Alloy single atom catalyst for selective hydrogenation of alkyne

A catalyst and alloy technology, which is applied in the preparation of catalysts and the research field of alkyne selective hydrogenation activity, can solve the problems of high ethylene selectivity and high selective hydrogenation activity, and achieve high ethylene selectivity, high hydrogenation activity, Reduce the effect of caloric variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] APTES Modified SiO 2 Carrier:

[0035] Measure 400 mL of ethanol into a 500 mL three-necked flask with a graduated cylinder, and then add 20.00 g of 3-aminopropyltriethoxysilane (APTES) to prepare a solution. Accurately weigh 8.00gSiO 2 , added to the above solution. The three-neck flask was placed in a water bath, stirred magnetically, and refluxed at 80°C for 24h. Then, filter, wash with ethanol, and dry in an oven at 60°C for 6h. APTES modified SiO 2 carrier.

Embodiment 2

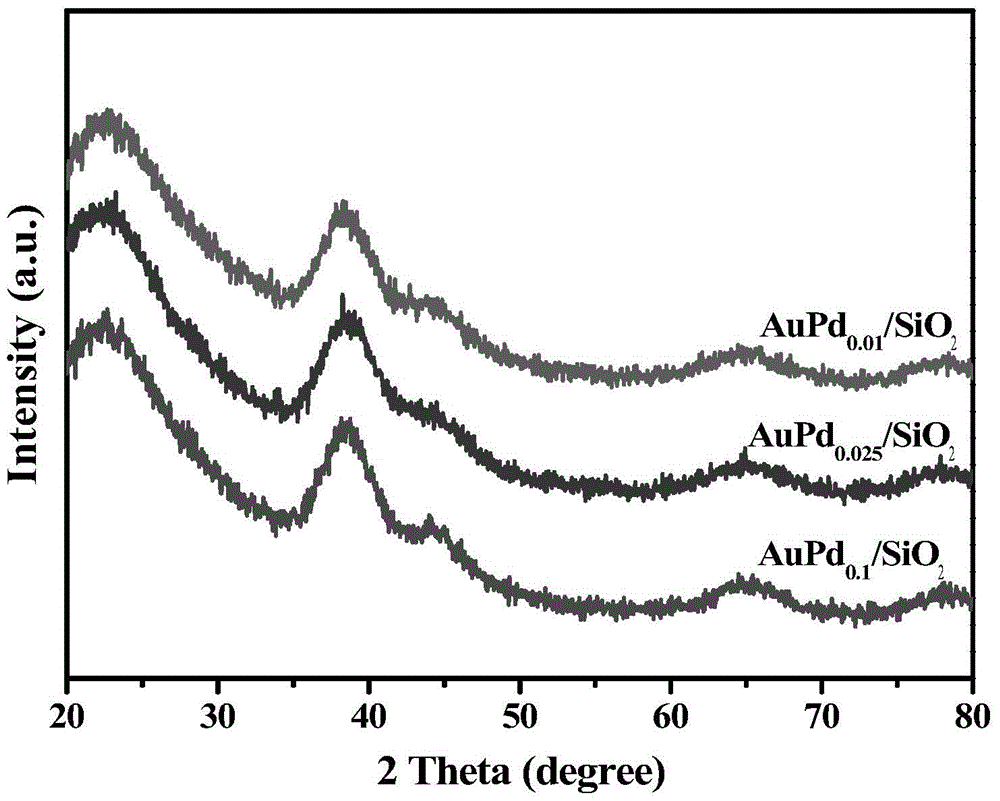

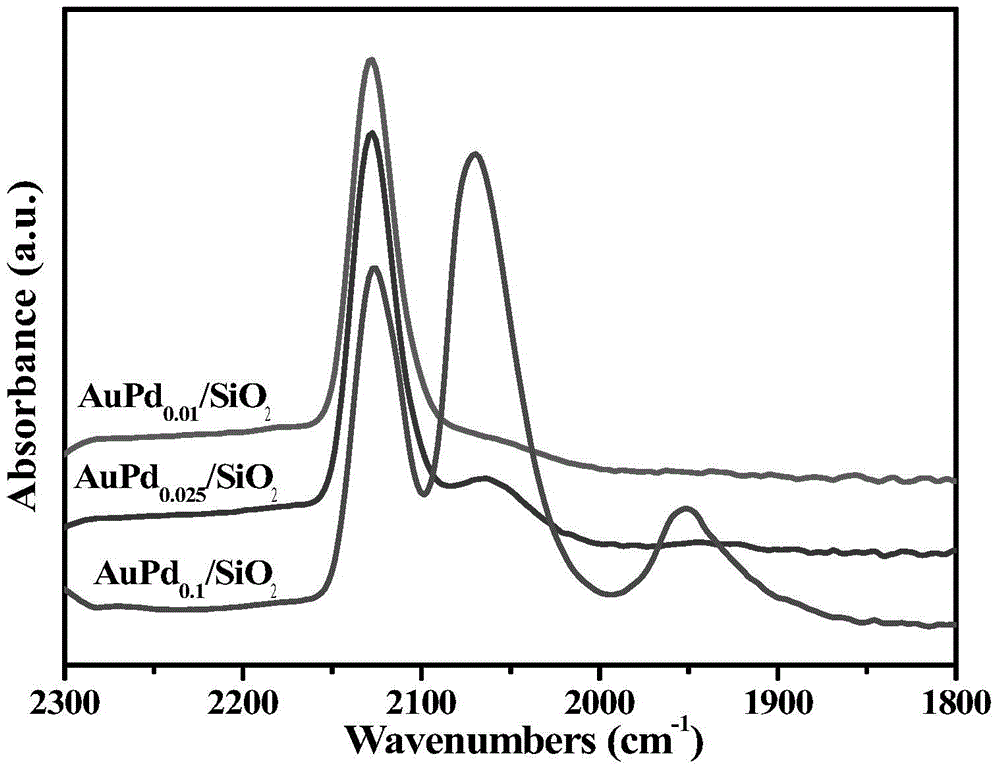

[0037] AuPd 0.01 / SiO 2 Catalyst preparation:

[0038] At room temperature (~25°C), measure 5.23mL (9.56mg / mL) HAuCl 4 Add water to the solution to 20mL, stir well and add 1.0g APTES-modified SiO 2 Carrier, continue to stir for 30min to make HAuCl 4 Adsorbed on the surface of the carrier, after filtering and washing, redisperse it in 20mL of 0.1M NaBH 4 in aqueous