Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Achieve anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

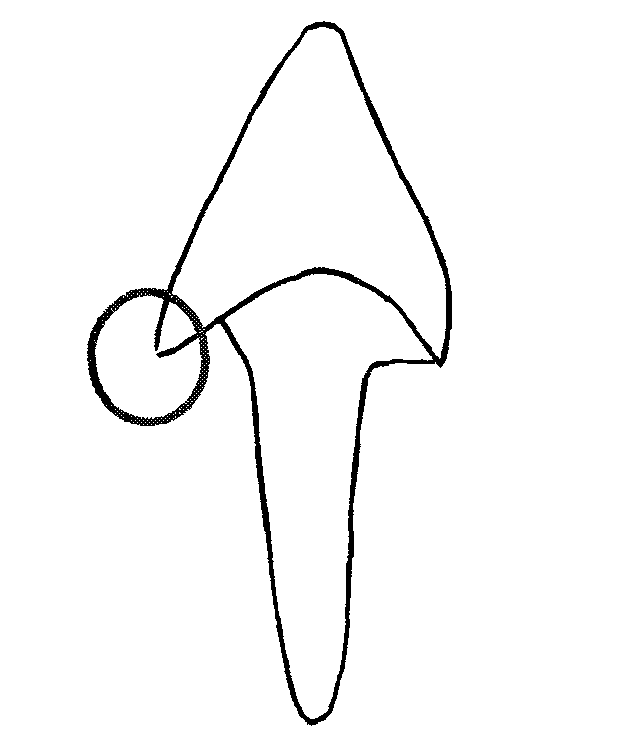

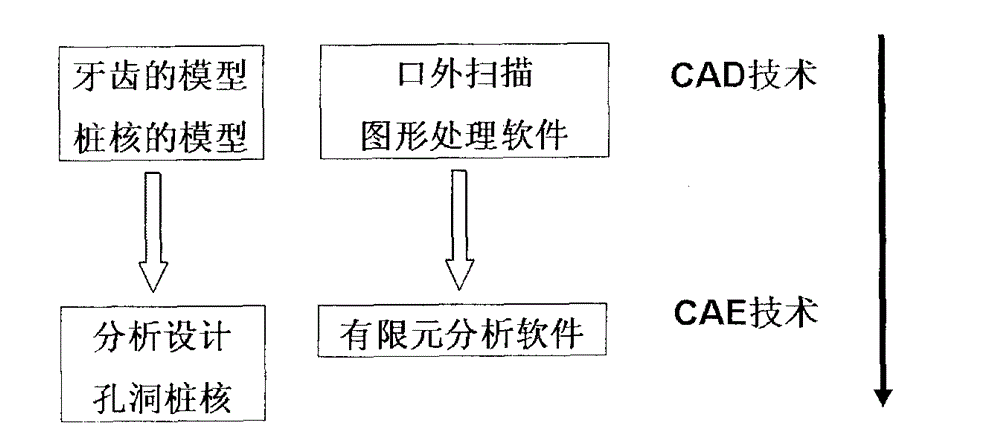

Integrated fiber post for dental restoration and preparation method thereof

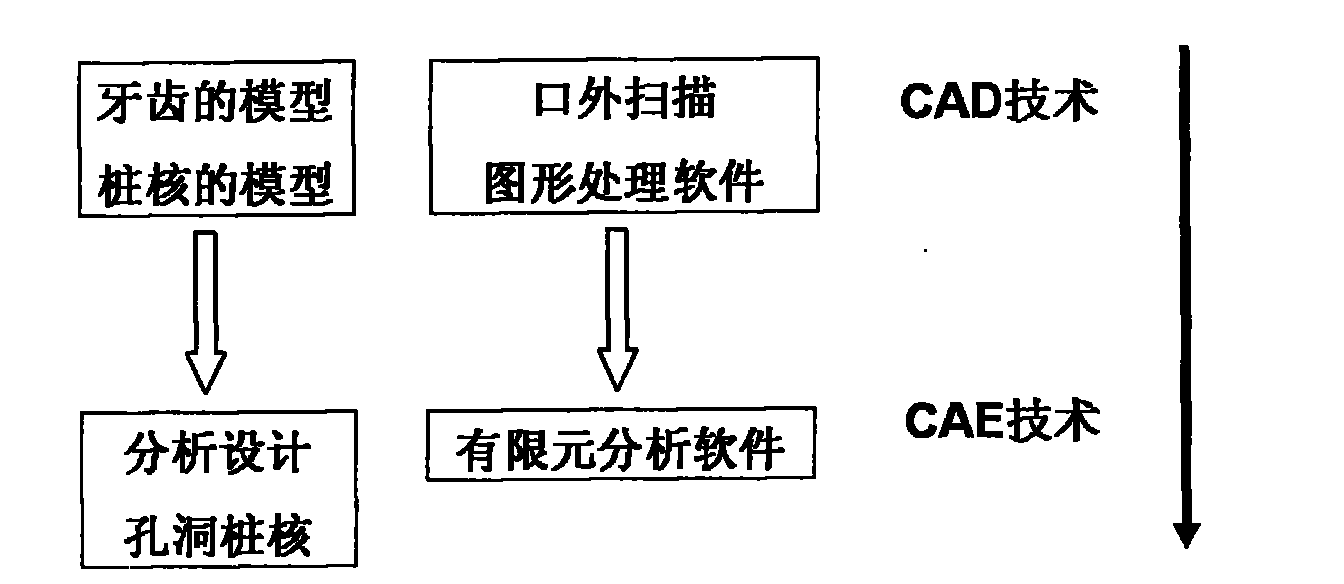

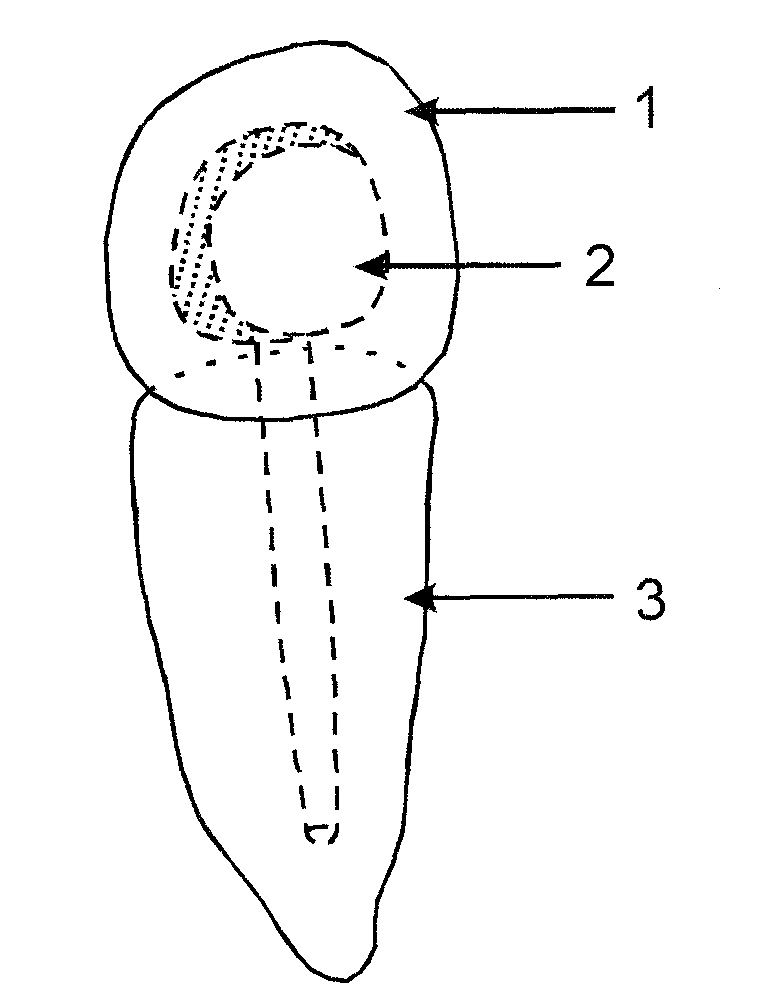

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

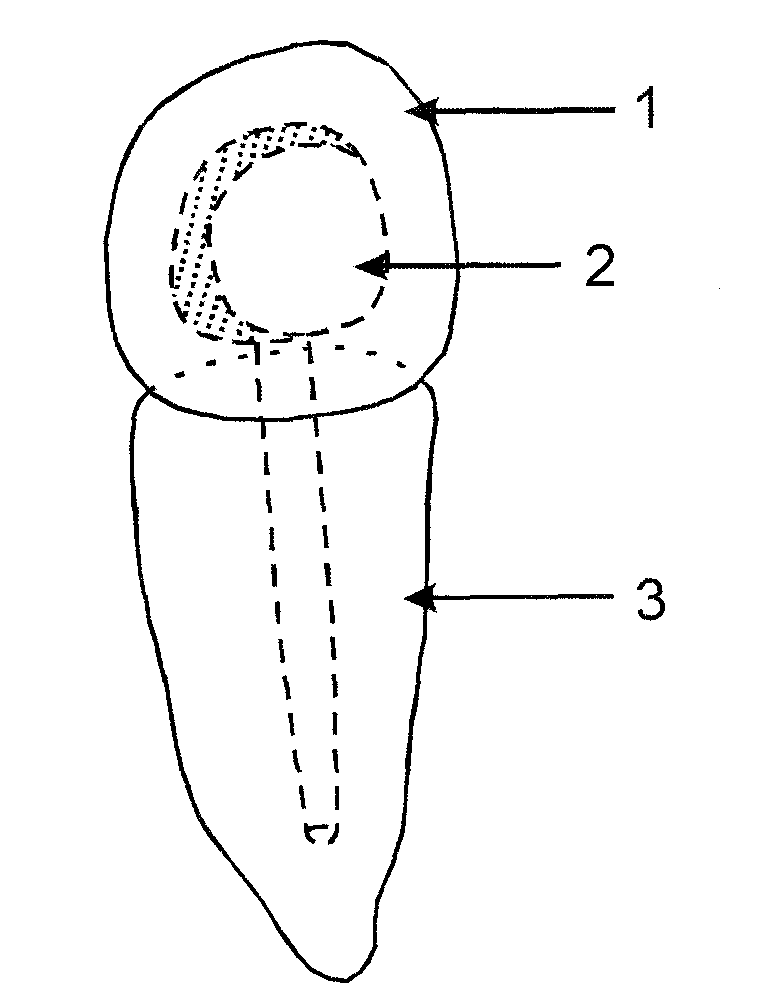

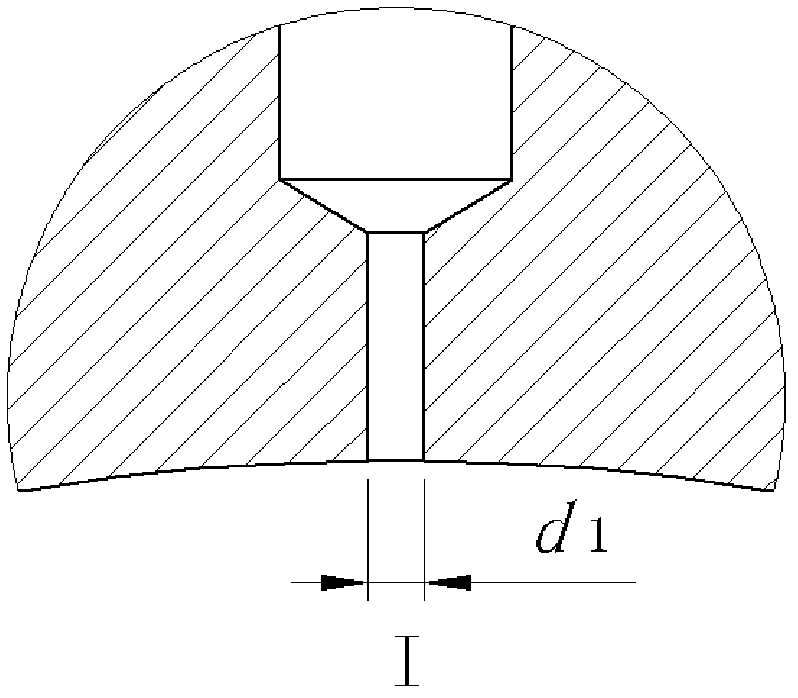

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

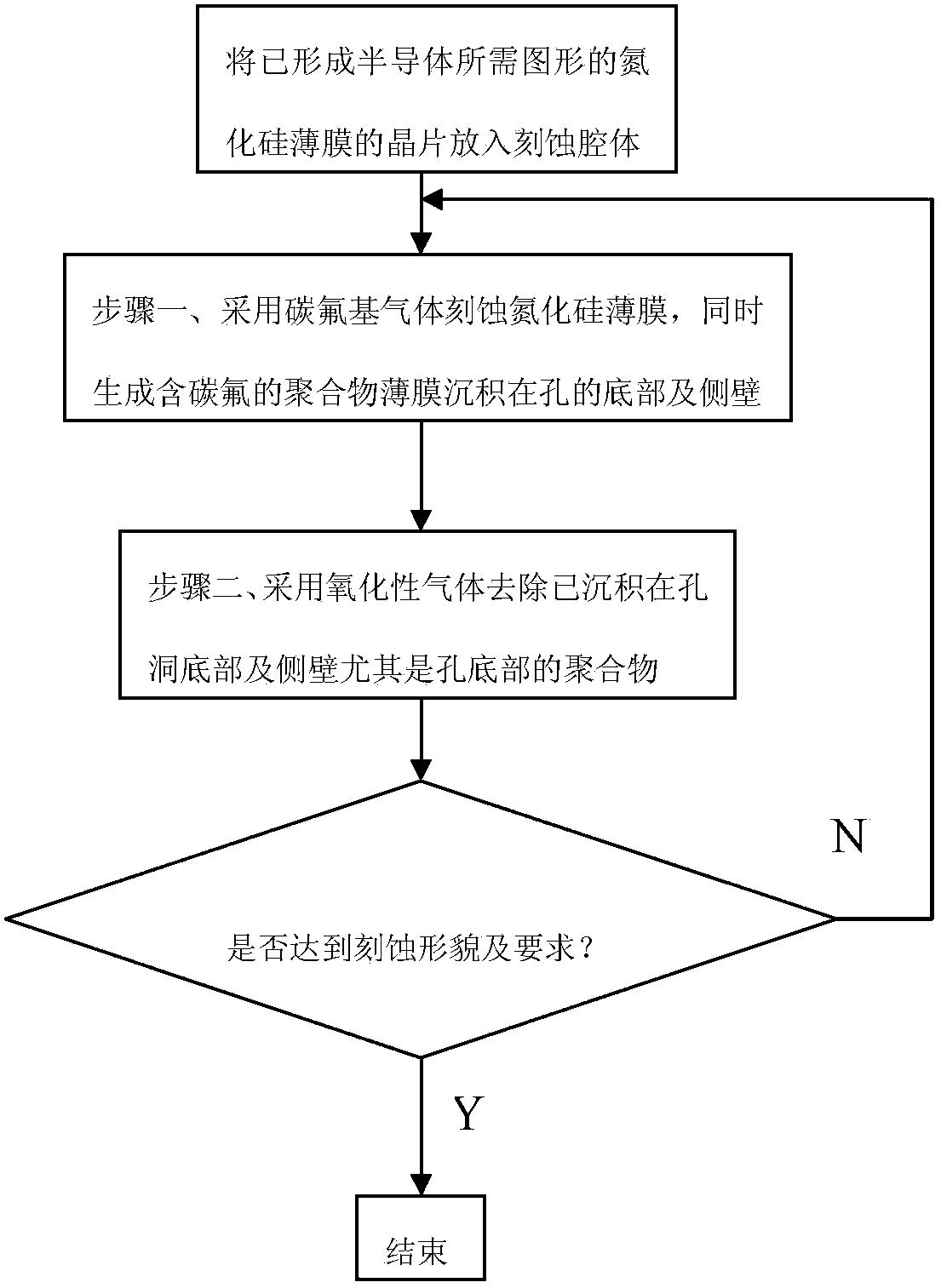

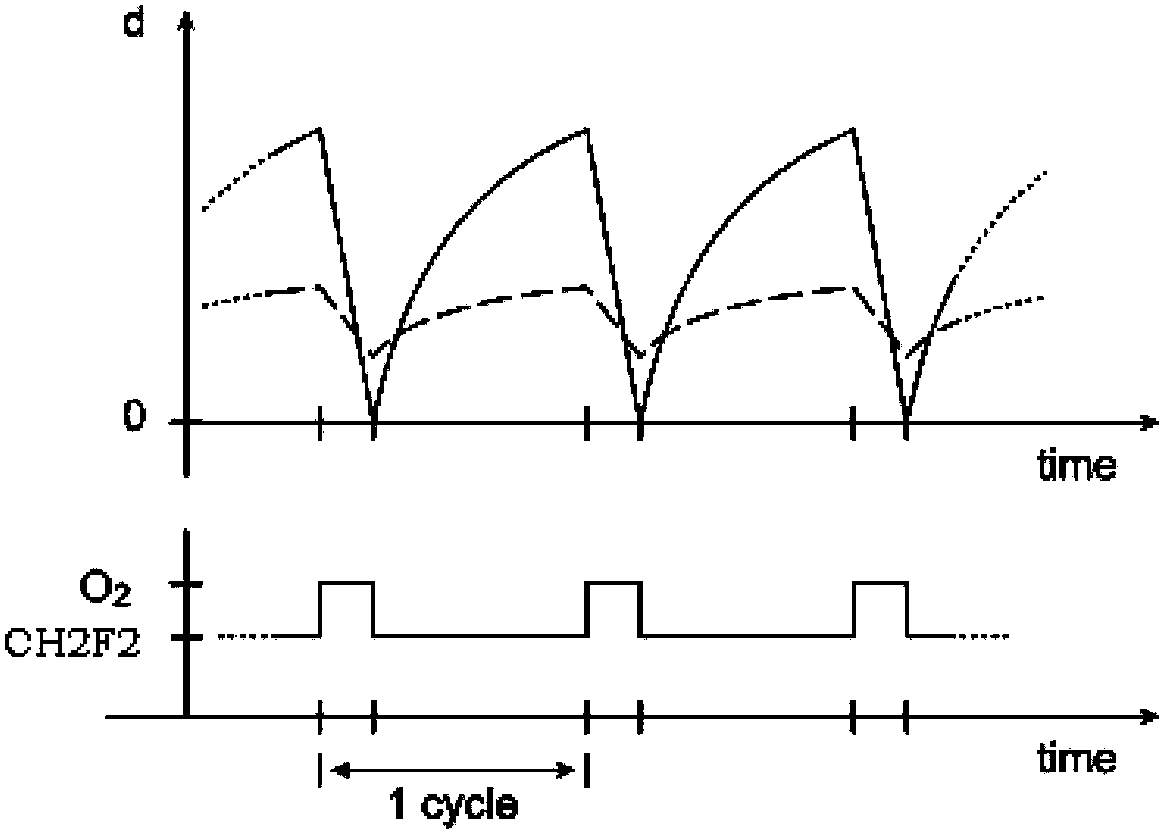

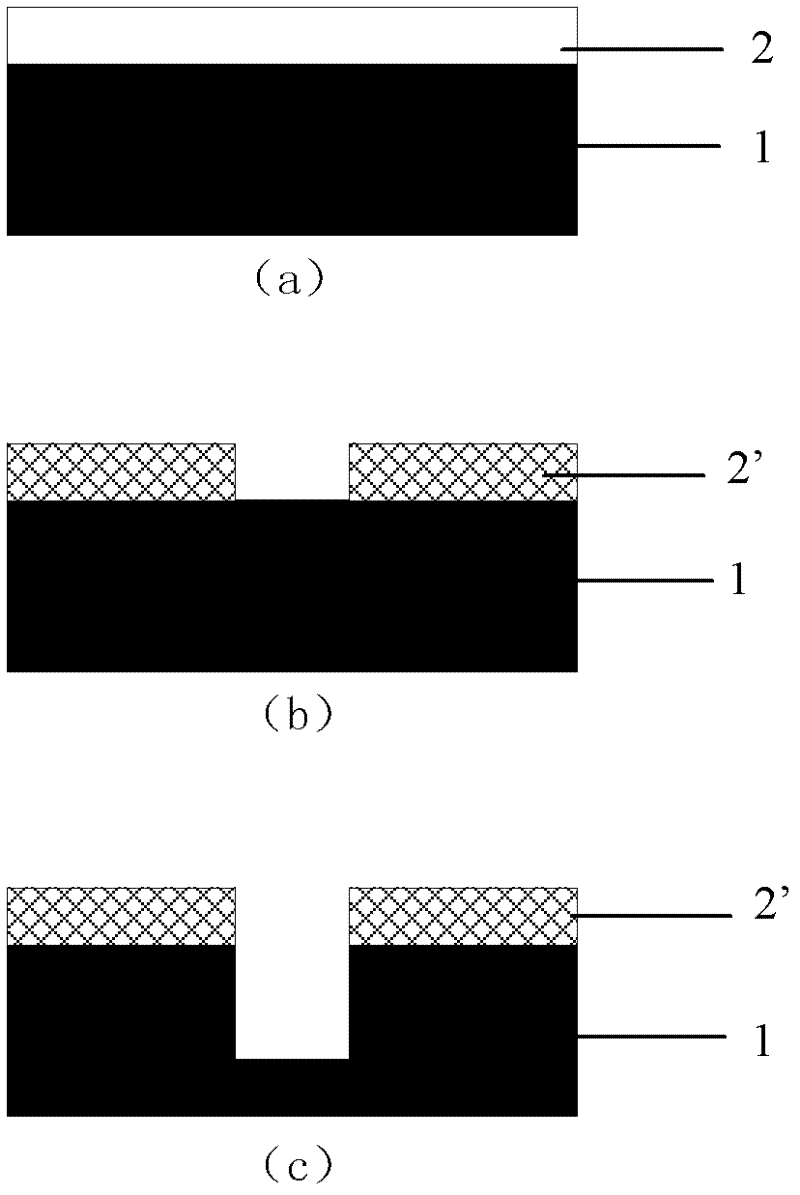

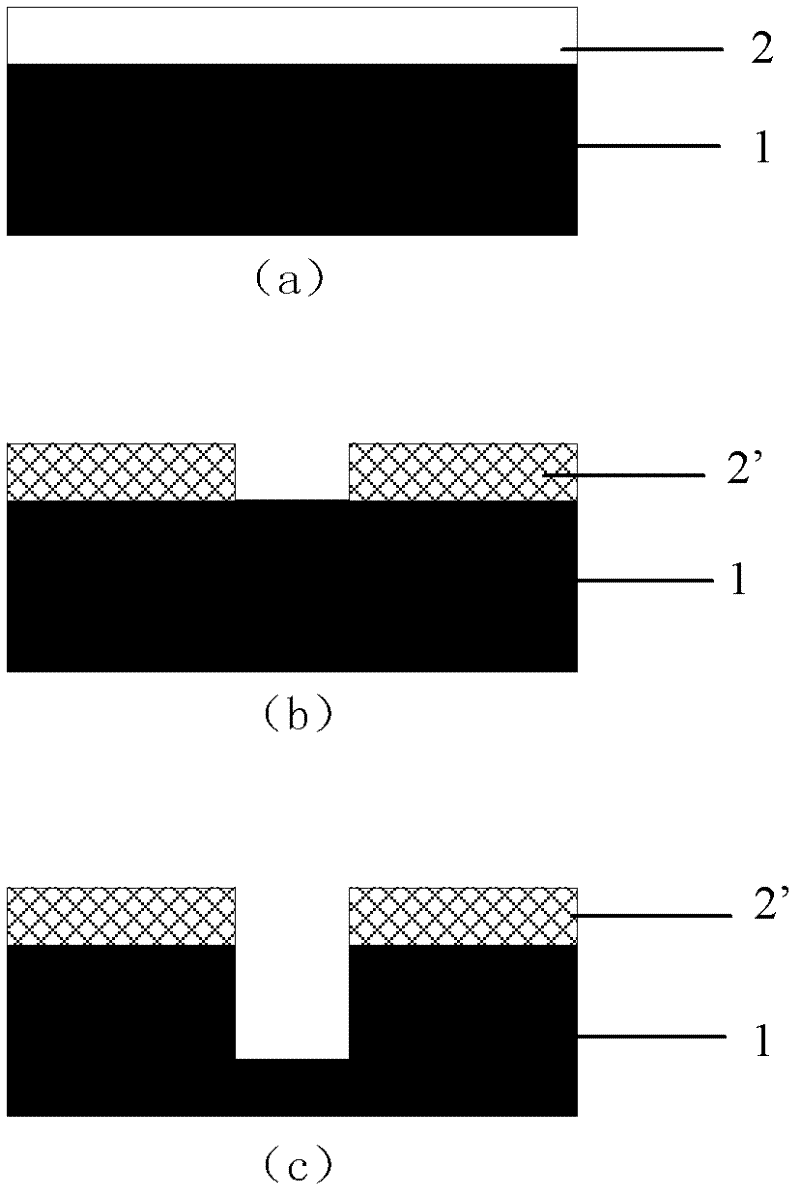

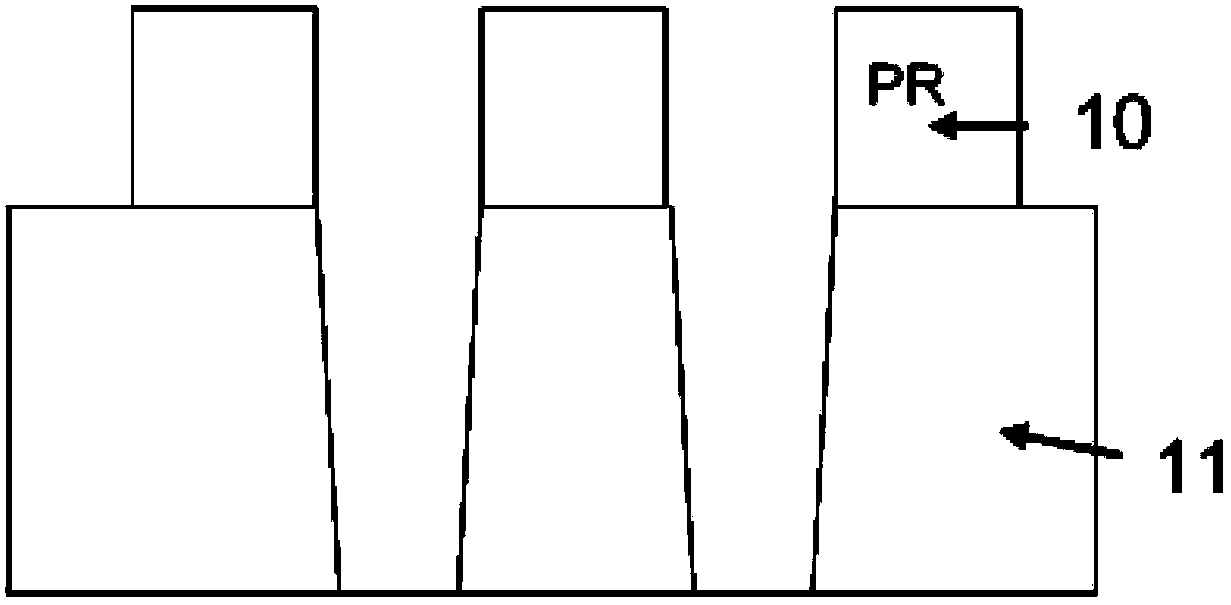

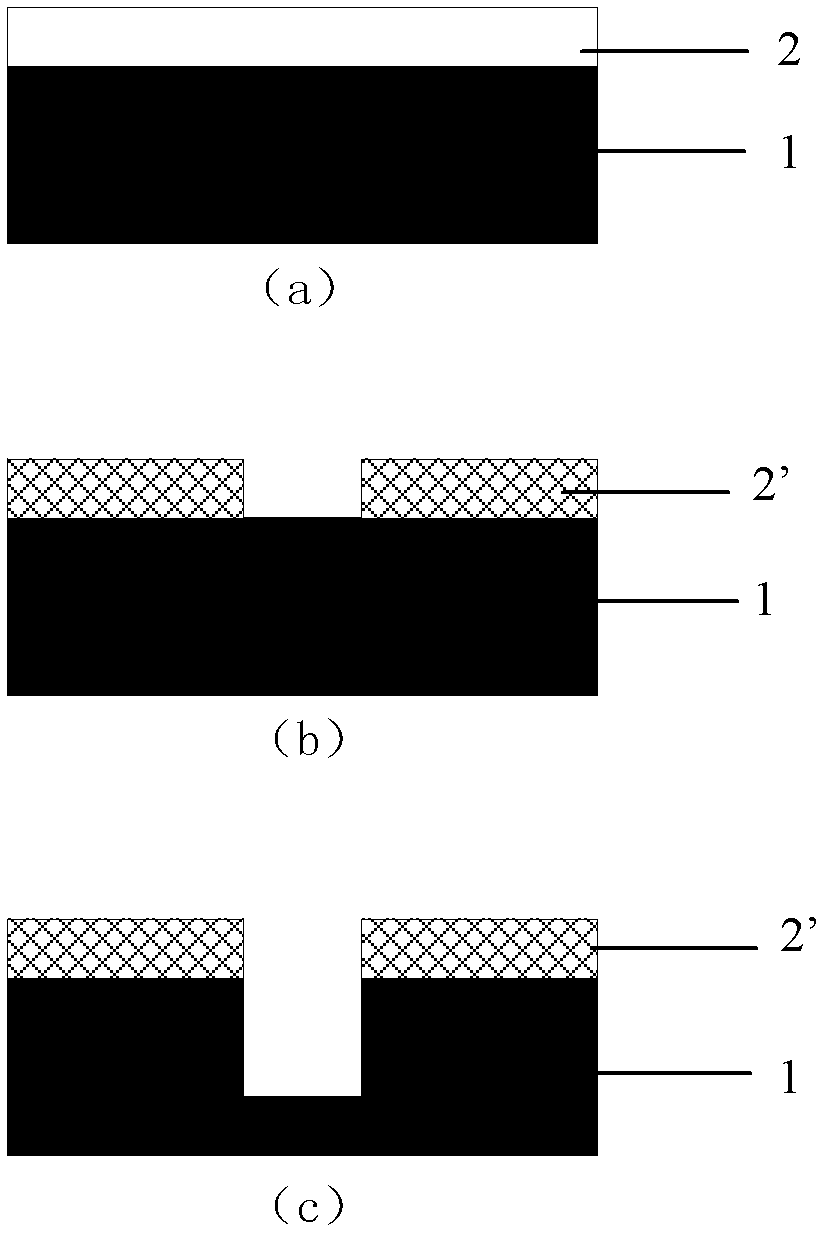

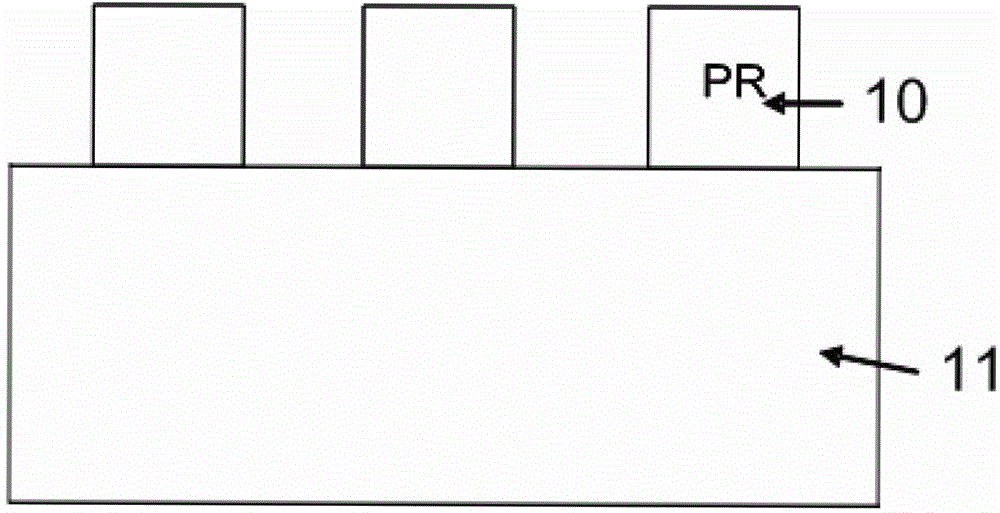

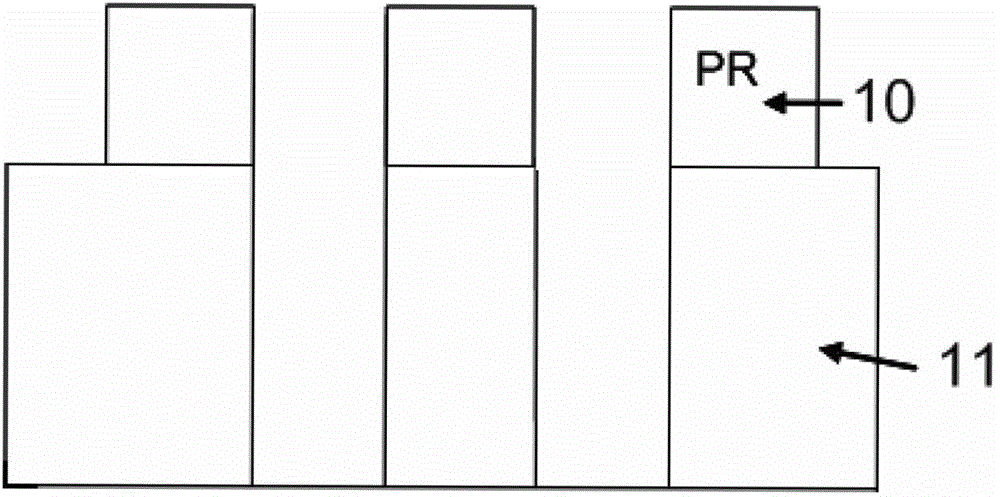

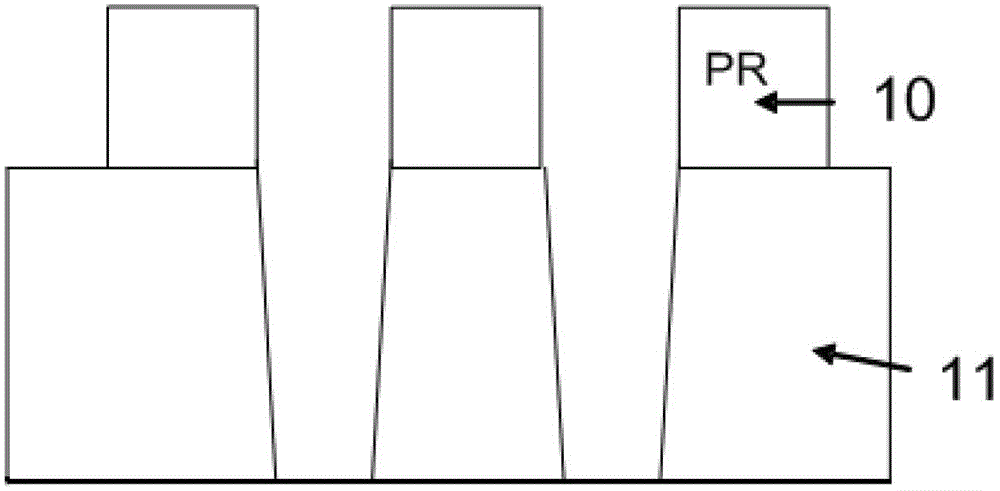

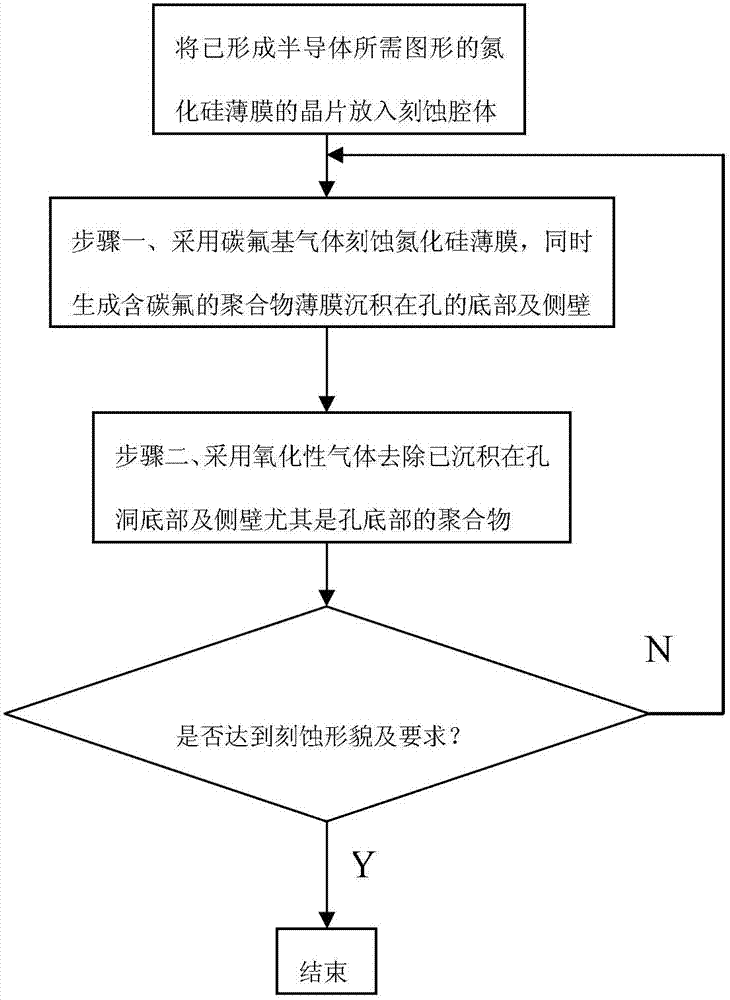

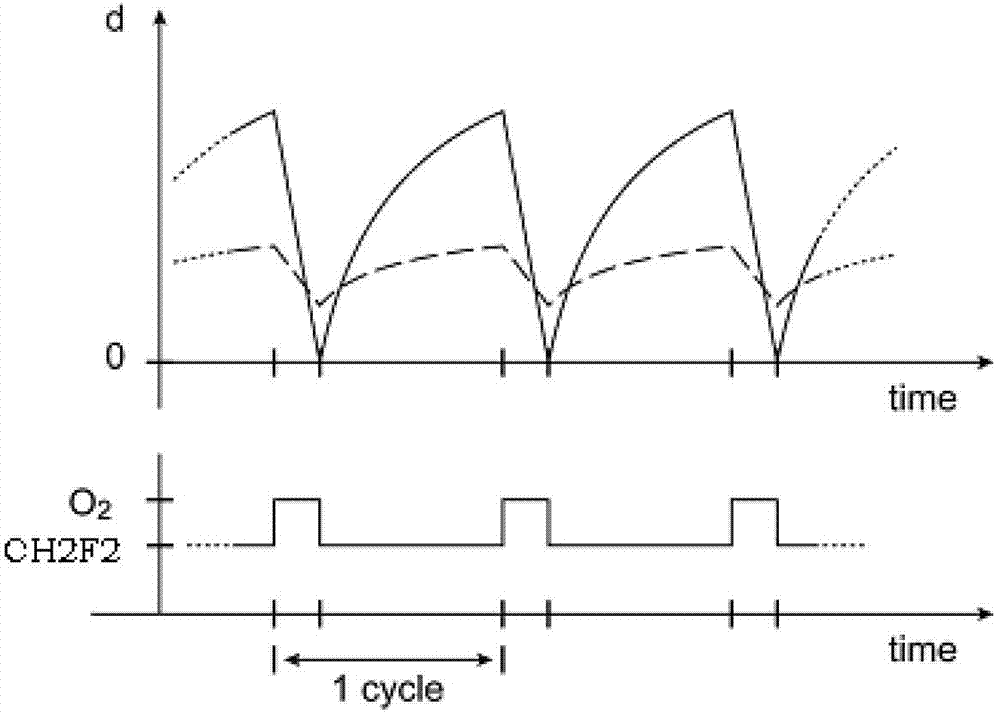

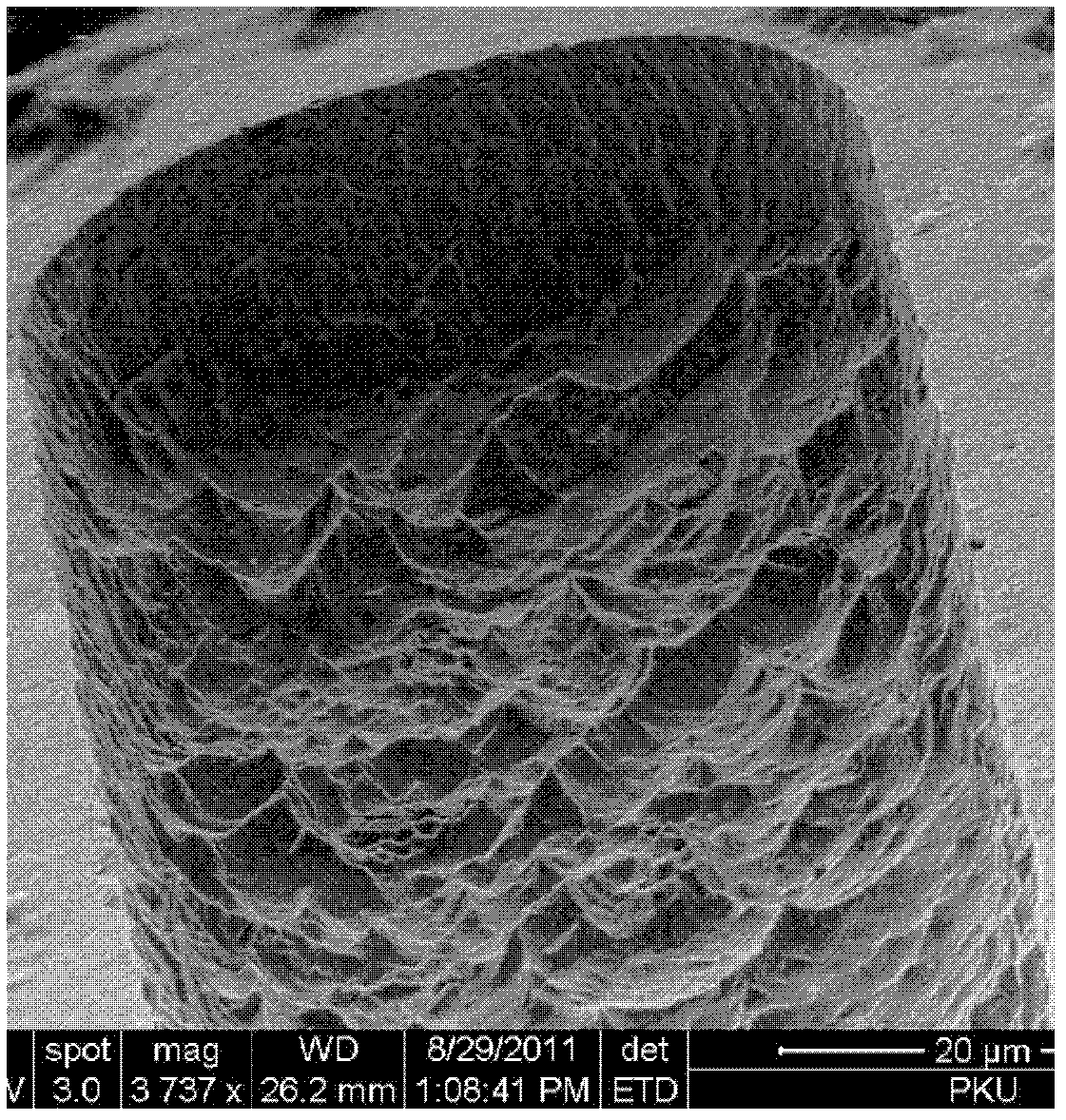

Circulating etching method of silicon nitride hole with high depth-to-width ratio

ActiveCN103578973AAdjust etch topographyAchieve anisotropySemiconductor/solid-state device manufacturingEtchingMetallurgy

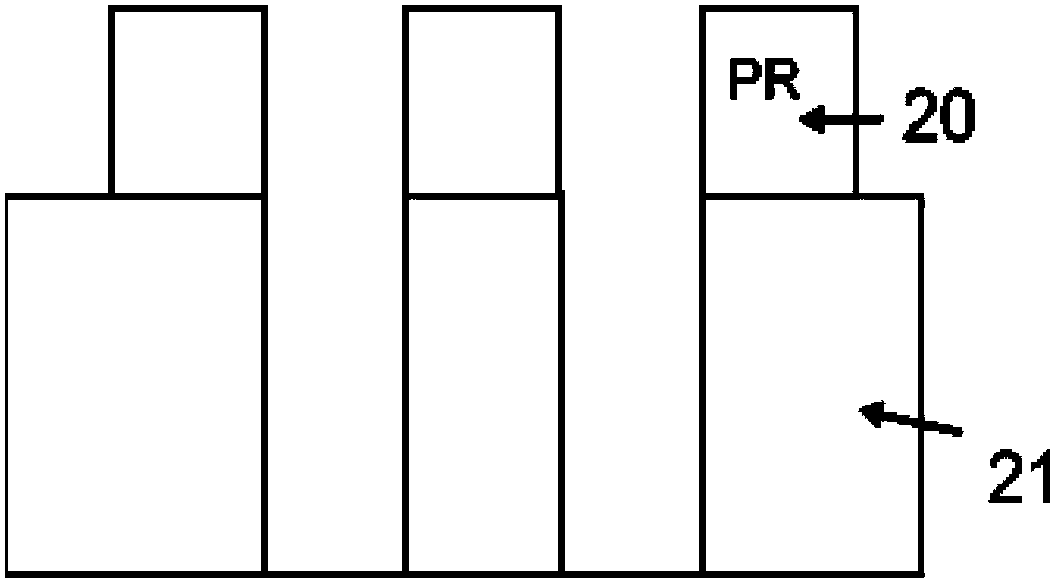

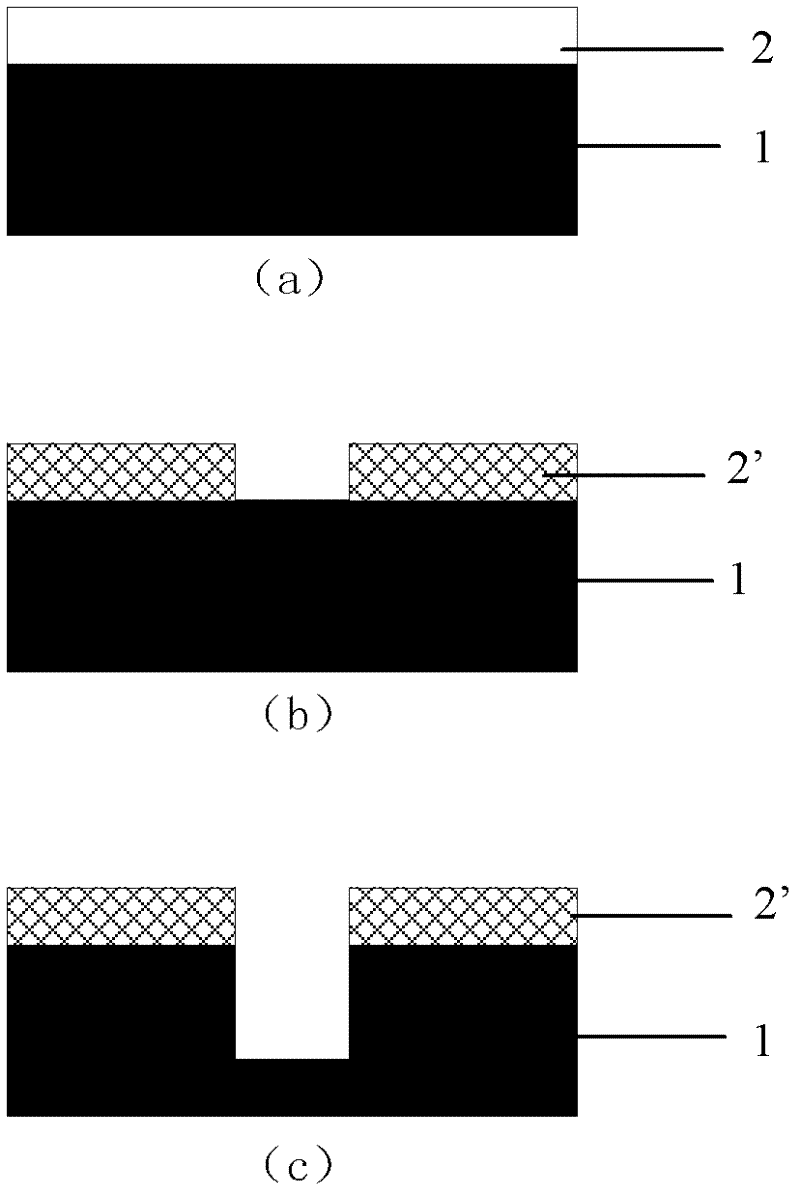

