Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Maintain corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

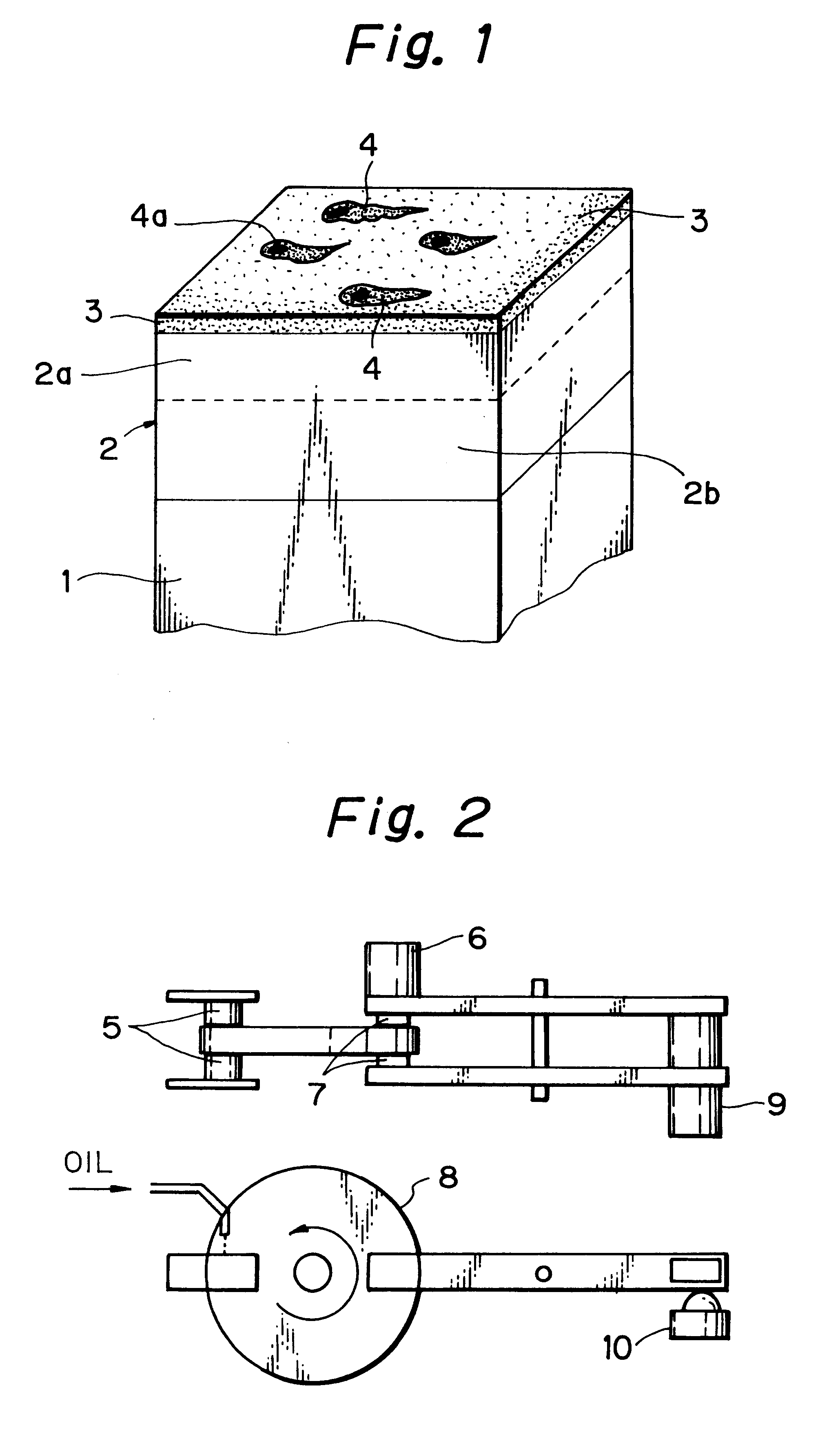

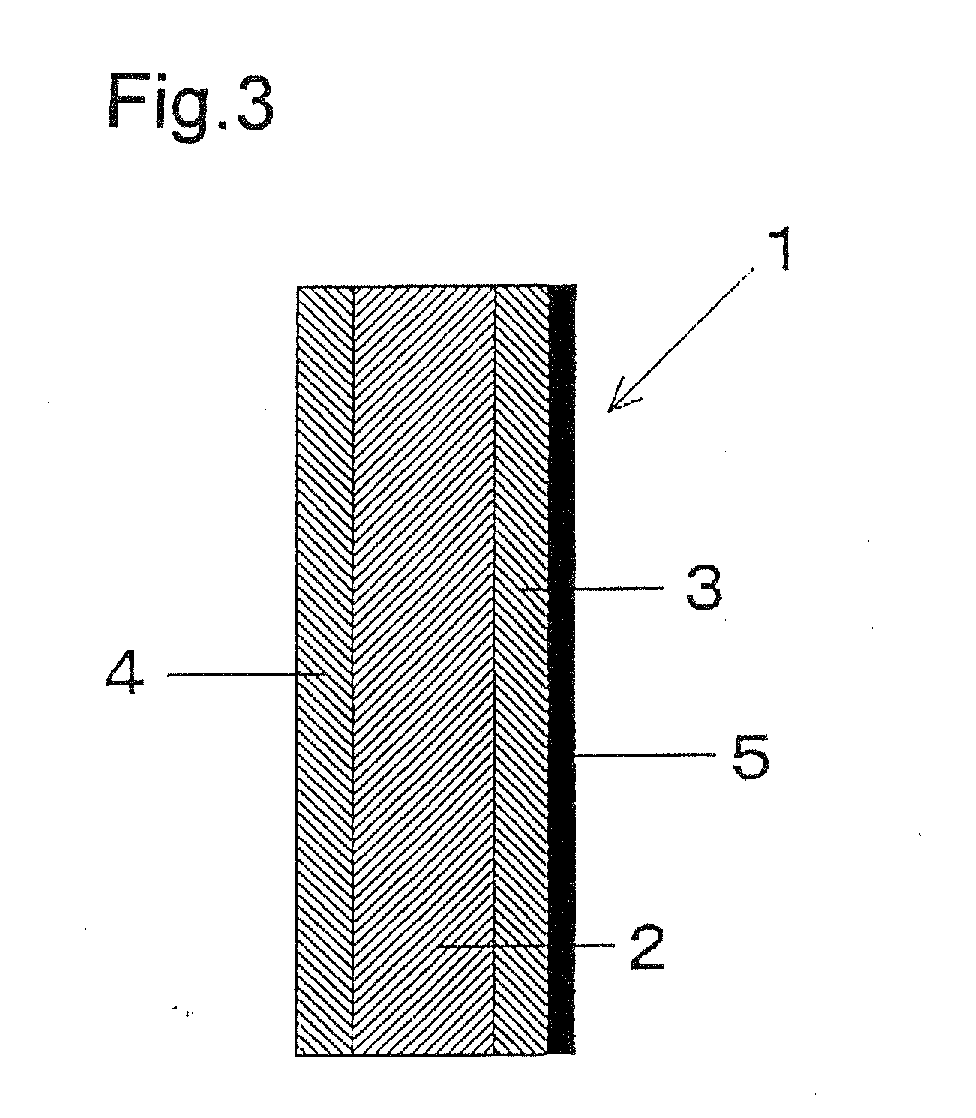

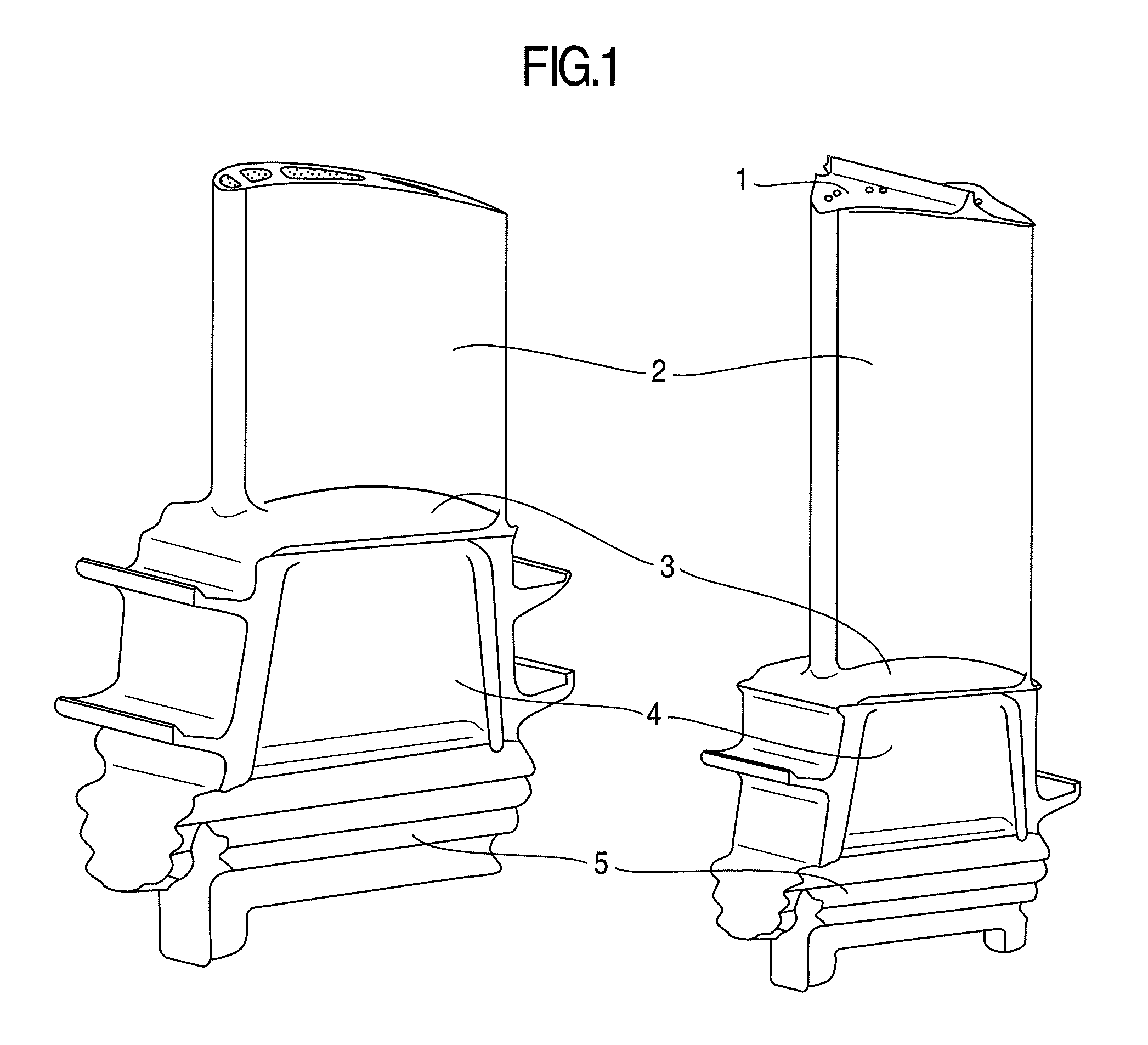

Copper alloy and sliding bearing having improved seizure resistance

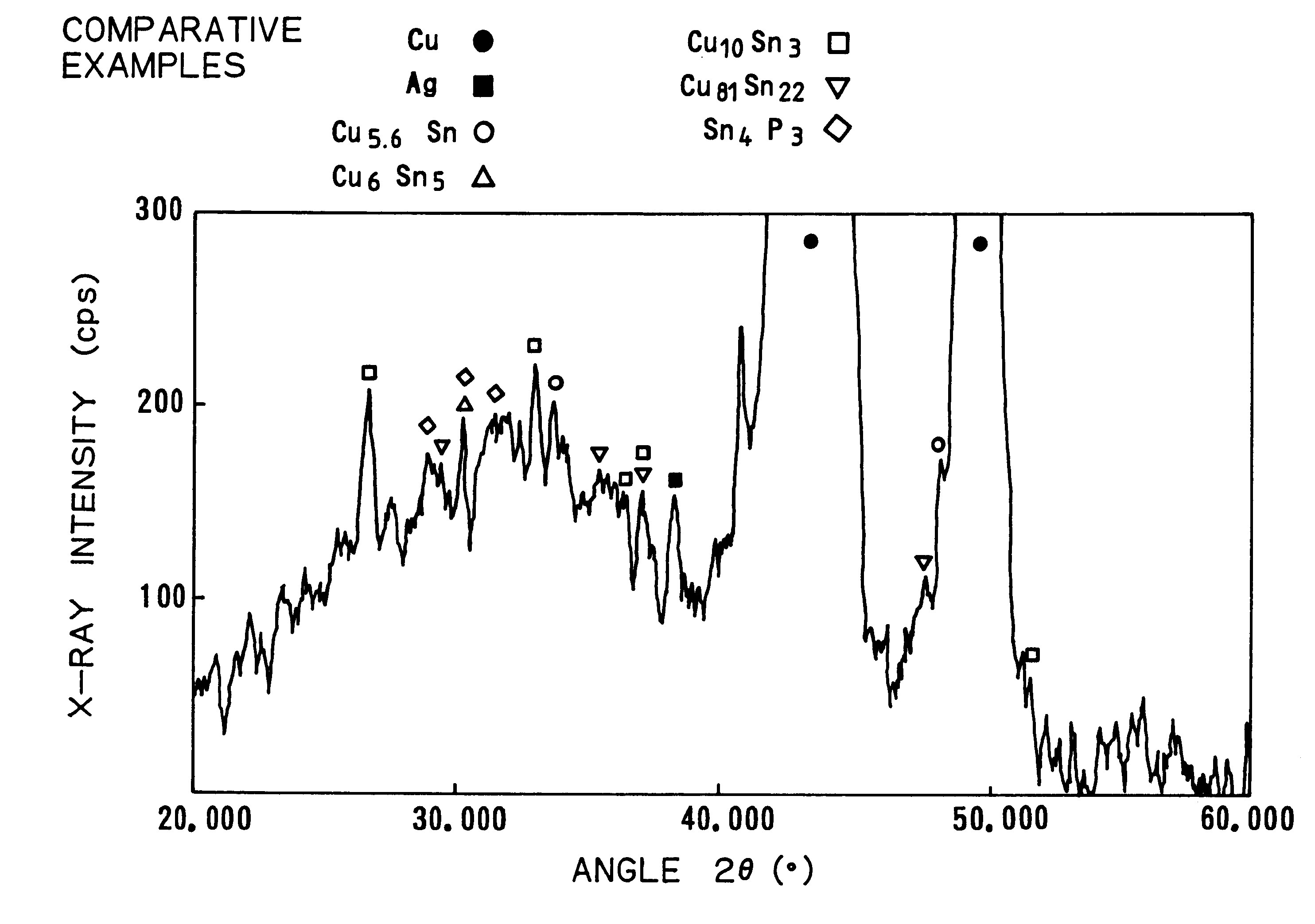

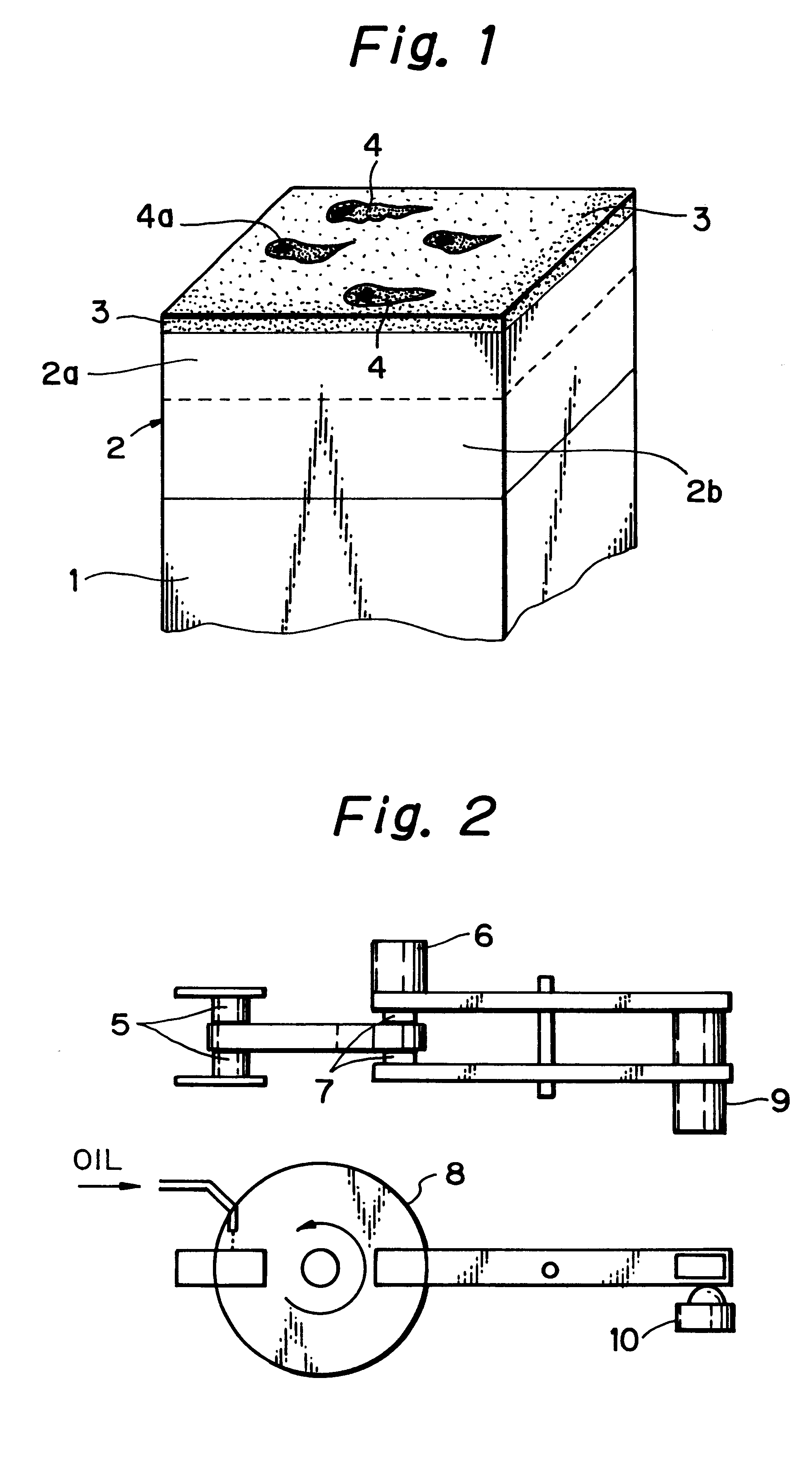

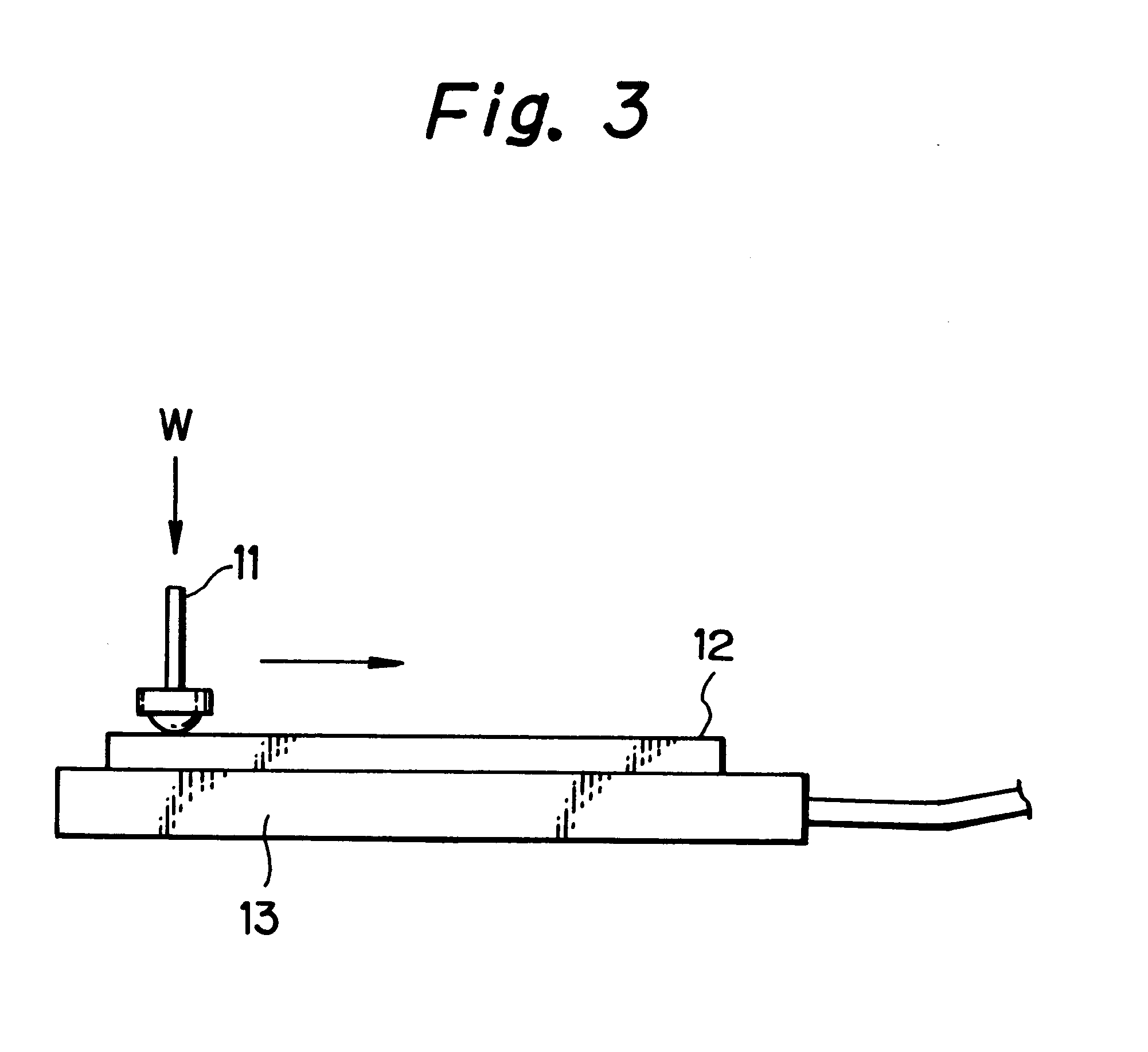

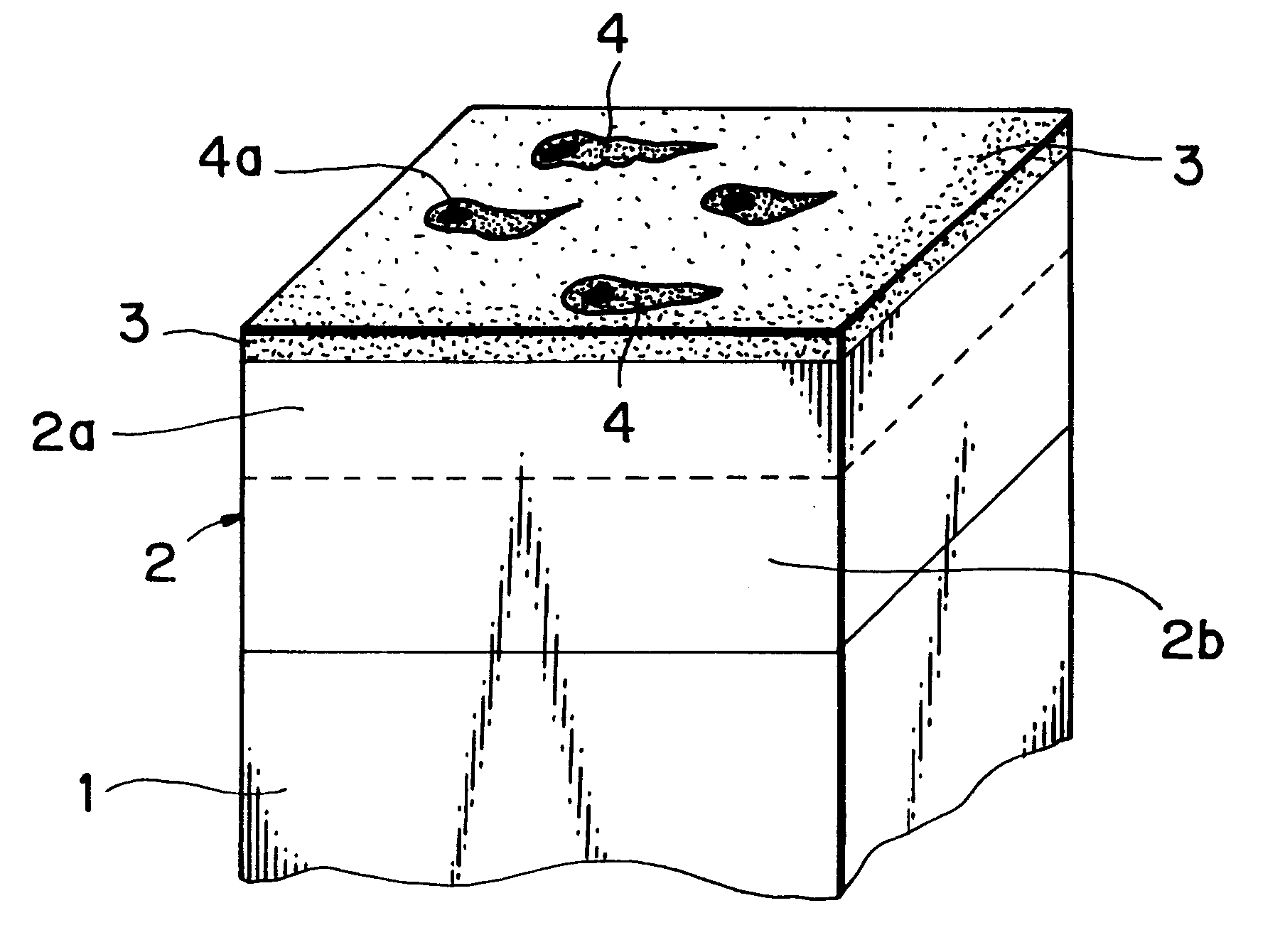

InactiveUS6254701B1Improved seizure resistanceMaintain corrosion resistanceBearing componentsSolid state diffusion coatingSolid solutionMetal

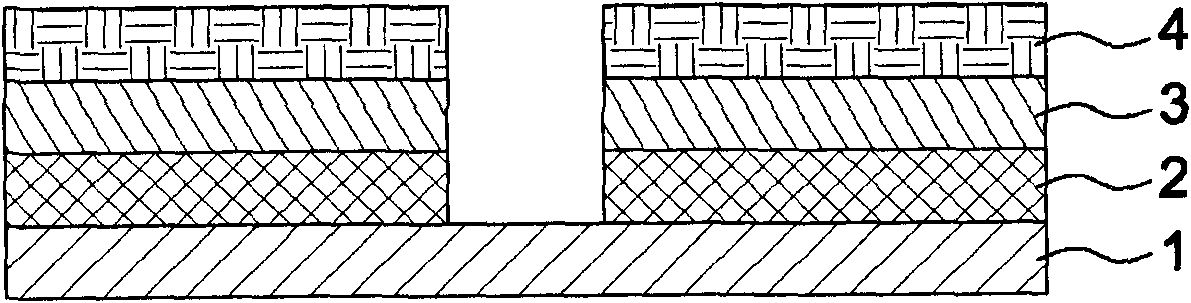

A sliding bearing having improved seizure resistance has the following structure.(a) A bearing layer (2). It comprises a copper alloy containing in a Cu matrix Ag, Sn, Sb, In, Mn, Fe, Bi, Zn, Ni and / or Cr.