solution. After stirring, filter and wash until AgNO 3 Cl cannot be detected - . The resulting precursor was redispersed to 0.14 mL (2 mg / mL) Pd(NO 3 ) 2 In the 20mL solution prepared by the solution, after stirring, filtering and washing, repeat the above NaBH 4 Restore step. Finally, it is dried at 80°C for 10h and calcined at 500°C for 6h to obtain AuPd 0.01 / SiO 2 bimetallic catalyst. The theoretical loading of Au was maintained at 5%, and the Pd / Au molar ratio was 0.01.

Embodiment 3

[0040] AuPd 0.025 / SiO 2 Catalyst preparation:

[0041] At room temperature (~25°C), measure 5.23mL (9.56mg / mL) HAuCl 4 Add water to the solution to 20mL, stir well and add 1.0g APTES-modified SiO 2 Carrier, continue to stir for 30min to make HAuCl 4 Adsorbed on the surface of the carrier, after filtering and washing, redisperse it in 20mL of 0.1M NaBH 4 in aqueous solution. After stirring, filter and wash until AgNO 3 Cl cannot be detected - . The resulting precursor was redispersed to 0.34 mL (2 mg / mL) Pd(NO 3 ) 2 In the 20mL solution prepared by the solution, after stirring, filtering and washing, repeat the above NaBH 4 Restore step. Finally, it is dried at 80°C for 10h and calcined at 500°C for 6h to obtain AuPd 0.025 / SiO 2 bimetallic catalyst. The theoretical loading of Au was maintained at 5%, and the Pd / Au molar ratio was 0.025.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com