A circulating etching method of a silicon nitride hole with high depth-to-width ratio comprises of the steps of 1 adopting a dry-method plasma process and fluorocarbon-based gas to perform silicon nitride thin film etching so as to form the hole and meanwhile generating a polymer depositing on the bottom and the side wall of the hole; 2 feeding oxidizing gas and diluting gas into an etching cavity. The deposition amount of fluorocarbon on the side wall of the deep hole can be controlled, the polymer depositing on the bottom of the deep hole can be removed so as to ensure continuous etching, and the two steps are repeatedly performed till the etching profile of the hole meets the requirement. When the fluorocarbon-based gas in the step 1 is increased and accordingly the fluorocarbon amount is increased, the hole is slightly oblique. When the oxidizing gas in the step 2 is increased, the hole is upright. Different hole etching profiles can be obtained as required by adjusting parameters to be between the two amounts.

Owner:SOI MICRO CO LTD

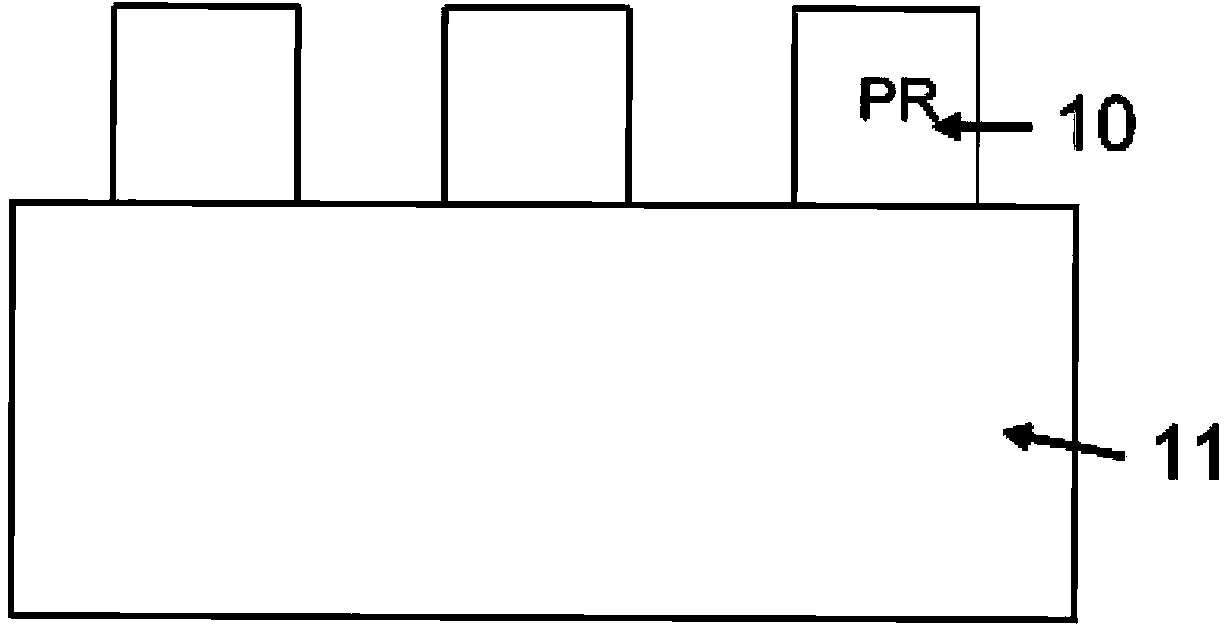

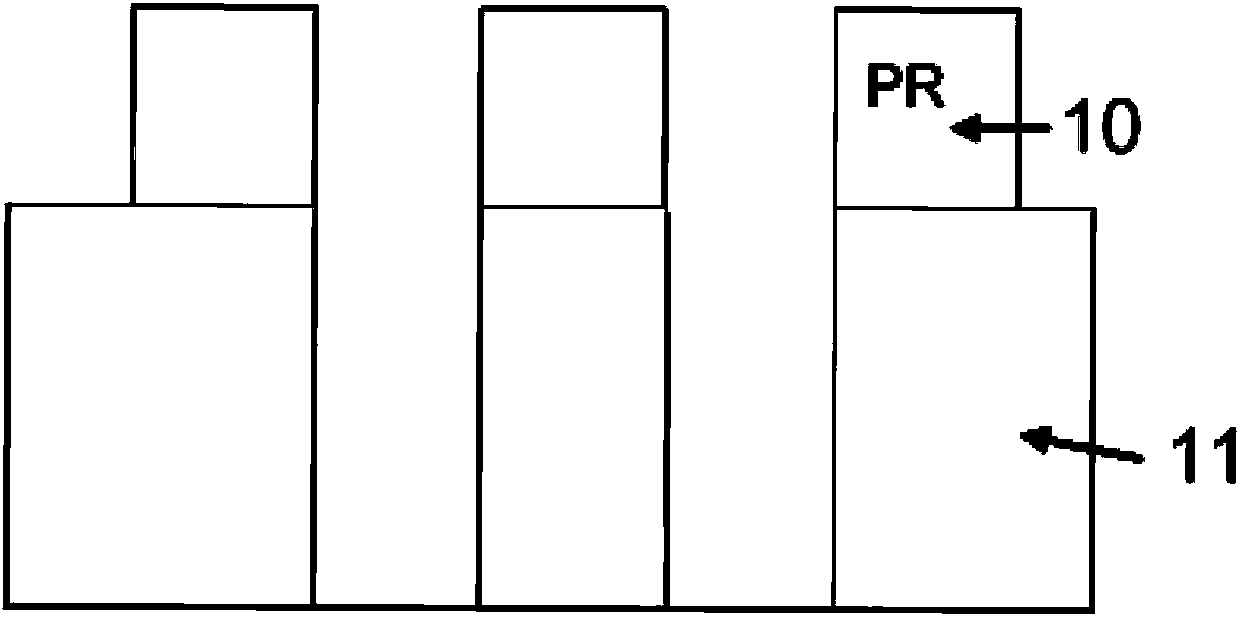

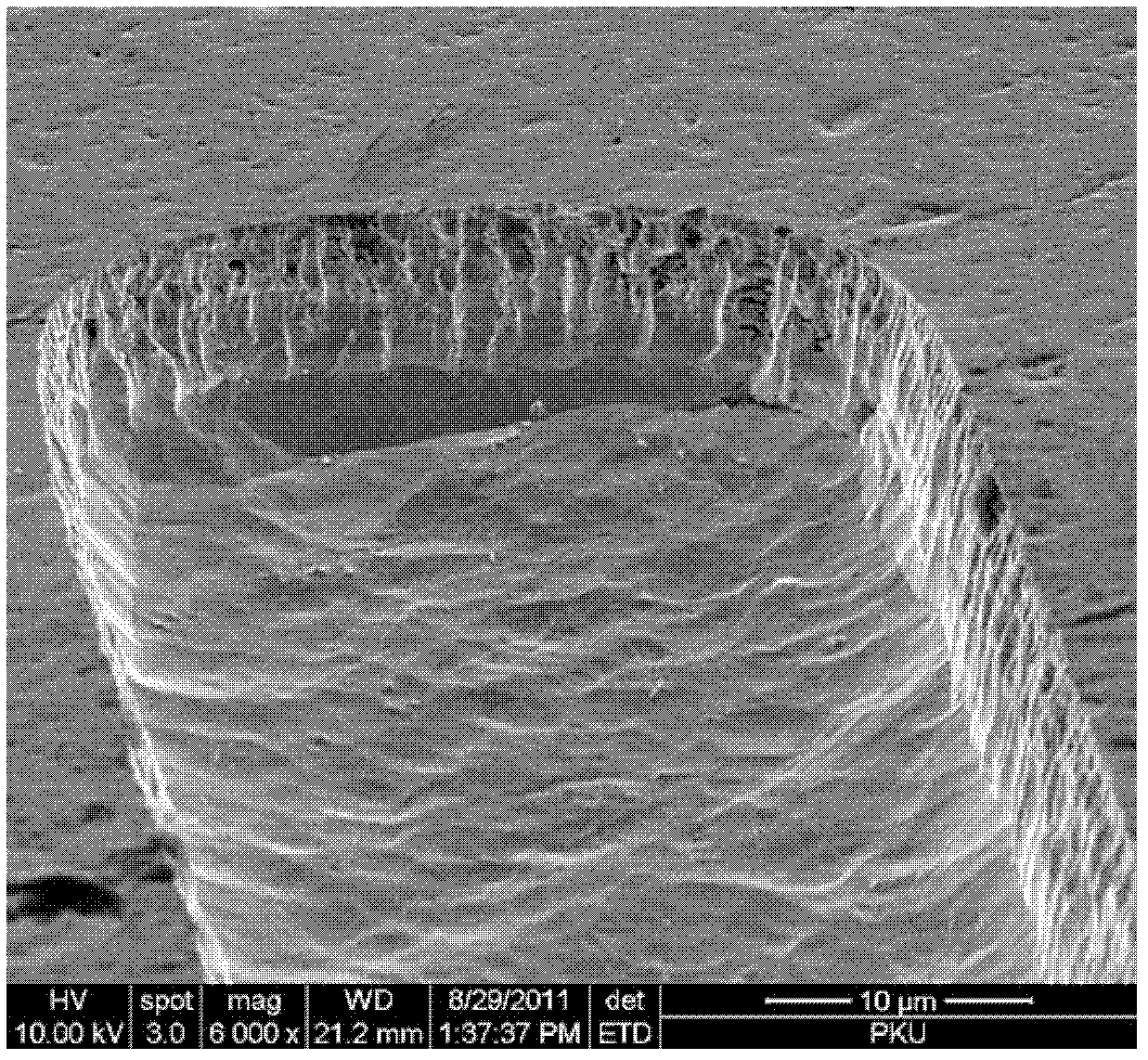

Method for etching metal tungsten material

ActiveCN102372250AIncrease speedHigh densityDecorative surface effectsChemical vapor deposition coatingHigh energyInductively coupled plasma

