Method for etching metal tungsten material

A metal tungsten, dry etching technology, applied in metal material coating process, process for producing decorative surface effects, coating and other directions, can solve the problems of low etching process rate and poor anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples will further illustrate the present invention, but this is not a limitation of the present invention. Those skilled in the art can make various modifications or improvements based on the basic idea of the present invention, but they are all available as long as they do not deviate from the basic idea of the present invention. Within the scope of the present invention.

[0020] 1. Preparation of etching mask:

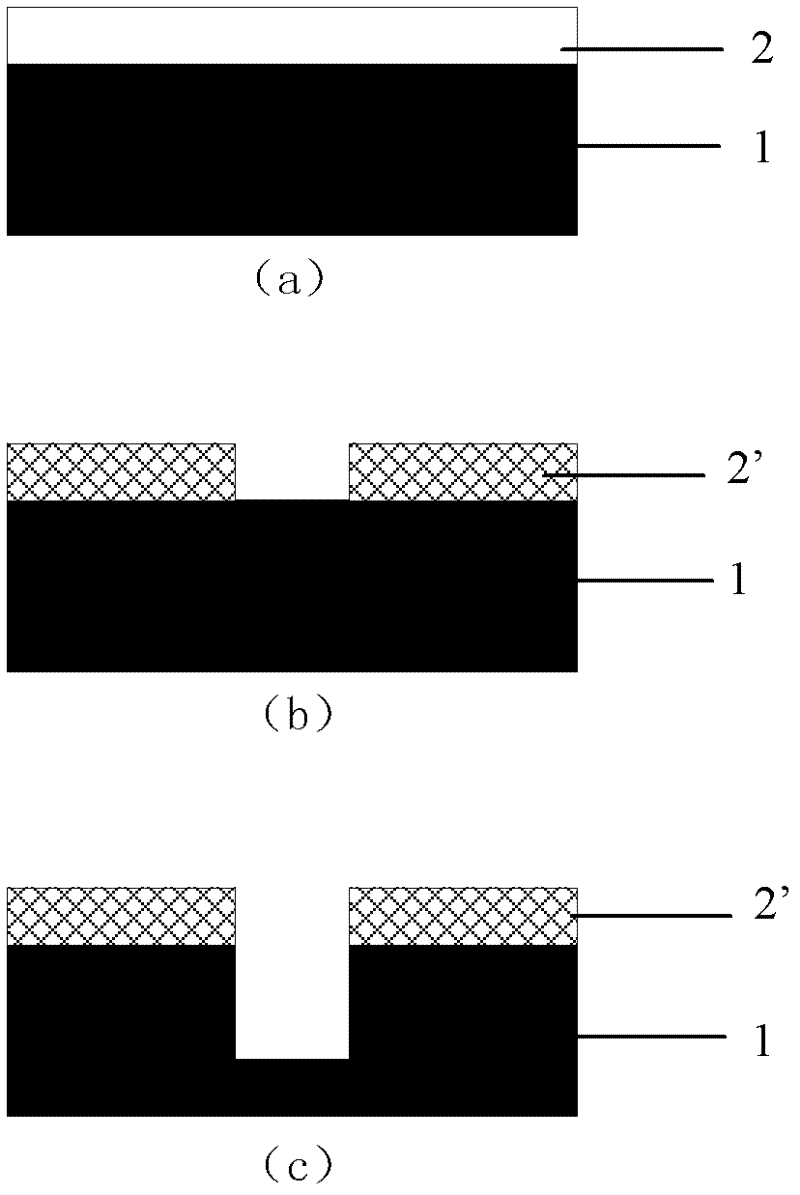

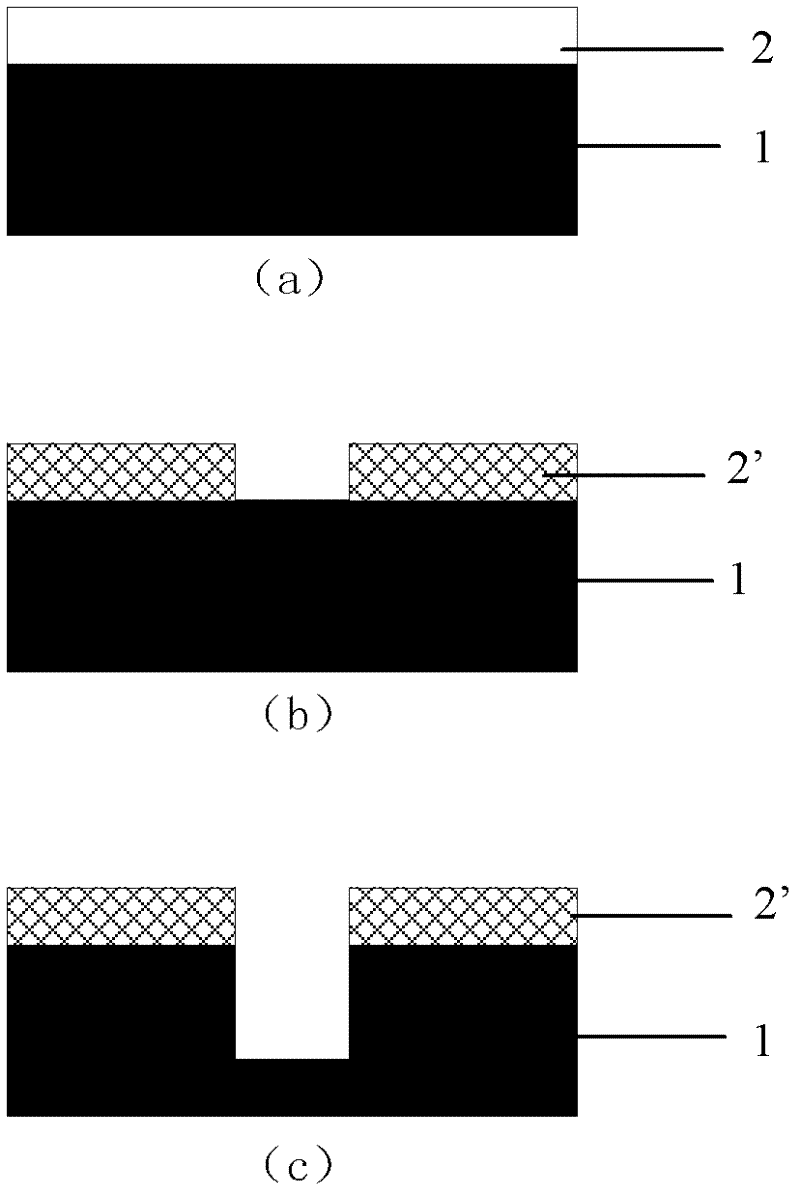

[0021] Such as figure 1 As shown, the negative photoresist SU-83050 is used as the mask material, and the polished high-purity wafer-grade metal tungsten substrate 1 is cleaned with acetone alcohol and dried, and then coated with a layer of Negative photoresist 2 with a thickness of 60 microns, such as figure 1 (a) Shown. After the photoresist 2 is patterned by pre-baking, exposure, post-baking, and developing, an etching mask 2'with the required etching pattern is obtained, see figure 1 (b).

[0022] 2. Etching:

[0023] Use Trion Technology ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com