(b) A fisrst sub-layer (3) of the bearing layer (2). It (3) contains concentrated element, hexagonal compound or eutectic of said element(s).(c) A second sub-layer (2a) in which said element in essential solid-solution state.(d) Metal backing (1).

Owner:LUCENT TECH INC +1

Copper alloy and sliding bearing having improved seizure resistance

InactiveUS6348114B1Improved seizure resistanceMaintain corrosion resistanceBearing componentsFurnace typesChemical compoundSolid solution

Owner:TAIHO INDUSTRIES CO LTD

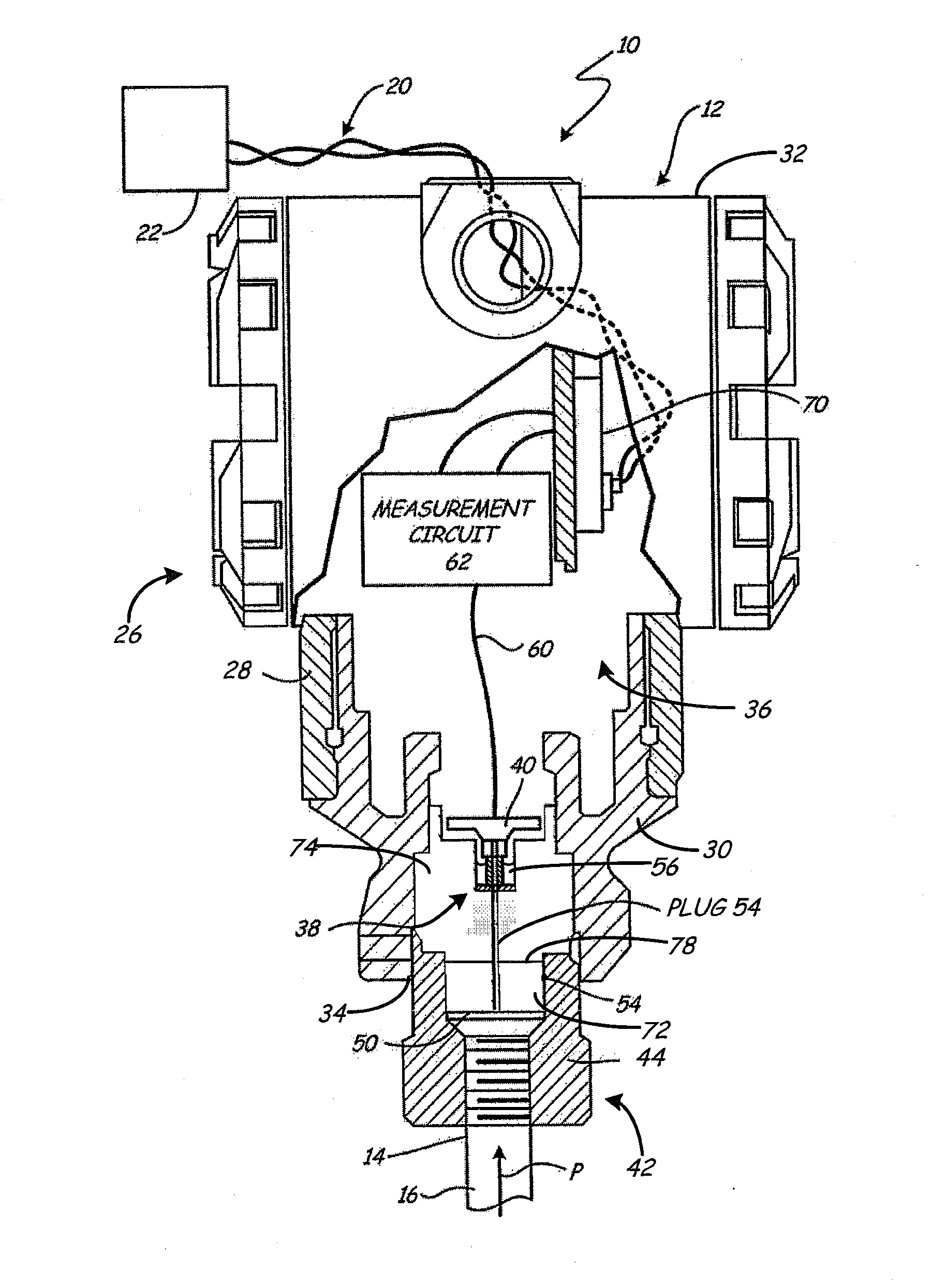

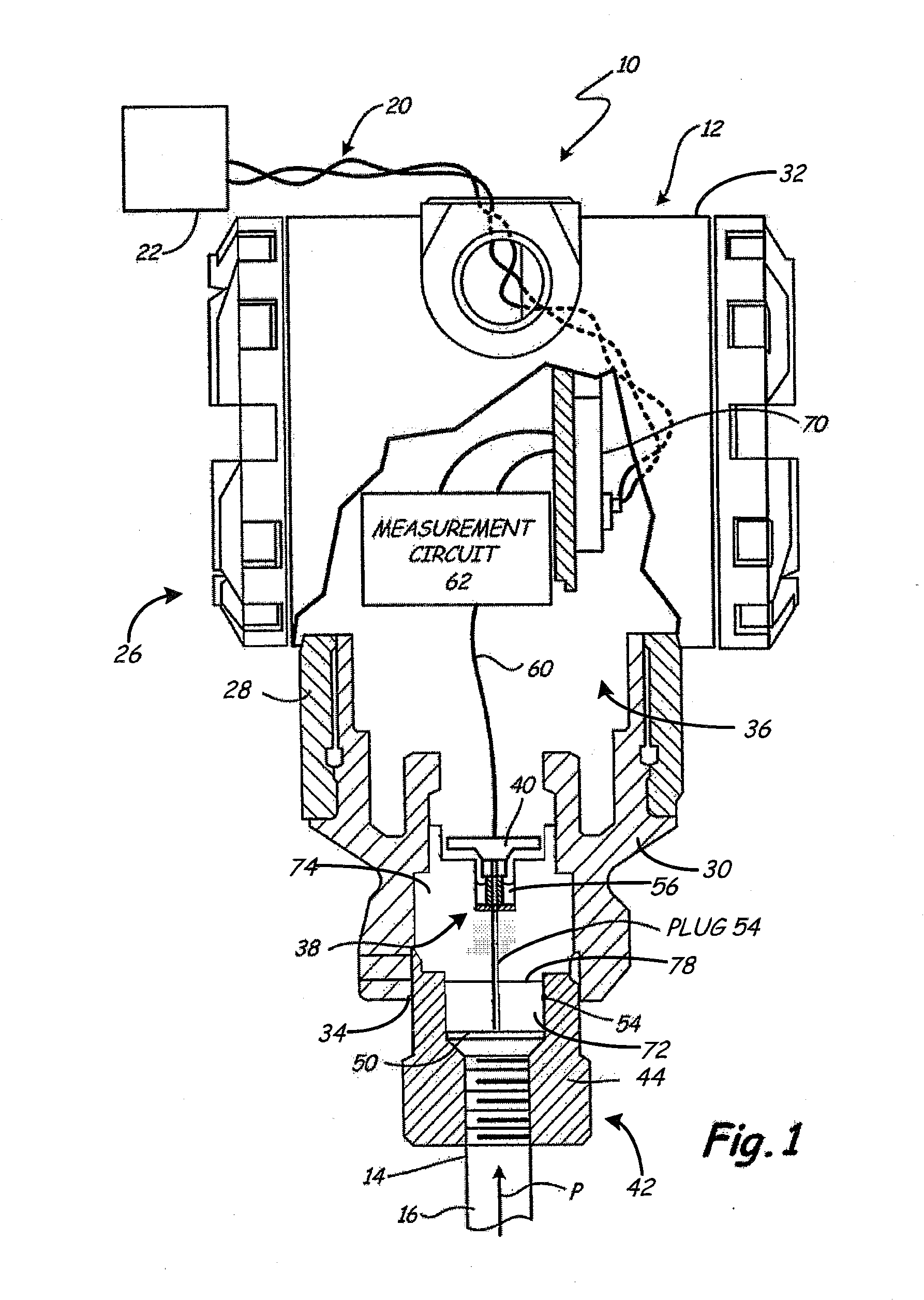

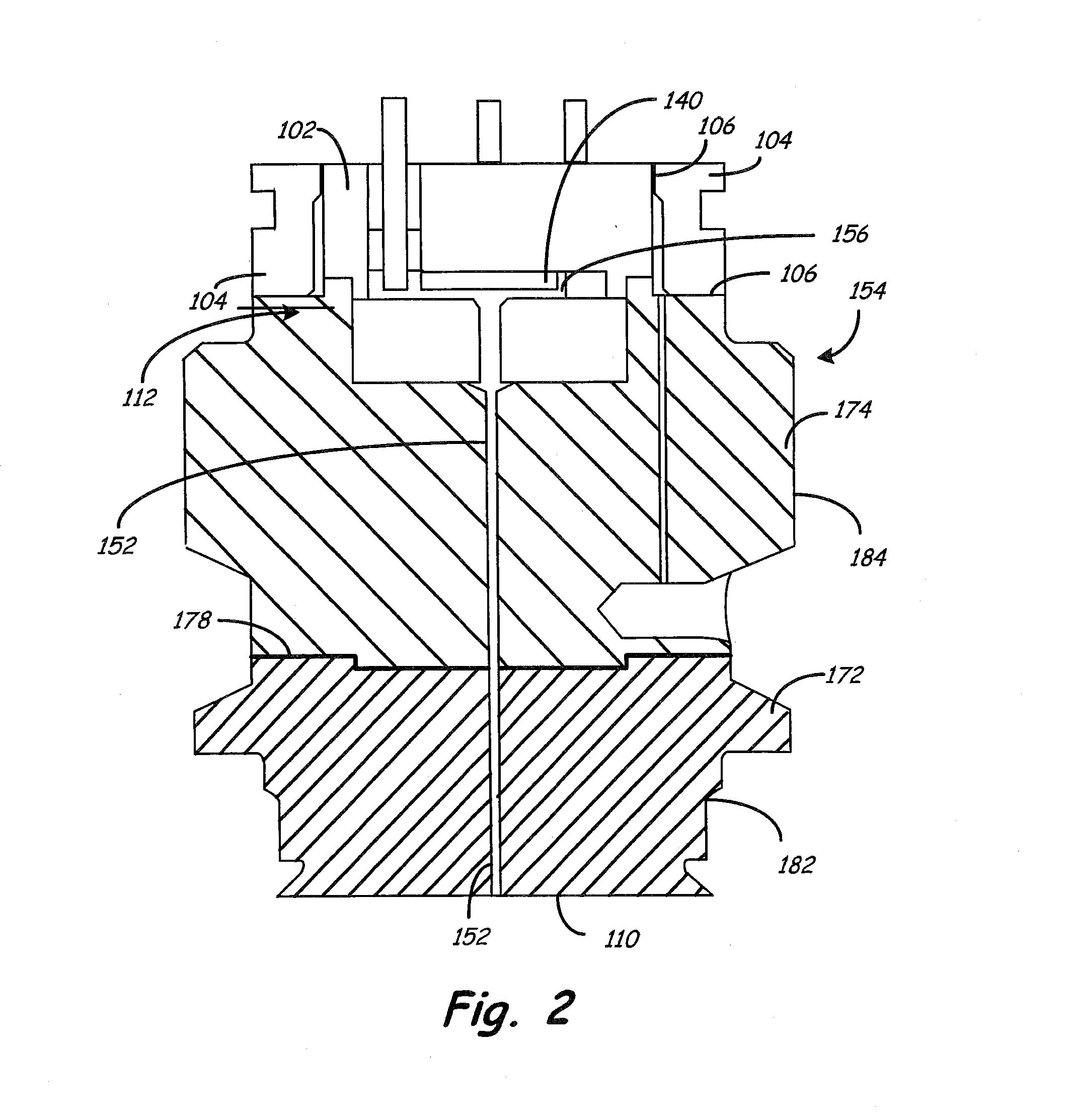

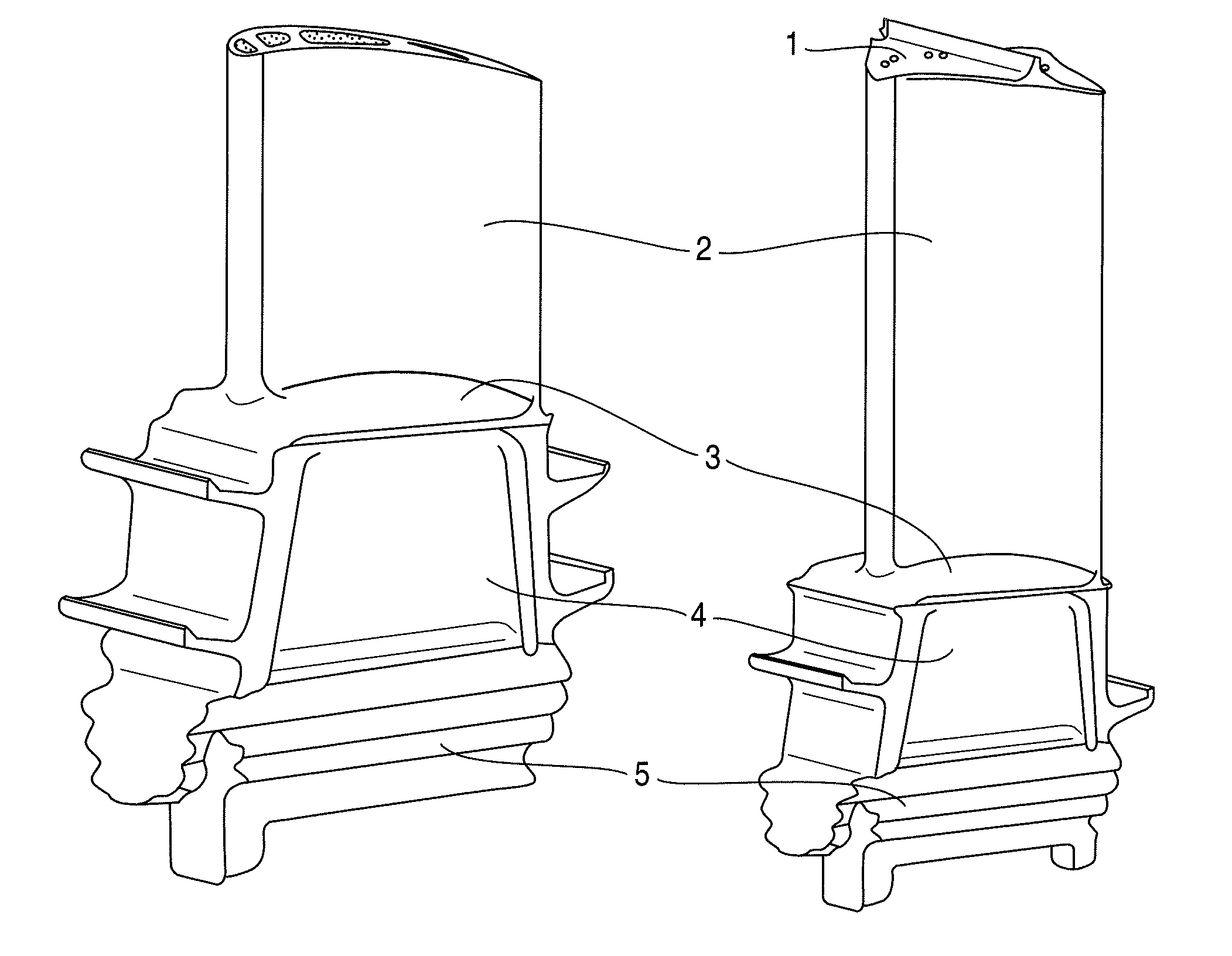

Pressure transmitter having an isolation assembly with a two-piece isolator plug

ActiveUS20150020600A1Maintain corrosion resistanceReduce material costsFluid pressure measurement by mechanical elementsProduction lineCapillary fill