The invention discloses a method for etching a metal tungsten material, which is characterized in that: an etching mask is formed on the metal tungsten material, and then a high-density plasma (such as inductively coupled plasma, transformer coupled plasma and the like) dry etching process is adopted to produce high-density and high-energy ions and free radicals and to realize the high-speed and anisotropic etching of the metal tungsten material. The etching speed can reach 2.95 micrometers per minute, and the verticality of an etching-resulted side wall can reach 60 degrees. Based on the method, a metal tungsten underlay substrate can be used as a main body material for preparing micro-electro-mechanical system (MEMS) devices.

Owner:苏州含光微纳科技有限公司

Method for etching metal molybdenum material

ActiveCN102417156AIncrease speedHigh densityDecorative surface effectsChemical vapor deposition coatingHigh densityHigh energy

The invention discloses a method for etching a metal molybdenum material. The method comprises the following steps of: forming an etching mask on the metal molybdenum material; and generating high-density and high-energy ions and free radicals by adopting a high-density plasma (such as ICP (Inductively Coupled Plasma), TCP (Transformer Coupled Plasma) and the like) dry etching process to realize high-speed and anisotropic etching of the metal molybdenum material. The etching speed can be up to 2.63 microns per minute, and the vertical degree of an etching result side wall can be up 70 degrees. On the basis of the method disclosed by the invention, a metal molybdenum substrate can be taken as a main body material for preparing an MEMS (Micro Electro Mechanical System) device.

Owner:苏州含光微纳科技有限公司

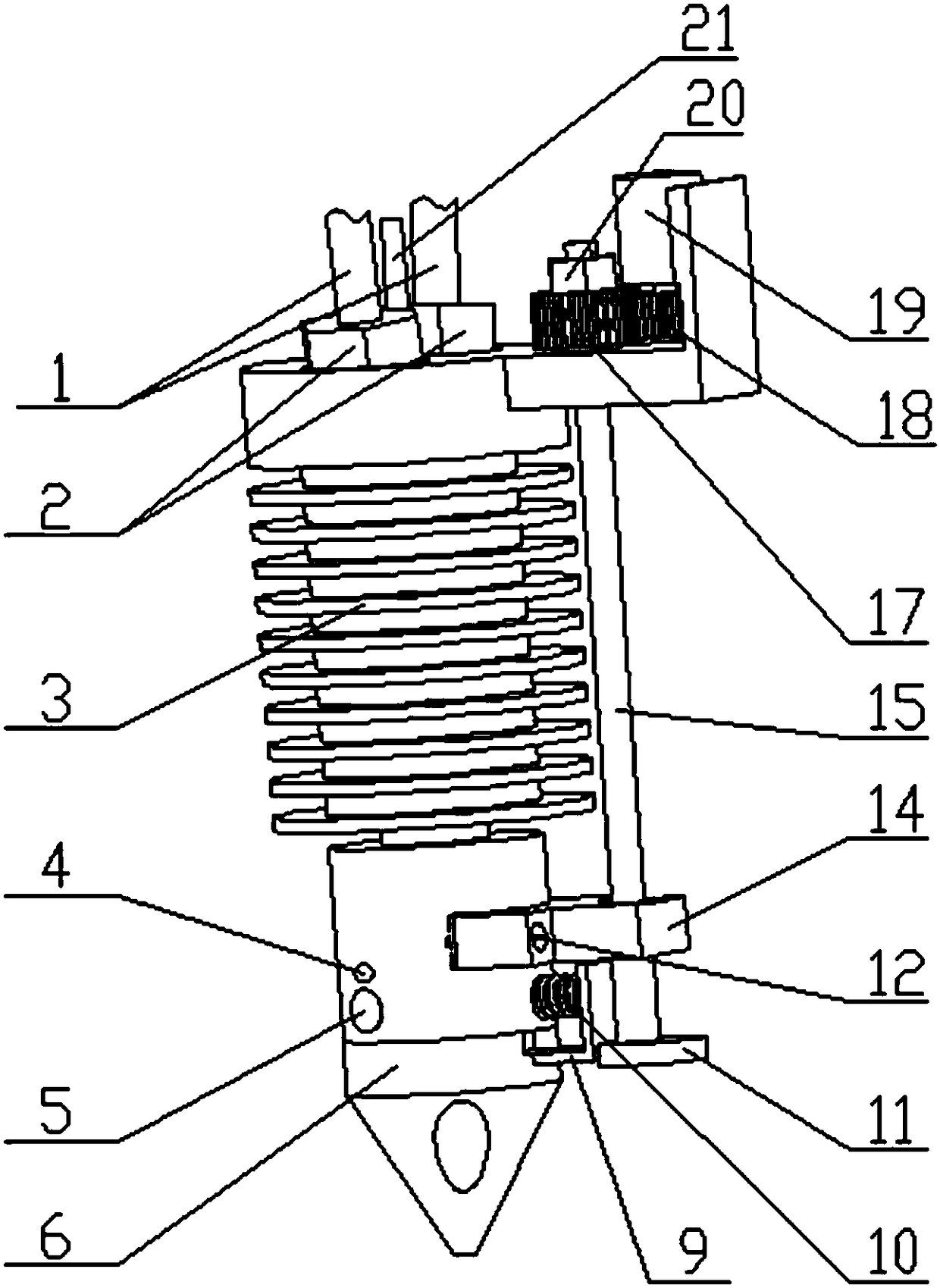

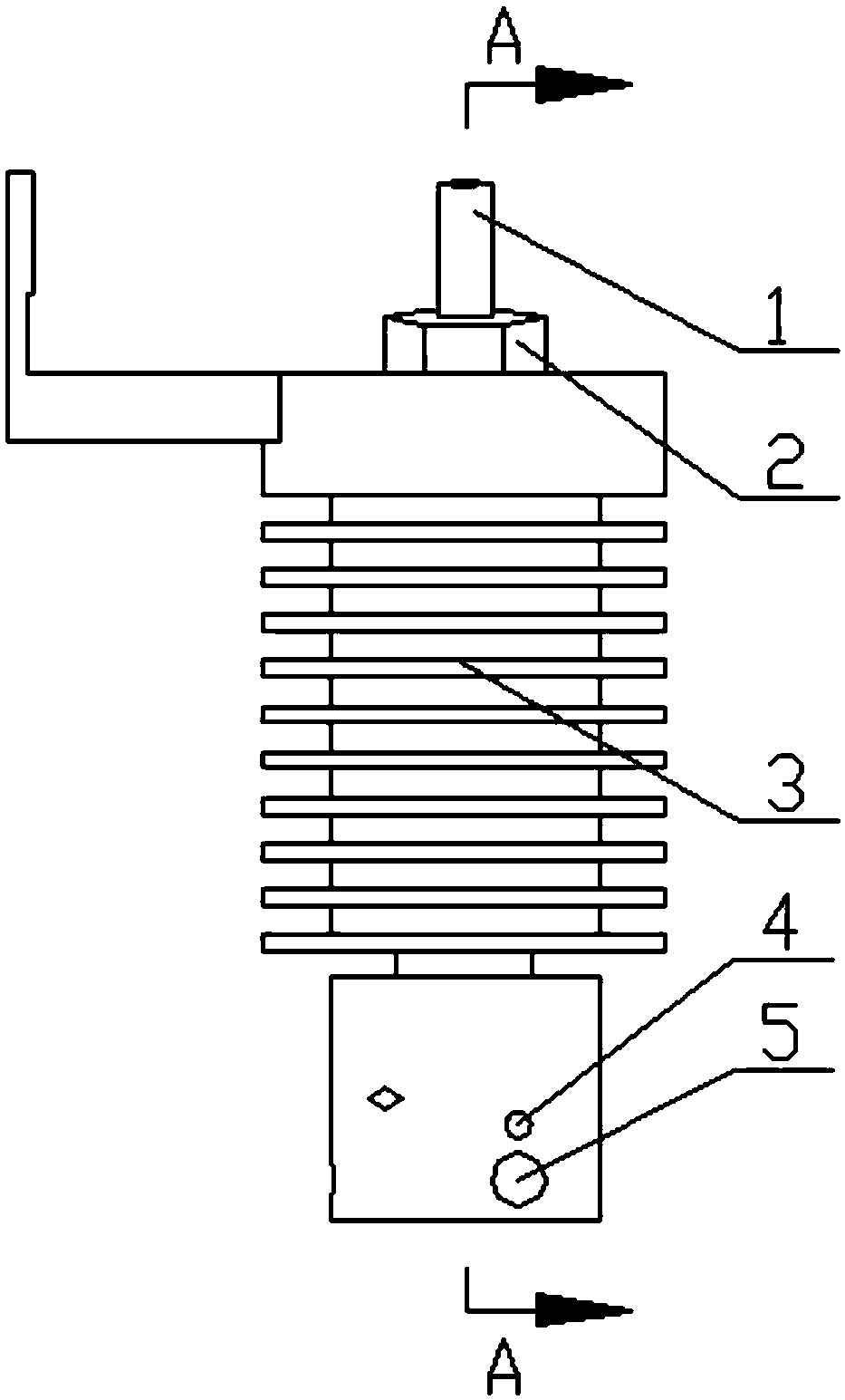

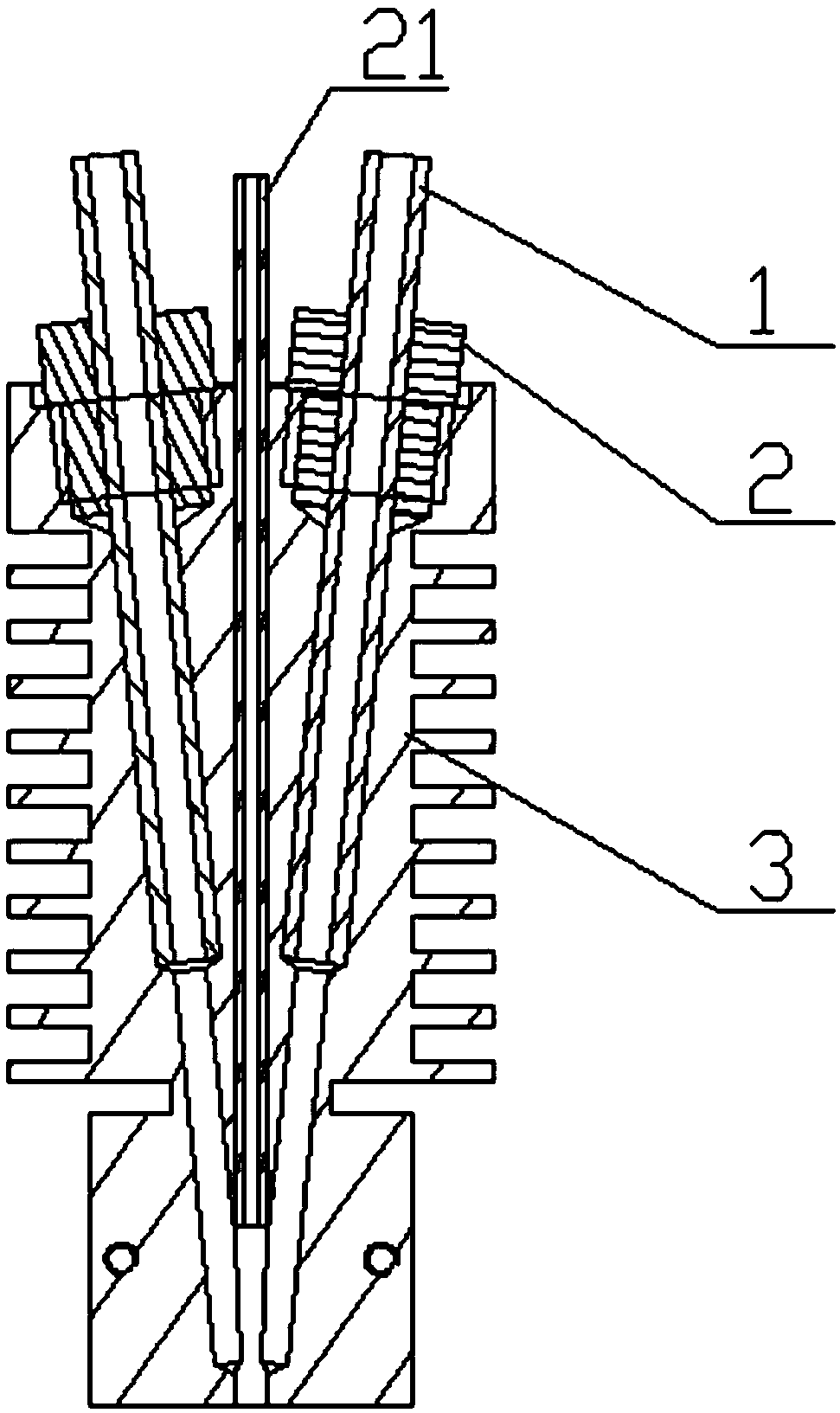

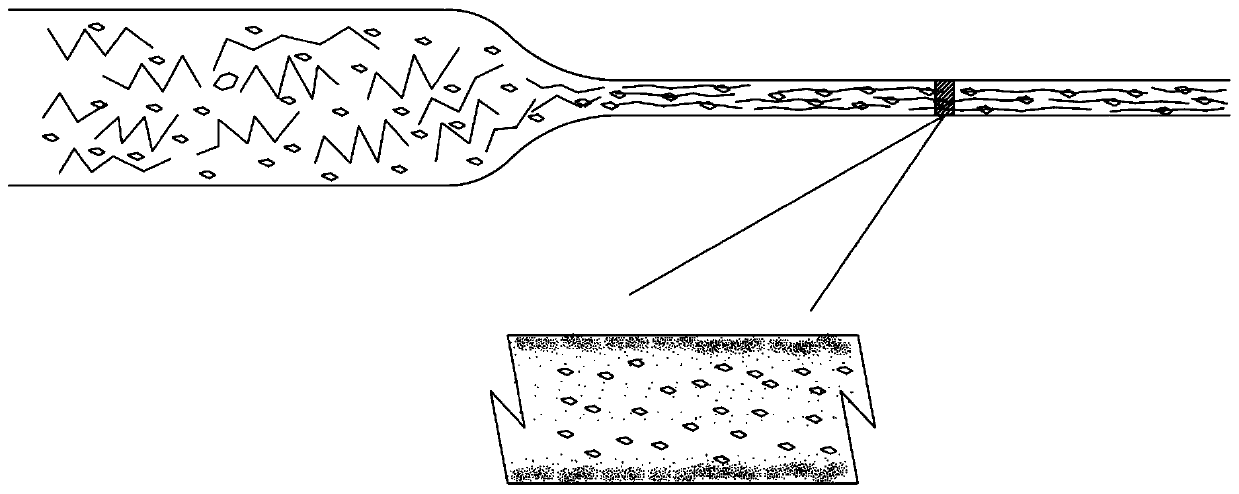

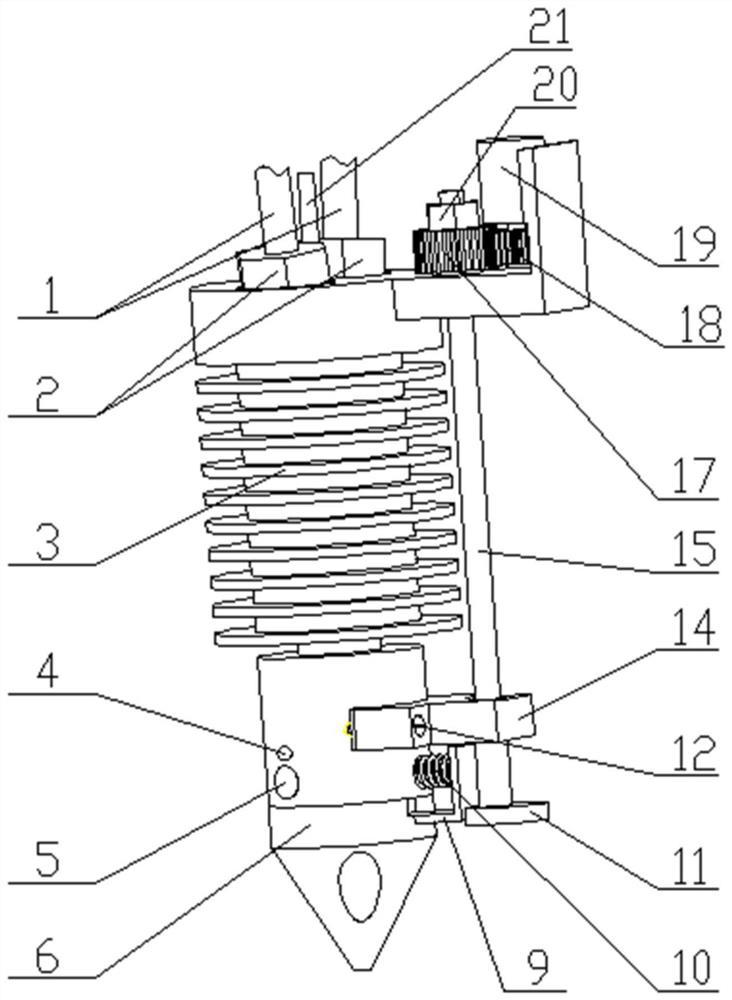

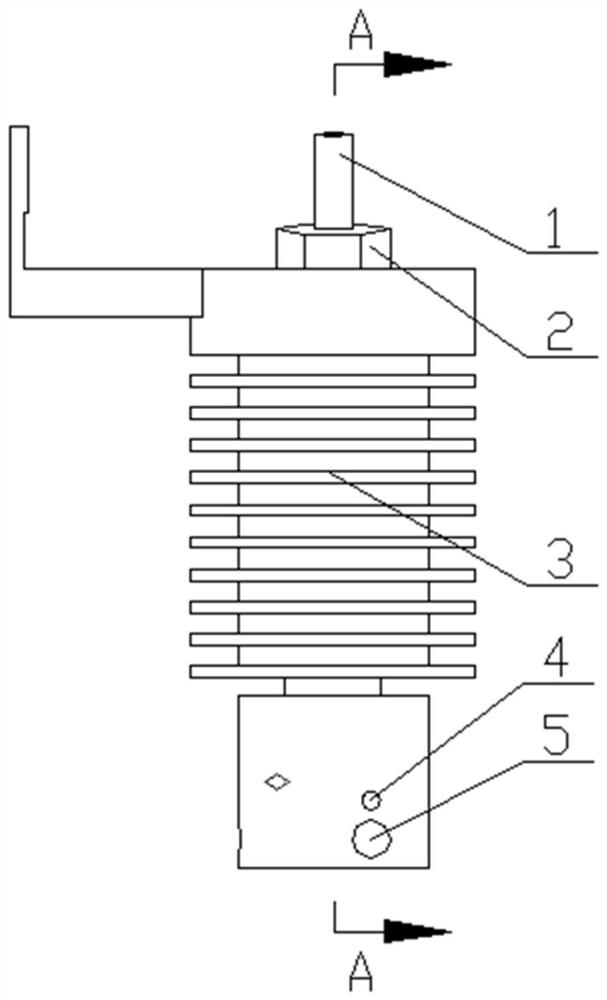

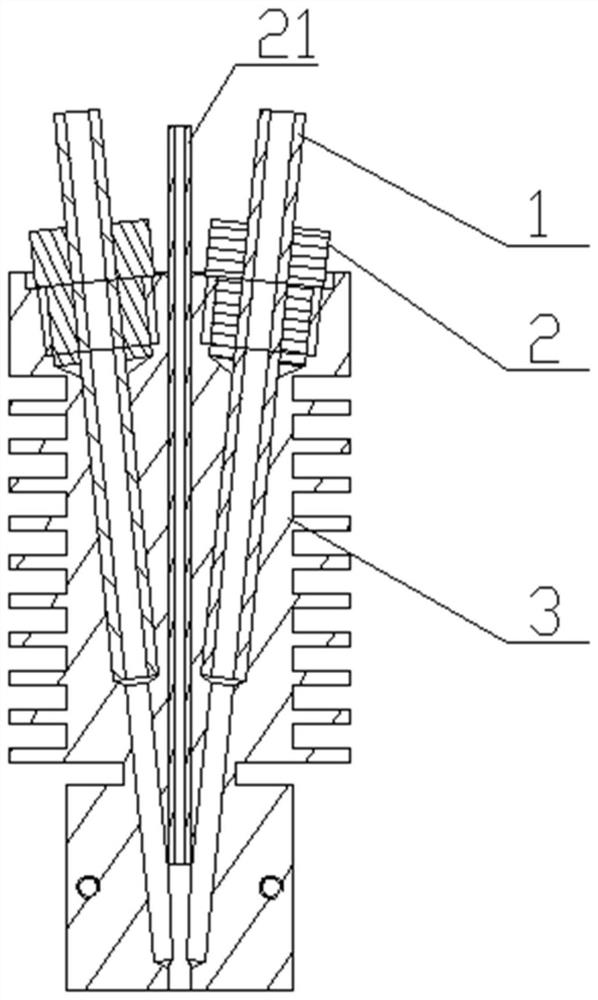

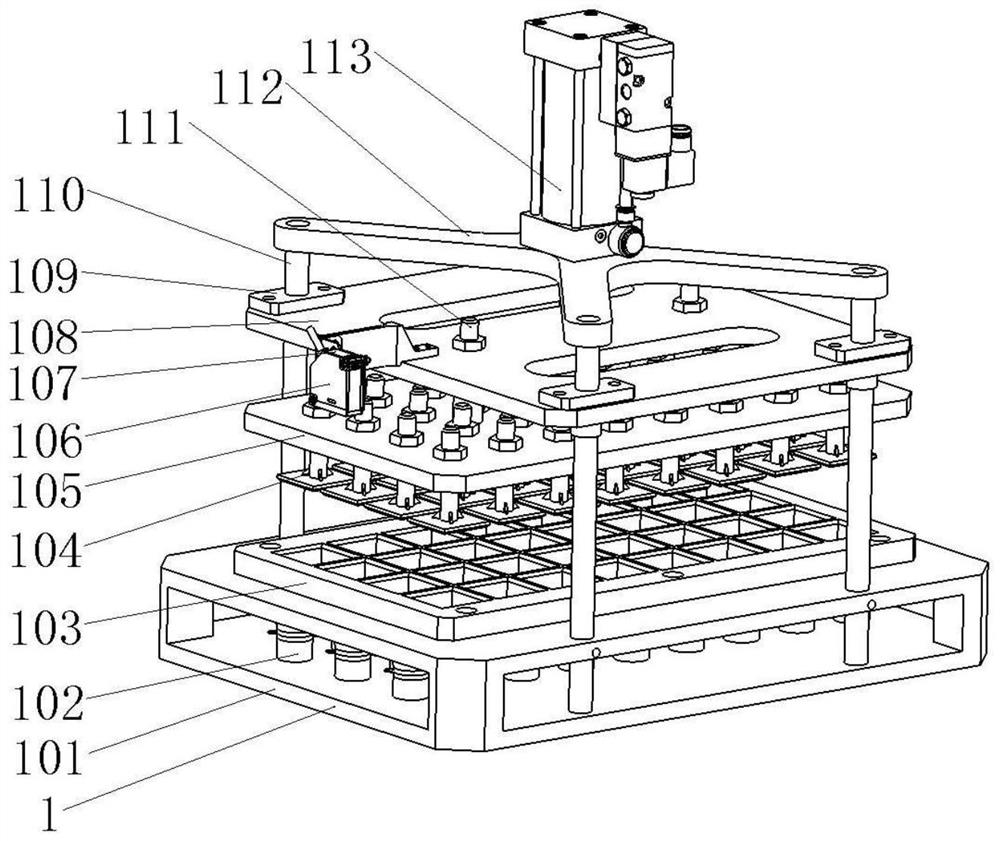

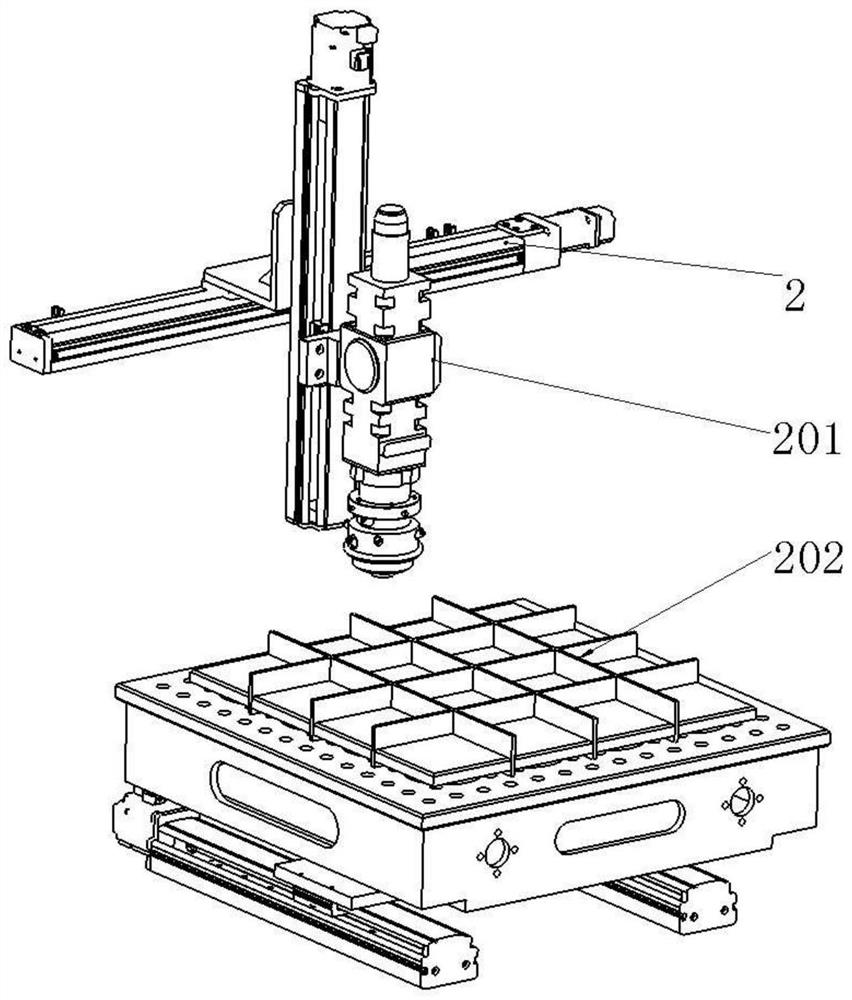

Continuous fiber reinforced composite 3D printing device comprising cutting-off mechanism

ActiveCN109177166AAchieve anisotropyImprove mechanical propertiesManufacturing heating elements3D object support structuresFiber-reinforced compositeRapid prototyping

The invention relates to a continuous fiber reinforced composite 3D printing device comprising a cutting-off mechanism. The continuous fiber reinforced composite 3D printing device comprises a feedingconnector module, a fiber and matrix material compositing module (3), a fiber cutting-off module and an extrusion nozzle (6). Compared with the prior art, compositing of fibers and a thermoplastic matrix material is achieved, and a structural member is rapidly molded by stacking a composite after extrusion; and most importantly, limitation that the fibers cannot be cut off in the fiber reinforcedcomposite 3D printing process is solved, thus, the fibers and the matrix material can be composited based on the requirement for force flow characteristics (a main stress trajectory line) of the printed structural member, the anisotropy of the molded structural member is reflected, and the mechanical properties of the structural member under actual working conditions are improved.

