A kind of anisotropic twisted fiber bundle and its preparation method and application

An anisotropic fiber bundle technology, applied in the field of anisotropic twisted fiber bundles and its preparation, can solve problems such as structure, mechanical and electrical properties that are rarely reported, and achieve excellent mechanical properties, good strength and toughness, fiber Effects with controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

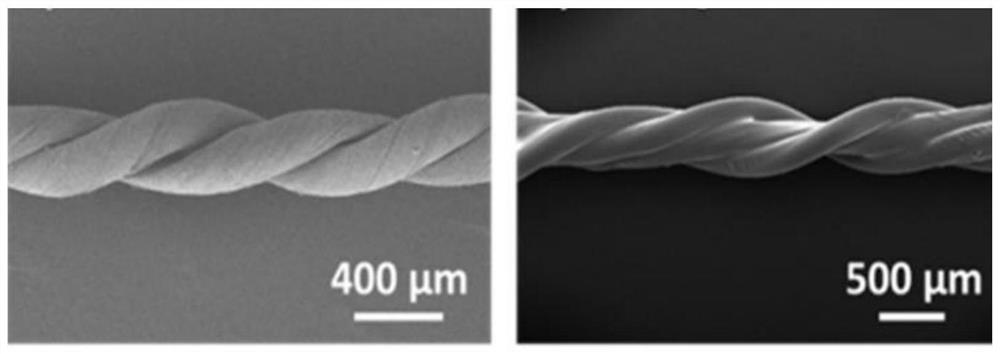

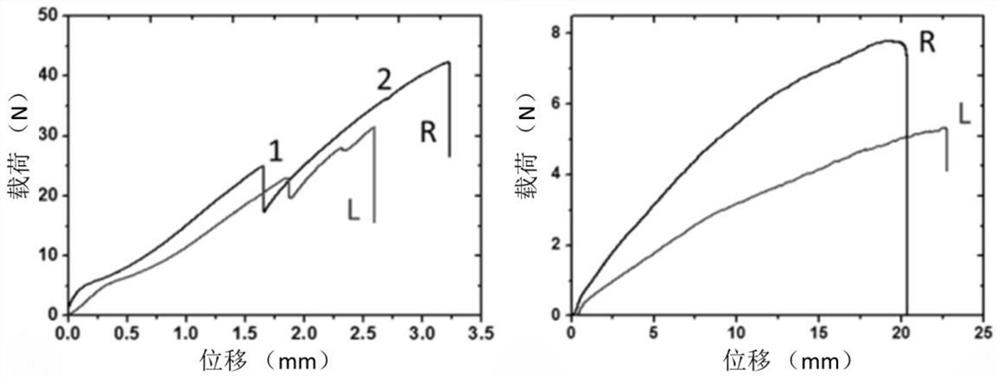

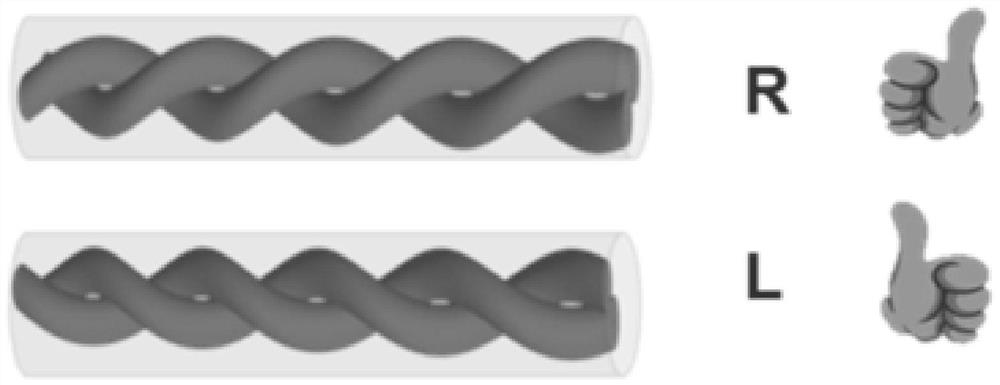

[0031] The PVDF fiber film was prepared by electrospinning, and the primary twisted fiber bundle was obtained by clockwise twisting method, the diameter of the single fiber was 100 nm, and the diameter of the primary twisted fiber bundle was 100 μm. The 2 primary twisted fiber bundles are double-twisted clockwise to obtain double-strand L-type twisted fiber bundles; The two primary twisted fiber bundles are double-twisted counterclockwise to obtain a double-strand R-type twisted fiber bundle. In the twisting process, the material GO is added by drip coating method, and the electrolyte PVA / H is added at the time of secondary twisting 3 PO 4 After reduction and post-treatment, the flexible capacitor device can be obtained. The mechanical properties of the obtained anisotropic fiber bundles were characterized, and the mechanical strength of the R-type structural fiber bundles was greater than that of the corresponding L-shaped fiber bundles. The mechanical fracture mode is smooth fra...

Embodiment 2

[0033] Using commercial cotton thread, the primary twisted fiber bundle is obtained by clockwise twisting method, and the diameter of the primary fiber bundle is 2 mm. The three primary twisted fiber bundles are double-twisted clockwise to obtain three L-shaped twisted fiber bundles; The three primary twisted fiber bundles were counterclockwise double-twisted to obtain three R-type twisted fiber bundles. By depositing Ni and GO during the twisting process, the battery device is obtained. The mechanical properties of the obtained anisotropic fiber bundles were characterized, and the mechanical strength of the R-type structural fiber bundles was greater than that of the corresponding L-shaped fiber bundles. The mechanical fracture mode is multi-stage jagged fracture. And the electrical properties of the two show obvious anisotropy.

Embodiment 3

[0035]Using wet-spun carbon fibers, the primary twisted fiber bundle is obtained by clockwise twisting method, the diameter of a single fiber is 500 nm, and the diameter of the primary twisted fiber bundle is 500 μm. The 2 primary twisted fiber bundles are double-twisted clockwise to obtain double-strand L-type twisted fiber bundles; The two primary twisted fiber bundles are double-twisted counterclockwise to obtain a double-strand R-type twisted fiber bundle. PPy is deposited during the twisting process, and electrolyte PVA / H is added at the time of secondary twisting 3 PO 4 , you can get the capacitor device. The mechanical properties of the obtained anisotropic fiber bundles were characterized, and the mechanical strength of the R-type structural fiber bundles was greater than that of the corresponding L-shaped fiber bundles. The mechanical fracture mode is smooth fracture. And the capacitive properties of the two show obvious anisotropy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com