Continuous fiber reinforced composite 3D printing device comprising cutting-off mechanism

A technology for reinforcing composite materials and continuous fibers, applied in coating devices, additive processing, manufacturing auxiliary devices, etc., can solve the problem of non-cutting fibers, and achieve the effect of improving mechanical properties and saving fiber materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

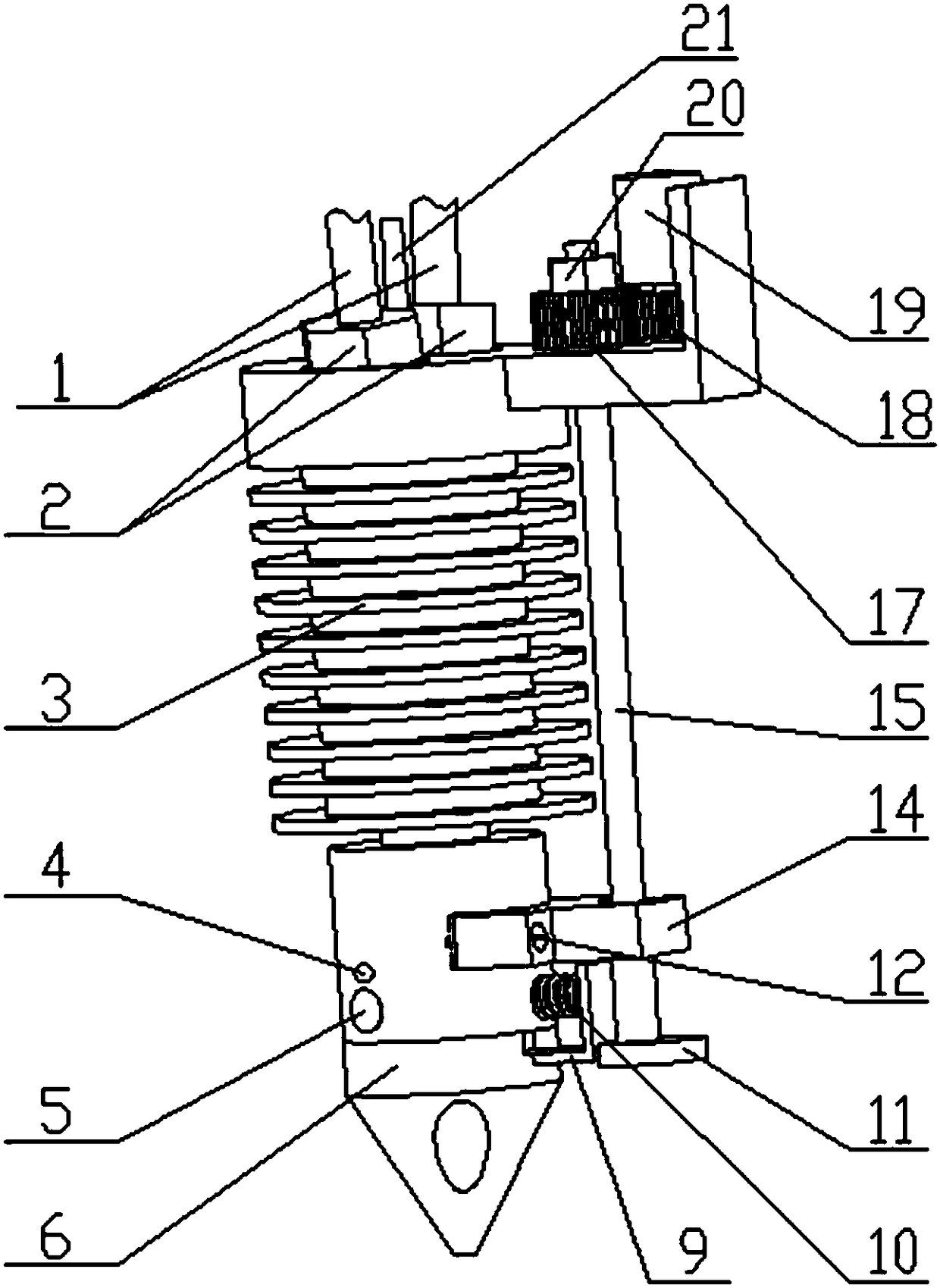

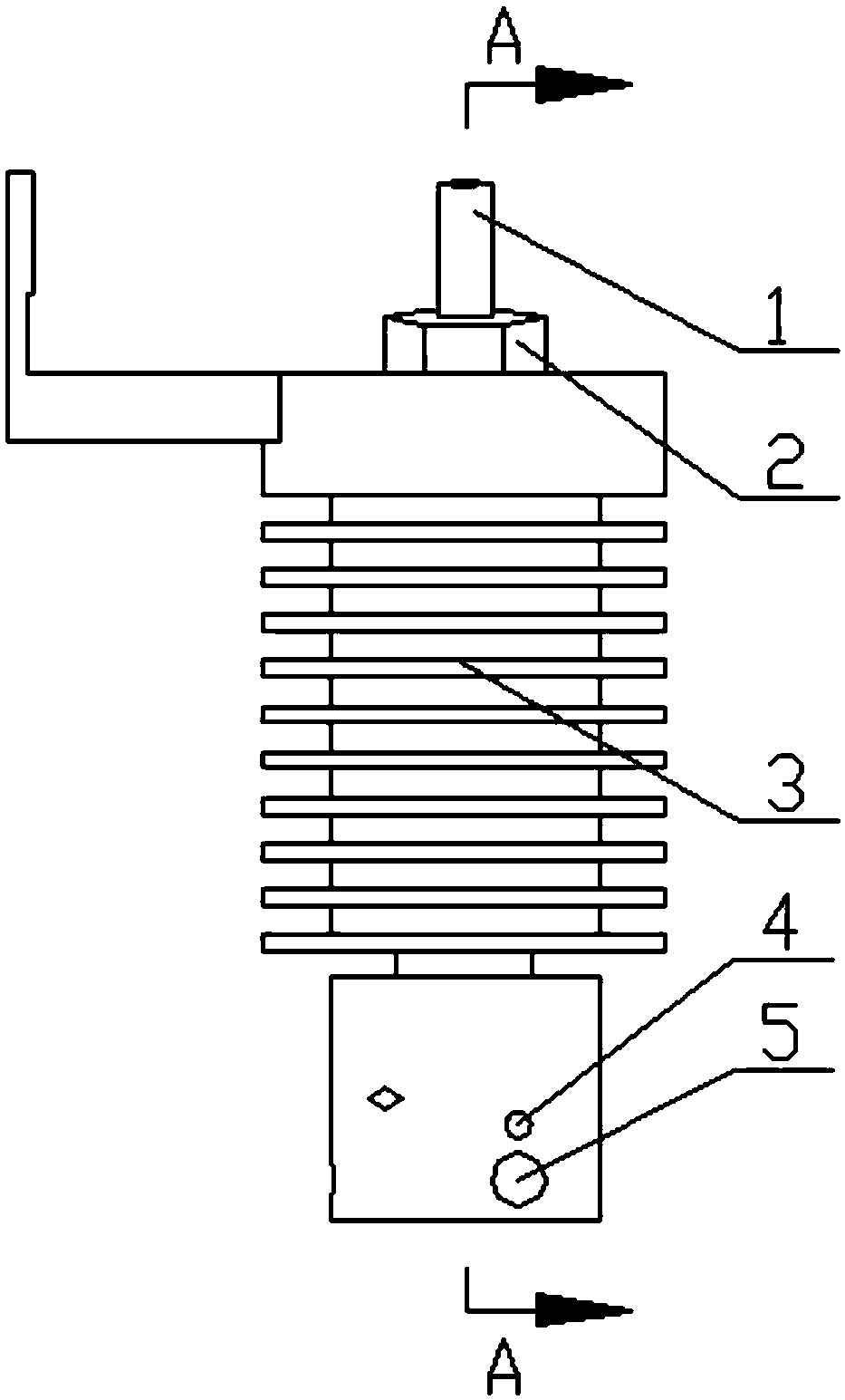

[0031] like figure 1 As shown, a continuous fiber reinforced composite material 3D printing device with a shearing mechanism includes a feeding interface module, a fiber and matrix material composite module 3, a fiber shearing module, and an extrusion nozzle 6; the feeding interface module plays a connecting role; the fiber The composite module with matrix material is used to melt the matrix material wire and composite with the fiber; the fiber cutting module is used to cut the fiber; the extrusion nozzle is used to extrude the material.