Owner:TONGJI UNIV

Metalized wood functional material and preparation method thereof

ActiveCN108407034AHigh strengthEnsure electrical and thermal conductionFlat articlesDomestic articlesBismuthBroad spectrum

The invention discloses a metalized wood functional material and a preparation method thereof. The metalized wood functional material is made of four types of materials of tall grass plant stalk, woodcomposite powder, tin-bismuth alloy and natural resin in a compound manner. The preparation method of the metalized wood functional material comprises six steps of plant stalk pretreatment, wood composite powder preparation, plant stalk threading, raw material mat formation, die forming and cutting. The metalized wood functional material prepared by adopting the method is high in strength and good in isotropy, electrical conductivity, heat-conducting performance and anisotropy, can be widely used in the fields such as electromagnetic shielding, system heat management and broad spectrum building materials, and is environmentally friendly.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

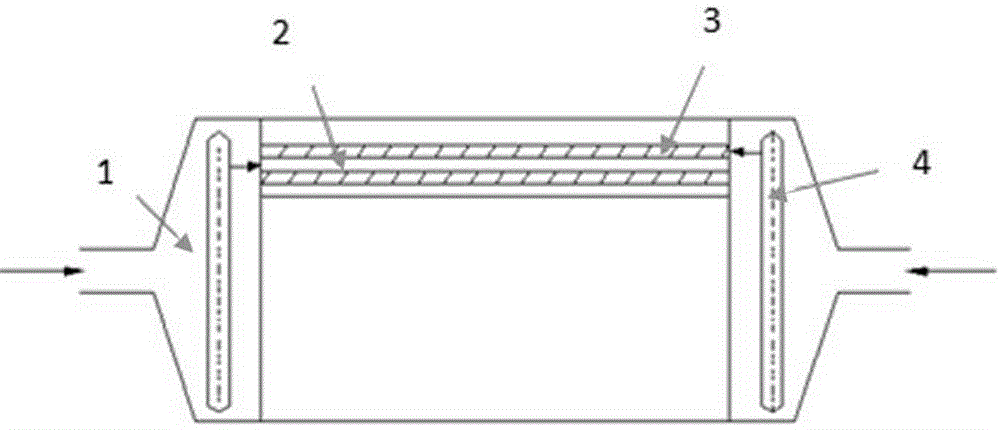

Multilayer optical thin film and manufacturing method thereof

InactiveCN104459834AGood optical performancePolarization effect is obviousOptical elementsCompound aReflecting telescope

The invention discloses a multilayer optical thin film and a manufacturing method of the multilayer optical thin film. The multilayer optical thin film is characterized in that the thin film is formed by compounding one to 10,000 optical thin film units, and the thickness is 0.11 micron to 5,000 microns; each optical thin film unit is formed by compounding a layer of * material thin film and a layer of . material thin film, the thickness speciation of the * material thin films is 0.053 micron to one micron, and the thickness speciation of the . material thin films is 0.053 micron to one micron; the * material thin film and the . material thin film in the same optical thin film unit are different in refractive index. The multilayer optical thin film is manufactured in the mode of carrying out multilayer coextrusion through two extruders and then carrying out unidirectional or bidirectional stretching. The multilayer optical thin film has the functions of totally reflecting visible light and ultraviolet light, filtering 550nm green light and the like, and can be applied to manufacturing of building curtain wall reflecting thin films, automobile glass sticker thin films and reflecting telescopes.

Owner:四川东方绝缘材料股份有限公司

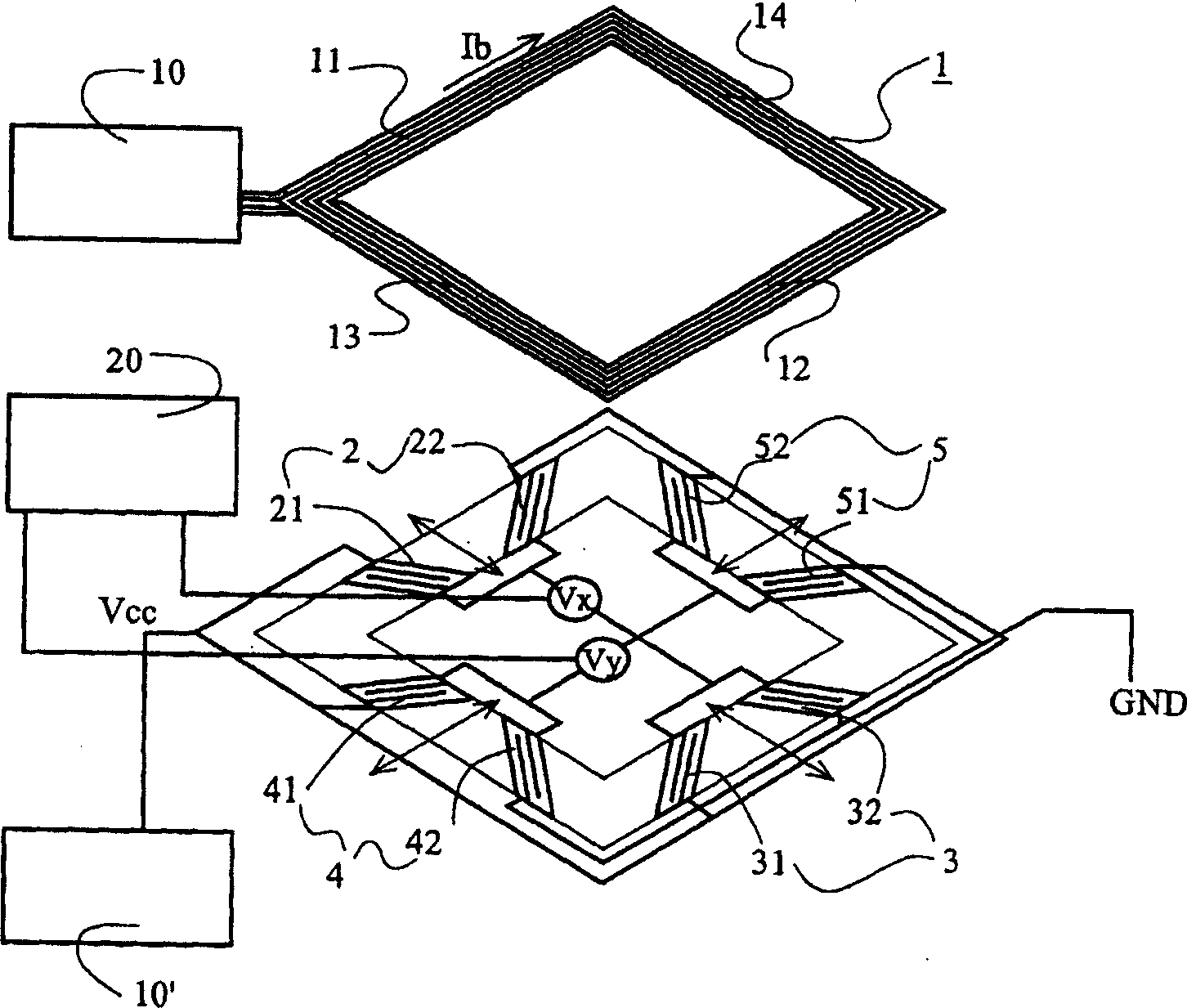

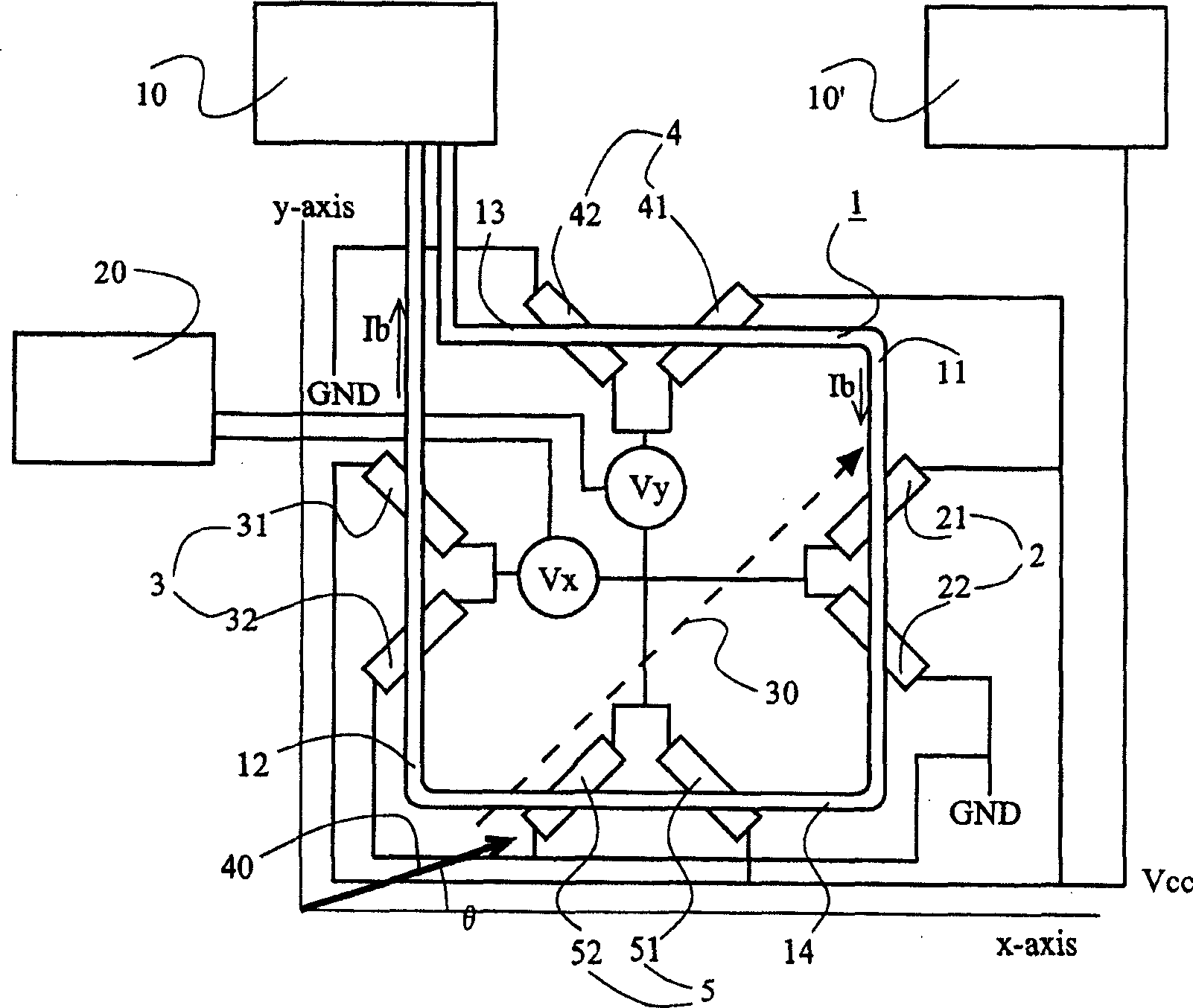

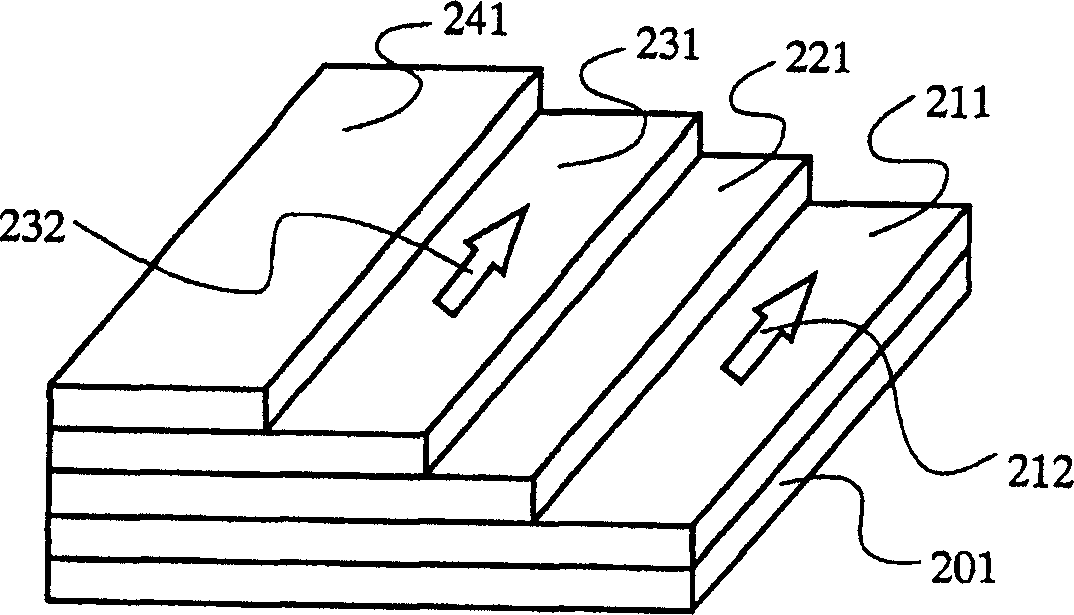

Azimuth measuring instrument with spin valve giant magnetoresistance element

InactiveCN1721870AEasy to manufactureAchieve anisotropyNanomagnetismThree-component magnetometersGiant magnetoresistanceMeasuring instrument

An azimuth meter using spin-valve giant magneto-resistive elements, which is simple in manufacturing process, can be made compact in size and contribute to power saving, is disclosed. The azimuth meter comprises a quadrilateral plane coil having two pairs of parallel opposed sides and four spin-valve giant magneto-resistive element pairs, each pair of the elements disposed on a plane parallel to the coil. The longitudinal directions of two elements of each pair orthogonally cross each other, and cross only a respective side or only the same side of a pair of the opposed sides of the plane coil at substantially 45 degrees. The pinned layer of one of the two elements is magnetized in its longitudinal direction, and that of the other element is magnetized in the same direction as the pinned layer of that one element. The paired elements are connected to each other at one end. While a voltage for measurement is being applied between the other ends, a midpoint potential is taken out of the ends of the elements connected to each other to determine an azimuth.

Owner:HITACHI METALS LTD

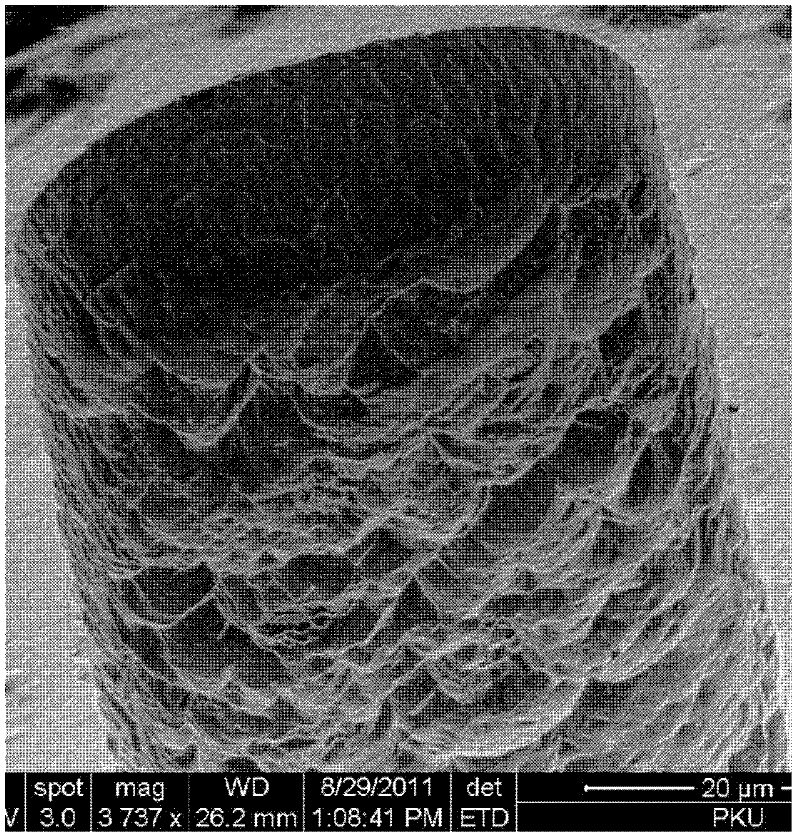

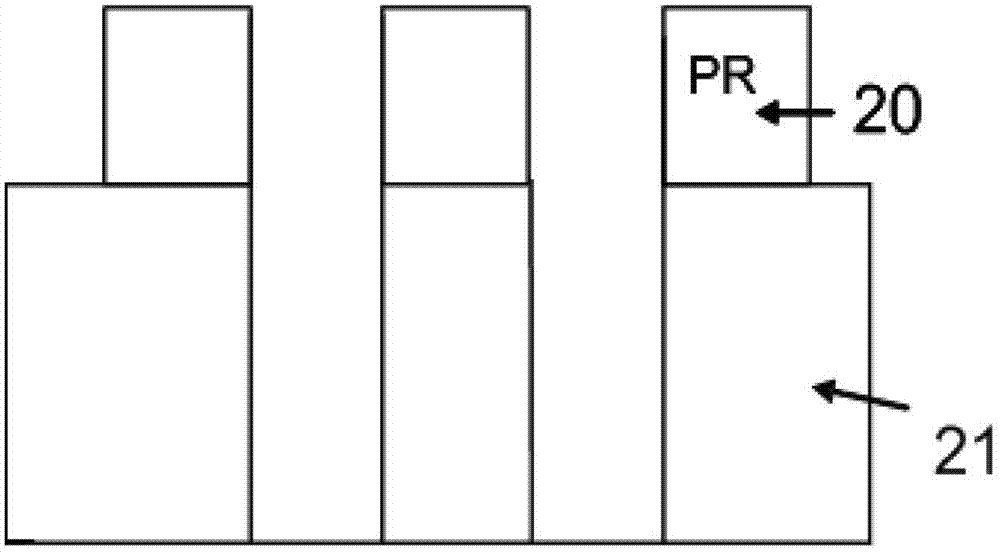

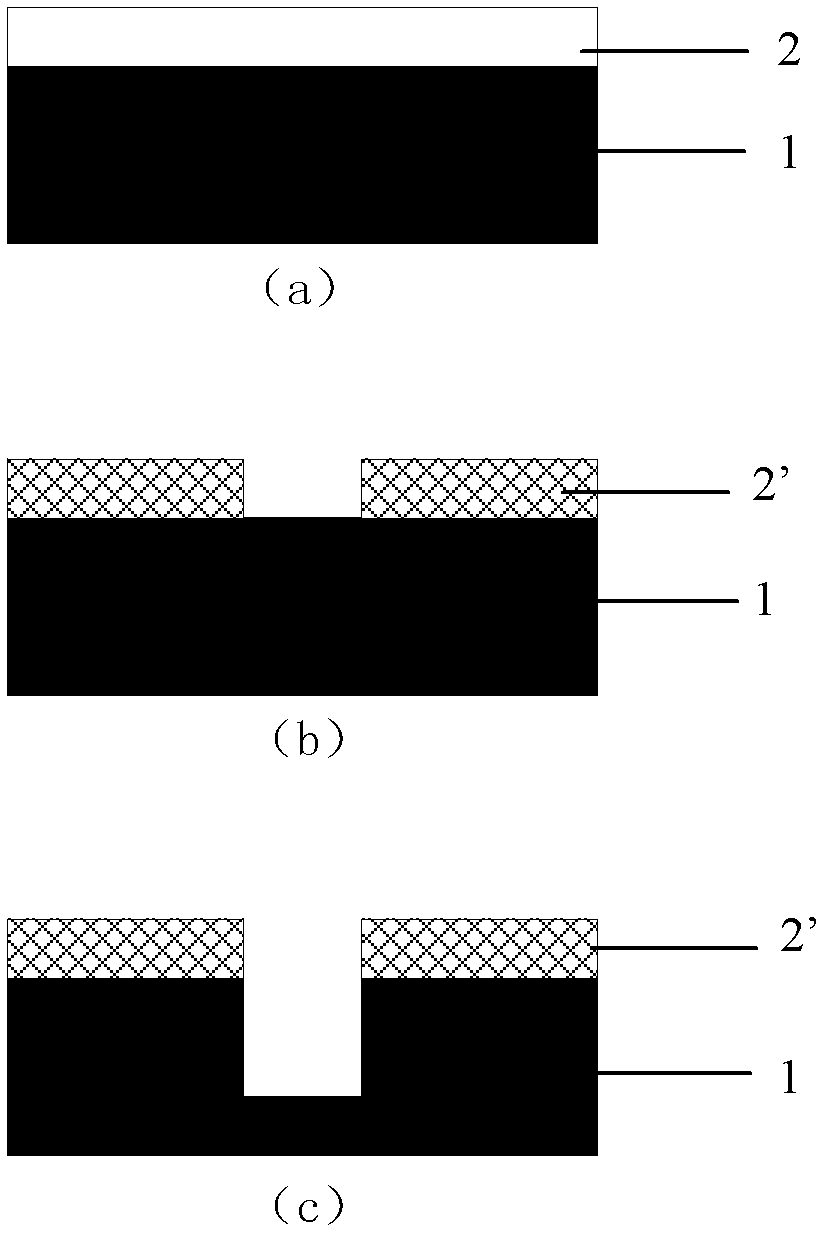

Etching method for silicon nitride high depth-to-width ratio hole

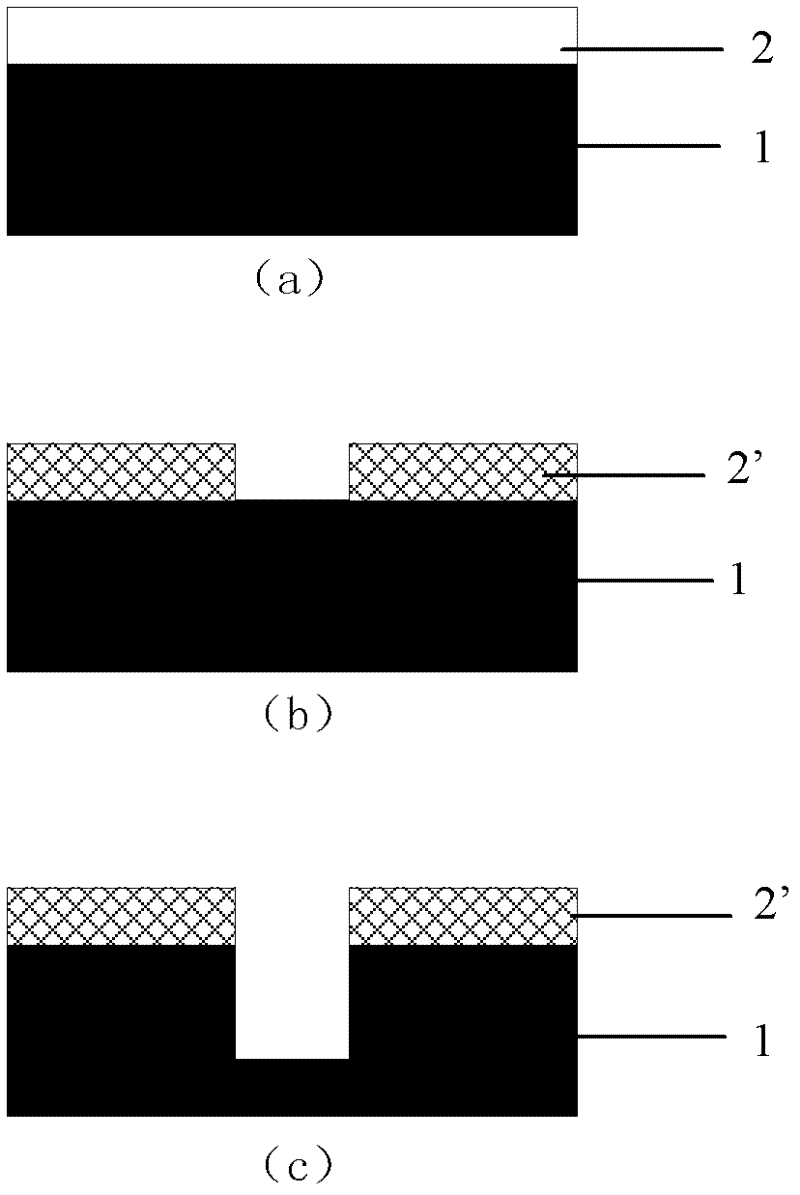

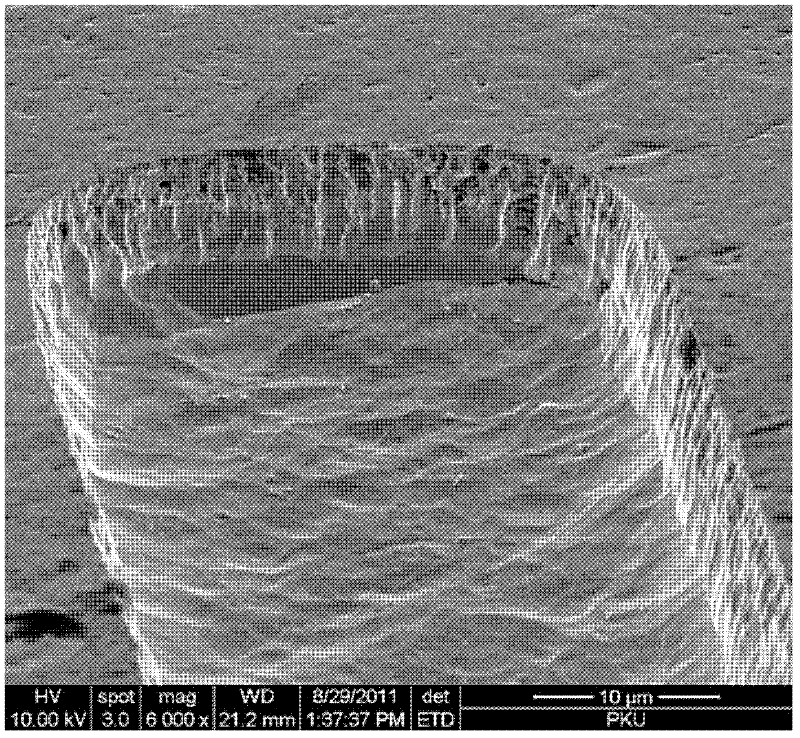

ActiveCN103531464AAchieve anisotropyAdjust etch topographySemiconductor/solid-state device manufacturingEtchingPlasma technology

The invention discloses an etching method for a silicon nitride high depth-to-width ratio hole. The method comprises: first of all, placing a semiconductor device of a silicon nitride film, already forming the graph needed by a semiconductor, into en etching cavity; then using a dry-method plasma technology, letting in a high carbon chain molecule fluorocarbon-based gas, an oxidizing gas, a dilution gas and a fluorocarbon-based gas containing hydrogen, adding radio frequency power and exciting plasma; and after a plasma stabilization step, performing etching of the silicon nitride film until the etching morphology, the hole diameter size and the depth of a high depth-to-width ratio hole reach requirements. According to the invention, the silicon nitride film is etched by using the unique fluorocarbon-based gas, through adjusting gas component and power size, the deposition amount of fluorocarbon polymers on the side wall of the deep hole can be controlled, the key dimensions of the hole can be prevented from becoming larger, and polymers already deposited at the bottom of the deep hole can be removed so as to ensure that the etching can be continued, thus the etching morphology of the hole can be adjusted.