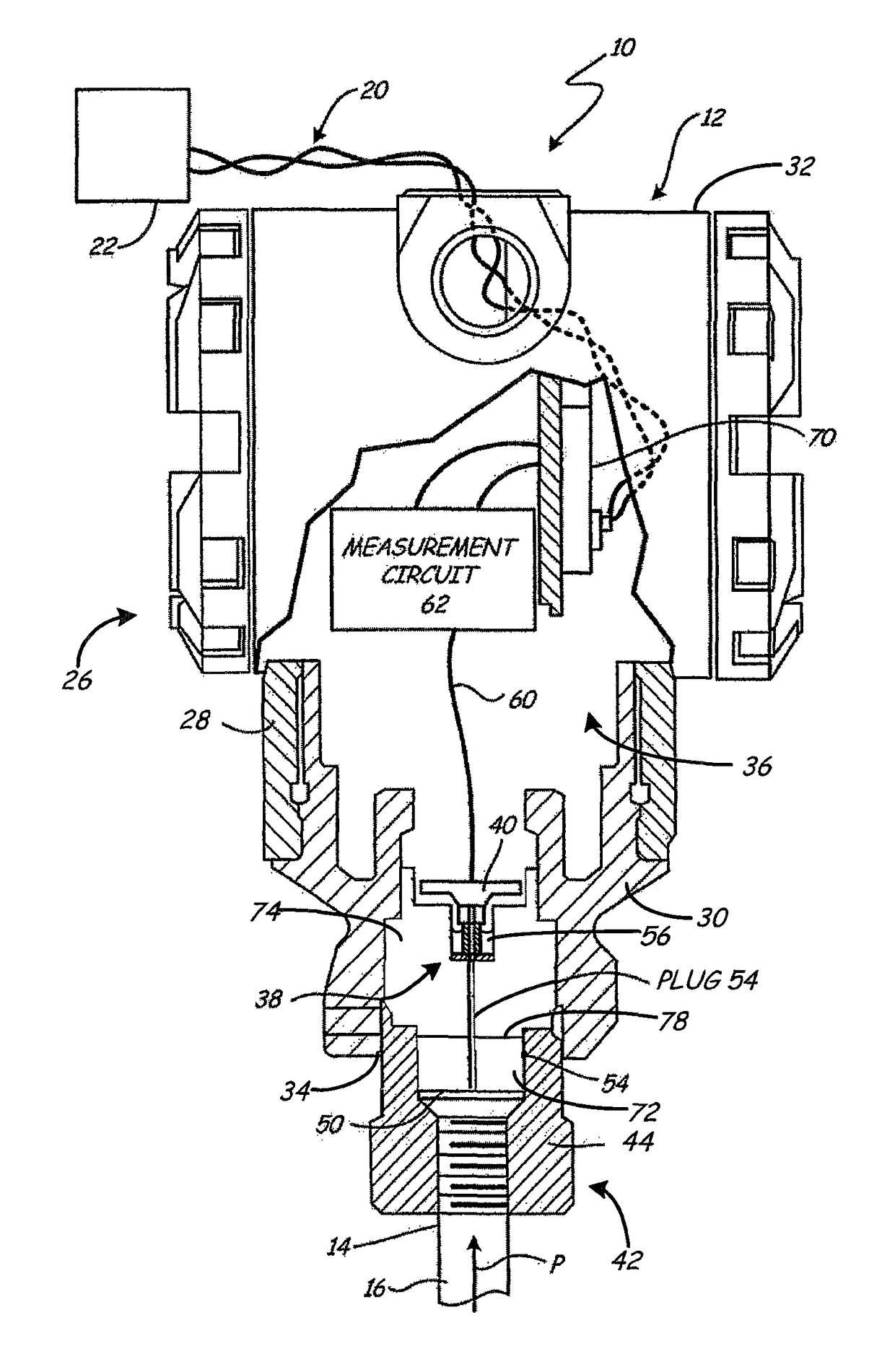

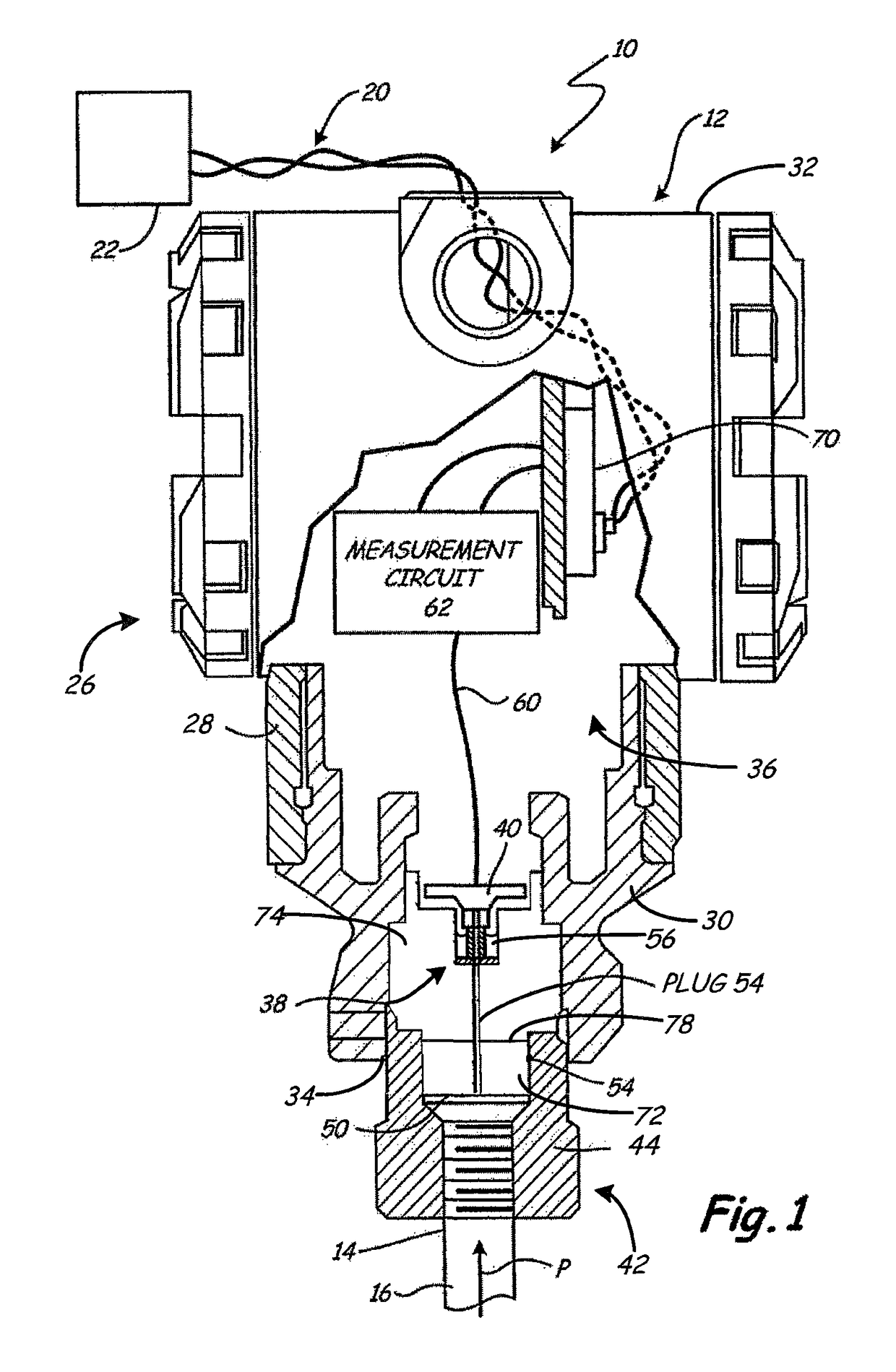

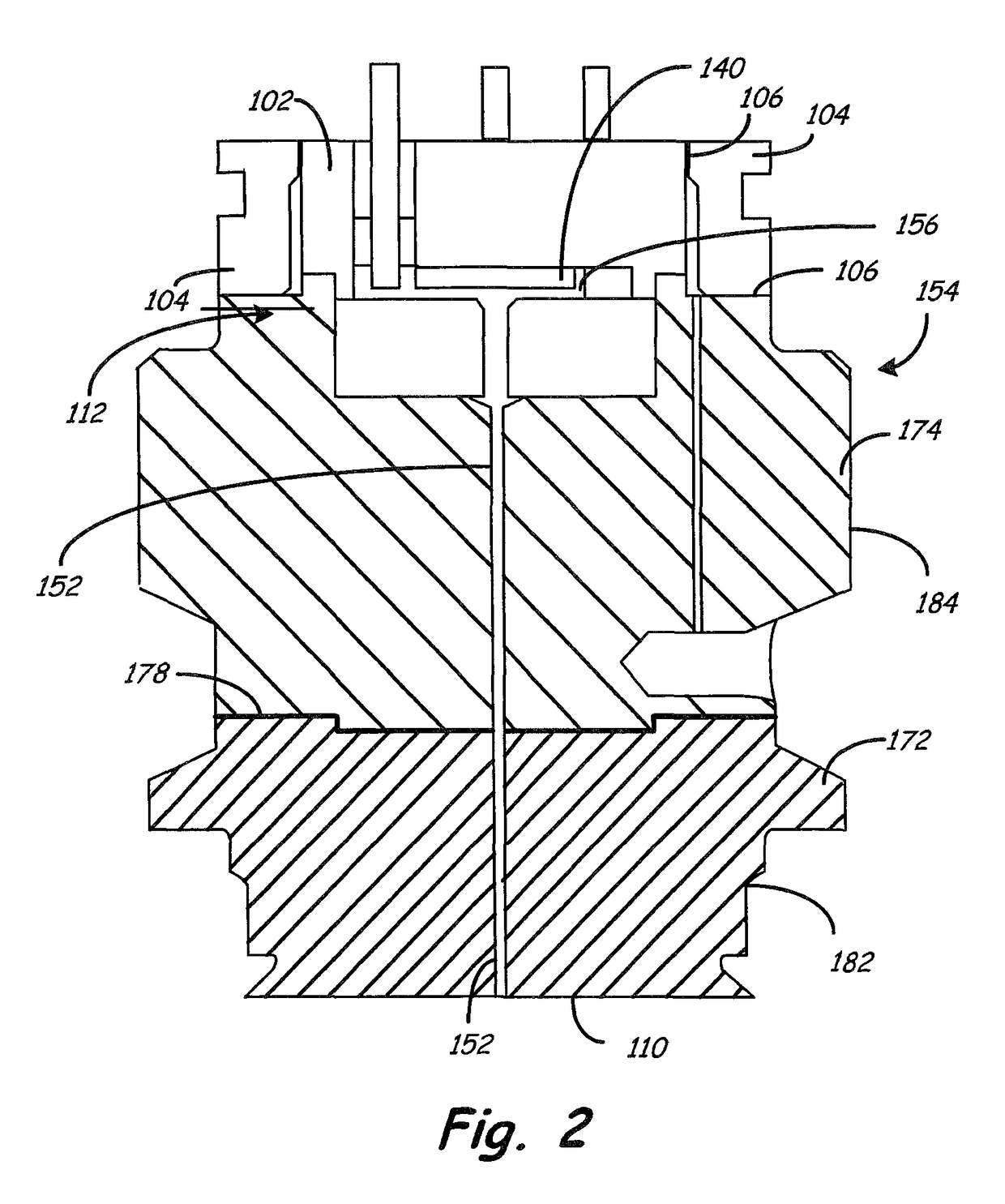

A pressure transmitter connectable to a process line provides an output responsive to a pressure in the process line. The transmitter includes a housing having a base with a process end coupled to an interior cavity formed in the housing, a sensor for sensing the pressure and an isolating assembly mounted at the process end of the housing and isolating fluid in the process line from the interior cavity. The isolating assembly includes an isolation diaphragm configured to be fluidically coupled to the process pressure in the process line, and an isolator plug positioned in the process of the housing adapter. The isolator plug having a lower plug portion providing a first end surface adjacent the isolation diaphragm, an upper plug portion providing a second end surface distally spaced from the first end surface and adjacent a sensor cavity in which the sensor is positioned, a connection mechanism connecting the lower and upper plug portions, and a capillary filled with isolation fluid and extending from the first end surface through the lower and upper plug portions to the second end surface thereby coupling the pressure through the isolation diaphragm and the capillary to the sensor cavity and the sensor. The upper plug portion is formed from a first material and the lower plug portion is formed from a second material having higher corrosion resistance than the first material.

