Polyether-ether-ketone modified pelletizing material with low heat-conducting coefficient as well as application thereof

A low thermal conductivity, modified material technology, applied in applications, smoker products, tobacco, etc., can solve the problems of reducing the life cycle of electronic accessories, high processing costs, poor user experience, etc., to improve the thermal insulation effect and energy utilization. Efficiency, thermal conductivity anisotropy, strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8 and comparative example 1-2

[0028] A preparation method of polyether ether ketone modified granulated material with low thermal conductivity, the specific steps are as follows:

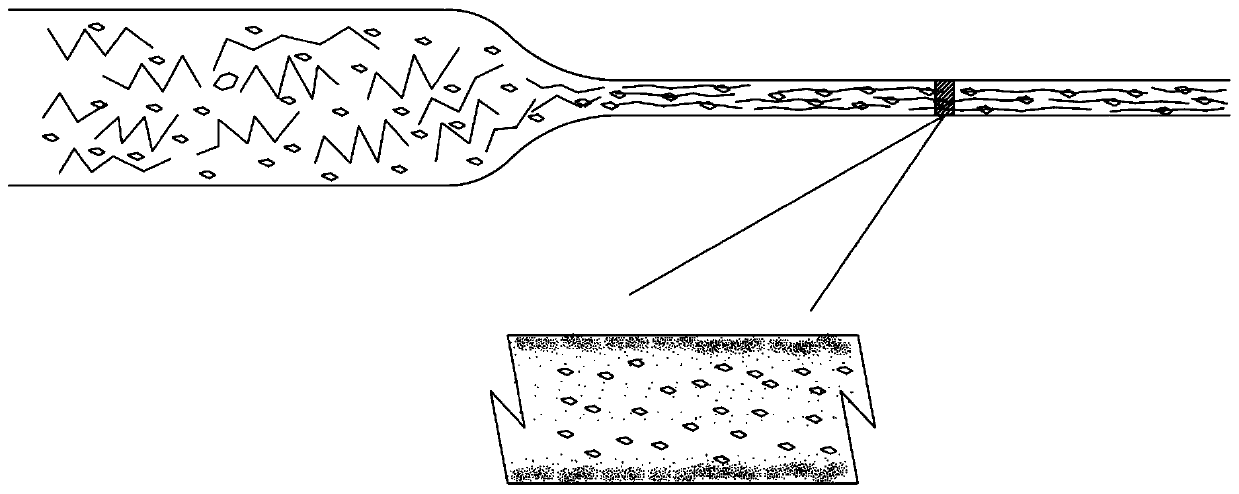

[0029] 1. Preparation of modified diatomite:

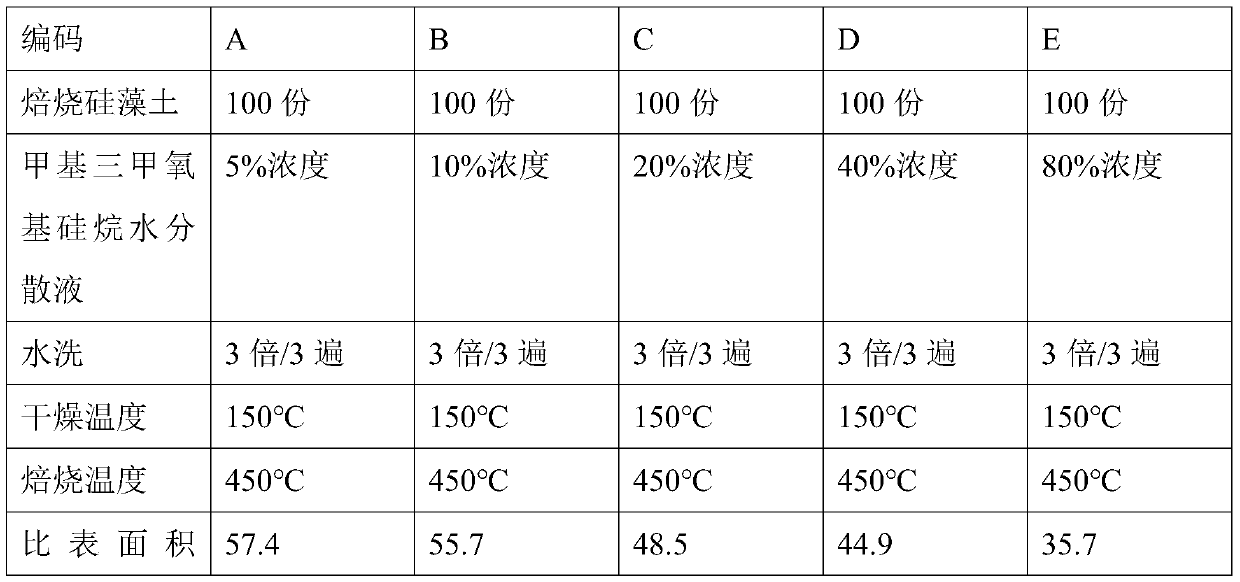

[0030] Take 100 parts of roasted diatomaceous earth, pour it into 1000 parts of the silicone monomer aqueous dispersion with a specified mass concentration, and continue stirring for 20 minutes after fully dispersing; filter the dispersion until there is no liquid material on the surface of the material; take out the filter cake, and use 300 parts of Disperse the filter cake with pure water, stir quickly for 20 minutes, and then centrifuge to separate the solid material; repeat the washing twice; take out the solid material obtained by centrifugation, spread it evenly, and the thickness does not exceed 10mm, put it in an oven at 180°C for 45 minutes, and then transfer it to 450°C Dry in an oven for 120 minutes; when the temperature of the material drops to 120±10°C, move it into a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com