Owner:SOI MICRO CO LTD

Thermal insulation workpiece based on fused deposition modeling and preparation method thereof

ActiveCN112339264AHigh porosityImprove thermal insulation3D object support structuresApplying layer meansMicro structureThermal insulation

The invention provides a thermal insulation workpiece based on fused deposition modeling and a preparation method thereof. Taking advantage of the designability of 3D printing, design optimization iscarried out from the following three aspects: material body-introduction of low thermal conductivity filler and microstructure into thermoplastic polymer-introduction of low melting point phase changematerial and printing process through design of a two-component spray head-introduction of sodium bicarbonate powder combined with post-treatment heating to improve the porosity of the workpiece. Thesynergistic effect of three aspects realizes excellent thermal insulation performance of the workpiece. Besides, a line deposited by adopting the spray head in the 3D printing process has a skin-corestructure, the change of micro-components of the deposited line can be realized by changing process parameters according to actual requirements, the regulation and control of microscopic performanceare realized, and further, the macroscopic anisotropy of the workpiece is realized.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Polyether-ether-ketone modified pelletizing material with low heat-conducting coefficient as well as application thereof

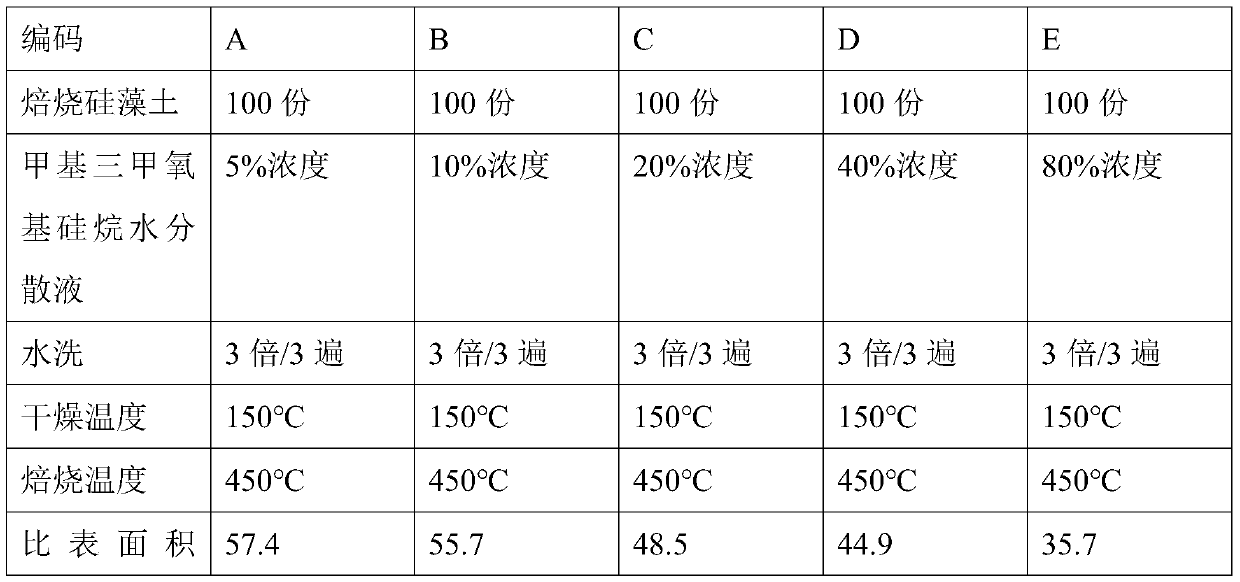

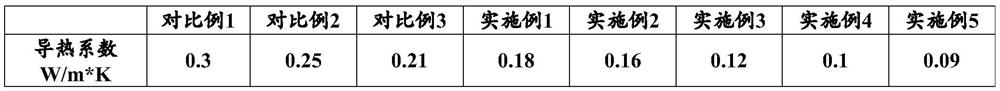

The invention relates to a heat-insulating material, particularly relates to a polyether-ether-ketone modified pelletizing material with low heat-conducting coefficient as well as application thereof,and belongs to the technical field of a macromolecular modified material. The polyether-ether-ketone modified pelletizing material with low heat-conducting coefficient is obtained by extruding and pelletizing the following components in percentage by mass: 60 to 89.9 percent of polyether-ether-ketone resin, 10 to 39.5 percent of modified diatomite and 0.1 to 5 percent of carbon nanotube; the modified diatomite is obtained by sequentially performing purification, modification and roasting treatment on roasted diatomite and / or fluxing roasted diatomite raw materials; and the roasting temperature of the roasted diatomite and / or fluxing roasted diatomite raw materials is not less than 450 DEG C and the roasting time of the roasted diatomite and / or fluxing roasted diatomite raw materials is not less than 2 hours. Compared with the common polyether-ether-ketone modified pelletizing material, the polyether-ether-ketone modified pelletizing material with low heat-conducting coefficient has better heat-insulating effect and has high strength and size stability.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

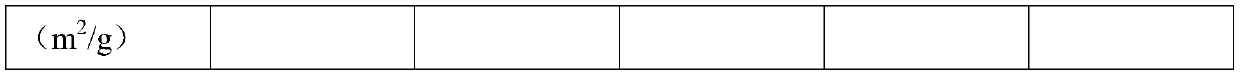

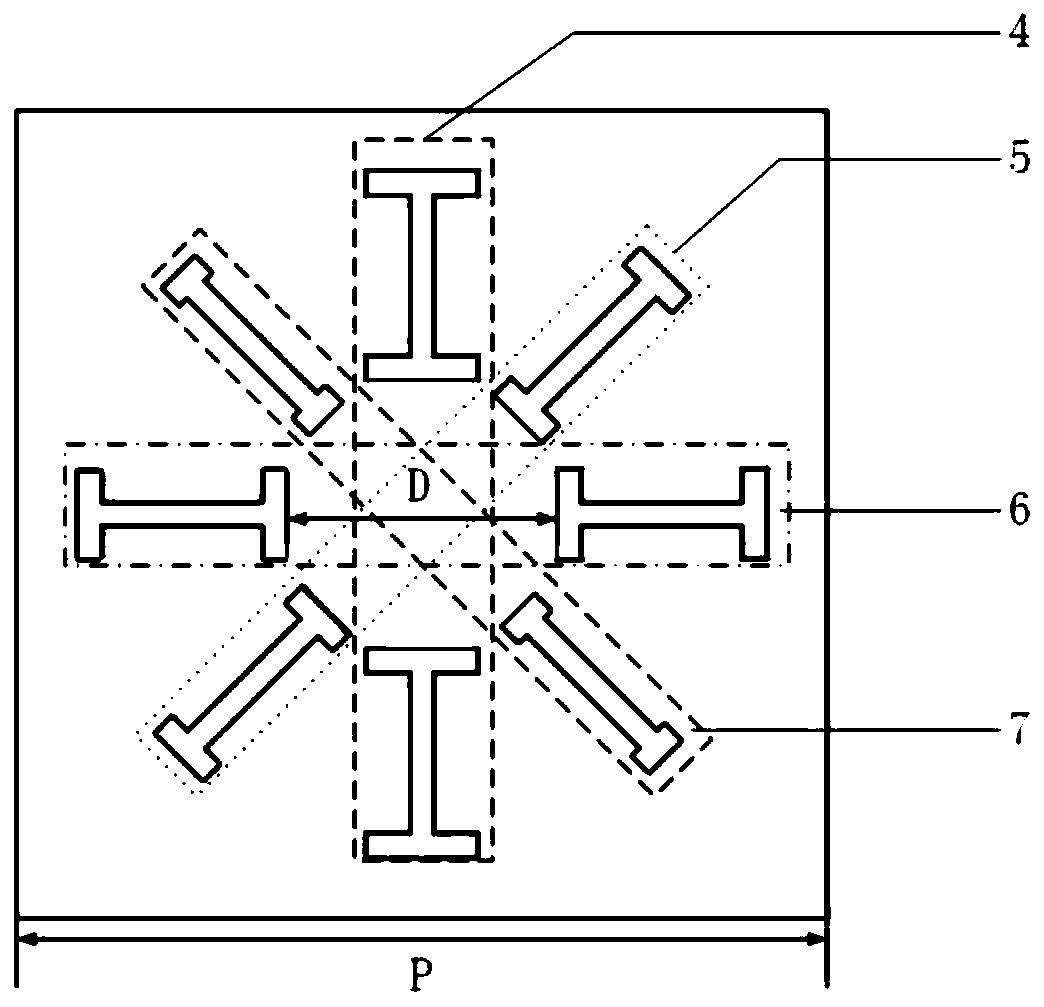

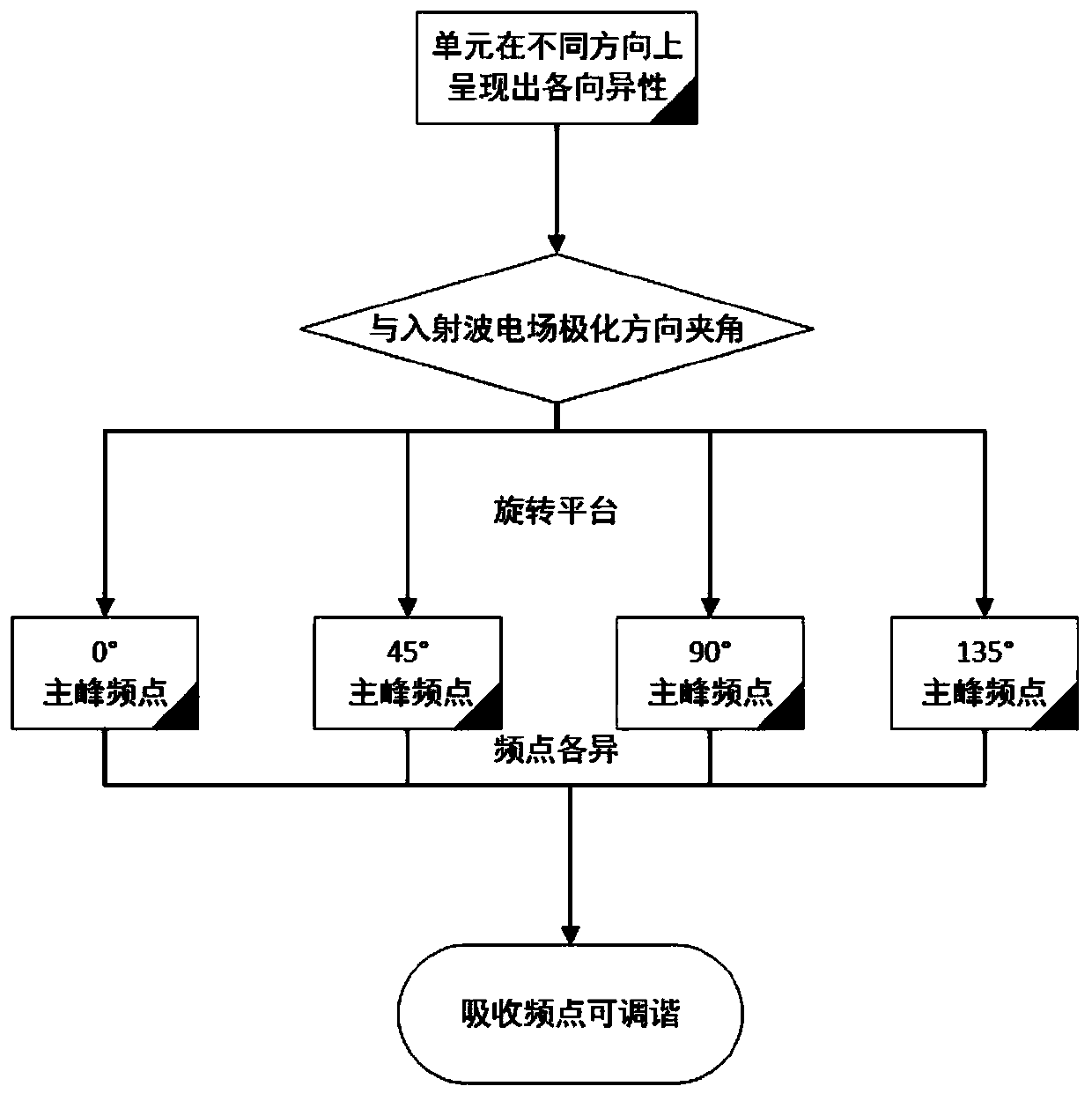

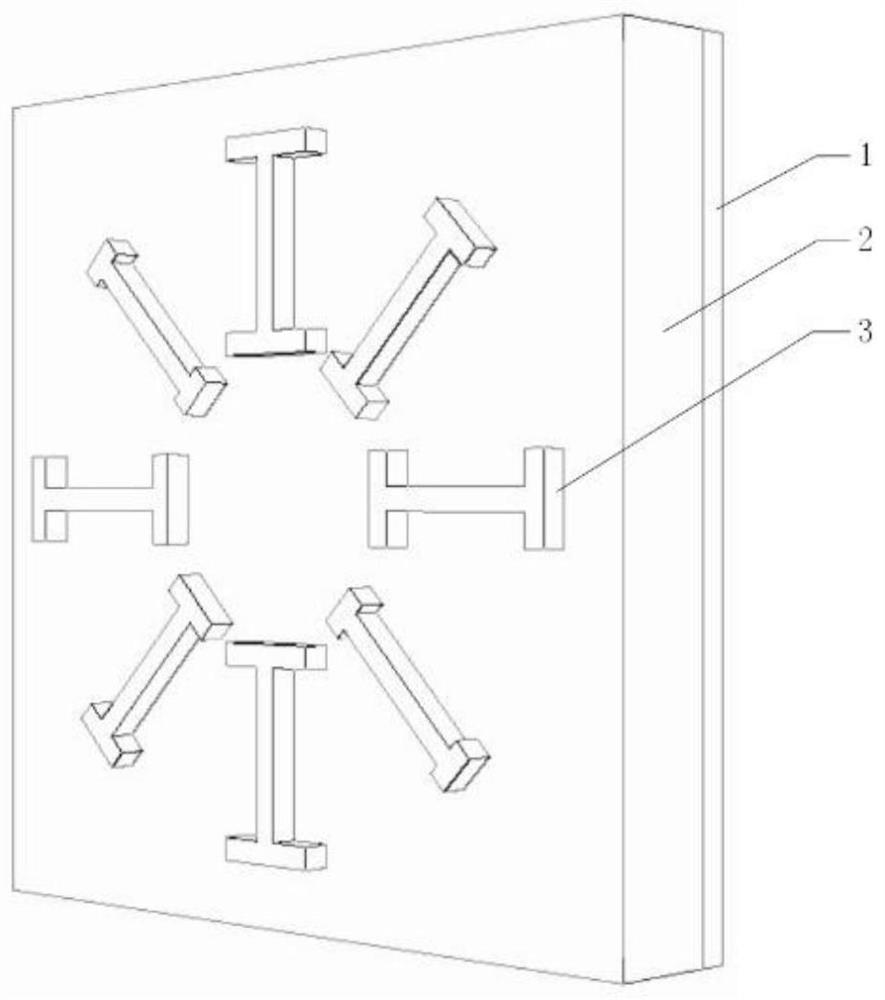

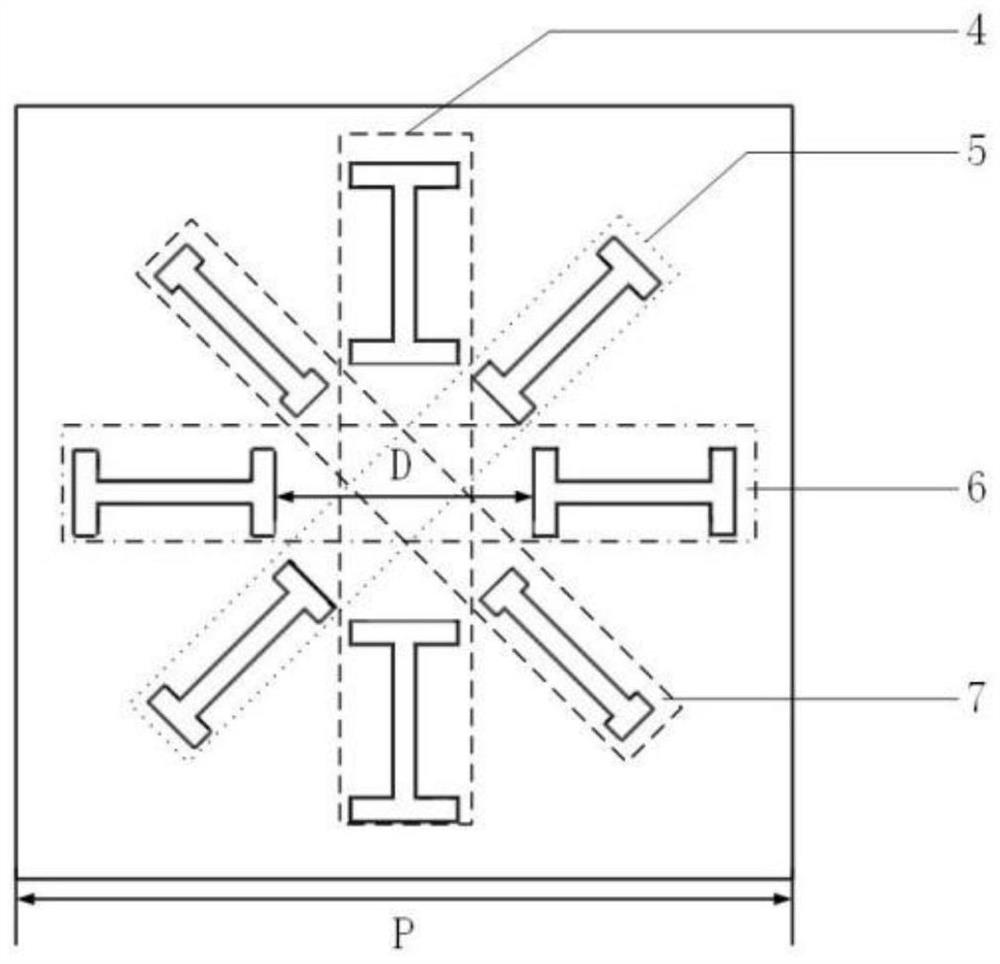

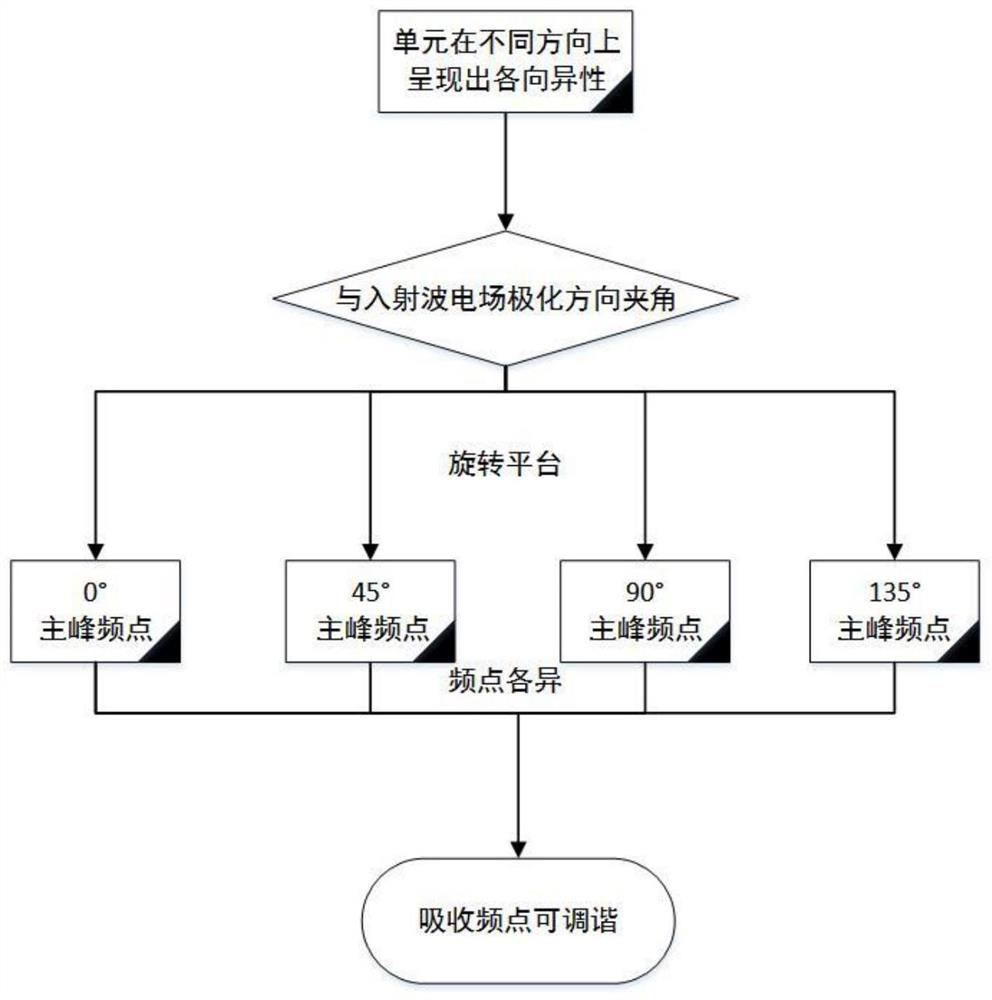

Frequency-adjustable terahertz multi-band absorber

ActiveCN109888506AAchieving Tunable FeaturesAchieve anisotropyAntennasOptical elementsMulti bandTerahertz metamaterials

The invention discloses a frequency-adjustable terahertz multi-band absorber. The frequency-adjustable terahertz multi-band absorber comprises an absorber body fixed on a rotatable platform, wherein aplurality of absorption units are distributed on the absorption surface of the absorber body; each absorption unit comprises a three-layer structure of a metal pattern layer, a loss dielectric layerand a bottom all-reflection layer which are tightly attached from top to bottom; the metal pattern layer comprises four pairs of H-shaped metal pattern symmetric structures symmetrically arranged around the center of the surfaces of the absorption units; each pair of H-shaped metal pattern symmetric structures comprises two H-shaped metal structures; and the four pairs of H-shaped metal pattern symmetric structures are sequentially and uniformly arranged in the clockwise direction. The problem that the actual application capability is limited due to the fact that a terahertz metamaterial absorber in the prior art can only show response to specific frequency electromagnetic waves is solved.