Owner:ROSEMOUNT INC

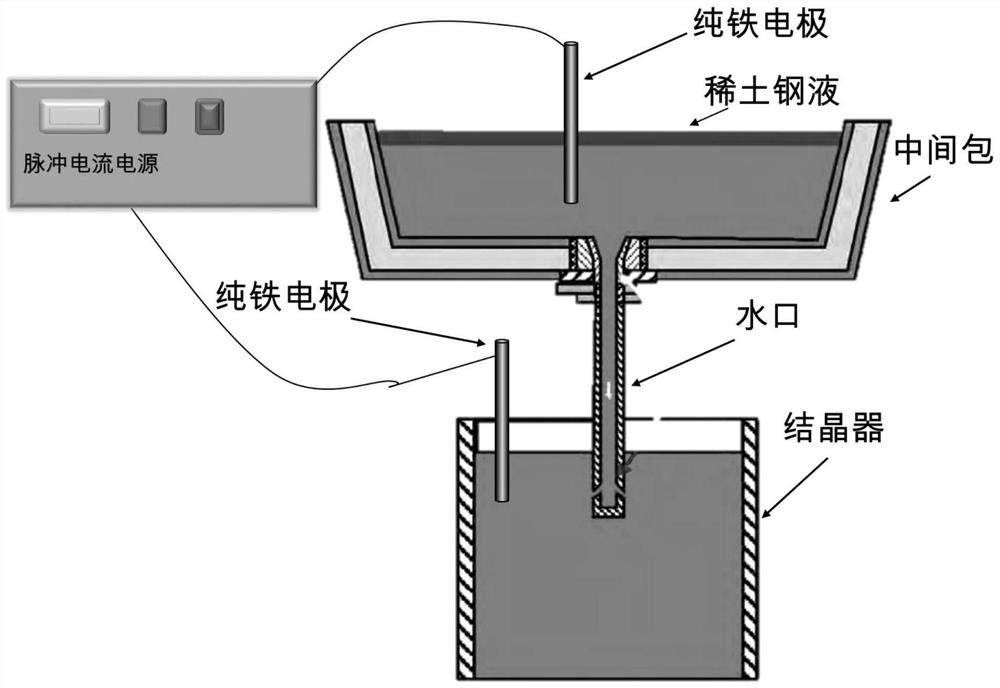

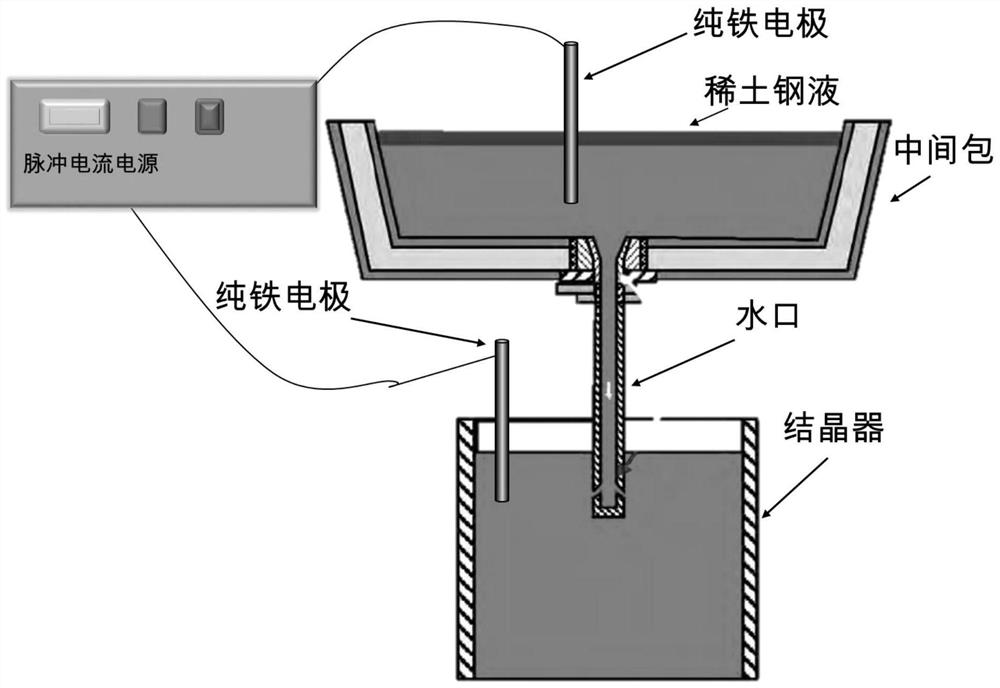

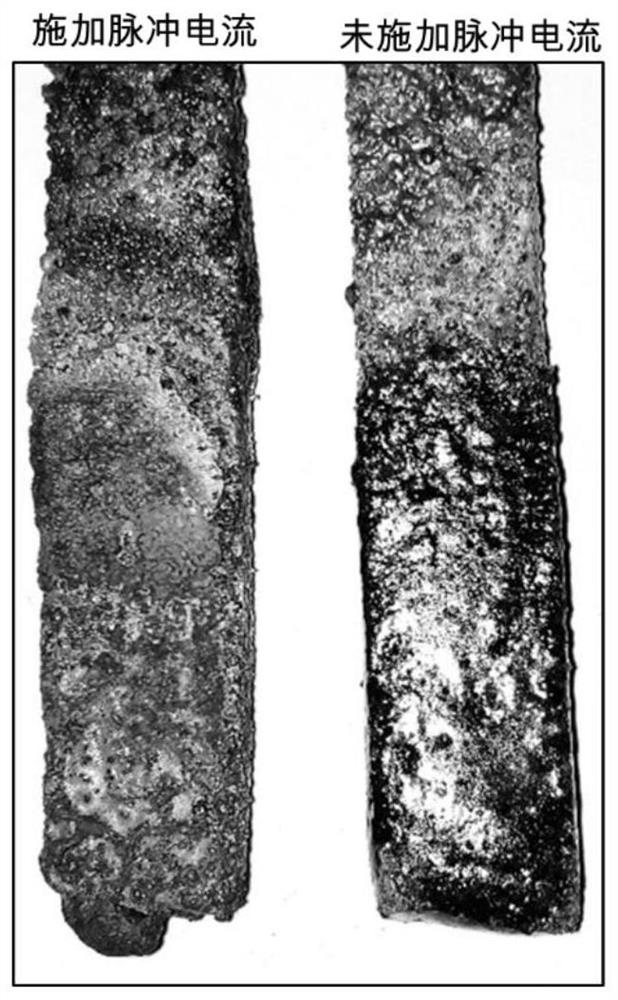

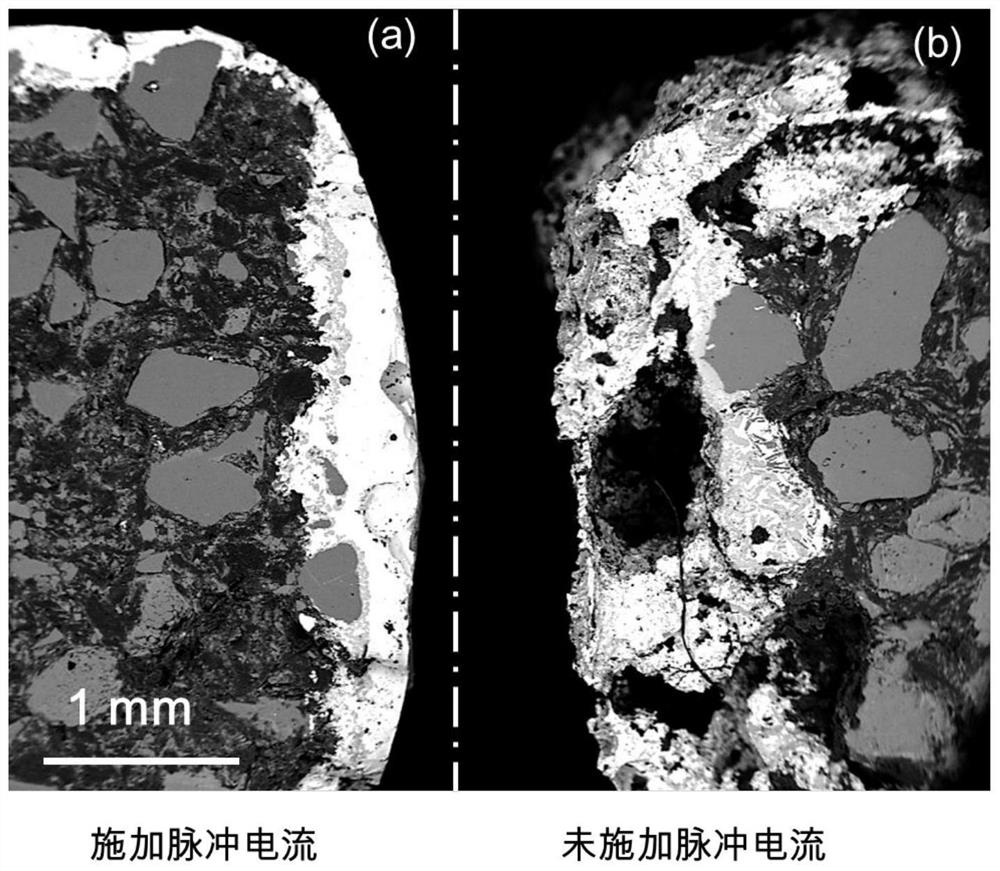

Method for inhibiting blockage of rare earth molten steel pouring nozzle through pulse currents

ActiveCN111906266AChemically activeAccelerated decarbonizationMelt-holding vesselsMischmetalEngineering

The method includes the steps that an electrode is inserted into rare earth molten steel, the pulse currents are applied to the electrode through a power supply device, the erosion reaction between the inner wall of the nozzle and an interface of the rare earth molten steel is intervened through the pulse currents, the rare earth molten steel corrosion resistance of the inner wall of the nozzle isimproved, and inclusions in the molten steel are further prevented from adhering to the inner wall of the nozzle. The method for inhibiting blockage of the rare earth molten steel pouring nozzle through the pulse currents is provided in order to solve the problems that rare earth metal elements in the molten steel erode the nozzle and rare earth inclusions adhere to the nozzle to cause nodulationand blockage of the nozzle in rare earth steel smelting and pouring, so that a rare earth steel smelting and continuous casting process is stabilized, and the quality of continuous casting billets isimproved. The invention discloses a method for inhibiting blockage of a rare earth molten steel pouring nozzle through pulse currents, and relates to the field of rare earth steel smelting and casting.

