Metal propellant storage tank for spaceflight and manufacturing method thereof

The technology of a propellant storage tank and its manufacturing method is applied in the metal propellant storage tank for aerospace and its manufacturing field, which can solve the problems of high cost, failure to solve product lightweight design, and inability to meet storage tank lightweight design requirements, etc. problems, to achieve the effect of improving material performance, realizing lightweight design, and improving differential pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

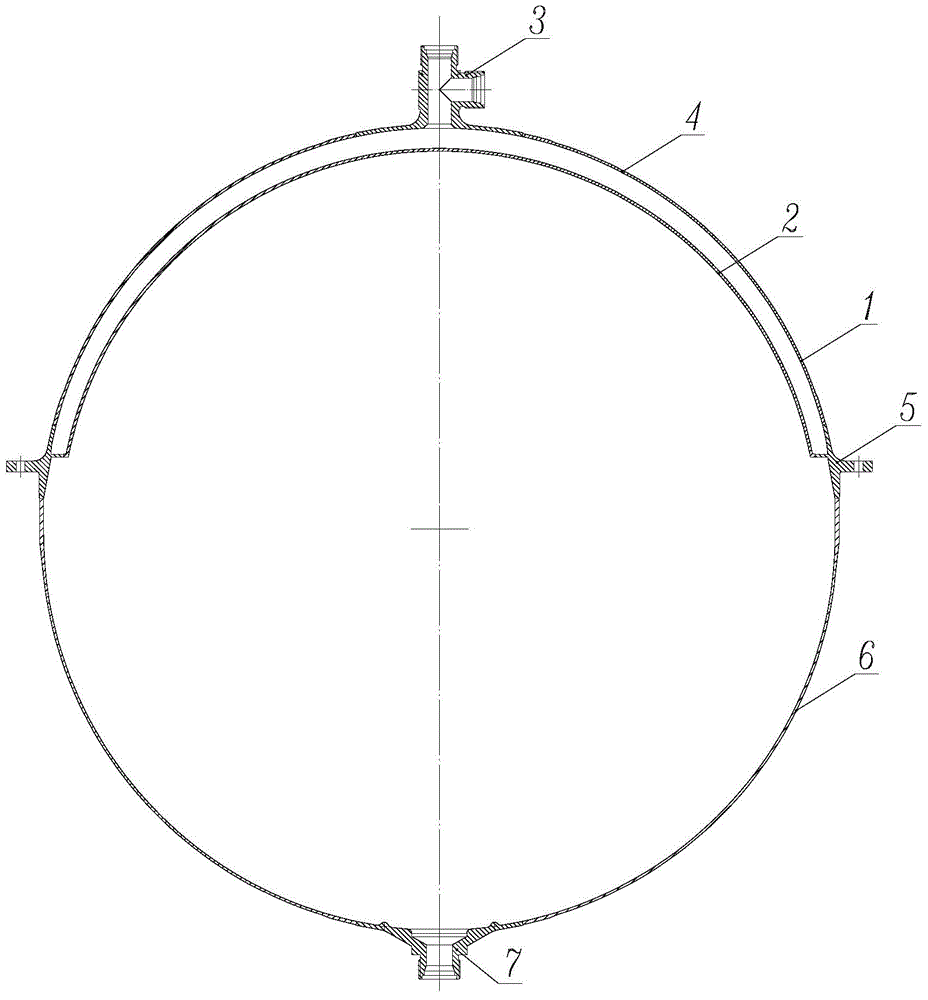

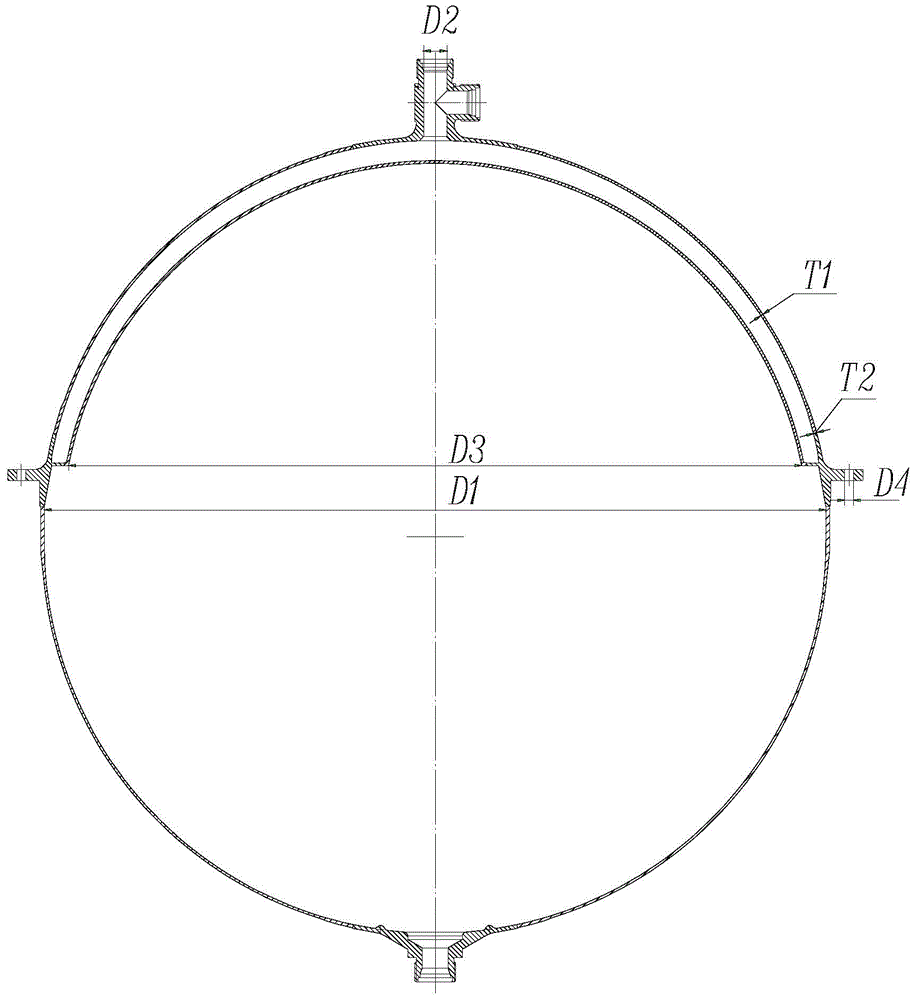

[0035] Please also see Figure 1 to Figure 2 .

[0036] This embodiment provides an aerospace metal propellant storage tank using a 5B70 aluminum-magnesium-scandium alloy, including a casing 1 and a metal diaphragm 2, and the casing 1 includes a gas path nozzle 3, an upper hemisphere 4, and a connecting ring 5. The lower hemisphere 6 is connected to the liquid circuit nozzle 7, the upper hemisphere 4 and the lower hemisphere 6 are connected through the connecting ring 5, the gas circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com