Owner:XIAN UNIV OF TECH

Integrated fiber post for dental restoration and preparation method thereof

ActiveCN101803958BHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlFiber

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aided design) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

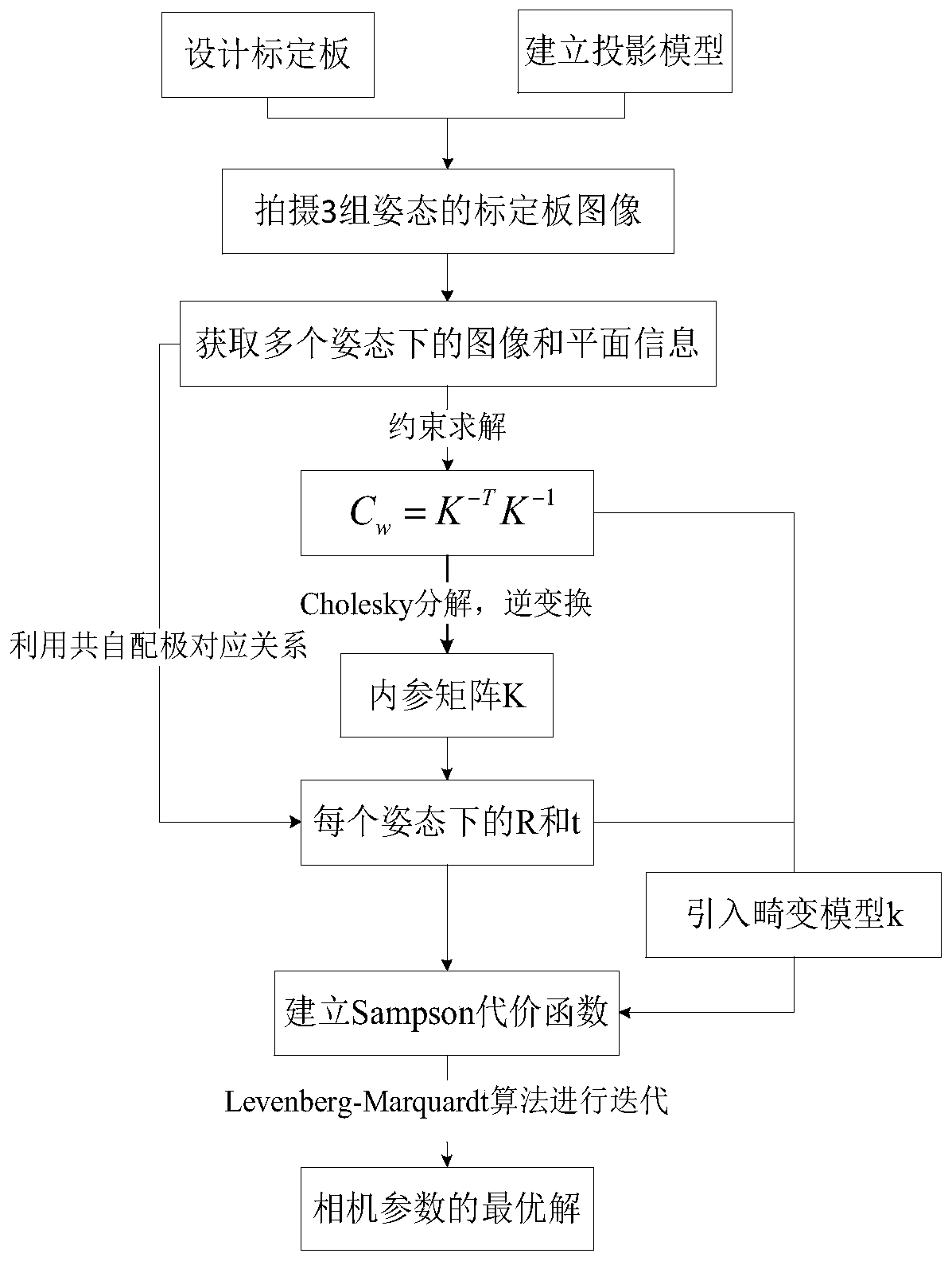

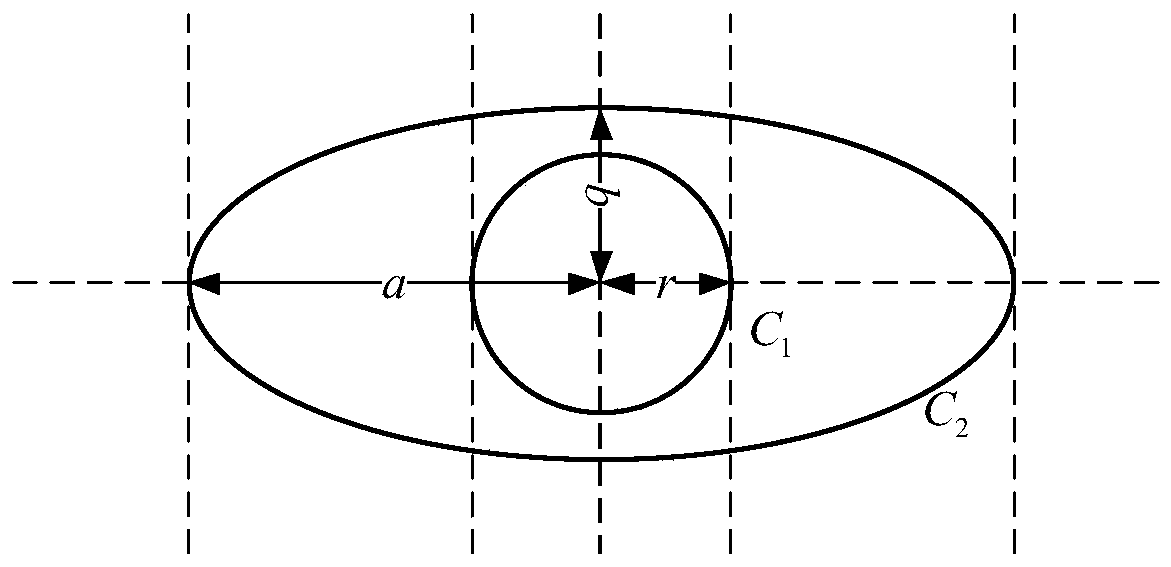

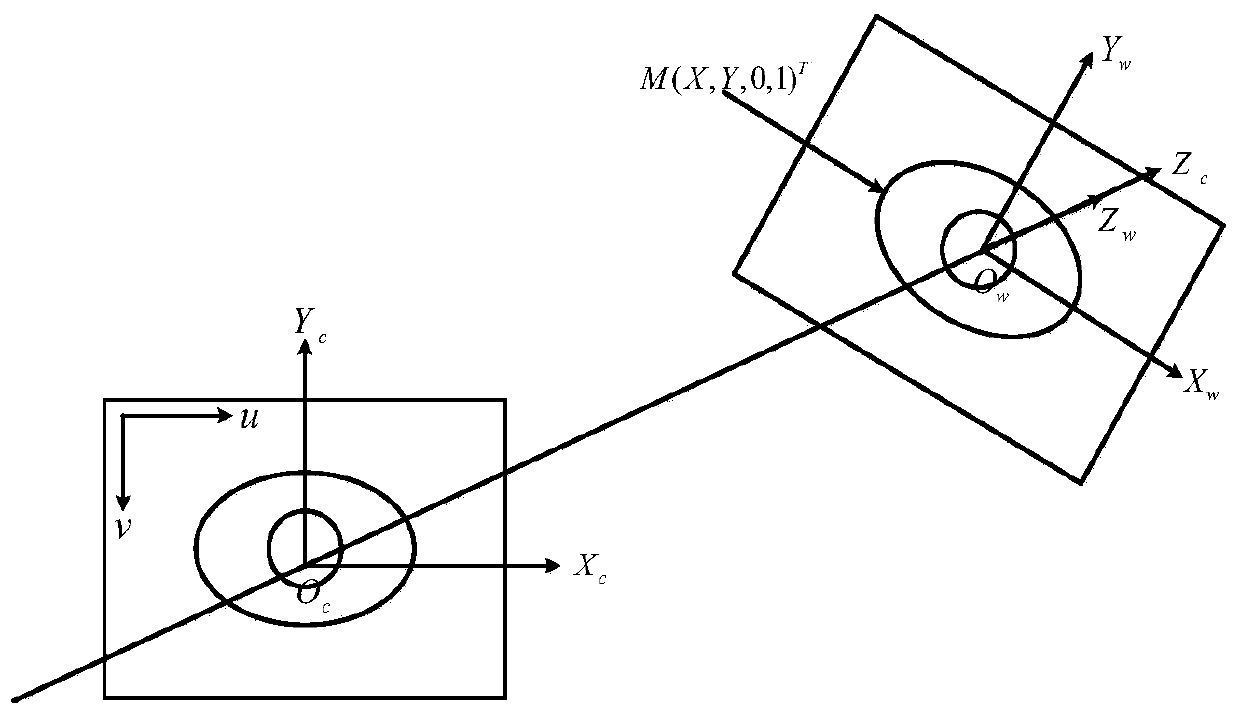

Camera parameter calibration method based on self-matching polar triangle

InactiveCN109754430AAdded self-aligning triangular characteristicsAchieve anisotropyImage analysisDistortionProjection model

The invention provides a camera parameter calibration method based on a self-matching polar triangle. The camera parameter calibration method mainly comprises the steps of calibration plate design andestablishment of a camera projection model, solving of internal parameters and external parameters of a camera in linear initialization, establishment of a distortion model and a cost function in nonlinear optimization and an iteration method of an optimal solution. According to the method, the internal parameters and the external parameters of the camera can be solved more flexibly and more robustly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A 3D printing device for continuous fiber reinforced composite materials with a shearing mechanism

ActiveCN109177166BAchieve anisotropyImprove mechanical propertiesManufacturing heating elements3D object support structuresFiber-reinforced compositeRapid prototyping

The invention relates to a continuous fiber reinforced composite 3D printing device comprising a cutting-off mechanism. The continuous fiber reinforced composite 3D printing device comprises a feedingconnector module, a fiber and matrix material compositing module (3), a fiber cutting-off module and an extrusion nozzle (6). Compared with the prior art, compositing of fibers and a thermoplastic matrix material is achieved, and a structural member is rapidly molded by stacking a composite after extrusion; and most importantly, limitation that the fibers cannot be cut off in the fiber reinforcedcomposite 3D printing process is solved, thus, the fibers and the matrix material can be composited based on the requirement for force flow characteristics (a main stress trajectory line) of the printed structural member, the anisotropy of the molded structural member is reflected, and the mechanical properties of the structural member under actual working conditions are improved.

Owner:TONGJI UNIV

Anisotropic conducting polypropylene composite material and preparation method thereof

The invention relates to the technical field of polypropylene composite materials and in particular discloses an anisotropic conducting polypropylene composite material and a preparation method thereof. The preparation method comprises the following steps: (1) adding dopamine and Fe3O4 magnetic particles into deionized water and ultrasonically treating the mixture for 1-3 hours at 20-30 DEG C; precipitating a product with an organic solvent, and centrifugalizing and drying the precipitate to obtain dopamine-loaded Fe3O4; (2) adding the dopamine-loaded Fe3O4, a multiwall carbon nanotube and a vinyl-vinyl acetate copolymer into an organic solvent to be ultrasonically treated for 1-3 hours, and then removing the organic solvent and pouring the mixture into a film to obtain an EVA / MWNT / Fe3O4 composite film; (3) blending the EVA / MWNT / Fe3O4 composite film with polypropylene and extruding the EVA / MWNT / Fe3O4 composite film to obtain a PP / EVA / MWNT / Fe3O4 composite material strip by injection molding; and (4) putting the PP / EVA / MWNT / Fe3O4 composite material strip into a 20-30 mT magnetic field for 5-15 min at 160-200 DEG C to obtain the anisotropic conducting polypropylene composite material.The anisotropic conducting polypropylene composite material prepared by the method shows an excellent anisotropic conducting property.

Owner:龙岩市润峰科技有限公司

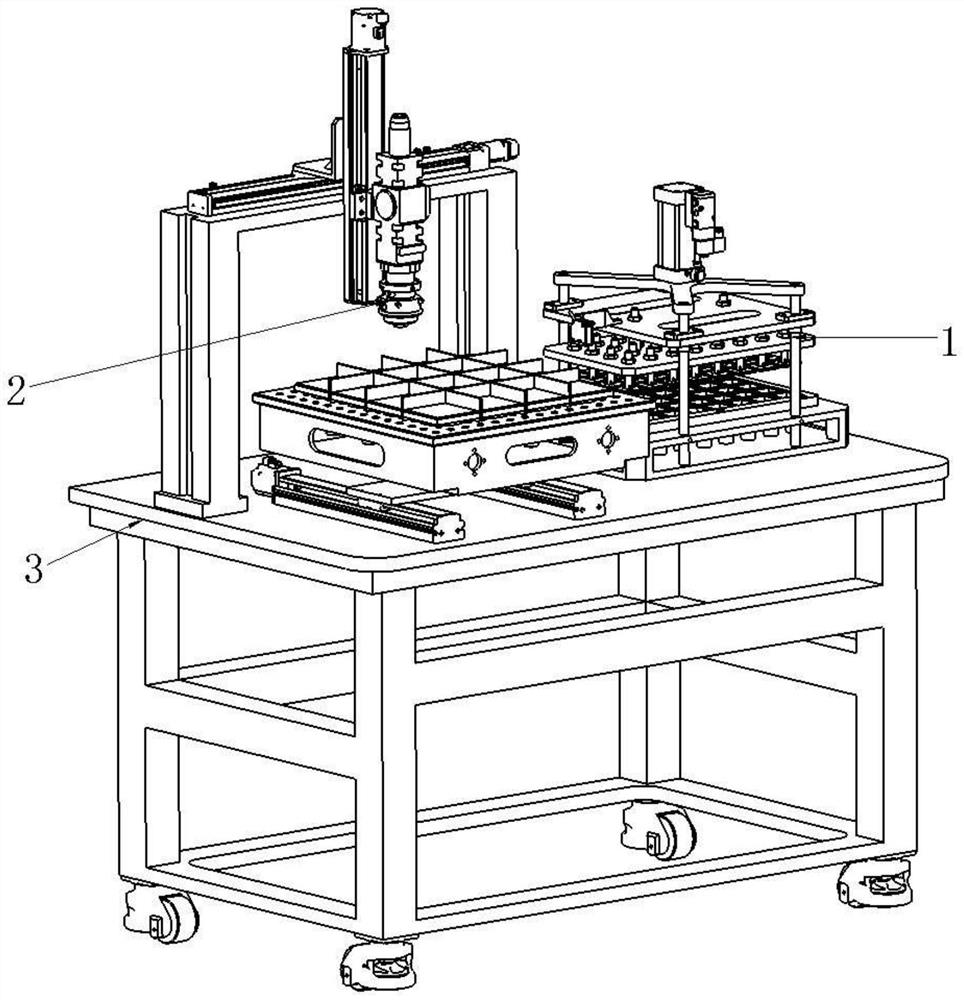

Ultrasonic-assisted laser micro-cladding method and device for gradient functional composite material

PendingCN114799182AImprove thermal conductivityFlat surfaceAdditive manufacturing apparatusMetallic material coating processesGradient materialGraphite

The invention provides an ultrasonic-assisted laser micro-cladding device for a gradient functional composite material. The ultrasonic-assisted laser micro-cladding device comprises a rack, a preset piece sample preparation assembly and an ultrasonic-assisted laser micro-cladding assembly, wherein the preset piece sample preparation assembly and the ultrasonic-assisted laser micro-cladding assembly are installed on the rack. The ultrasonic-assisted laser micro-cladding assembly comprises a laser micro-cladding head assembly and an ultrasonic-assisted workbench assembly. The invention also provides an ultrasonic-assisted laser micro-cladding method for the functional gradient composite material, which comprises the following steps: in the early stage of implementation, according to the gradient material theory, preparing a preset sheet sample through the procedures of controlling the component proportion of the copper-based composite material, performing a wet ball milling process, performing ultrasonic-assisted processing on the preset sheet, performing vacuum drying and demolding and the like; and then preparing the preset sheet sample into the graphene / copper-based gradient functional composite coating through a multi-channel and multi-layer processing mode under the action of a composite energy field based on an ultrasonic-assisted laser micro-cladding process. According to the method, the high-quality gradient functional composite coating can be formed in a metallurgical bonding mode through the laser micro-cladding technology.

Owner:WENZHOU POLYTECHNIC

Method for etching metal tungsten material

ActiveCN102372250BAchieve anisotropyHigh rate etchDecorative surface effectsChemical vapor deposition coatingHigh densityHigh energy

The invention discloses a method for etching a metal tungsten material, which is characterized in that: an etching mask is formed on the metal tungsten material, and then a high-density plasma (such as inductively coupled plasma, transformer coupled plasma and the like) dry etching process is adopted to produce high-density and high-energy ions and free radicals and to realize the high-speed and anisotropic etching of the metal tungsten material. The etching speed can reach 2.95 micrometers per minute, and the verticality of an etching-resulted side wall can reach 60 degrees. Based on the method, a metal tungsten underlay substrate can be used as a main body material for preparing micro-electro-mechanical system (MEMS) devices.

Owner:苏州含光微纳科技有限公司

Etching Method of Silicon Nitride High Aspect Ratio Hole

ActiveCN103531464BAchieve anisotropyAdjust etch topographySemiconductor/solid-state device manufacturingEtchingHydrogen

The invention discloses an etching method for a silicon nitride high depth-to-width ratio hole. The method comprises: first of all, placing a semiconductor device of a silicon nitride film, already forming the graph needed by a semiconductor, into en etching cavity; then using a dry-method plasma technology, letting in a high carbon chain molecule fluorocarbon-based gas, an oxidizing gas, a dilution gas and a fluorocarbon-based gas containing hydrogen, adding radio frequency power and exciting plasma; and after a plasma stabilization step, performing etching of the silicon nitride film until the etching morphology, the hole diameter size and the depth of a high depth-to-width ratio hole reach requirements. According to the invention, the silicon nitride film is etched by using the unique fluorocarbon-based gas, through adjusting gas component and power size, the deposition amount of fluorocarbon polymers on the side wall of the deep hole can be controlled, the key dimensions of the hole can be prevented from becoming larger, and polymers already deposited at the bottom of the deep hole can be removed so as to ensure that the etching can be continued, thus the etching morphology of the hole can be adjusted.

Owner:SOI MICRO CO LTD

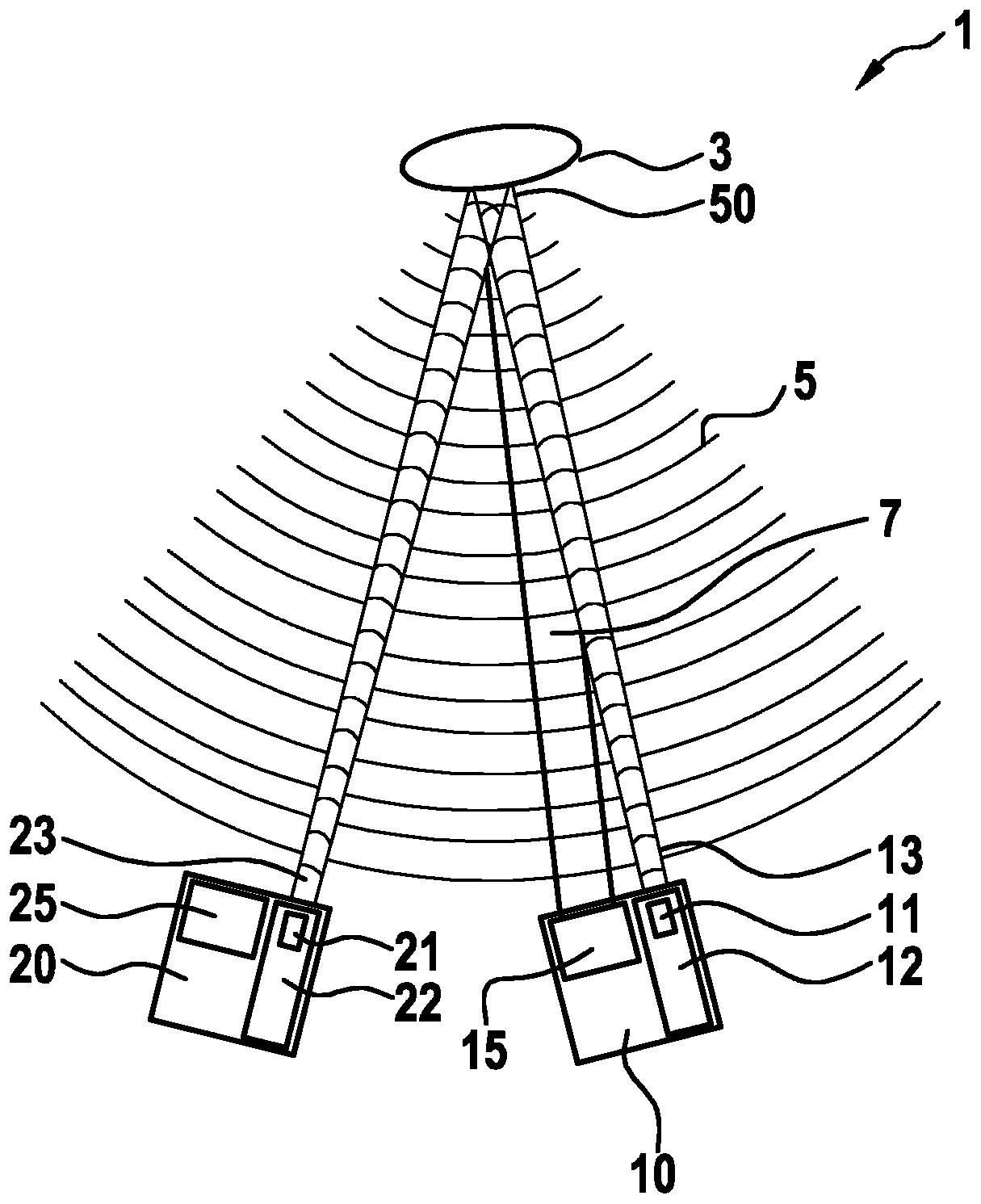

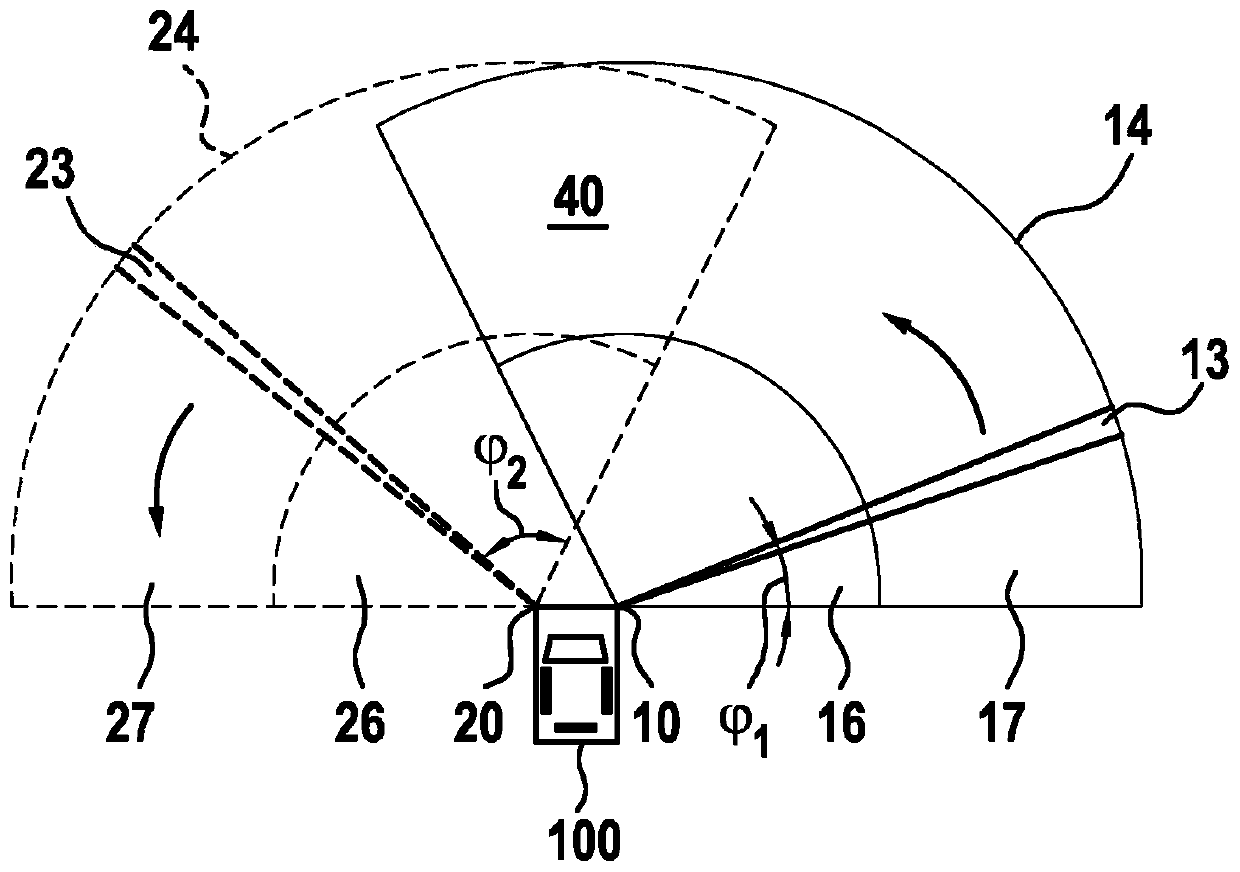

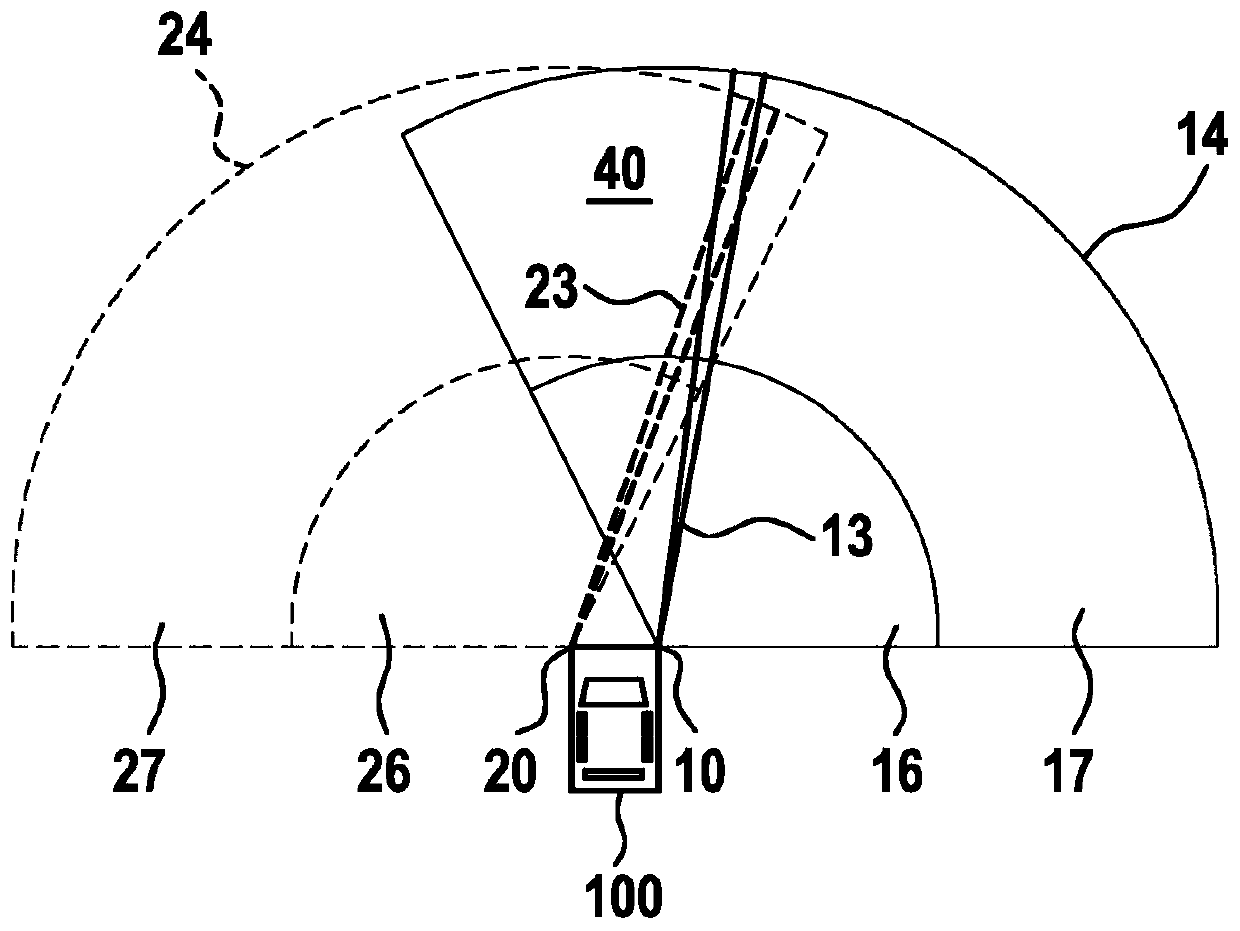

Lidar arrangement, vehicle, and robot comprising a lidar arrangement of this type

ActiveCN111295598AHigh strengthEnsure safetyElectromagnetic wave reradiationEngineeringAtmospheric sciences

The invention relates to a LIDAR assembly (1) comprising a plurality of LIDAR systems (10, 20). The first LIDAR system (10) is spaced apart from the second LIDAR system (20). A first laser beam (13) of the first LIDAR system (10) and a second laser beam (23) are synchronized such that said first laser beam (13) and second laser beam (23) are mutually amplifying in a common remote region (50).