Owner:UNIV OF SCI & TECH BEIJING

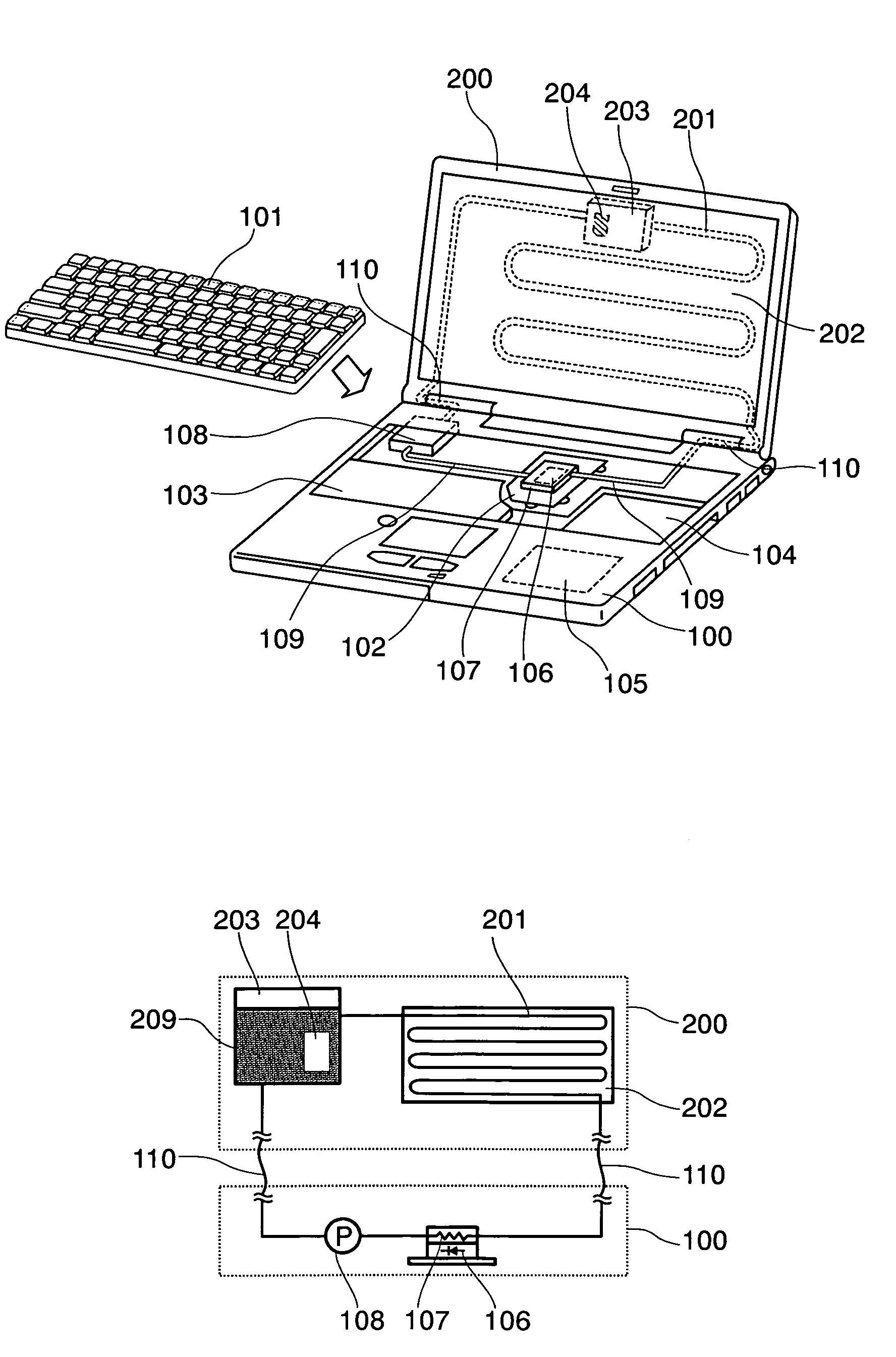

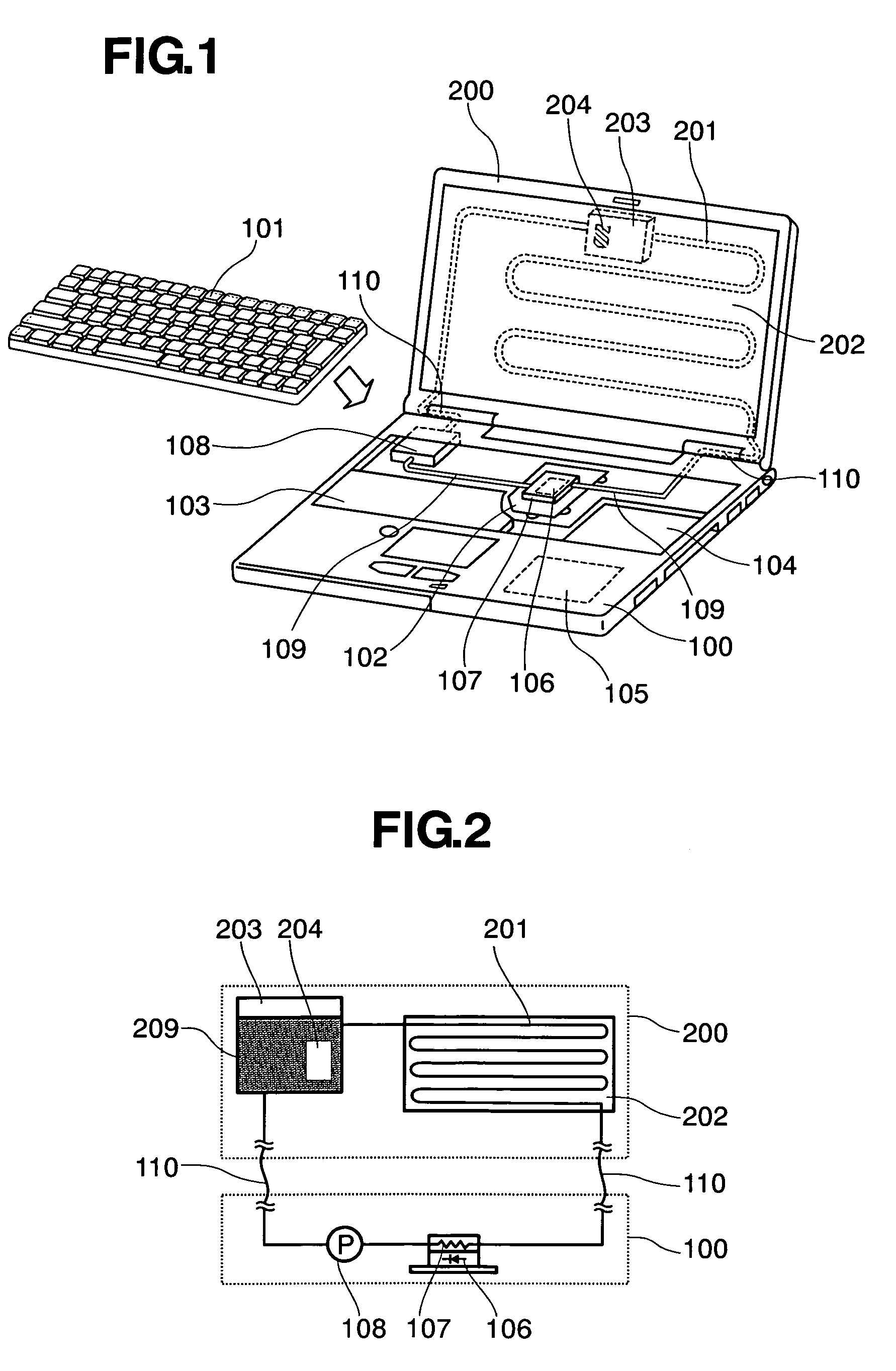

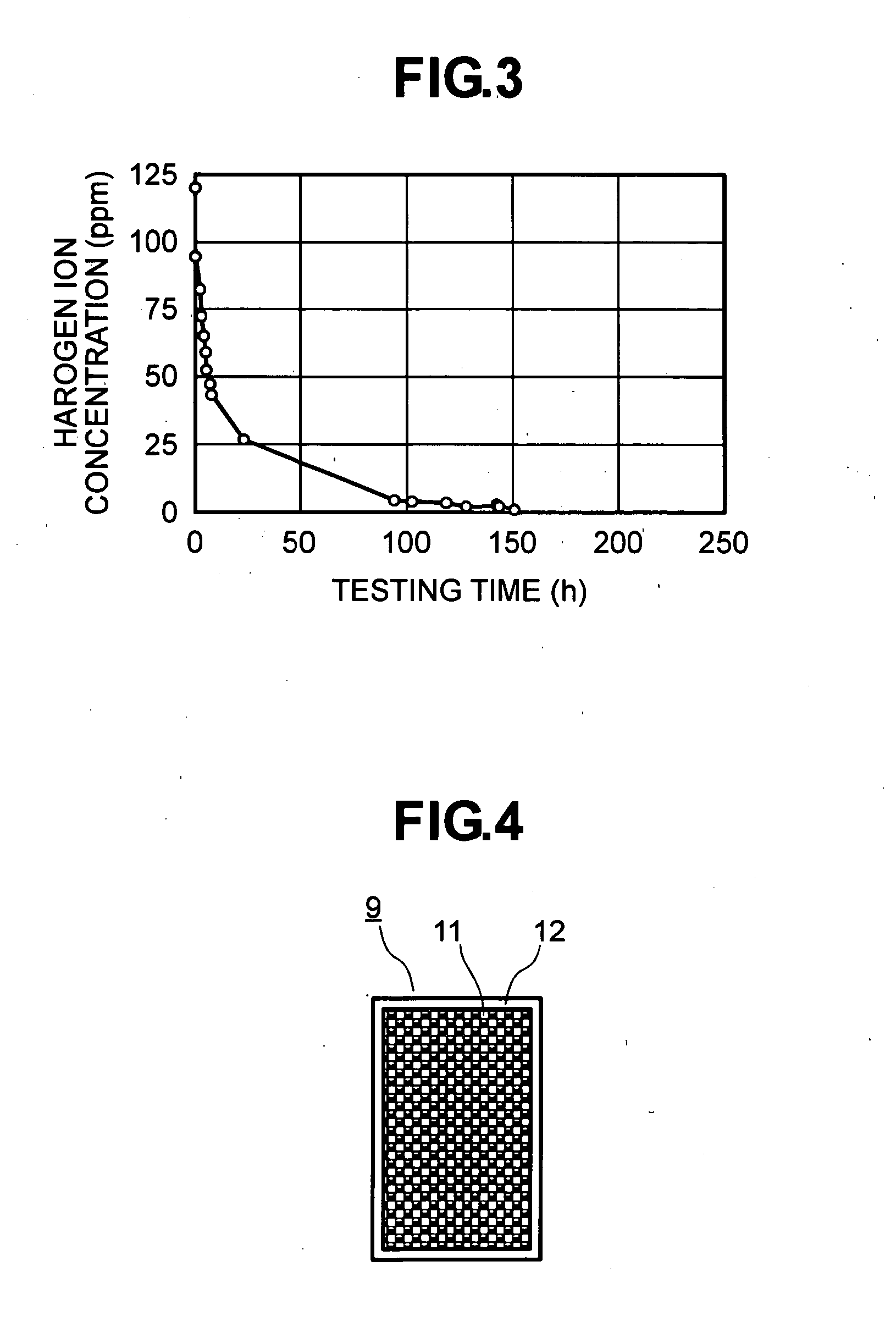

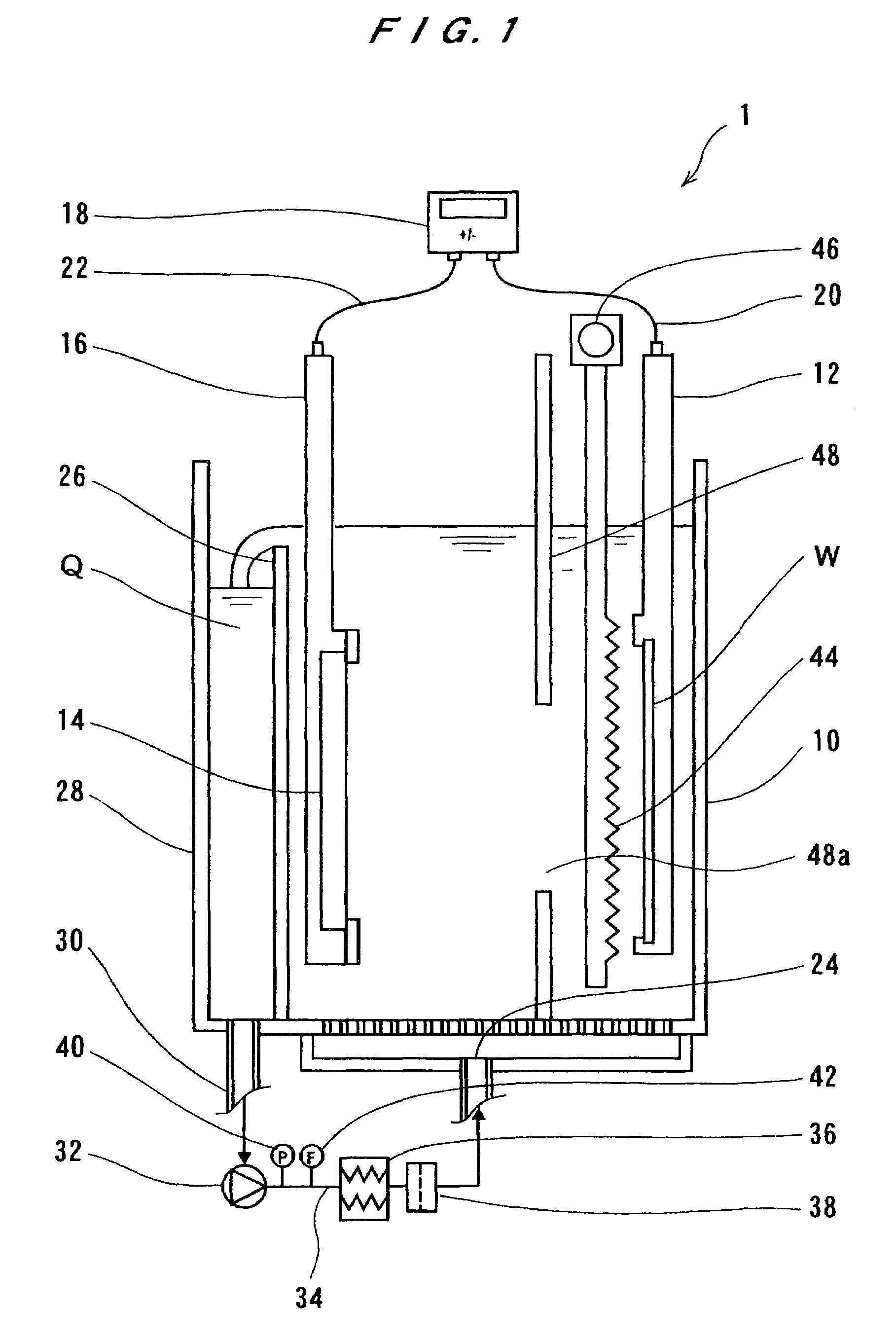

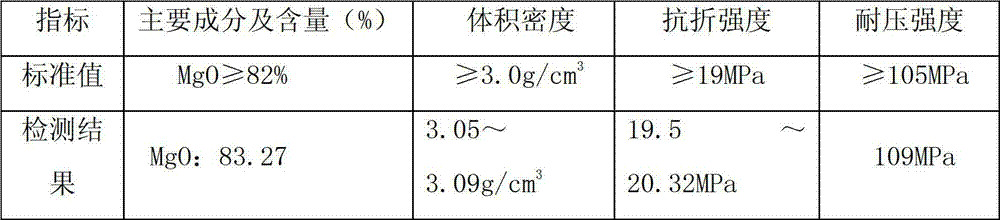

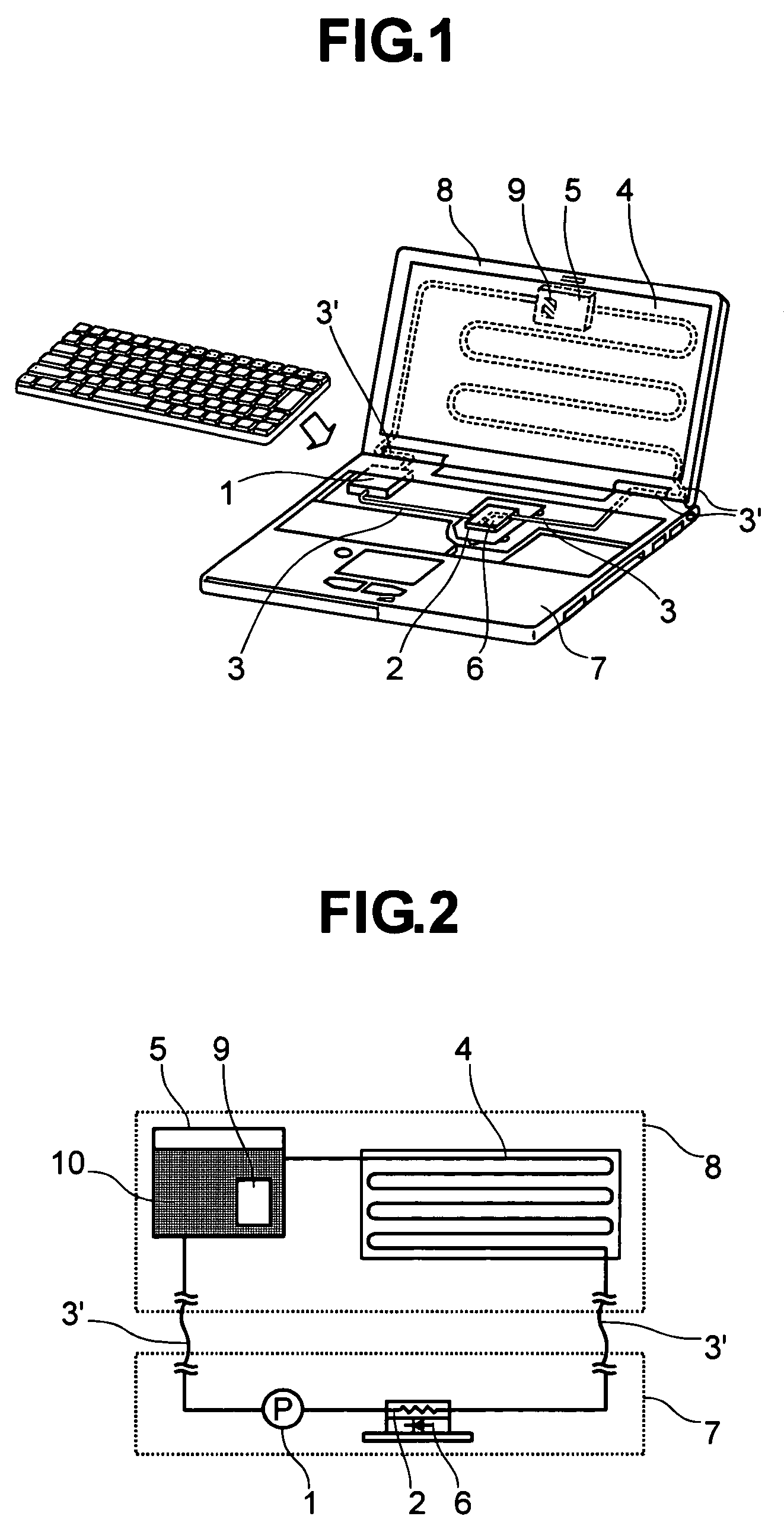

Liquid cooling system and an electronic apparatus applying the same therein

InactiveUS7242581B2Easy to applyMaintain corrosion resistanceDigital data processing detailsCorrosion preventionClosed loopLiquid cooling system

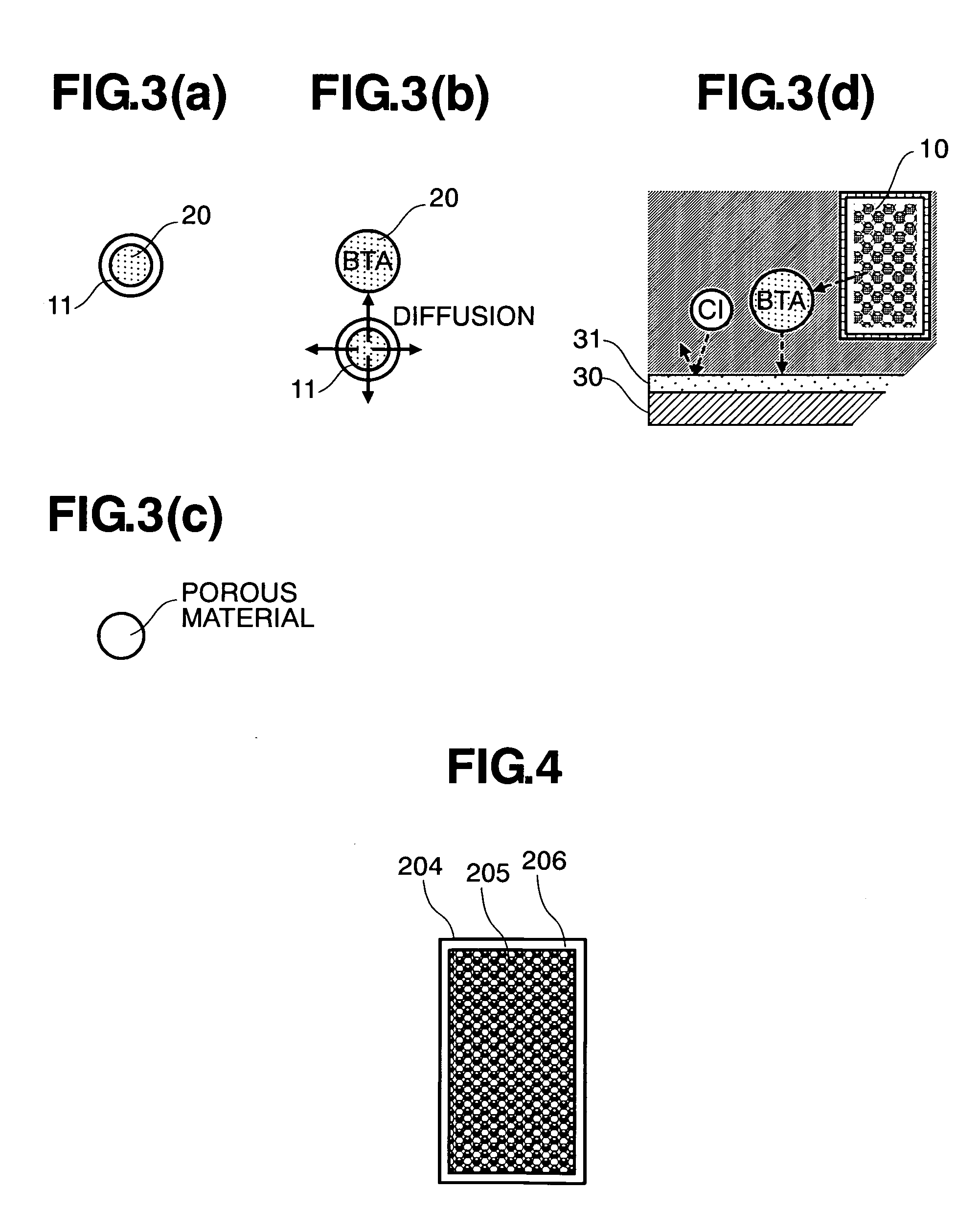

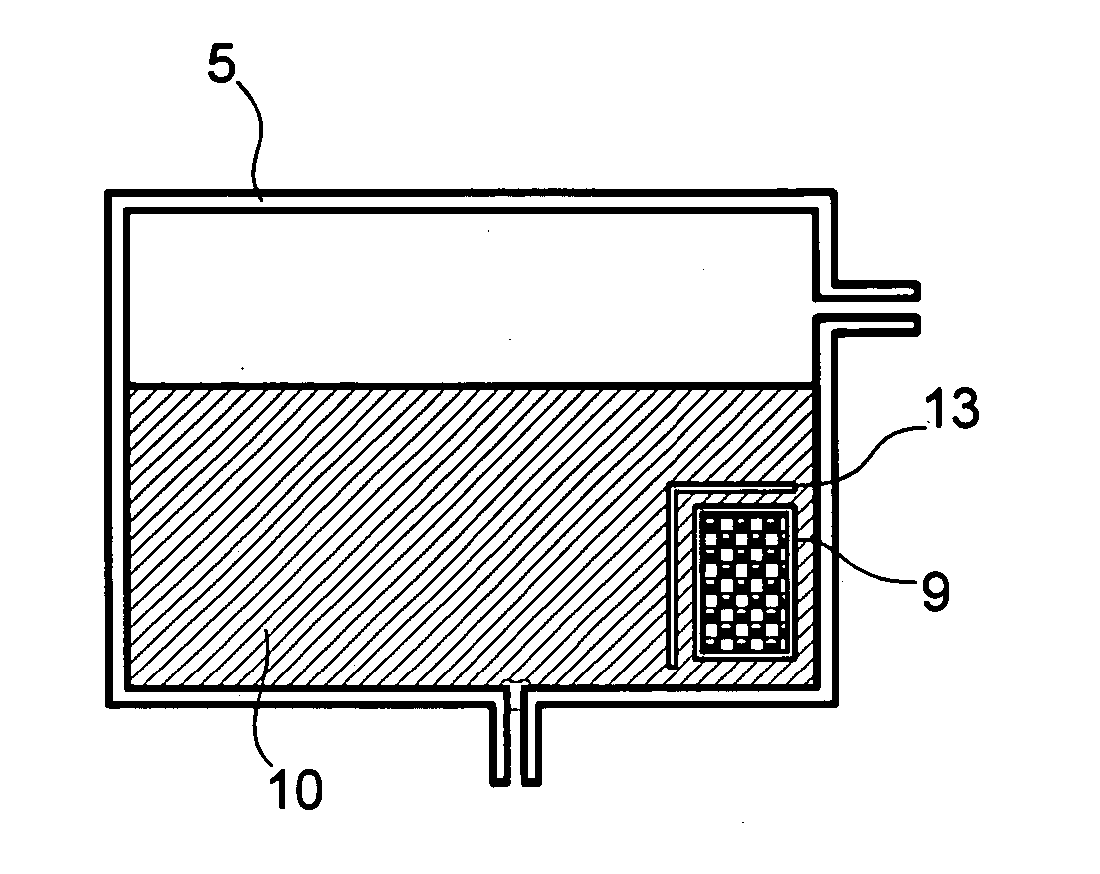

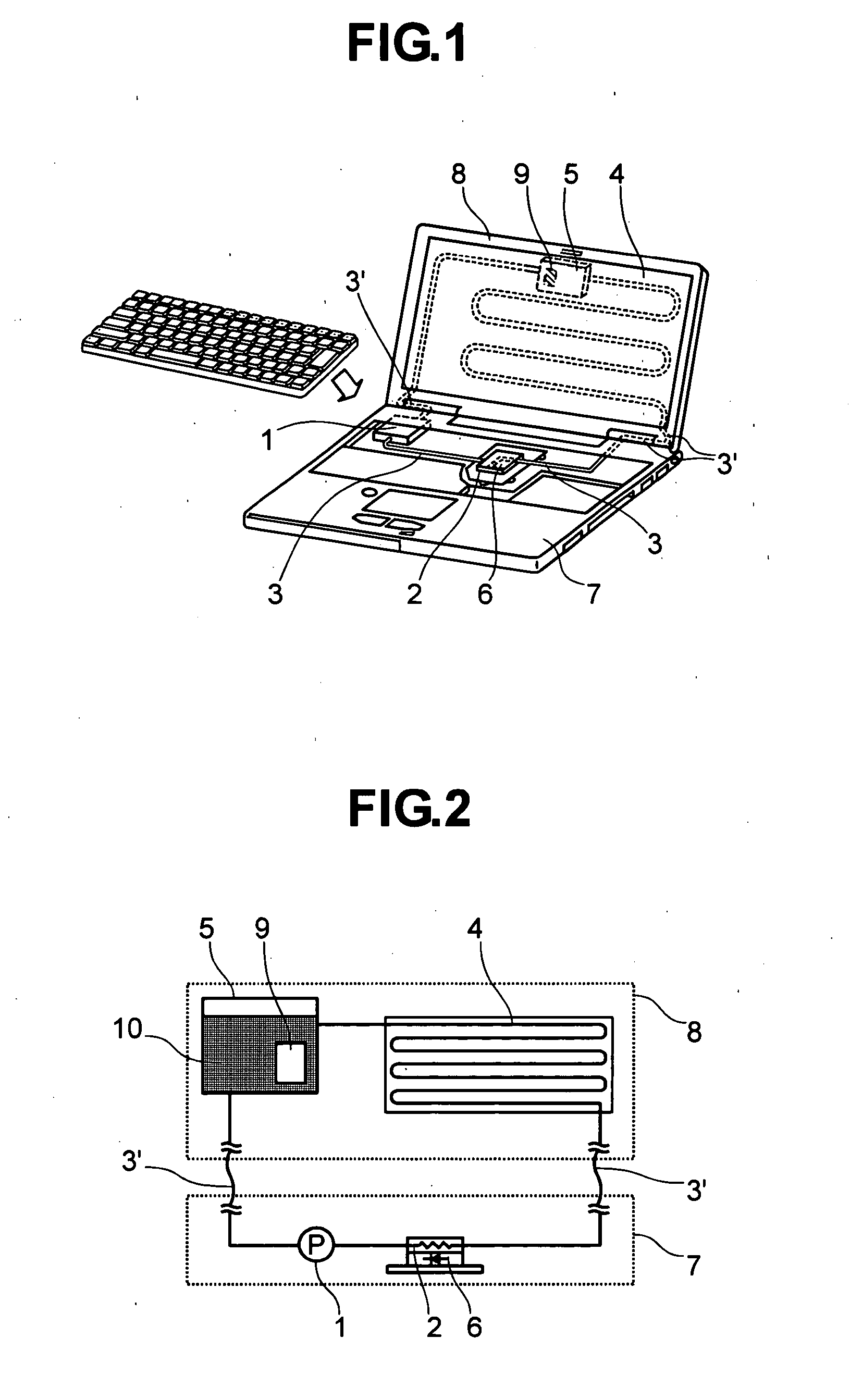

A liquid cooling system, enabling protection from corrosion due to liquid coolant for a long time-period (5–10 years) while cooling a heat-generation body effectively, comprises a pump 108, a heat-receiving jacket 107, a radiator for radiating heat into an outside, being made up with a heat-radiation pipe 201 and a heat-radiation plate 202, and further a tank 203 for accumulating the liquid coolant 209 within an inside thereof, wherein those are connected in a closed-loop, so as to circulating the cooling liquid therein, thereby cooling the heat-generation of a CPU 106, being a heat-generation element, effectively, through the heat-receiving jacket 107, and further a water-permeable bag 204 is disposed in a portion of flow path of the cooling liquid, which receives microcapsules 10 therein, each enclosing in an inside thereof anti-corrosion agent 20 for suppressing the corrosion due to the cooling liquid, including such as, a water, etc.

Owner:HITACHI LTD

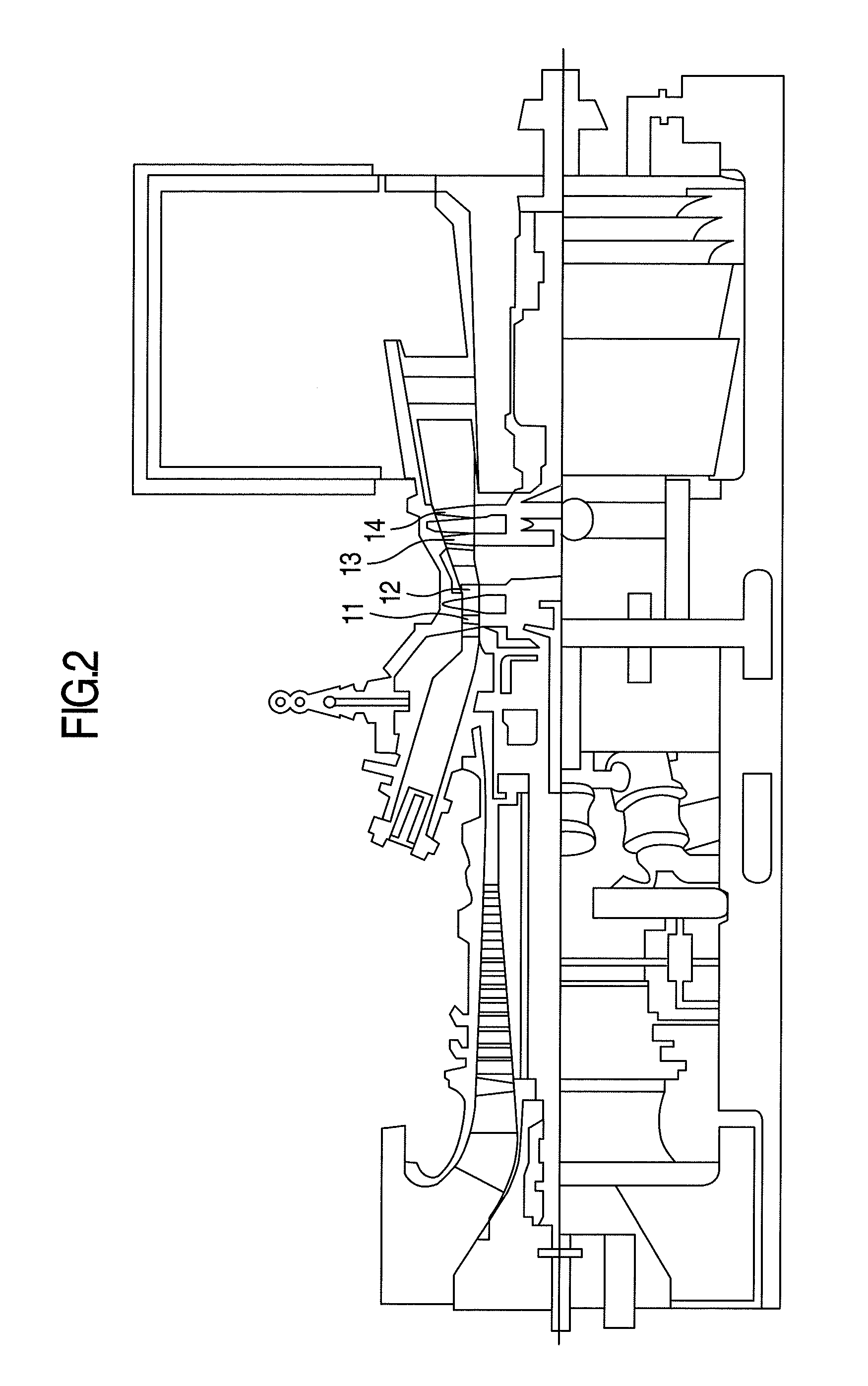

Thread-forming screw

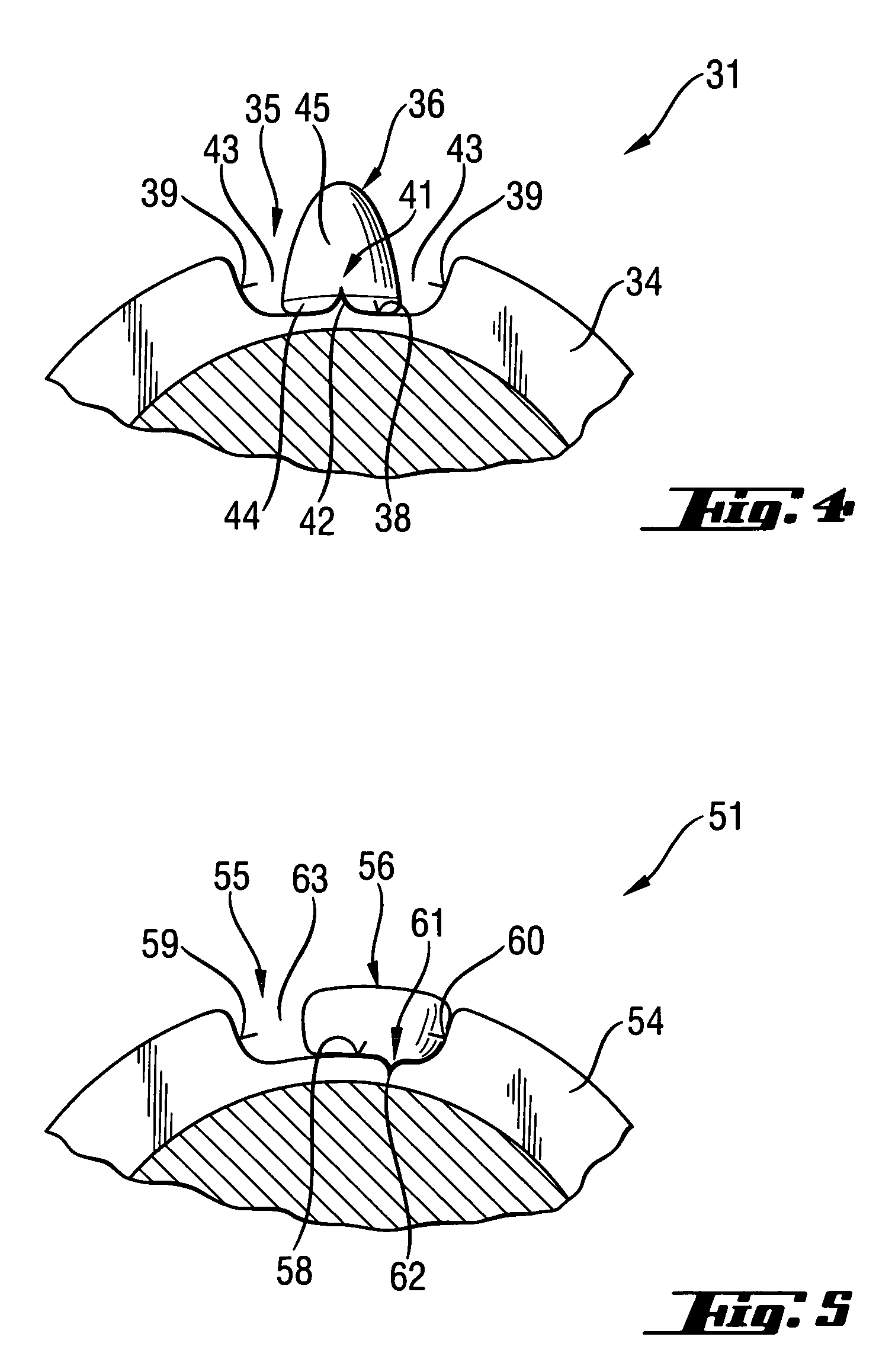

ActiveUS7484920B2Lower average tensionAdvantageous cutting behaviorNutsBoltsEngineeringMechanical engineering

A thread-forming screw (11; 21; 31; 51), has a stem (12) with at least one thread (14; 24; 34; 54) arranged, at least regionwise, over its circumference, and a plurality of cutting elements (16; 26; 36; 56) arranged in a respective plurality of recesses (15; 25; 35; 55) formed in the at least one thread (14; 24; 34; 54), with the cutting elements (16; 26; 36; 56) having a hardness greater than a hardness of the at least one thread (14; 24; 34; 54) and formed as weld beads received in the recesses (15; 25; 35; 55).

