Rare earth terbium complex and preparation method thereof

A technology of rare earth complexes and rare earth salts, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of weak adsorption force, easy detachment and aggregation, high solubility of rare earth complexes, etc., and achieves the effect of improving the fluorescence lifetime and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Weigh 10g of terbium oxide in a beaker, pour 80ml of deionized water into the beaker, then slowly alternately add concentrated hydrochloric acid and hydrogen peroxide dropwise into the beaker, and then add an appropriate amount of hydrochloric acid to react until the solution is clear. Evaporate the solvent while stirring at 90°C. After a crystal film appears and covers the liquid surface, the reaction system is cooled, and a large amount of crystals are precipitated. After the crystals are filtered out with a Buchner funnel, terbium chloride is obtained. Dry at room temperature for later use.

[0061] Weigh 0.1 anhydrous sodium carbonate and place it in a 100mL beaker, add 15mL of absolute ethanol and disperse by ultrasonic vibration in an ultrasonic instrument for one hour.

[0062] Then weigh 0.5 mmol of dried terbium chloride and 1.5 mmol of acetylsalicylic acid into a beaker, and place the beaker on a magnetic stirrer to stir for 2 hours.

[0063] Finally, a solid...

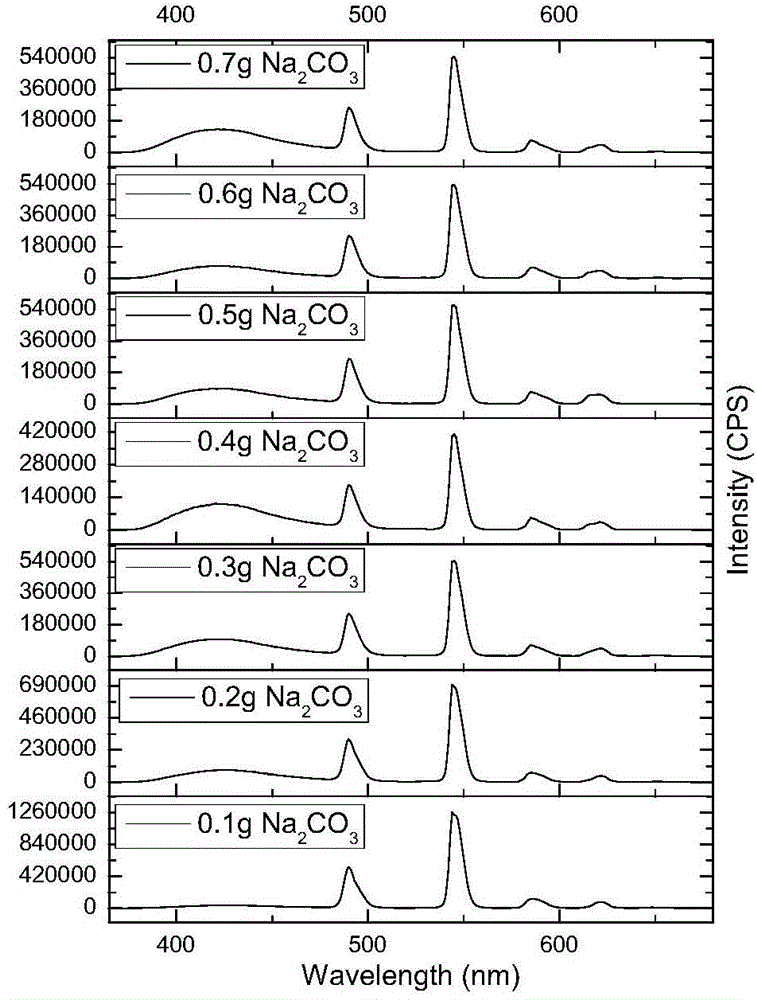

Embodiment 2-7

[0065] Repeat Example 1, the only difference is to change the quality of anhydrous sodium carbonate to 0.2g, 0.3g, 0.4g, 0.5g, 0.6g, 0.7g respectively, to obtain the composite rare earth terbium complexes, whose characterization is shown in the following experimental example 1 -6.

Embodiment 8-15

[0067] Repeat Examples 1-7 respectively, the only difference is that commercially available terbium chloride is used as a raw material to finally obtain a composite rare earth terbium complex, its emission spectrum, excitation spectrum, infrared spectrum, fluorescence microscope photos, fluorescence emission intensity 1. The experimental results of the average fluorescence lifetime are similar to those of Examples 1-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com