Owner:ROBERT BOSCH GMBH

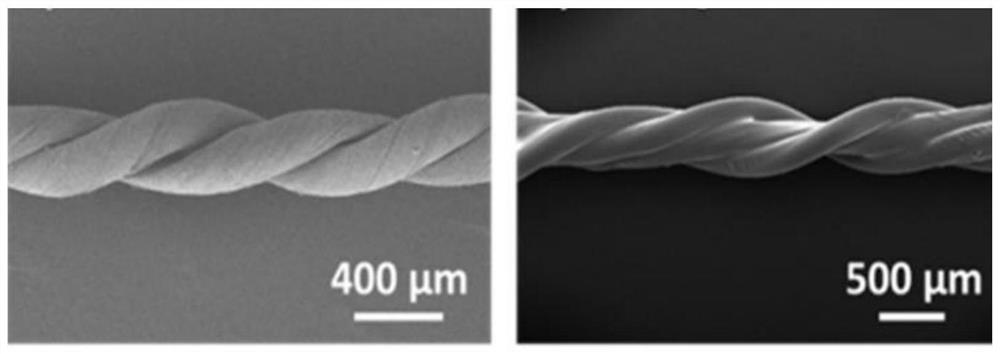

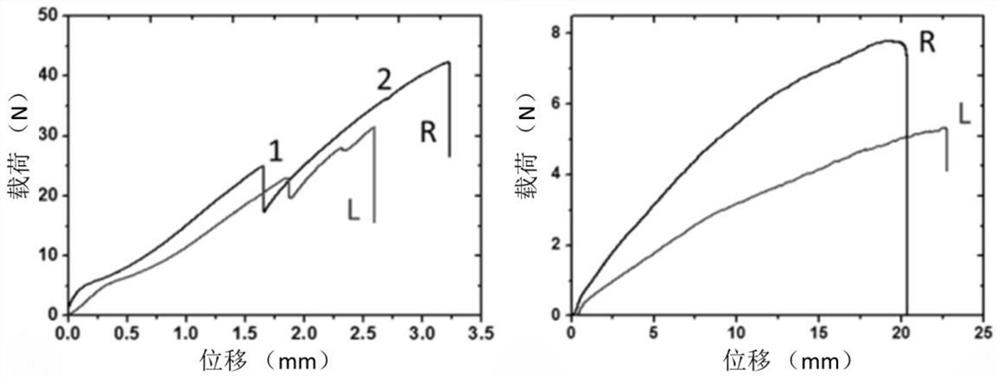

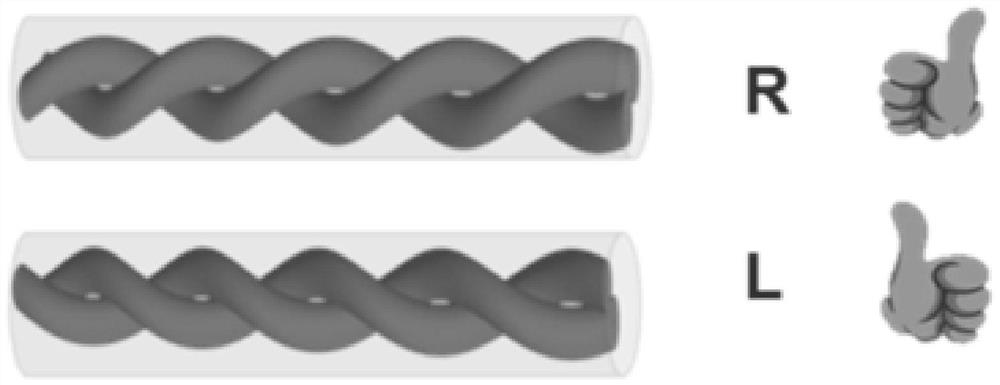

A kind of anisotropic twisted fiber bundle and its preparation method and application

ActiveCN113430692BControllable fiber sizeImprove mechanical propertiesYarnPolymer scienceFiber bundle

The invention provides an anisotropic twisted fiber bundle and its preparation method and application. The method comprises the following steps: performing primary processing on the initial single fiber obtained by wet spinning or electrospinning by clockwise twisting method. twisting to obtain primary twisted fiber bundles; using the primary twisted fiber bundles obtained by multiple strands for secondary twisting to obtain anisotropic twisted fiber bundles. The anisotropic twisted fiber bundle provided by the invention can realize the compounding of various materials and the integration of various functions, has structure and performance anisotropy, high strength and flexibility, and the size of the fiber is controllable and can be bent arbitrarily and braiding, which have broad applications in energy storage devices and anisotropic liquid transport.

Owner:ZHEJIANG SCI-TECH UNIV

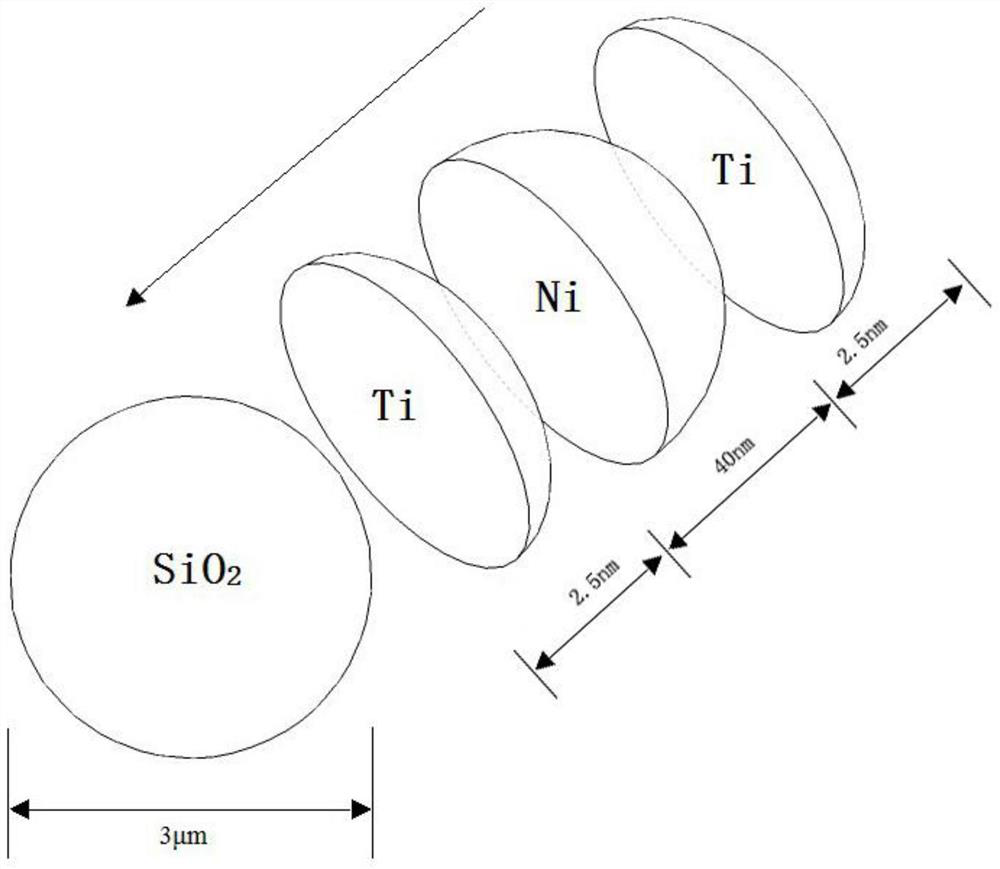

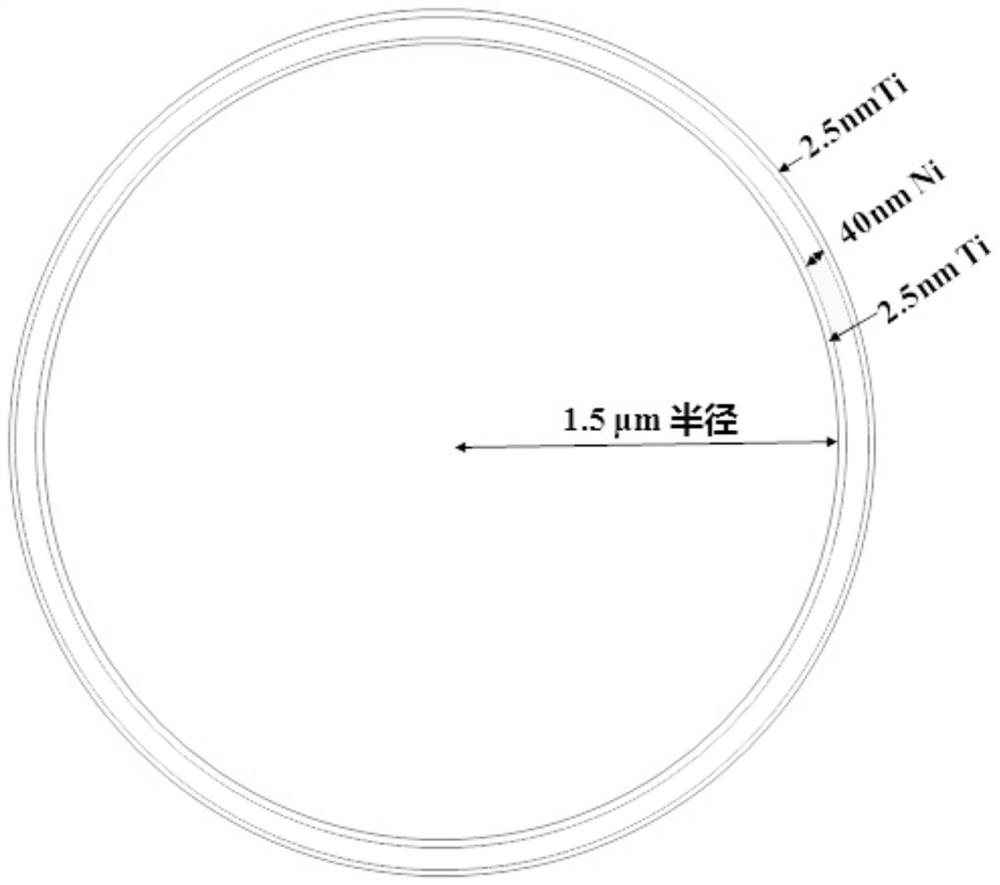

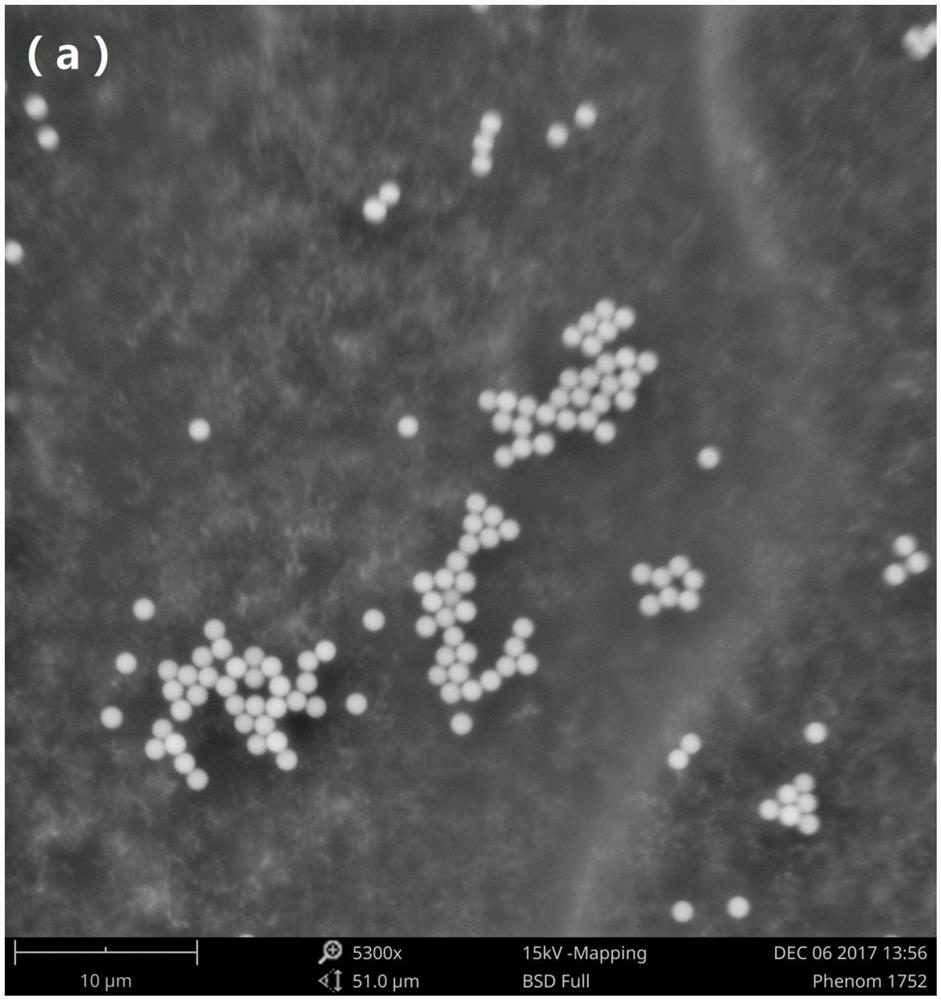

A double-sided human nanocoating particle capable of modulating drilling fluid rheology

ActiveCN113025290BReduce use costEasy to control speedFlushingDrilling compositionTitanium coatingChemical physics

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Cyclic Etching Method of Silicon Nitride High Aspect Ratio Holes

ActiveCN103578973BAdjust etch topographyAchieve anisotropySemiconductor/solid-state device manufacturingEtchingFluorocarbon

A circulating etching method of a silicon nitride hole with high depth-to-width ratio comprises of the steps of 1 adopting a dry-method plasma process and fluorocarbon-based gas to perform silicon nitride thin film etching so as to form the hole and meanwhile generating a polymer depositing on the bottom and the side wall of the hole; 2 feeding oxidizing gas and diluting gas into an etching cavity. The deposition amount of fluorocarbon on the side wall of the deep hole can be controlled, the polymer depositing on the bottom of the deep hole can be removed so as to ensure continuous etching, and the two steps are repeatedly performed till the etching profile of the hole meets the requirement. When the fluorocarbon-based gas in the step 1 is increased and accordingly the fluorocarbon amount is increased, the hole is slightly oblique. When the oxidizing gas in the step 2 is increased, the hole is upright. Different hole etching profiles can be obtained as required by adjusting parameters to be between the two amounts.

Owner:SOI MICRO CO LTD

Method for etching metal molybdenum material

ActiveCN102417156BAchieve anisotropyHigh rate etchDecorative surface effectsChemical vapor deposition coatingHigh densityHigh energy

The invention discloses a method for etching a metal molybdenum material. The method comprises the following steps of: forming an etching mask on the metal molybdenum material; and generating high-density and high-energy ions and free radicals by adopting a high-density plasma (such as ICP (Inductively Coupled Plasma), TCP (Transformer Coupled Plasma) and the like) dry etching process to realize high-speed and anisotropic etching of the metal molybdenum material. The etching speed can be up to 2.63 microns per minute, and the vertical degree of an etching result side wall can be up 70 degrees. On the basis of the method disclosed by the invention, a metal molybdenum substrate can be taken as a main body material for preparing an MEMS (Micro Electro Mechanical System) device.

Owner:苏州含光微纳科技有限公司

A frequency-tunable terahertz multi-band absorber

ActiveCN109888506BAchieving Tunable FeaturesAchieve anisotropyAntennasOptical elementsTerahertz metamaterialsEngineering

The invention discloses a frequency-tunable terahertz multi-band absorber, which comprises an absorber body fixed on a rotatable platform. Several absorbing units are arranged on the absorbing surface of the absorber body, and each absorbing unit includes a The three-layer structure of metal pattern layer, lossy dielectric layer and bottom total reflection layer closely attached from top to bottom. The metal pattern layer includes four pairs of H-shaped metal pattern symmetrical structures centered on the surface of the absorbing unit. Each pair of H-shaped metal patterns is symmetrical The structures all include two H-shaped metal structures, and four pairs of H-shaped metal pattern symmetrical structures are uniformly arranged in a clockwise direction. Generate responses to problems that limit practical application capabilities.

Owner:XIAN UNIV OF TECH

A thermal insulation product based on fused deposition modeling and its preparation method

ActiveCN112339264BHigh porosityImprove thermal insulation3D object support structuresApplying layer meansThermal insulationEngineering

The invention provides a thermal insulation product based on fused deposition molding and its preparation method. Taking advantage of the designability advantages of 3D printing, the material body—introducing low thermal conductivity fillers and microstructures into thermoplastic polymers—through Design a two-component nozzle to introduce low-melting point phase-change materials and the printing process—by introducing sodium bicarbonate powder combined with post-treatment heating to increase the porosity of the part, and optimize the design in three aspects. The synergistic effect of the three achieves the excellent thermal insulation performance of the parts. In addition, the lines deposited by the spray head in the 3D printing process have a skin-core structure, and the change of the micro-components of the deposited lines can be realized by changing the process parameters according to actual needs, so as to realize the regulation of microscopic properties, and then realize the workpiece in the 3D printing process. Macroscopic anisotropy.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