Owner:HILTI AG

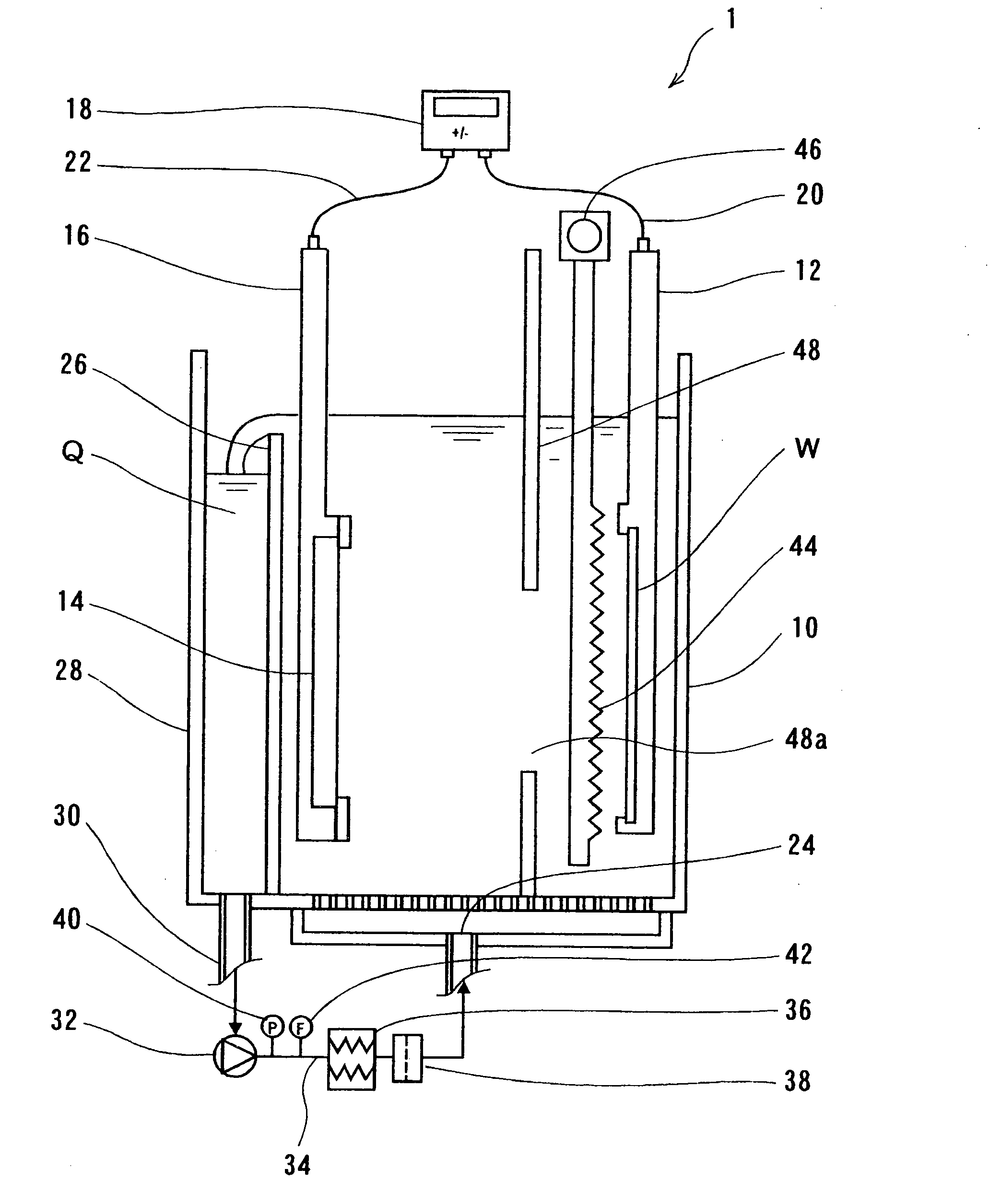

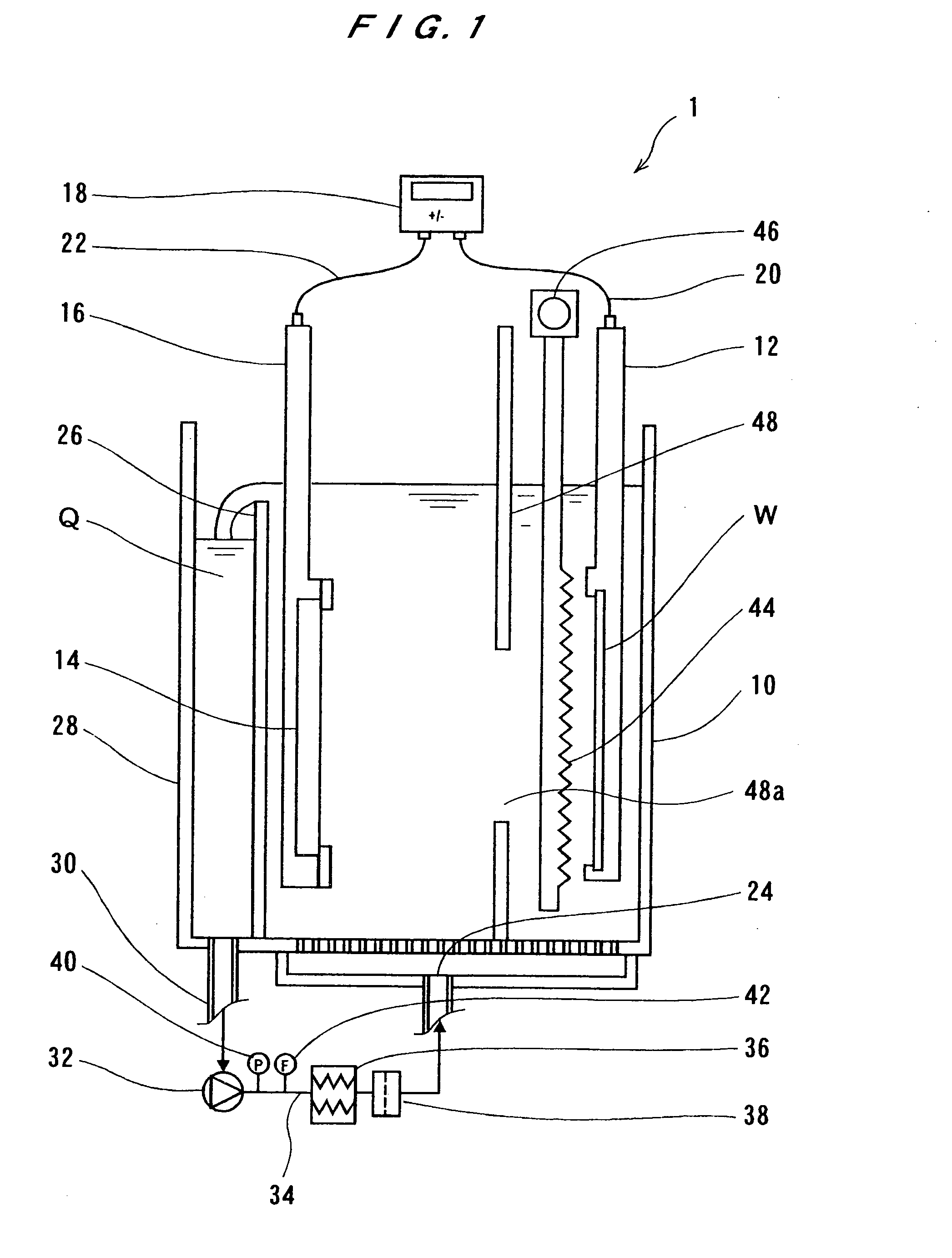

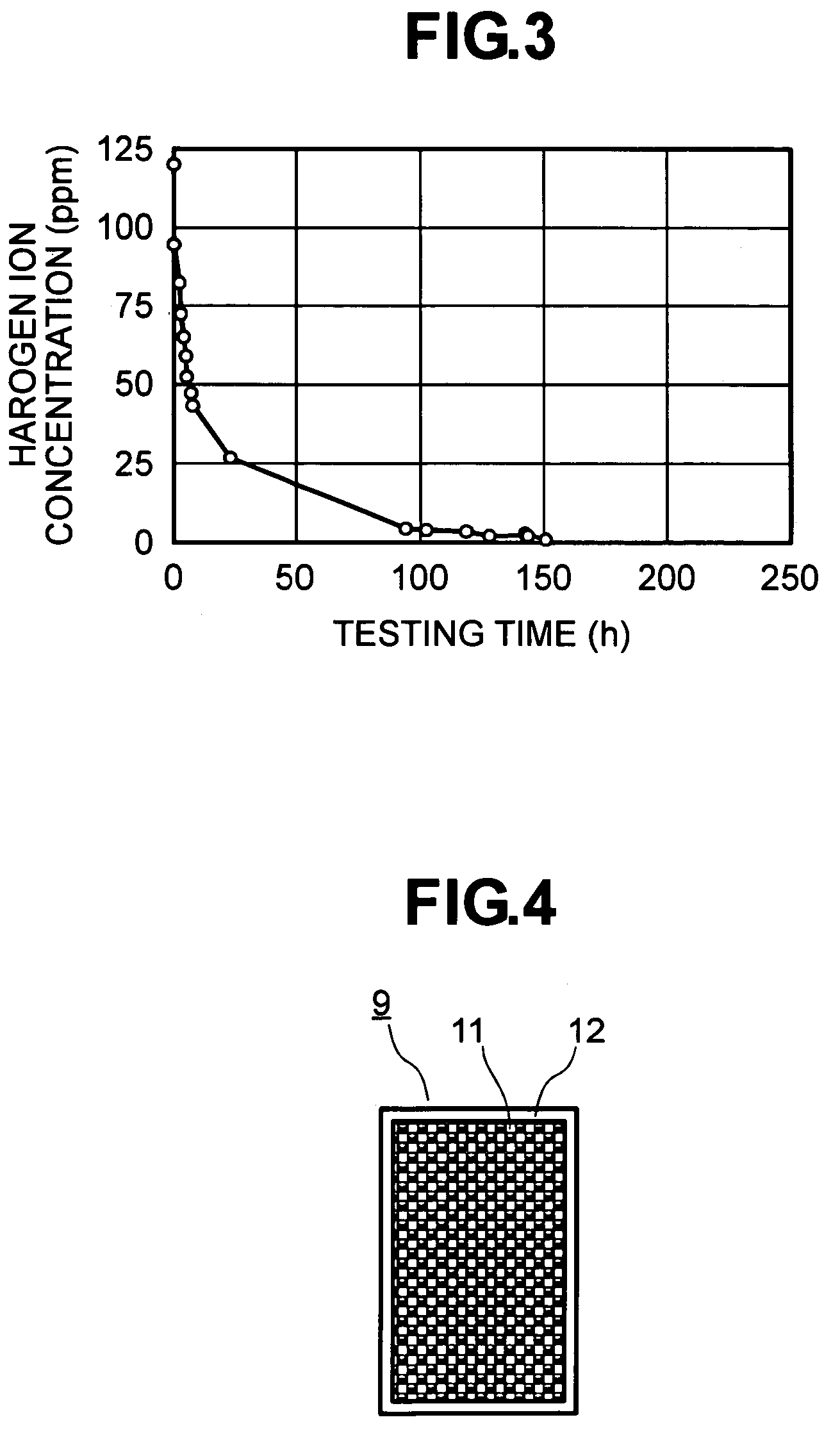

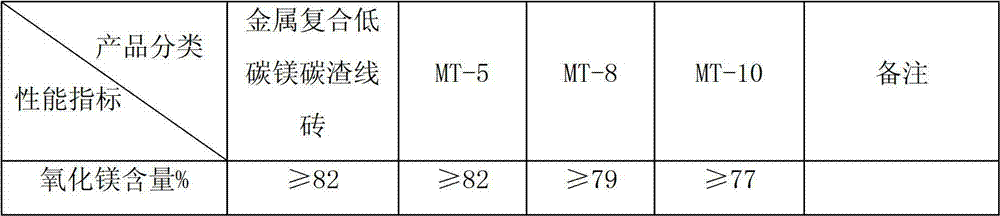

Liquid cooling system and electronic apparatus using the same

InactiveUS20050047091A1Maintain corrosion resistanceDigital data processing detailsSemiconductor/solid-state device detailsNuclear engineeringIon exchange

A liquid cooling system for use in an electronic apparatus, being super small-sized and thin in the shape and being suitable for cooling a heat-generation part, such as, a semiconductor element having large amount of heat generation, for example, with maintaining the corrosion resistance thereof for a long time period, comprises: a pump for supplying a cooling liquid; a heat-receiving jacket, being supplied with the cooling liquid, for receiving heat from an electronic parts; a radiator, being supplied with the cooling liquid passing through the heat-receiving jacket, for radiation heat; and flow passages for circulating the cooling liquid in a route passing through the radiator back to said pump, wherein an ion exchange bag, having an ion exchange resin and a bag enclosing it therein, is disposed in a part of the constituent parts of the liquid cooling system, and / or the ion exchange bag is exchangeable.

