Multilayer composite metal oxide catalyst and preparation method thereof

A multi-layer composite and catalyst technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, organic compound preparation, etc., can solve the problem that the catalyst can no longer provide higher activity and reduce the catalyst reactivity , loading, dismantling, separation, catalyst recovery troubles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

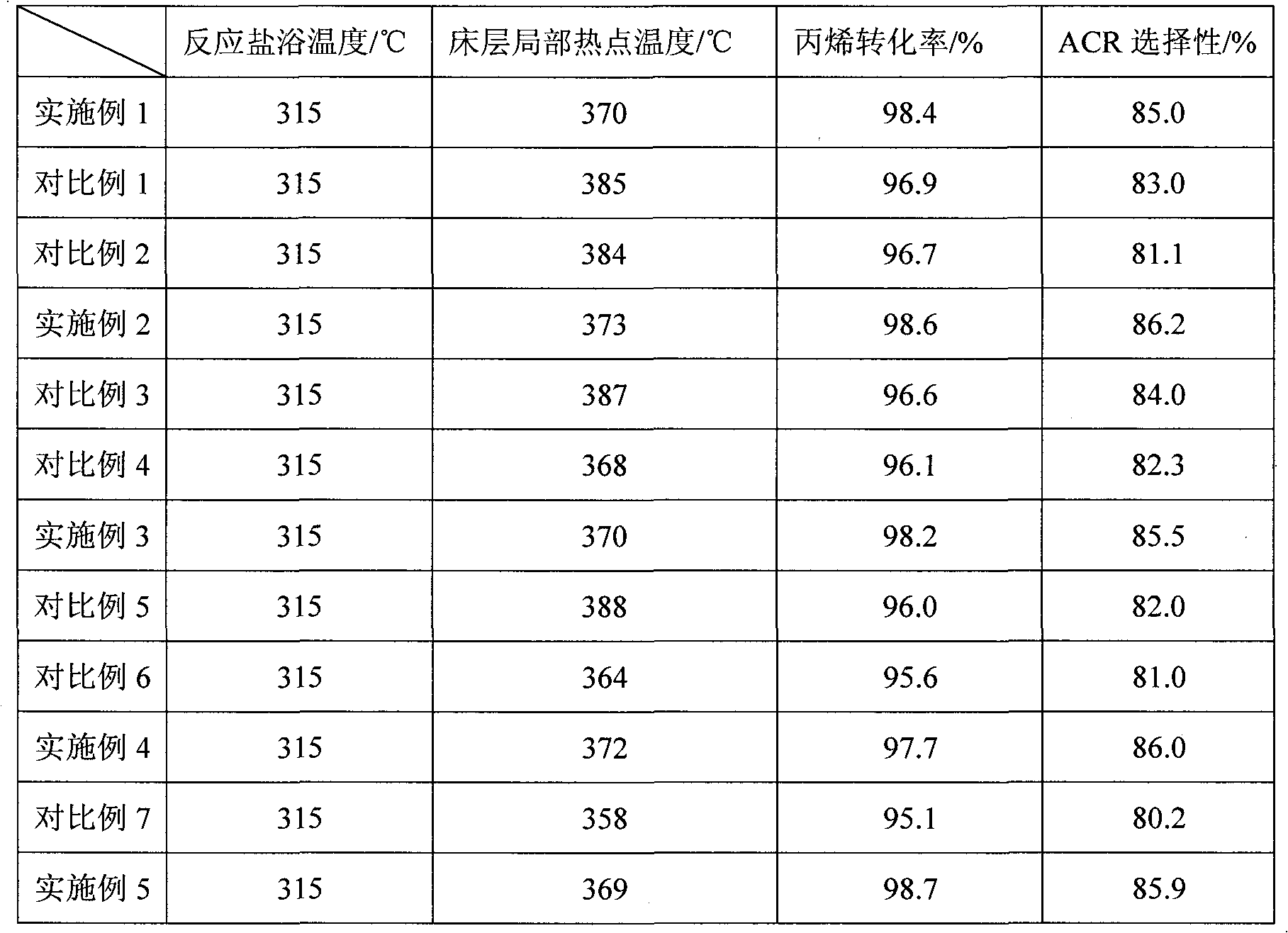

Embodiment 1

[0032] Preparation of Catalyst 1

[0033] Step 1: Prepare catalyst inner layer matrix

[0034] (1) Preparation of active component slurry (a)

[0035] Under stirring conditions, take 1147.6 grams of ammonium molybdate and 243.7 grams of cesium nitrate and dissolve them in 1000ml of pure water (water temperature above 65°C) to obtain a slurry (1), then take 1358.3 grams of bismuth nitrate and 407 grams of copper nitrate, and add 1000ml of pure water, fully stirred and mixed evenly to obtain slurry (2). Take 776 grams of nickel acetate and dissolve it in 1000 ml of pure water (water temperature above 65° C.) under stirring to obtain slurry (3). Then, the slurry (1) was mixed with the slurry (2), and then 50 grams of ammonia were added to obtain the slurry (4). After 20 minutes, the slurry (3) was slowly added to the slurry (4), and 91.9 grams of titanium dioxide were added simultaneously, 80 °C vigorously stirred for 2 hours.

[0036] (2) Preparation of auxiliary material sl...

Embodiment 2

[0054] Preparation of Catalyst 2

[0055] Step 1: Prepare catalyst inner layer matrix

[0056] (1) Preparation of active component slurry (a)

[0057] Under stirring conditions, take 1235.9 grams of ammonium molybdate and 97.5 grams of cesium nitrate and dissolve them in 1000ml of pure water (water temperature above 65°C) to obtain a slurry (1), then take 970 grams of bismuth nitrate and 599 grams of copper acetate, and add 1000ml of pure water, fully stirred and mixed evenly to obtain slurry (2). Then take 465.3 grams of nickel nitrate and dissolve it in 1000 ml of pure water (water temperature above 65° C.) with stirring to obtain slurry (3). Then, the slurry (1) was mixed with the slurry (2), and then 50 grams of ammonia were added to obtain the slurry (4). After 20 minutes, the slurry (3) was slowly added to the slurry (4), and 24 grams of titanium dioxide were added simultaneously, 80 °C vigorously stirred for 2 hours.

[0058] (2) Preparation of auxiliary material sl...

Embodiment 3

[0076] Step 1: Prepare catalyst inner layer matrix

[0077] (1) Preparation of active component slurry (a)

[0078] Under stirring conditions, take 1103.4 grams of ammonium molybdate and 97.5 grams of cesium nitrate and dissolve them in 1000ml of pure water (water temperature above 65°C) to obtain a slurry (1), then take 1940 grams of bismuth nitrate and 209.3 grams of copper nitrate, and add 1000ml of pure water, fully stirred and mixed evenly to obtain slurry (2). Then take 363.8 grams of nickel acetate and dissolve it in 1000 ml of pure water (water temperature above 65° C.) with stirring to obtain slurry (3). Then, the slurry (1) was mixed with the slurry (2), and then 60 grams of ammonia were added to obtain the slurry (4). After 20 minutes, the slurry (3) was slowly added to the slurry (4), and 47.9 grams of titanium dioxide were added simultaneously, 80 °C vigorously stirred for 2 hours.

[0079] (2) Preparation of auxiliary material slurry (b)

[0080] Under heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com