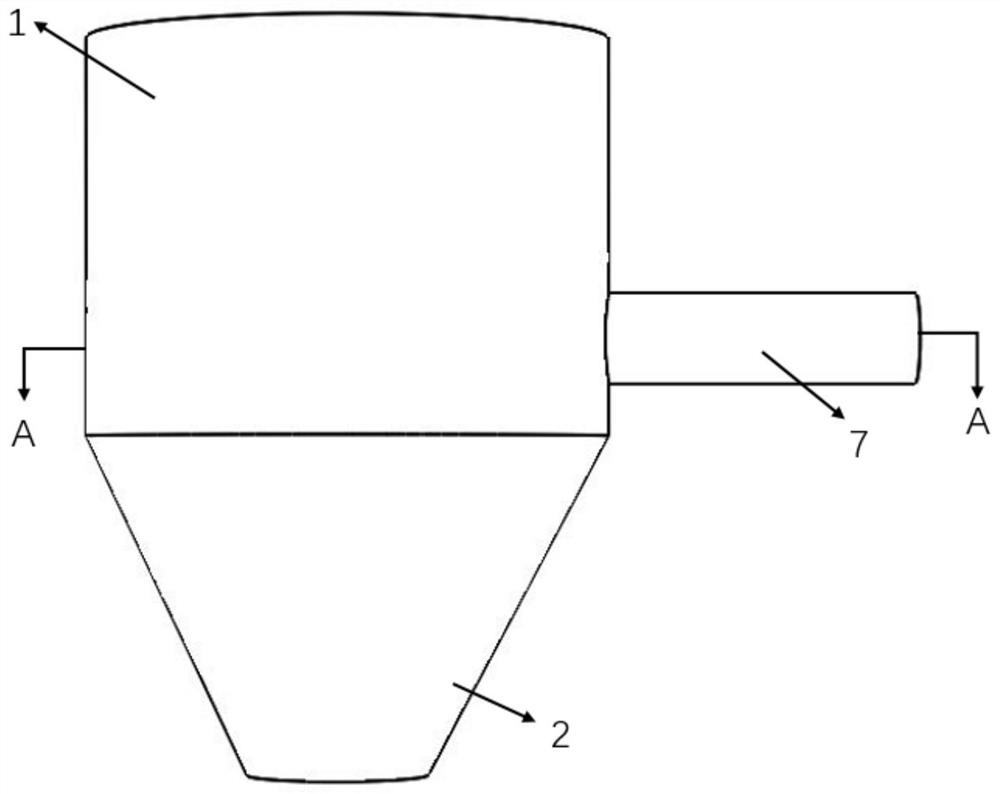

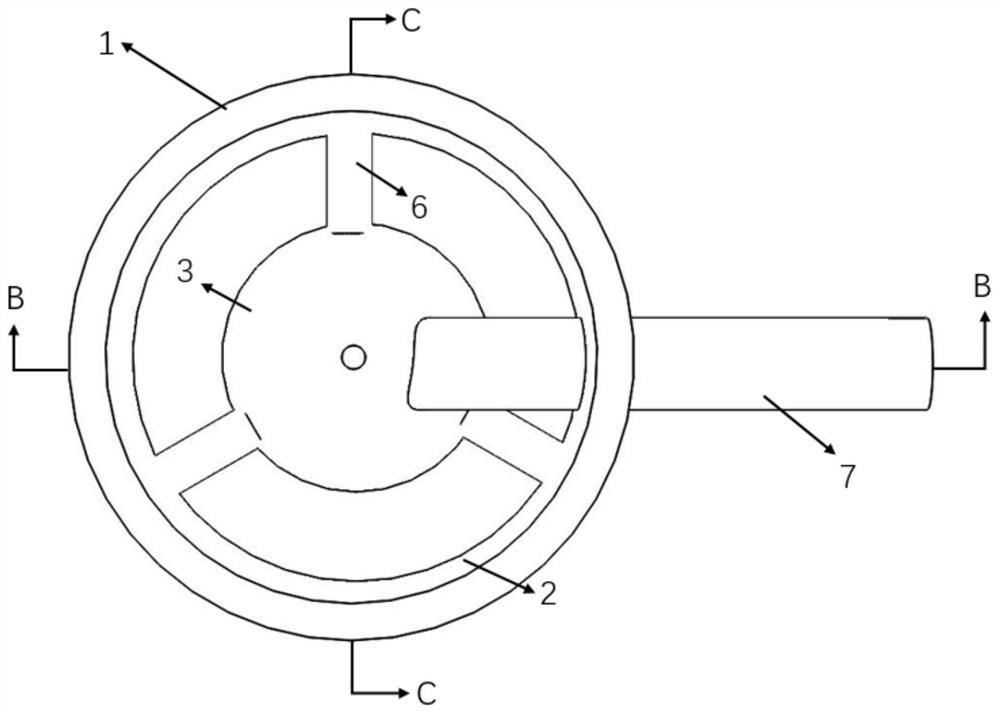

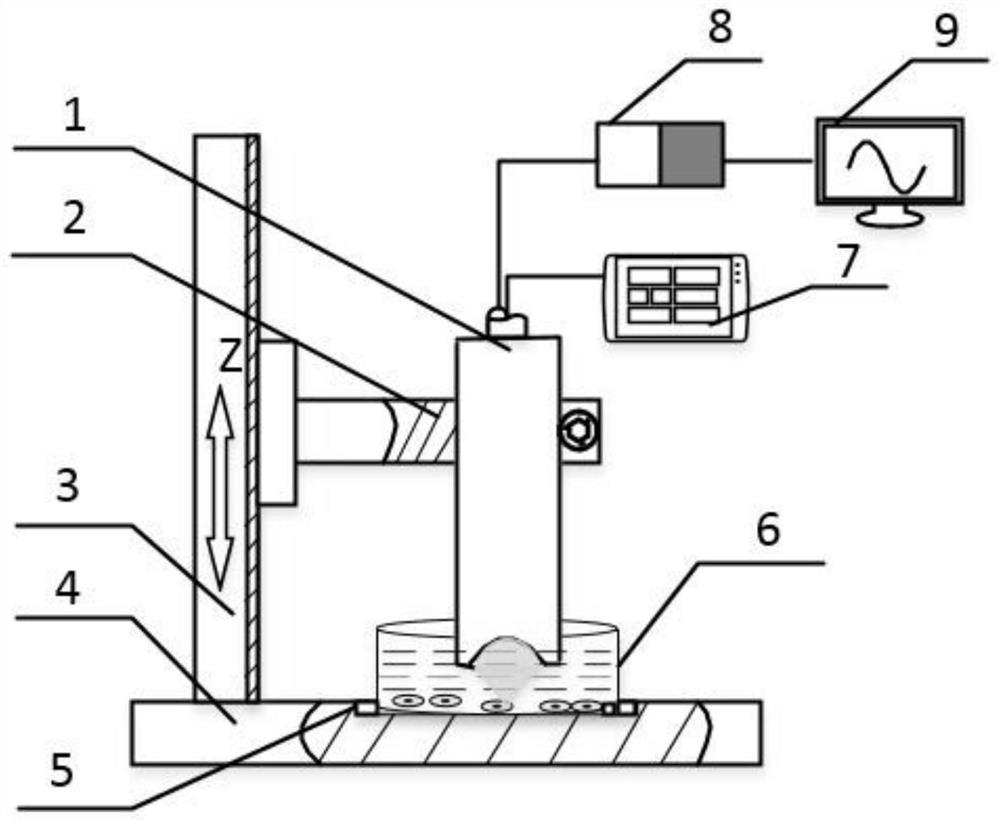

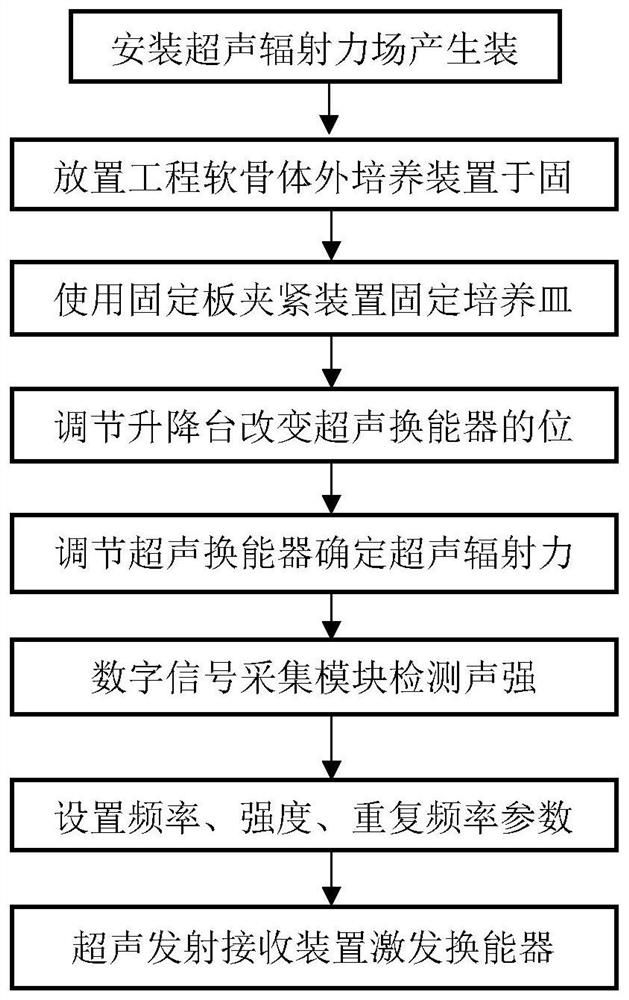

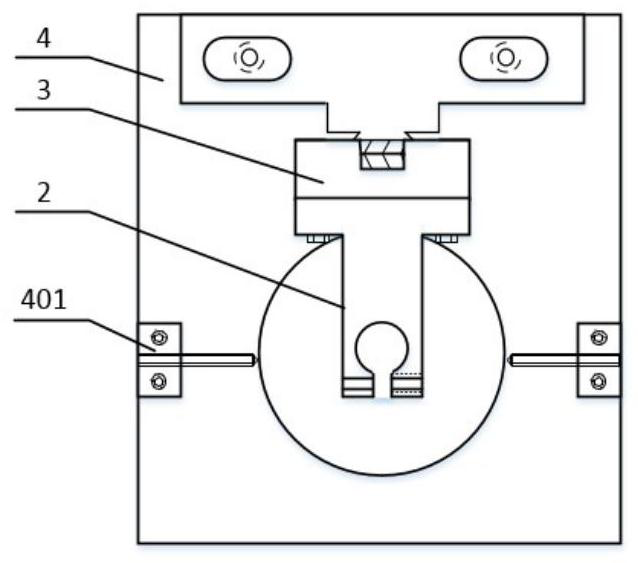

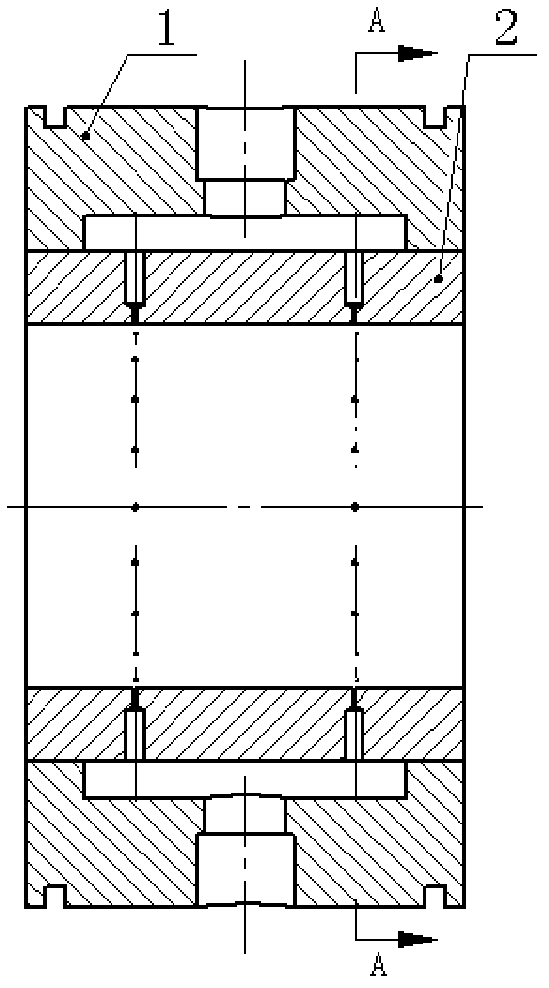

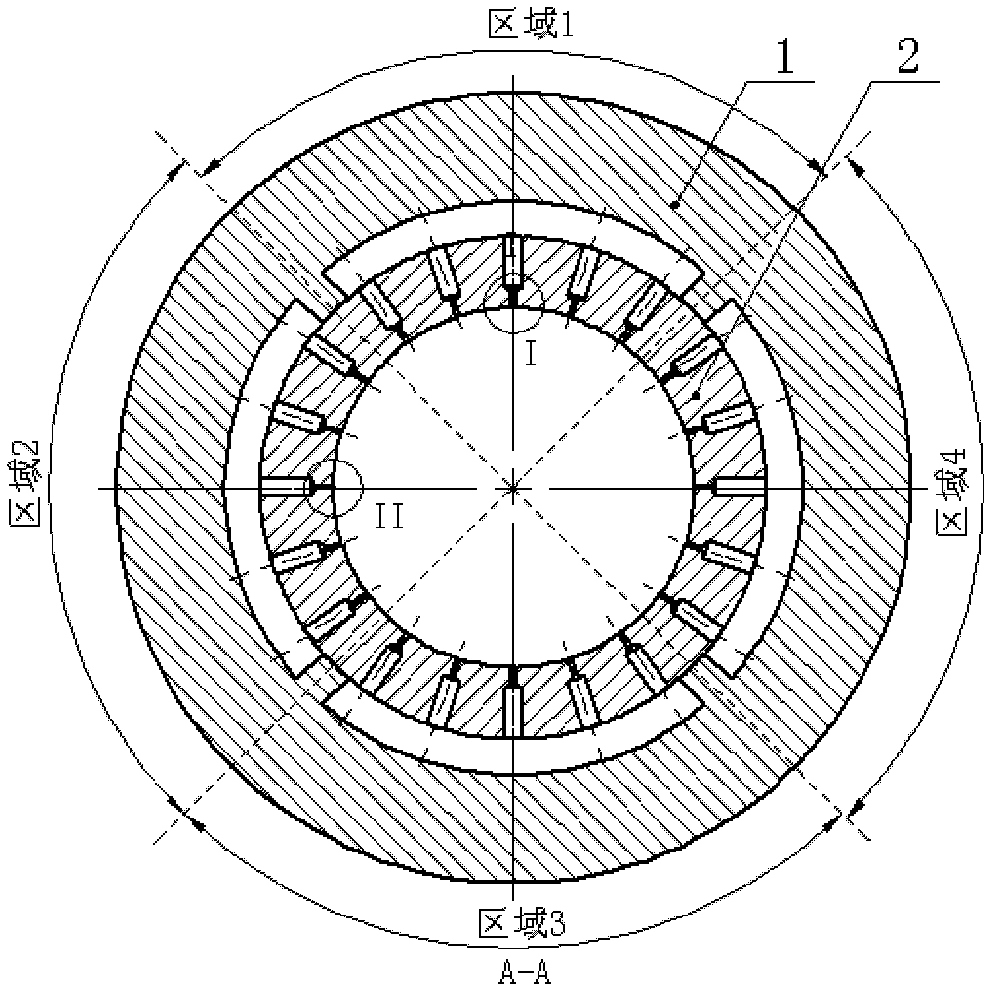

A method and device for generating an ultrasonic radiation force field for engineering cartilage cultured in vitro

ActiveCN110760441BExcellent mechanical propertiesAchieve anisotropyBioreactor/fermenter combinationsBiological substance pretreatmentsUltrasonic radiationTransducer

The invention provides a method and a device for generating an ultrasonic radiation force field for culturing engineering cartilage in vitro. The device of the invention includes an ultrasonic transducer, a connecting frame, a lifting platform, a fixed base, a guide ring, an engineering cartilage culture device in vitro, an ultrasonic transmitting and receiving device, a signal acquisition and processing module and an oscilloscope. The method of the present invention firstly adjusts the built-in gear of the lifting platform to control so that the emitting head of the ultrasonic transducer is immersed in the culture medium of the engineering cartilage in vitro culture device. Determine the focal length of the emitter of the ultrasonic transducer in the culture medium through the signal acquisition and processing module and the oscilloscope, so that the engineered cartilage is at the focal point of the emitter of the ultrasonic transducer; determine the direction of the ultrasonic radiation force field by rotating the ultrasonic transducer; Finally start the ultrasonic transmitting and receiving device to excite the ultrasonic transducer. The ultrasonic radiation force field generated by the method and device of the invention can mechanically regulate the engineered cartilage cultured in vitro to obtain normal engineered cartilage with good biological properties.

Owner:ZHEJIANG UNIV

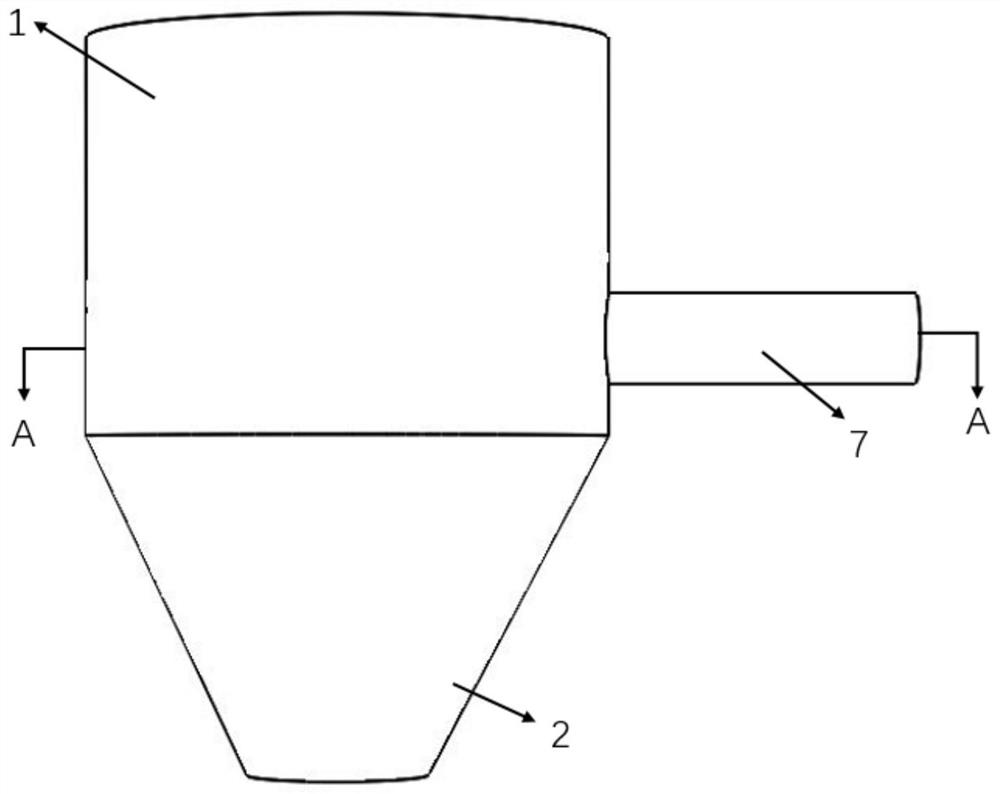

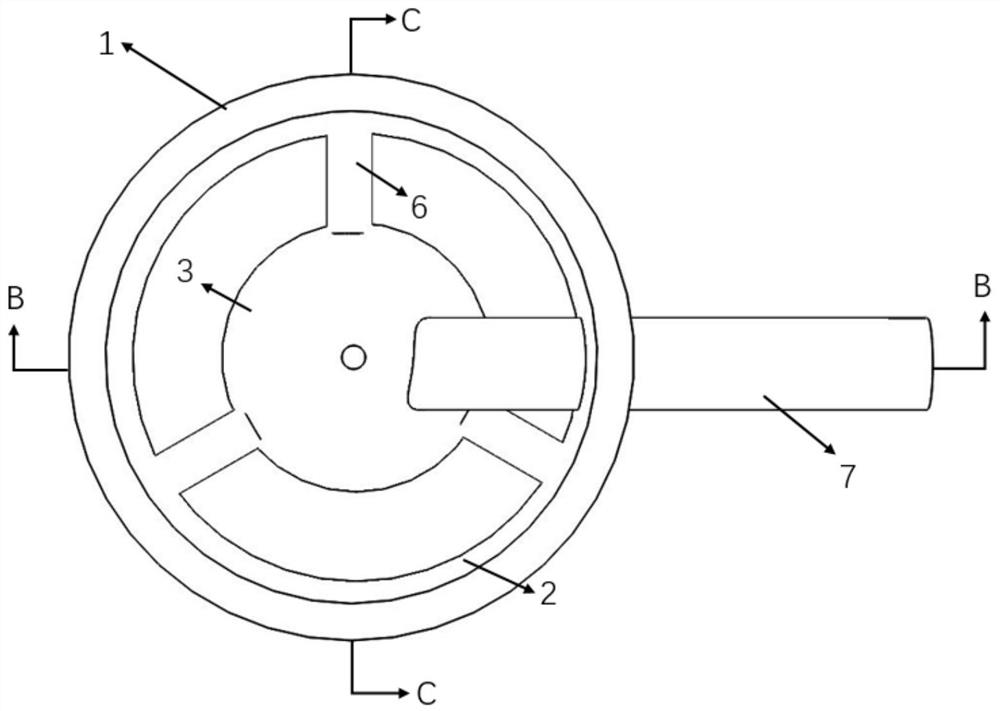

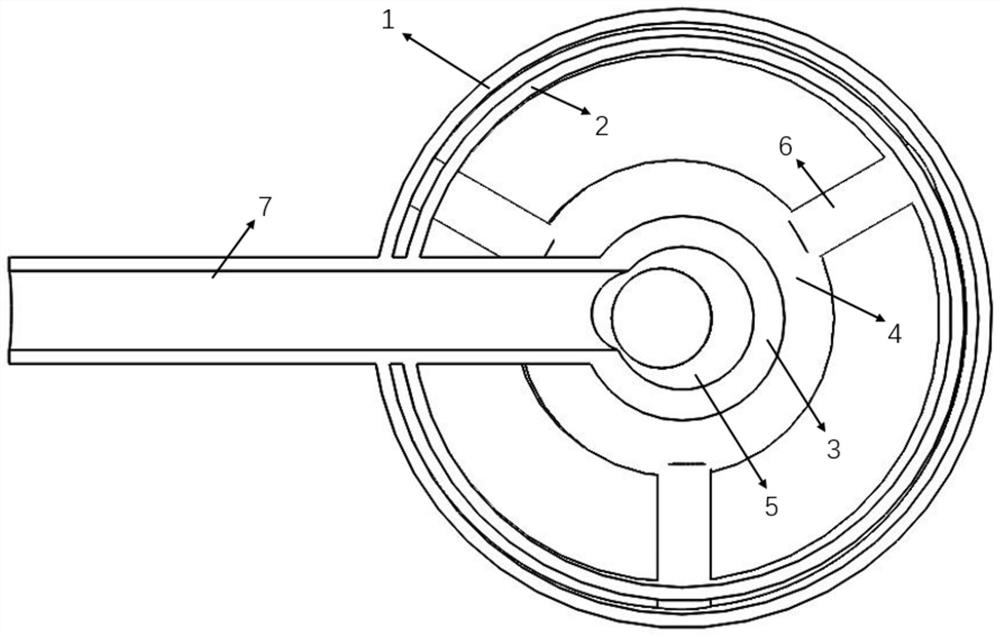

Static pressure gas bearing

InactiveCN102252023BChange pressure distributionChange stiffness propertiesBearingsAudio power amplifierControl signal

The invention discloses a static pressure gas bearing comprising a bearing base body and an air-supply hole loop. Air-supply holes on the air-supply hole loop adopt a mode of loop surface throttling; the air-supply hole loop is divided into a plurality of independent regions along the circumferential direction, the diameters of the air-supply holes in all the regions are different; every region has an independent air-supply passage; every air-supply passage is connected with an industrial personal computer via an electric proportional valve and an amplifier; and the industrial personal computer sends a control signal to the amplifier according to a rotor operation condition detected by a displacement transducer to adjust air-supply pressure. The air-supply holes on the air-supply hole loop adopt a reversely tangential air-supply mode or a vertical air-supply mode. The pressure distribution in a flow field is changed because the diameters of the air-supply holes are different, therefore, the rigidity characteristic of the bearing in different directions is changed and the rigidity anisotropy of the bearing is realized. The system stability can be effectively improved due to rigidity anisotropy when the diameters of the air-supply holes in different regions are reasonably matched.

Owner:DALIAN MARITIME UNIVERSITY

Bamboo-like copper crystal particles having a highly preferred orientation

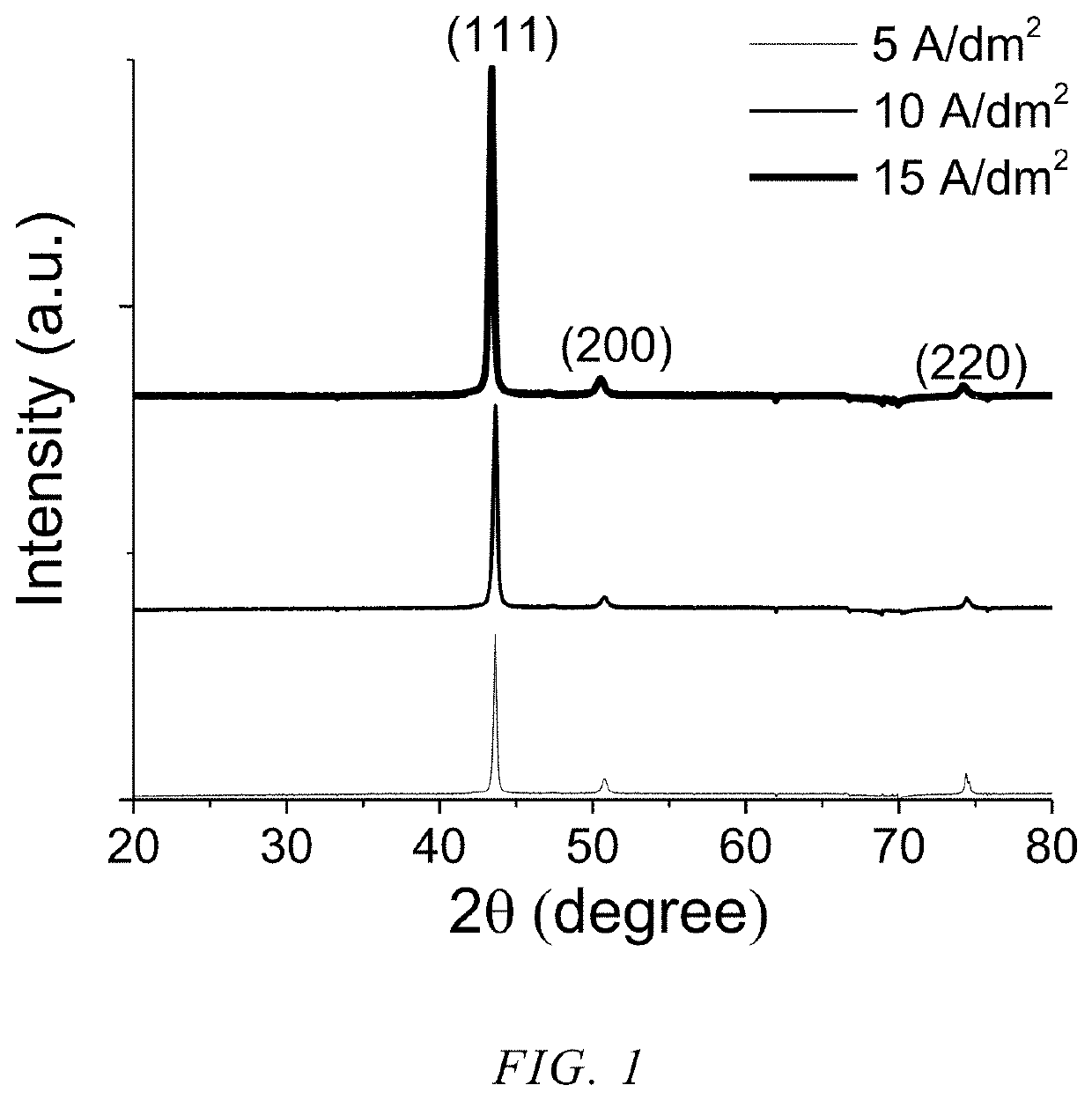

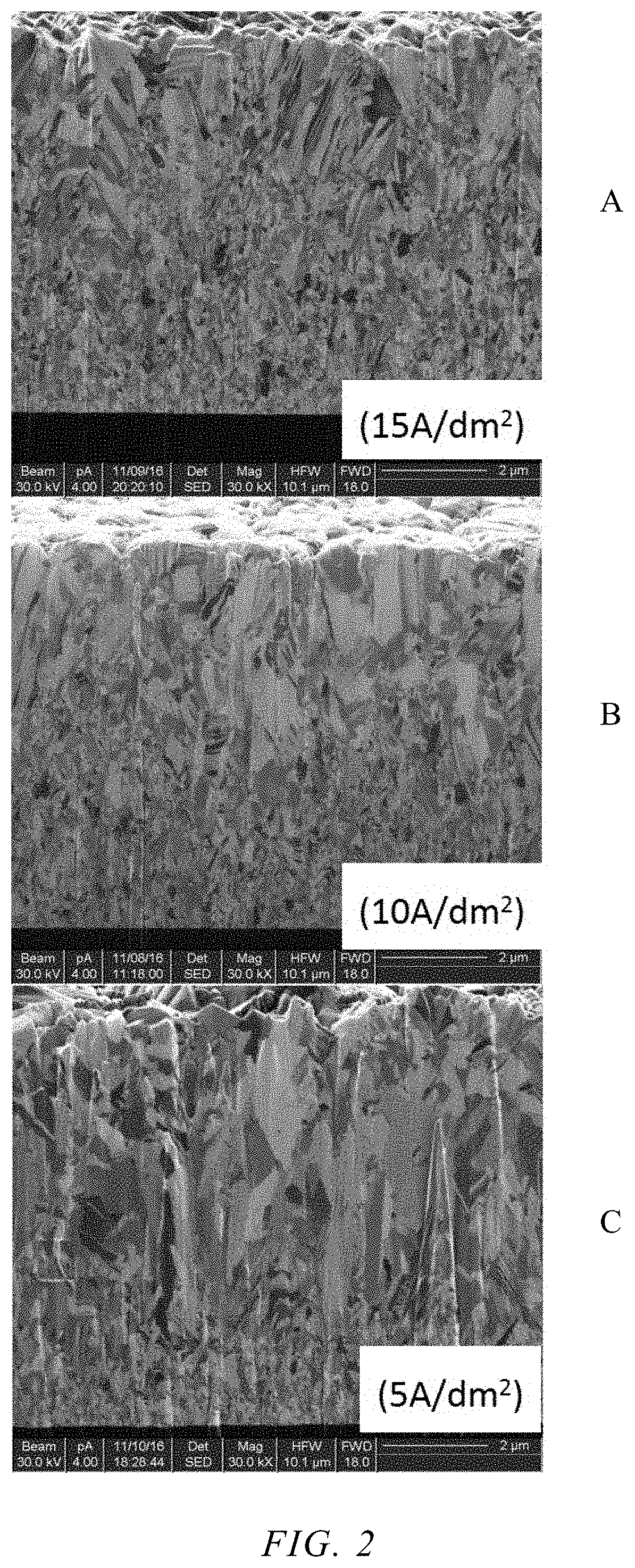

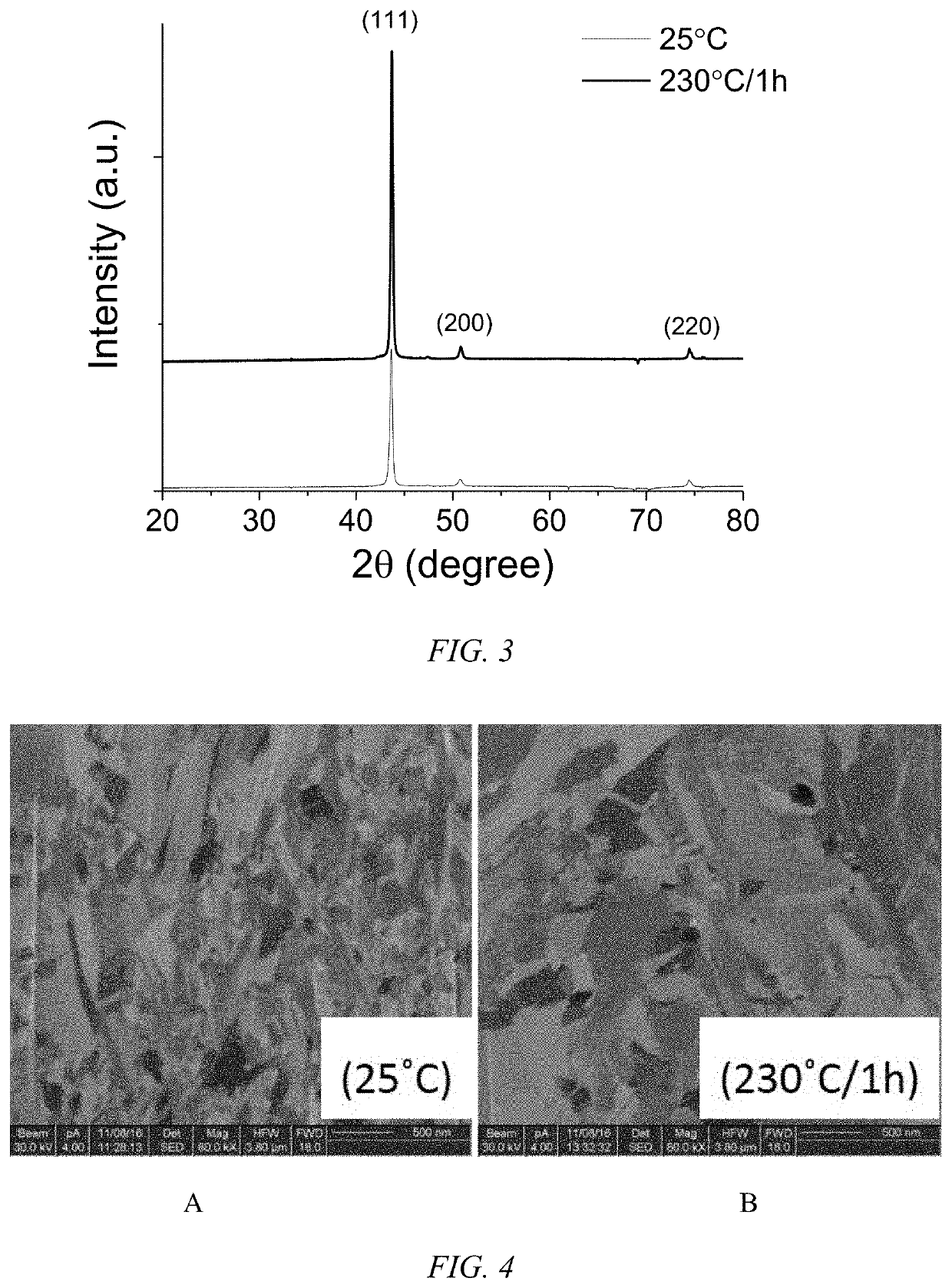

ActiveUS20200208286A1Highly preferred orientationReduce complexityPolycrystalline material growthOrganic chemistryCondensed matter physicsElectroplating

Owner:SUZHOU SHINHAO MATERIALS

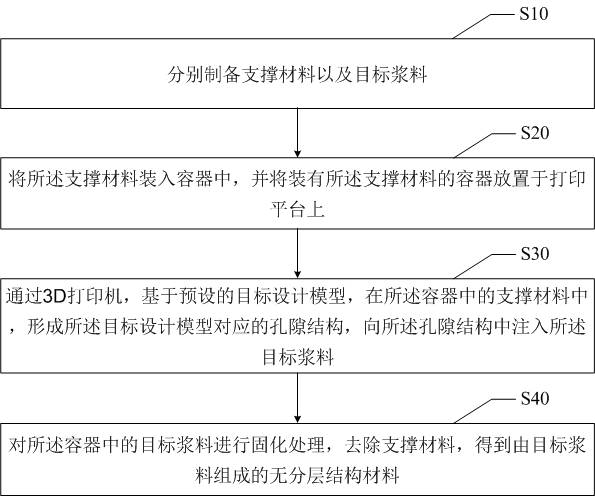

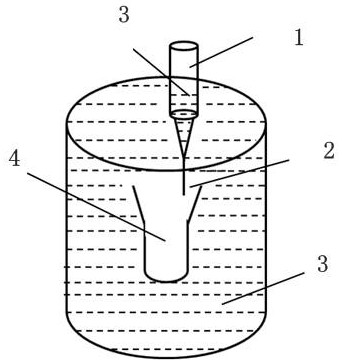

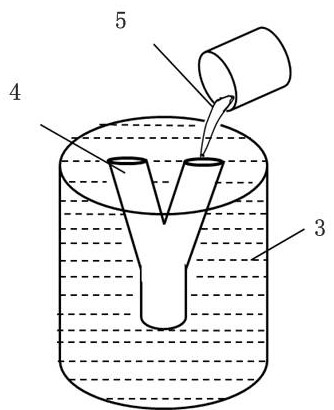

Method for preparing non-layered structure material in combination with 3D printing

ActiveCN114750412AImprove molding efficiencyImprove qualityAdditive manufacturing apparatusAuxillary shaping apparatusComputer printingSlurry

The invention discloses a method for preparing a non-layered structure material in combination with 3D printing, and relates to the technical field of additive manufacturing, and the method for preparing the non-layered structure material in combination with 3D printing comprises the following steps that a supporting material and target slurry are prepared separately; the supporting material is loaded into a container, and the container loaded with the supporting material is placed on a printing platform; a pore structure corresponding to a target design model is formed in the supporting material in the container based on the preset target design model through a 3D printer, and the target slurry is injected into the pore structure; and curing the target slurry in the container, and removing the support material to obtain the non-layered structure material composed of the target slurry. The technical problem that in the prior art, the quality of opaque materials such as ceramic and metal manufactured through additive manufacturing is poor is solved.

Owner:JIHUA LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com