Owner:HITACHI LTD

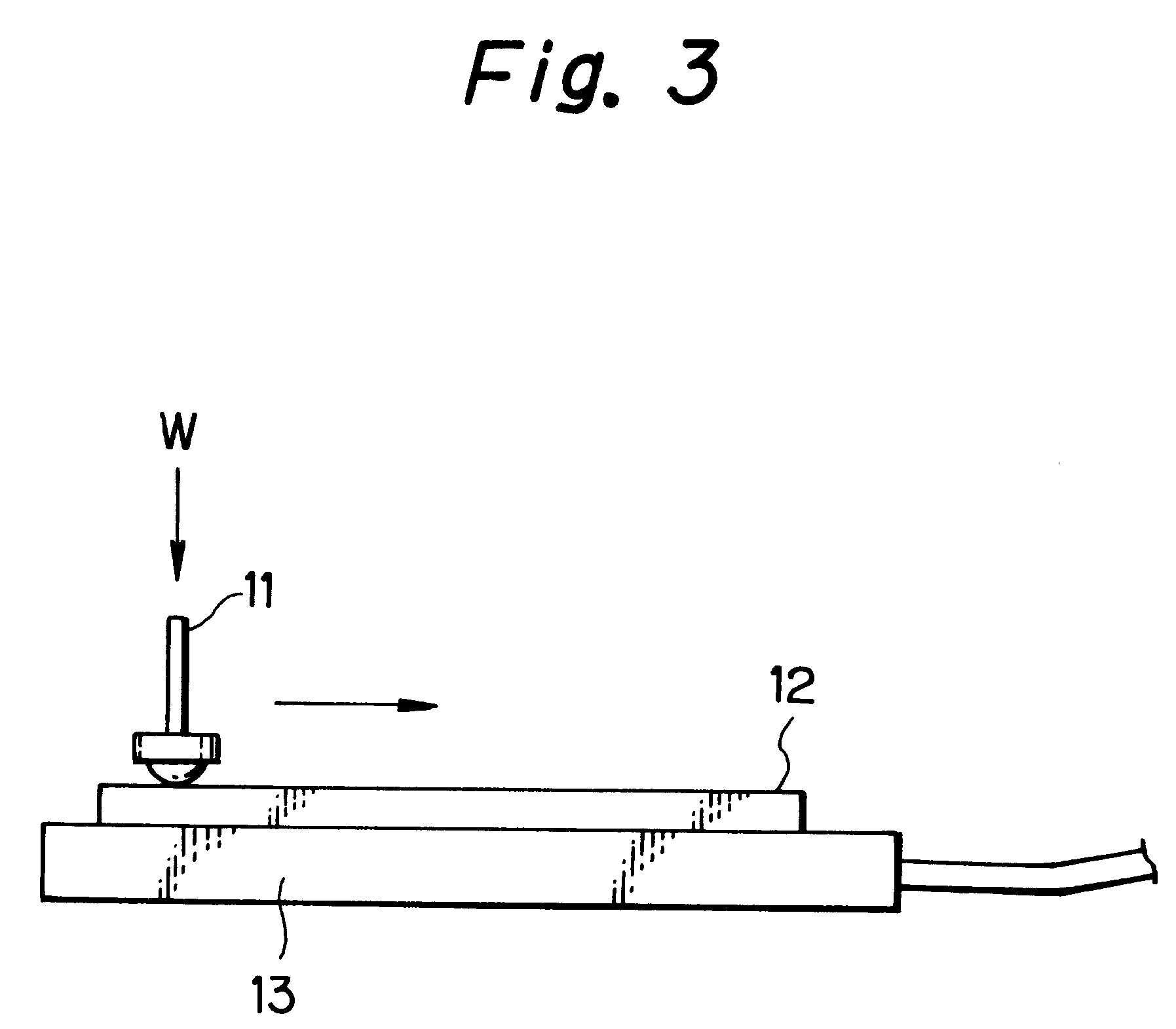

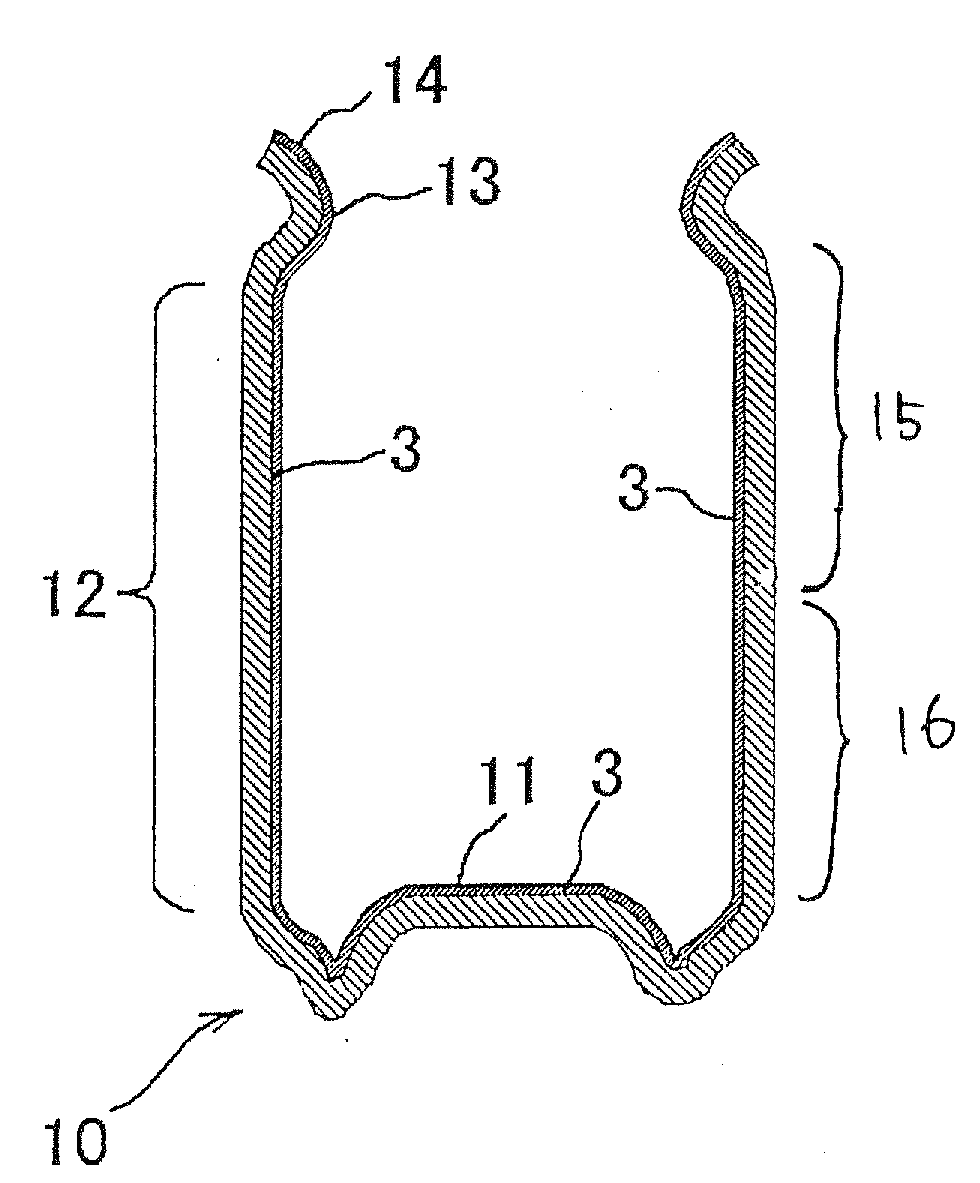

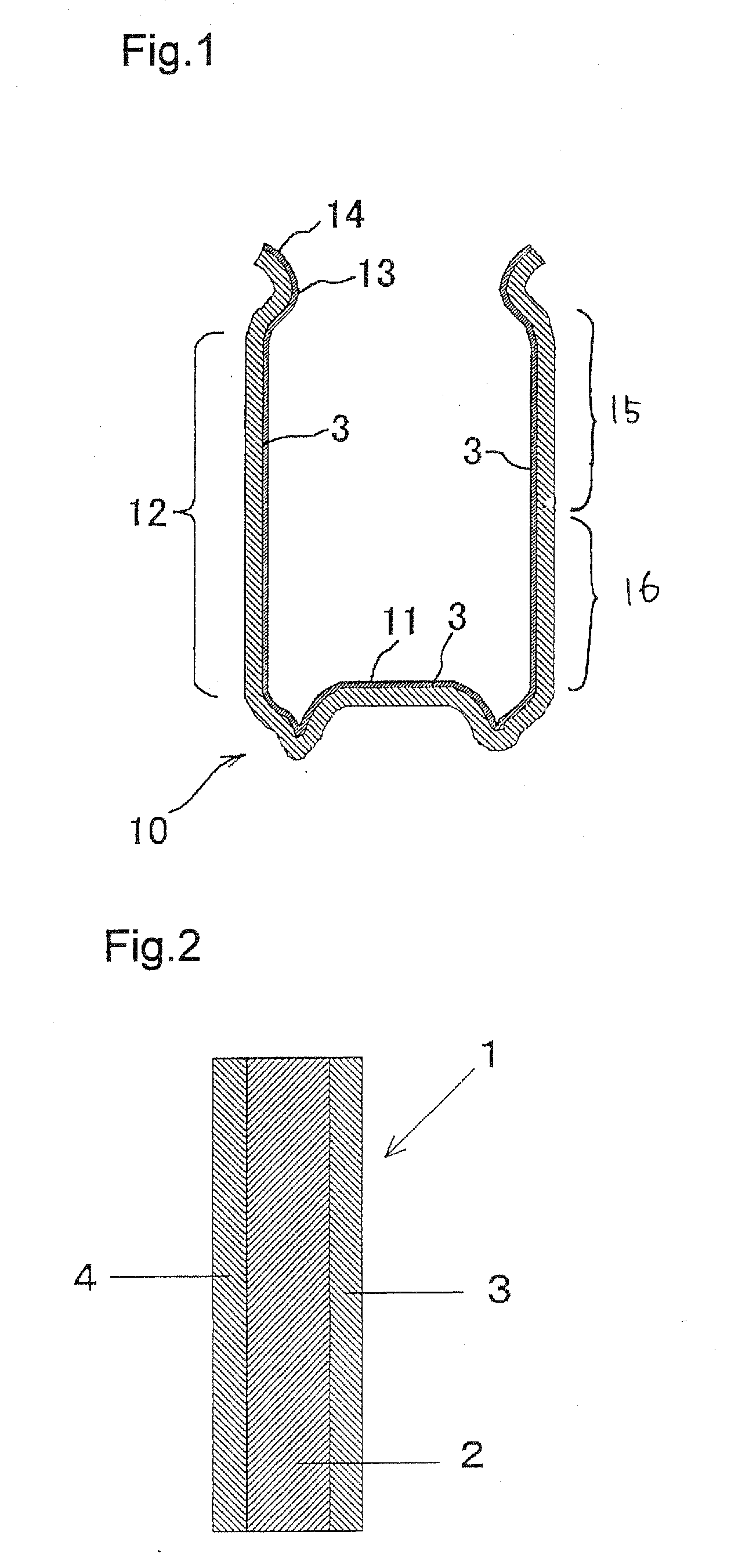

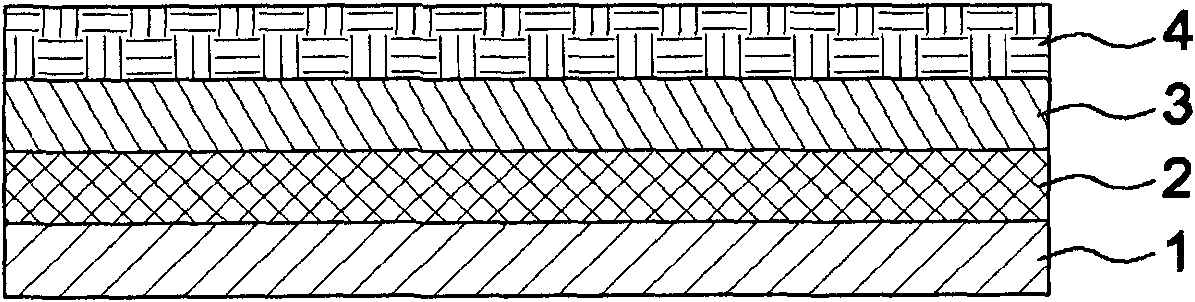

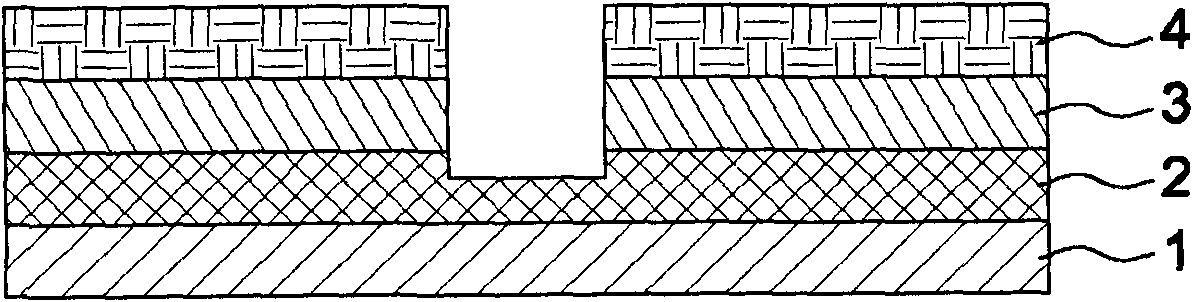

Resin coated seamless can

ActiveUS20080241448A1Avoid changeMaintain corrosion resistanceEnvelopes/bags making machineryFlexible coversInfraredPolyethylene terephthalate

A resin-coated seamless can of the present invention is a resin-coated seamless can formed of a resin-coated metal sheet 1 which is produced by coating a polyester resin layer 3 containing polyethylene terephthalate onto a surface of a metal substrate 2, wherein the density of a polyester resin layer of a can inner surface side is set to equal to or more than 1.36 at a can barrel upper portion. Further, an infrared dichroic ratio (R1) of the polyester resin layer at the inner surface side of the can barrel portion which is expressed by a following formula (1) is set to equal to or more than 1.1. R1=Iw(⊥) / Iw(∥) . . . (1). In the formula (1), Iw(⊥) indicates an infrared absorption intensity of 973 cm−1 with respect to polarized infrared rays perpendicular to the can height direction at the can barrel portion, and Iw(∥) indicates an infrared absorption intensity of 973 cm−1 with respect to polarized infrared rays parallel to the can height direction at the can barrel portion.

Owner:TOYO SEIKAN KAISHA LTD

Platinum alloy material and preparation method

The invention provides a platinum alloy material which consists of the following components in percentage by mass: 0.3-1% of Ti, 0.02-0.15% of Zr and the balance of Pt. The preparation method of the alloy comprises the following steps of: smelting to prepare a Pt-Ti-Zr master alloy in a vacuum arc furnace, and smelting and casting in a vacuum induction furnace to prepare a Pt-Ti-Zr alloy ingot; performing solution heat treatment and low-temperature aging heat treatment of the alloy ingot in the vacuum arc furnace; performing plastic processing such as room-temperature forging, rolling (drawing) and the like to prepare a platinum alloy material sheet or wire of the proportion. The alloy provided by the invention maintains the corrosion resistance and plasticity of platinum while the hardness is over twice the hardness of platinum; the alloy is widely applied to electrode materials, jewelry and the like.

Owner:YUNNAN UNIV

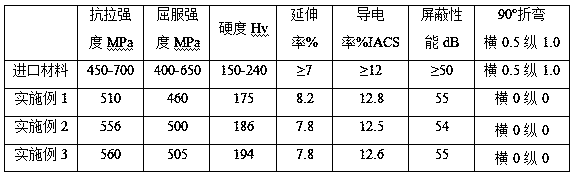

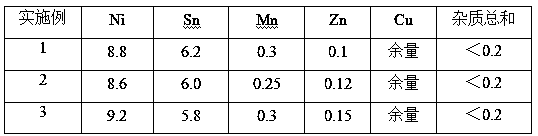

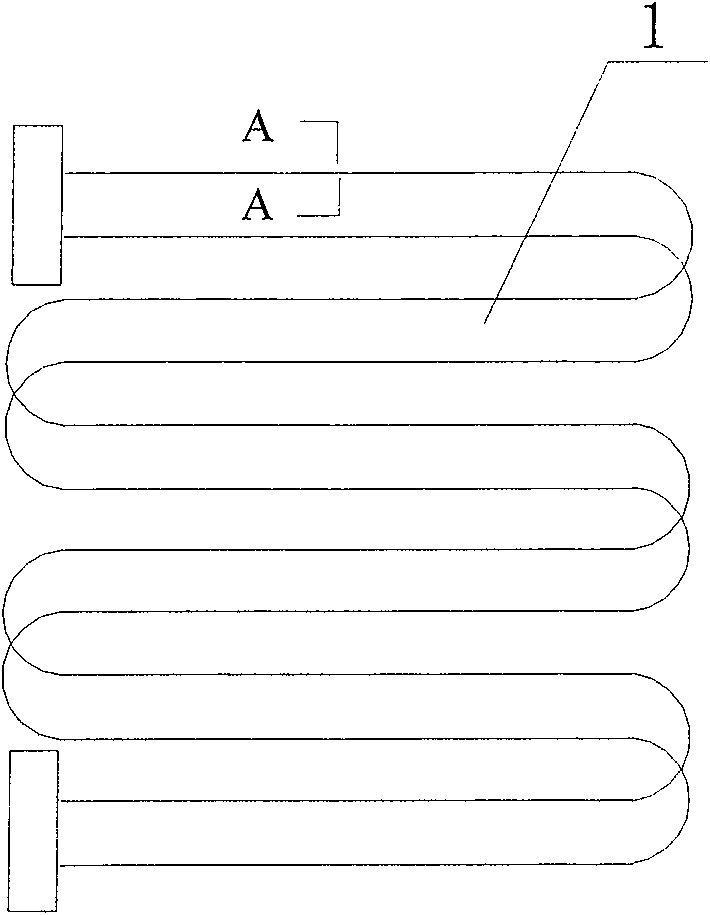

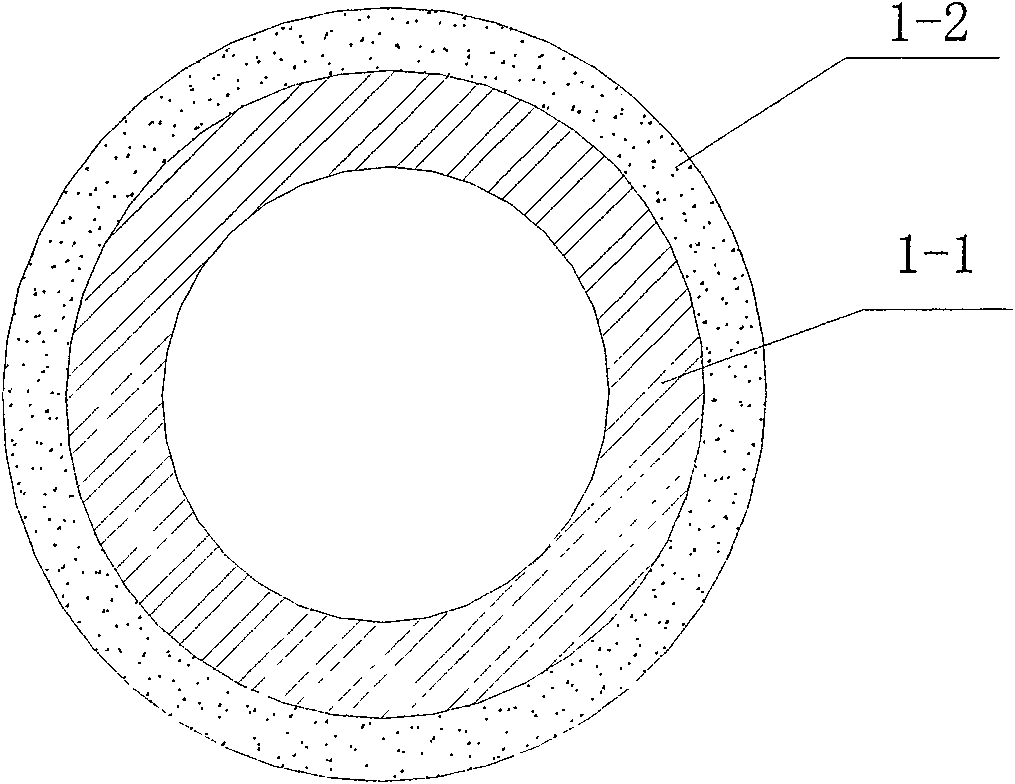

Cu-Ni-Sn alloy belt foil for 5G communication and preparation method thereof

The invention discloses a Cu-Ni-Sn alloy belt foil for 5G communication and a preparation method thereof. The Cu-Ni-Sn alloy belt foil is prepared from the following raw material components in percentage by weight: 8.5-9.5% of nickel, 5.5-6.5% of tin, 0.2-0.5% of manganese, 0.1-0.3% of zinc, and the balance copper and impurities. The preparation method comprises the following steps: melting weighed copper and nickel, covering with wood charcoal, sequentially adding manganese, tin and zinc, stirring and dissolving after heating up to a temperature of 1300-1330 DEG C, slagging-off, covering withwood charcoal, standing and converting, slagging-off, and covering with wood charcoal; performing pull-casting, homogenizing annealing treatment, face-milling, cold-rolling cogging, intermediate solid-solution treatment, intermediate rolling, intermediate solid-solution treatment and finished product rolling by adopting a reverse pushing-pulling and stopping blank pulling way, and obtaining foilwith a thickness being 0.04-0.1mm. Elasticity, wear resistance and corrosion resistance of a Cu-Ni-Sn copper alloy in the prior art are kept, and meanwhile, the Cu-Ni-Sn alloy belt has good forming property, relatively high conductivity and excellent shielding performance, can realize industrial production of the Cu-Ni-Sn alloy belt foil for 5G communication, replaces import, fills up the domesticblank to promote copper processing industry development needs of the current stage.

Owner:CNMC ALBETTER ALBRONZE

Steaming type anti-corrosion anti-scale heat conducting coating on surface of condenser coil pipe

InactiveCN100558833CImprove thermal conductivityImprove heat transfer efficiencyAlkali metal silicate coatingsChemical industryHeat conductingPhosphate