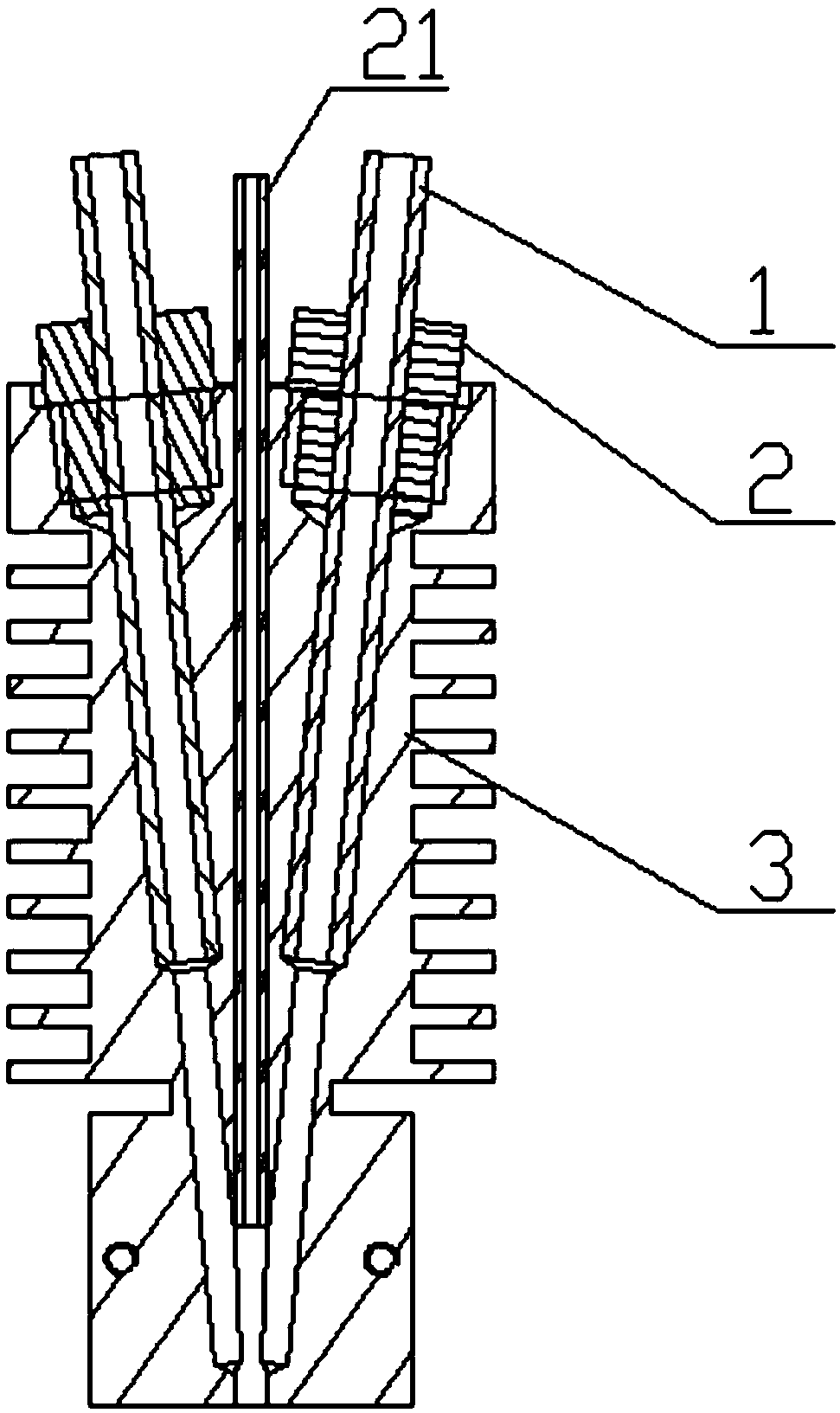

[0032] like figure 1 and image 3 As shown, the feeding interface module includes a base material supply hose 1, a connecting head 2, and a fiber conduit 21. One end of the base material supply hose 1 is connected to a commonly used 3D printing wire feeding mechanism, and the other end passes through the connecting head 2. Insert into the fiber and matrix material composite module 3 , the connector 2 is connected to the feed port of the fi...

Embodiment 2

[0044] There are three inclined material guide holes arranged inside the fiber and matrix material composite module (3), and the three inclined material guide holes are equally divided along the circumference and intersect with the vertical material guide holes to form a vertical "four-in-one" cavity.

[0045] The inclined angle of the inclined material guide hole is: the included angle with the vertical direction is 5°, the heating block and the heat dissipation block are detachably connected, and a heat insulation sheet is arranged between the heating block and the heat dissipation block. The rest are the same as in Example 1.

Embodiment 3

[0047] The number of the inclined guide holes is 1, and the inclination angle is 15°, and the rest are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com