Preparation method of nanoscale glass fiber and product thereof

A glass fiber and nano-scale technology, applied in the field of nano-scale glass fiber preparation, can solve the problems of complicated production process, complex raw material composition, unsuitable for industrial production, etc., and achieve good continuity, controllable fiber size, stable and single orientation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

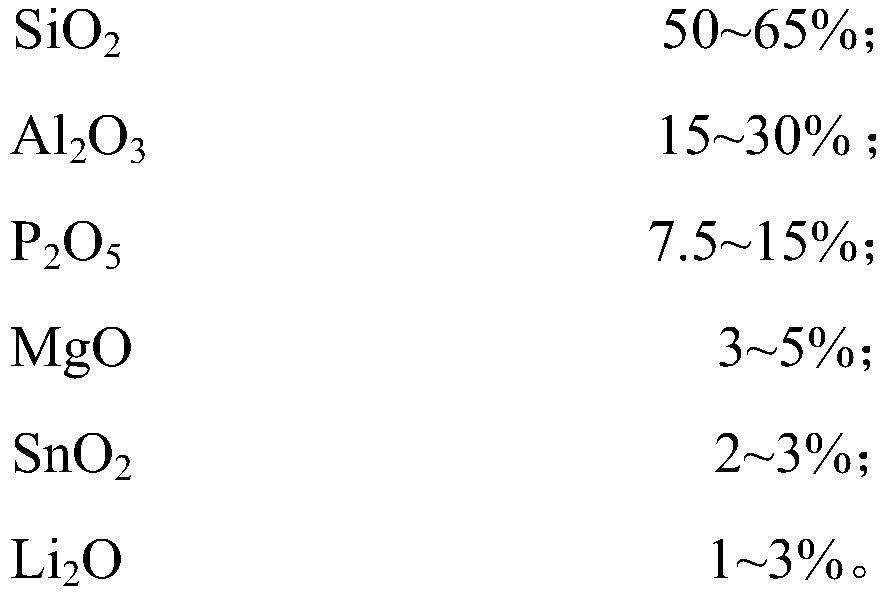

[0040] According to SiO 2 60%, Al 2 o 3 20%, P 2 o 5 10%, MgO4%, SnO 2 2%, Li 2 O3%, CeO 2 0.5% and TiO 2 The mass fraction ratio of 0.5% is accurately weighed, placed in a mixer and mixed evenly, then put into a glass high-temperature furnace, melted at 1500°C, and then the molten glass is supplied to the bushing device, and spinning and forming is performed at 1300°C , to obtain monofilament glass fibers with a diameter of 15 μm. The fiber was fixed in the conveying device, the fiber tip was heated by a laser and maintained at 1080°C, and the glass fiber was pulled by a platinum tip with a diameter of 30 nm to obtain nano glass fiber.

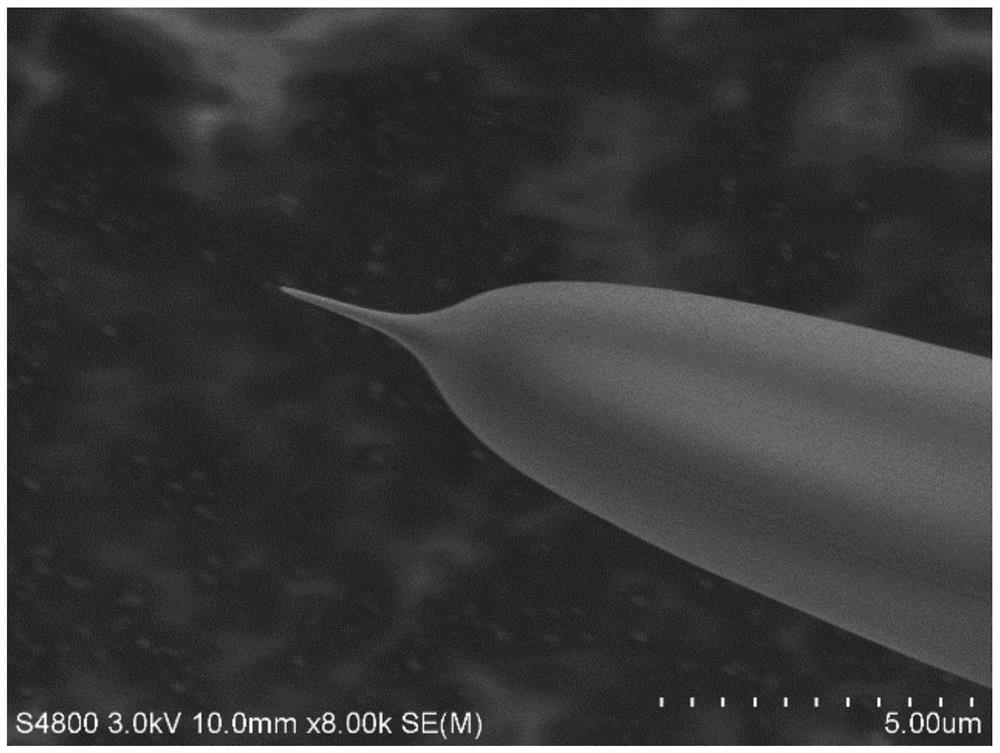

[0041] figure 1 It is the SEM photo of the forming process of micron glass fiber forming nano-glass fiber through secondary stretching in this embodiment, as can be seen from the figure, in the secondary stretching forming process, nano-glass fiber will not bend, thereby ensuring its The orientation is stable and single; and the s...

Embodiment 2

[0043] According to SiO 2 60%, Al 2 o 3 20%, P 2 o 5 10%, MgO4%, SnO 2 2%, Li 2 O3%, CeO 2 0.5% and TiO 2 0.5% mass fraction ratio is accurately weighed, placed in a mixer and mixed evenly, then put into a high-temperature glass furnace, melted at 1470°C, and then the molten glass is supplied to the bushing device, and spun and formed at 1350°C , to obtain monofilament glass fibers with a diameter of 10 μm. The fiber was fixed in the delivery device, the fiber tip was heated by a laser and maintained at 1100°C, and the glass fiber was pulled by a platinum tip with a diameter of 30 nm to obtain nano glass fiber.

Embodiment 3

[0045] According to SiO 2 65%, Al 2 o 3 18%, P 2 o 5 9%, MgO3.5%, SnO 2 2%, Li 2 O1.5%, CeO 2 1% mass fraction ratio is accurately weighed, placed in a mixer and mixed evenly, then put into a glass high-temperature furnace, melted at 1500 ° C, and then the molten glass is supplied to the bushing device, and spinning and forming at 1300 ° C , to obtain monofilament glass fibers with a diameter of 15 μm. The fiber was fixed in the conveying device, the fiber tip was heated by a laser and maintained at 1080°C, and the glass fiber was pulled by a platinum tip with a diameter of 30 nm to obtain nano glass fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com