3 ) diffusion, the surface concentration is ≥5×10 19 / cm 3 ;

[0114] 4). Dephosphorization of P surface: use a screen printing machine to print the P-shaped surface, and corrode the phosphorus on the P-shaped surface;

[0115] 5). Phosphorus propulsion: clean the diffusion sheet, and propel at a constant temperature of 1230°C diffusion furnace;

[0116] 6). Diffusion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com