Owner:SOUTH CHINA UNIV OF TECH

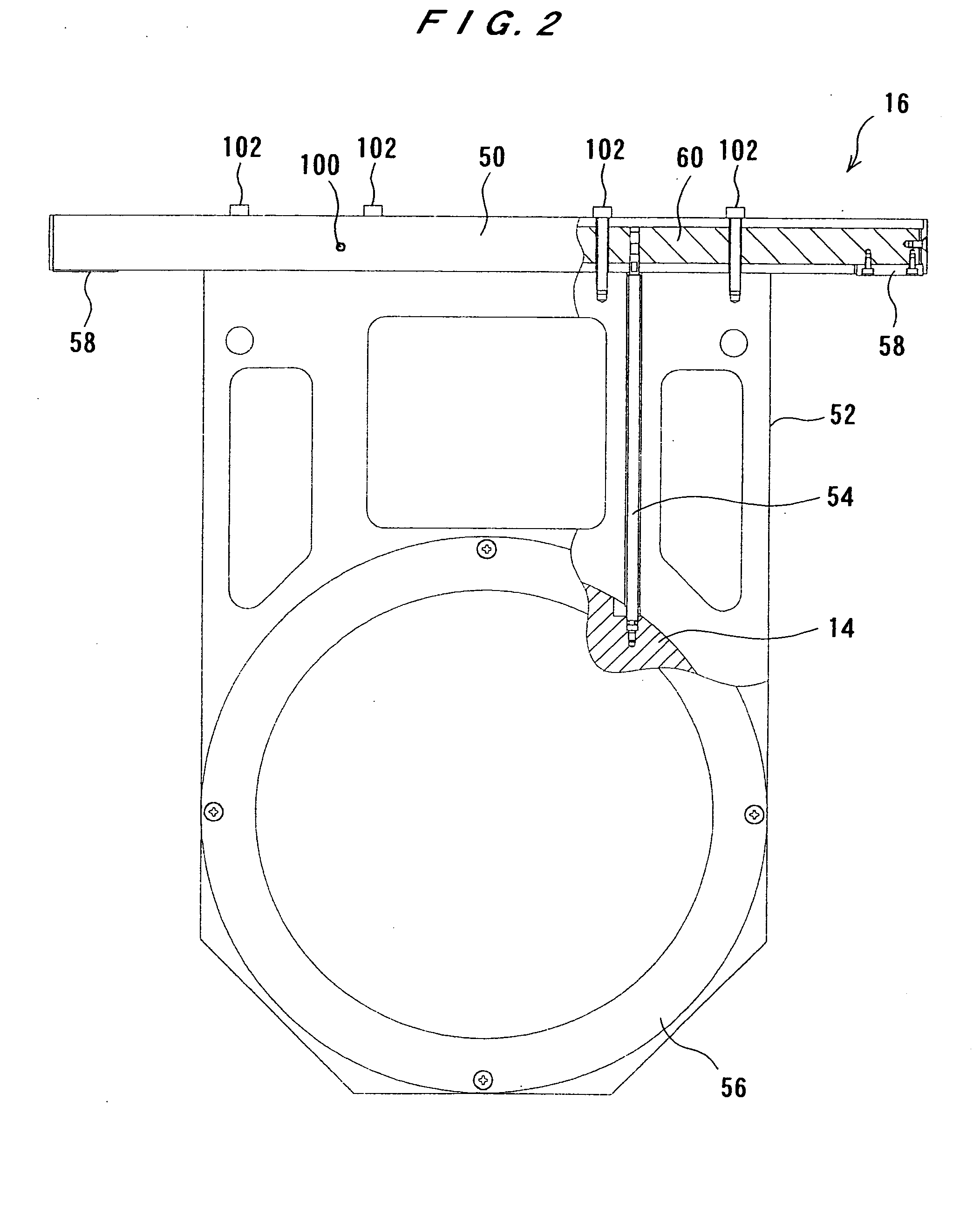

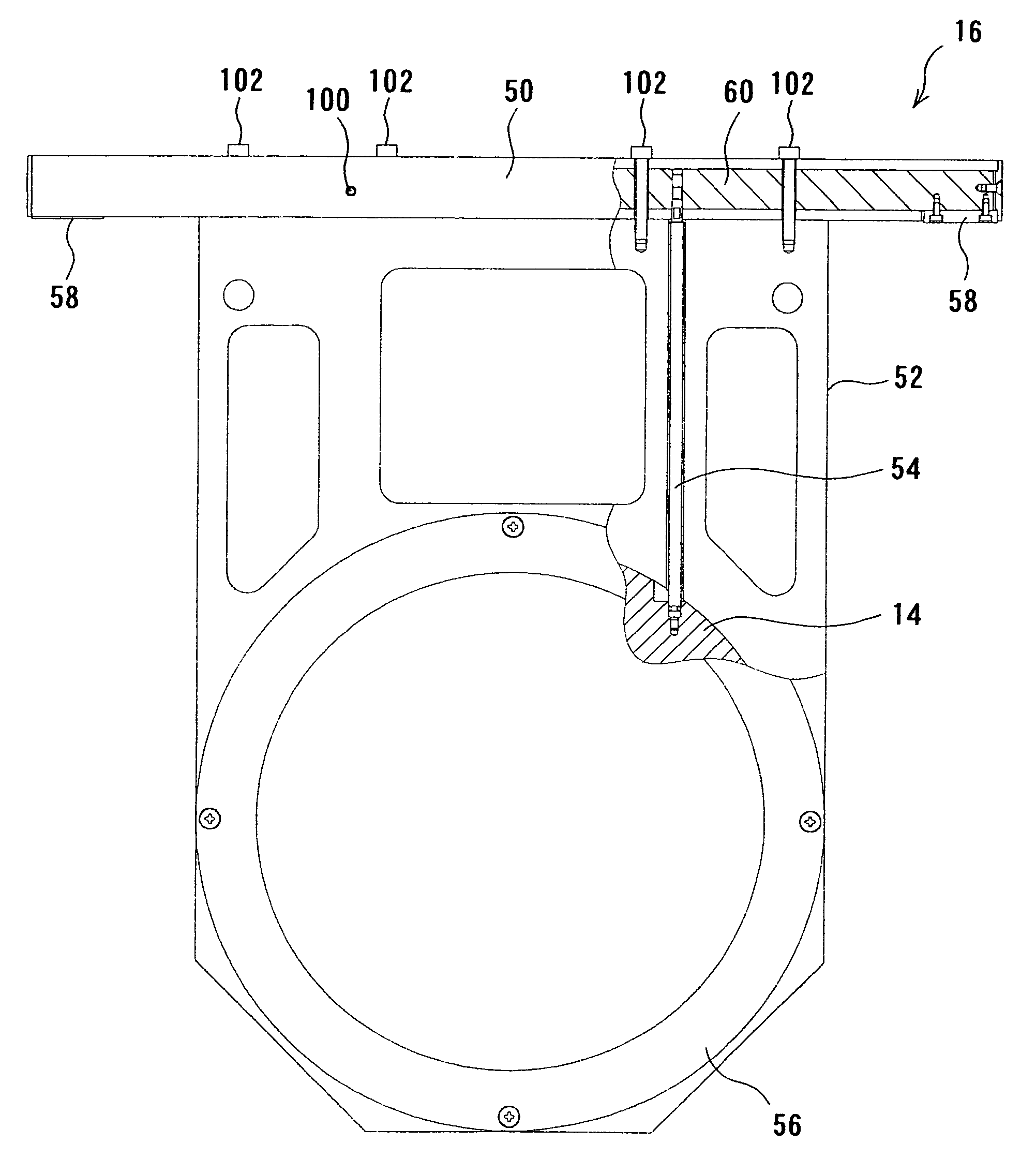

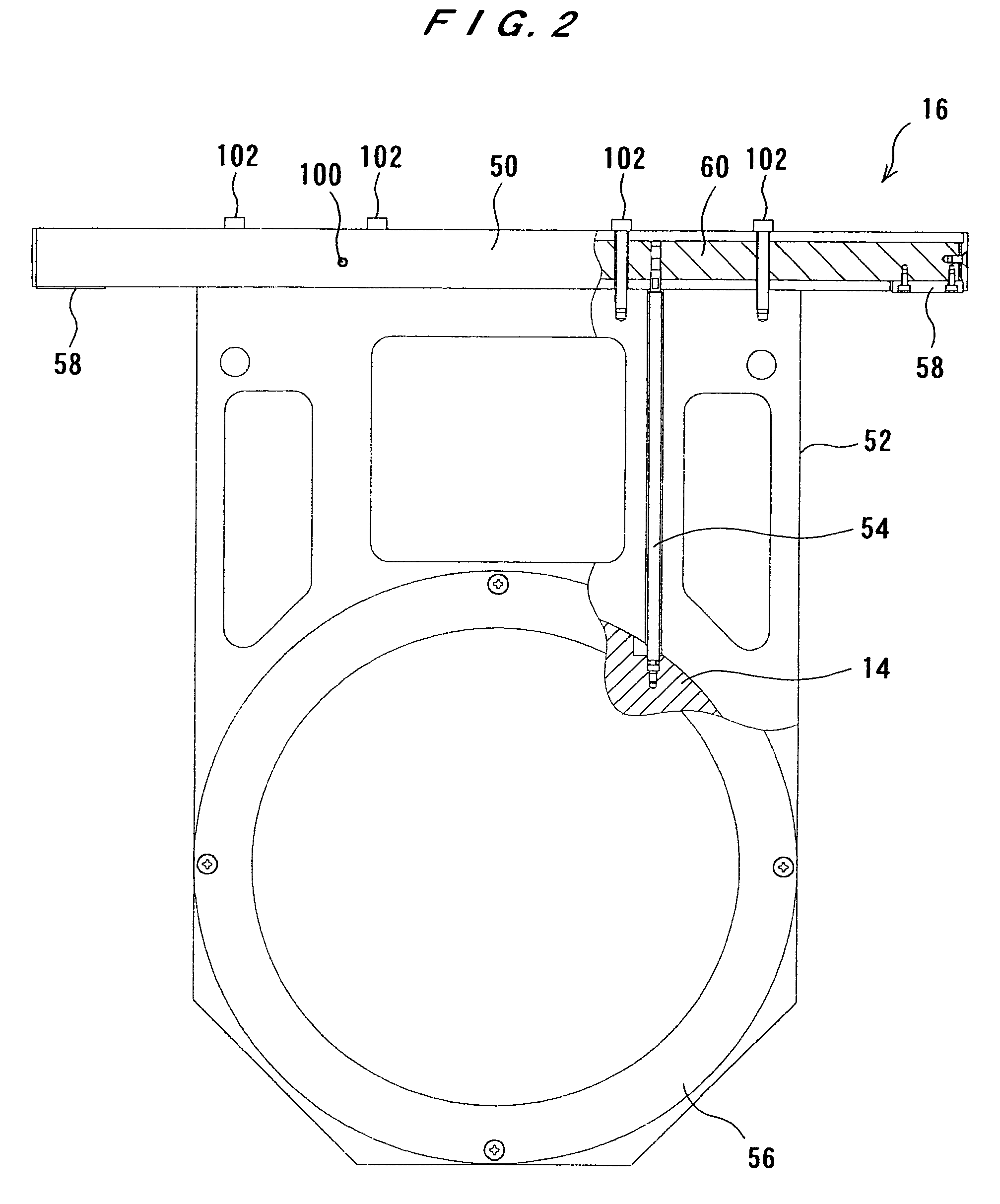

Anode holder

ActiveUS20080017505A1Maintain corrosion resistanceGood electrical connectionCellsMachining electrodesOptoelectronicsElectroplating

An anode holder is used to hold an anode in a plating tank. The anode holder includes a bar having a conductive portion connected to a power source, a conductive anode shaft attached to the bar, and an anode connected to the conductive anode shaft. The conductive anode shaft includes an external thread portion provided at an end of the conductive anode shaft, an O-ring, and a step portion provided between the O-ring and the external thread portion. The step portion has a diameter larger than a diameter of the external thread portion but smaller than a diameter of the O-ring. The anode includes an internal thread hole to which the external thread portion of the conductive anode shaft is screwed. The anode also includes a receiving portion for receiving the step portion of the conductive anode shaft in a state such that the O-ring of the conductive anode shaft is brought into contact with an inner surface of the receiving portion.

Owner:EBARA CORP

Anode holder

ActiveUS7507319B2Reliable electrical connectionMaintain corrosion resistanceMachining electrodesCellsOptoelectronicsScrew thread

An anode holder is used to hold an anode in a plating tank. The anode holder includes a bar having a conductive portion connected to a power source, a conductive anode shaft attached to the bar, and an anode connected to the conductive anode shaft. The conductive anode shaft includes an external thread portion provided at an end of the conductive anode shaft, an O-ring, and a step portion provided between the O-ring and the external thread portion. The step portion has a diameter larger than a diameter of the external thread portion but smaller than a diameter of the O-ring. The anode includes an internal thread hole to which the external thread portion of the conductive anode shaft is screwed. The anode also includes a receiving portion for receiving the step portion of the conductive anode shaft in a state such that the O-ring of the conductive anode shaft is brought into contact with an inner surface of the receiving portion.

Owner:EBARA CORP

Plate capable of providing double-color surface and forming method of plate

ActiveCN102582159ARemains Scratch ResistantMaintain wear resistanceVacuum evaporation coatingSputtering coatingChemical solutionOptoelectronics

The invention relates to a plate capable of providing a double-color surface and a forming method of the plate. The plate comprises a metal or ceramic substrate, a sacrificial layer, a first color layer and a transitional layer, wherein the sacrificial layer is positioned above the substrate and is corroded by a chemical solution easily as compared with the substrate; the first color layer is positioned above the sacrificial layer; and the transitional layer is positioned below the first color layer so as to enhance the binding force of the the transitional layer and the first color layer. The plate can form the background and the pattern and provides patterns with the thin line width by utilizing different colors, and has scratching resistance, wear resistance and corrosion resistance.

Owner:VITALNK IND SHENZHEN

Surface-treated aluminum alloy and surface-treated aluminum alloy clad material

InactiveUS20170115076A1Deterioration of corrosion resistanceSufficient corrosion prevention effectLiquid surface applicatorsLiquid/solution decomposition chemical coatingFree energiesAlloy composite

The present invention provides an aluminum alloy and an aluminum alloy clad material which are capable of retaining corrosion resistance even when a sacrificial material is not used.The present invention is a surface-treated aluminum alloy, in which: a surface film is formed at least on one surface of the aluminum alloy; the thickness of the surface film is 0.1 to 10 μm; a material forming the surface film contains oxides having a standard free energy of formation of 500 kJ / mol or less at a temperature of 500 K by 80% by mass or more in total; and the average particle size of the oxides is 5 to 50 nm.

Owner:KOBE STEEL LTD

Palladium-silver alloy material for dental department

InactiveCN103205594AImprove corrosion resistanceGuaranteed ductilityImpression capsDentistry preparationsGold alloysMechanical property

The invention discloses palladium-silver alloy for repairing an oral cavity. Alloy ingredients are optimized by an alloy material. Compared with the prior art, the obtained material has the advantages of good mechanical property, good corrosion resistance, low sensitization, and beautiful color and luster under the premise of not reducing the alloy property and clinical use effect; and the cost is just 1 / 4 to 1 / 3 of gold alloy.

Owner:SICHUAN QIHE PRECIOUS METALS CO LTD

Pressure transmitter having an isolation assembly with a two-piece isolator plug

ActiveUS9689769B2Maintain corrosion resistanceReduce material costsFluid pressure measurement using elastically-deformable gaugesLower upperManufacturing line

Owner:ROSEMOUNT INC

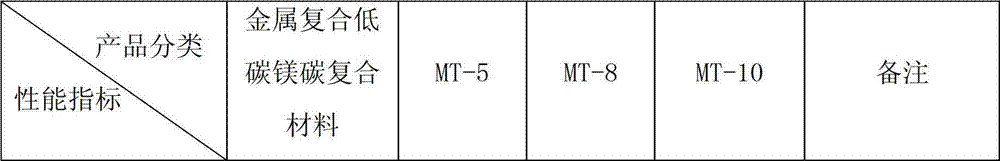

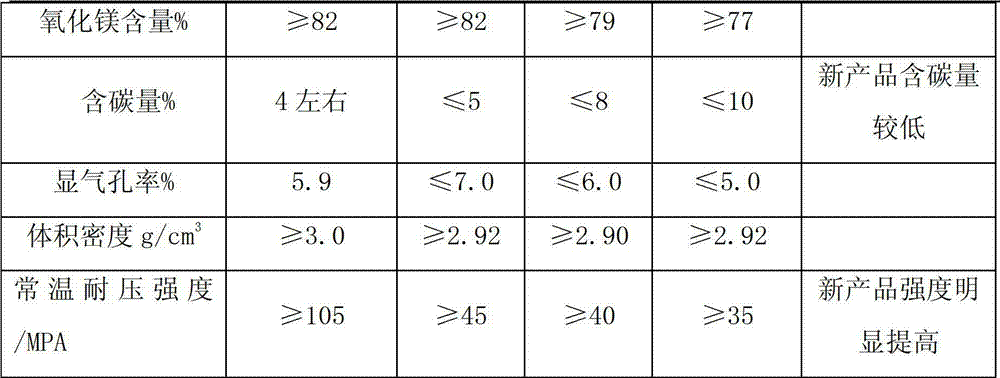

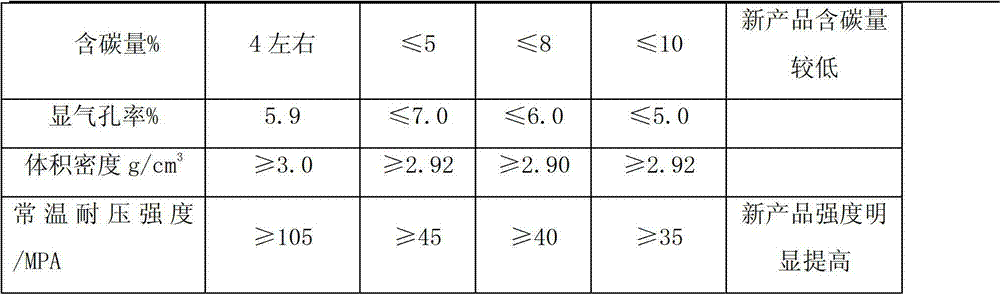

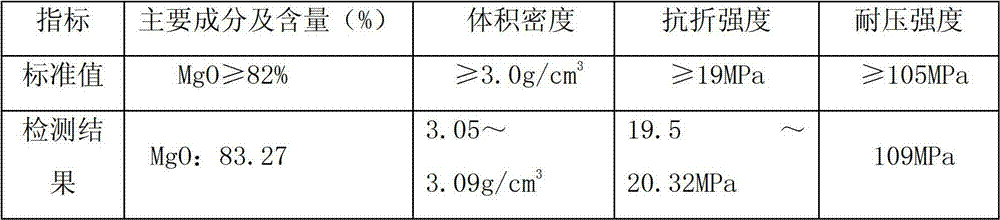

Metal composite low-carbon magnesium-carbon composite material

The invention relates to a refractory material for steel making, particularly a metal composite low-carbon magnesium-carbon composite material. The metal composite low-carbon magnesium-carbon composite material is prepared by carrying out pressure molding on the following components in percentage by weight: 85-95% of magnesite, 2.0-4.5% of graphite, 1.0-6.0% of metal steel fiber, 0.5-2.0% of phenol formaldehyde resin and 1.5-5.0% of metal deoxidizer. The metal deoxidizer is composed of metal aluminum powder and silicon powder in a ratio of 2.0:1-3.0:1. The composite material enhances thermal shock stability and high-temperature strength of the low-carbon magnesium-carbon brick.

Owner:德清县力拓炉料有限公司

Liquid cooling system and electronic apparatus using the same

InactiveUS7296618B2Maintain corrosion resistanceDigital data processing detailsSemiconductor/solid-state device detailsReduced sizeLiquid cooling system

Owner:HITACHI LTD

Metallic composite low-carbon magnesium carbon slag line brick and preparation method thereof

The invention relates to a refractory material line brick for steelmaking and the preparation method of the refractory material line brick, in particular to a metallic composite low-carbon magnesium carbon slag line brick and the preparation method of the metallic composite low-carbon magnesium carbon slag line brick. The composite low-carbon magnesium carbon slag line brick is prepared by pressing and moulding the following components in percentage by weight: 85%-95% of magnesia, 2.0%-4.5% of graphite, 1.0%-6.0% of metallic steel fibre, 0.5%-2.0% of phenolic resin, and 1.5%-5.0% of metal deoxidizer, wherein the metal deoxidizer is composed of metal aluminium powder and silicon powder, wherein the silicon-aluminium ratio is 2.0: 1-3.0: 1. The method for preparing the metallic composite low-carbon magnesium carbon slag line brick comprises the steps of mixing, ageing the mixture, pressing and moulding, and curing to obtain the finished product. The metallic composite low-carbon magnesium carbon slag line brick has the advantages of improving the thermal shock stability and high-temperature strength of the low-carbon magnesium carbon brick.

Owner:德清县力拓炉料有限公司

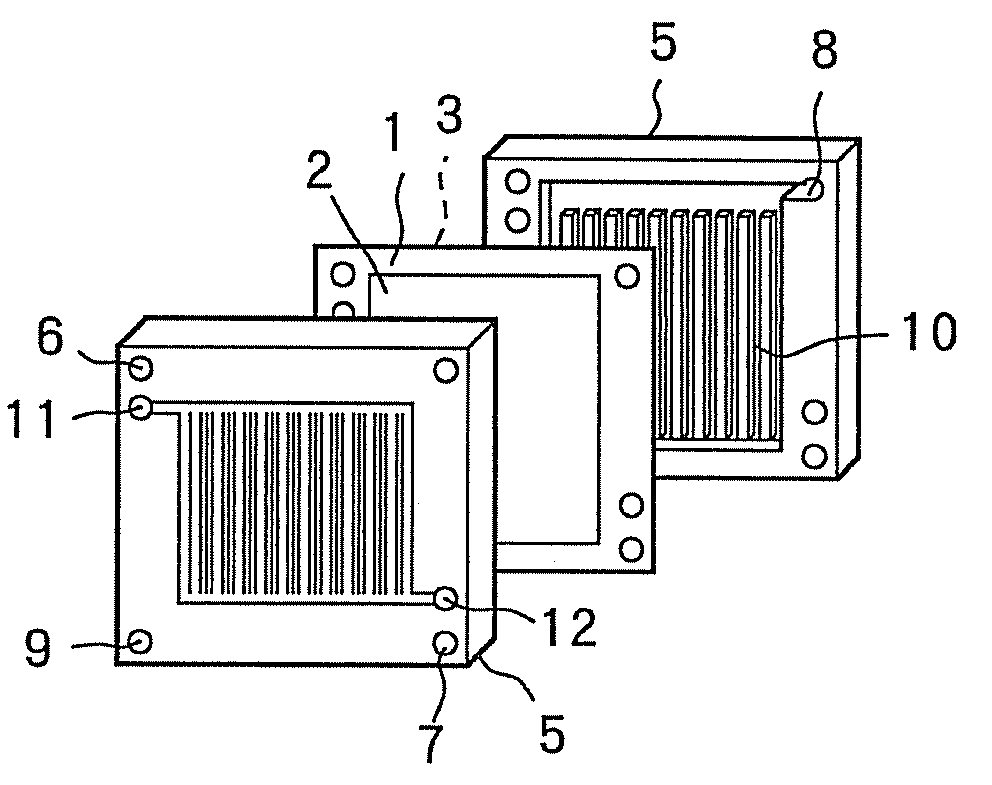

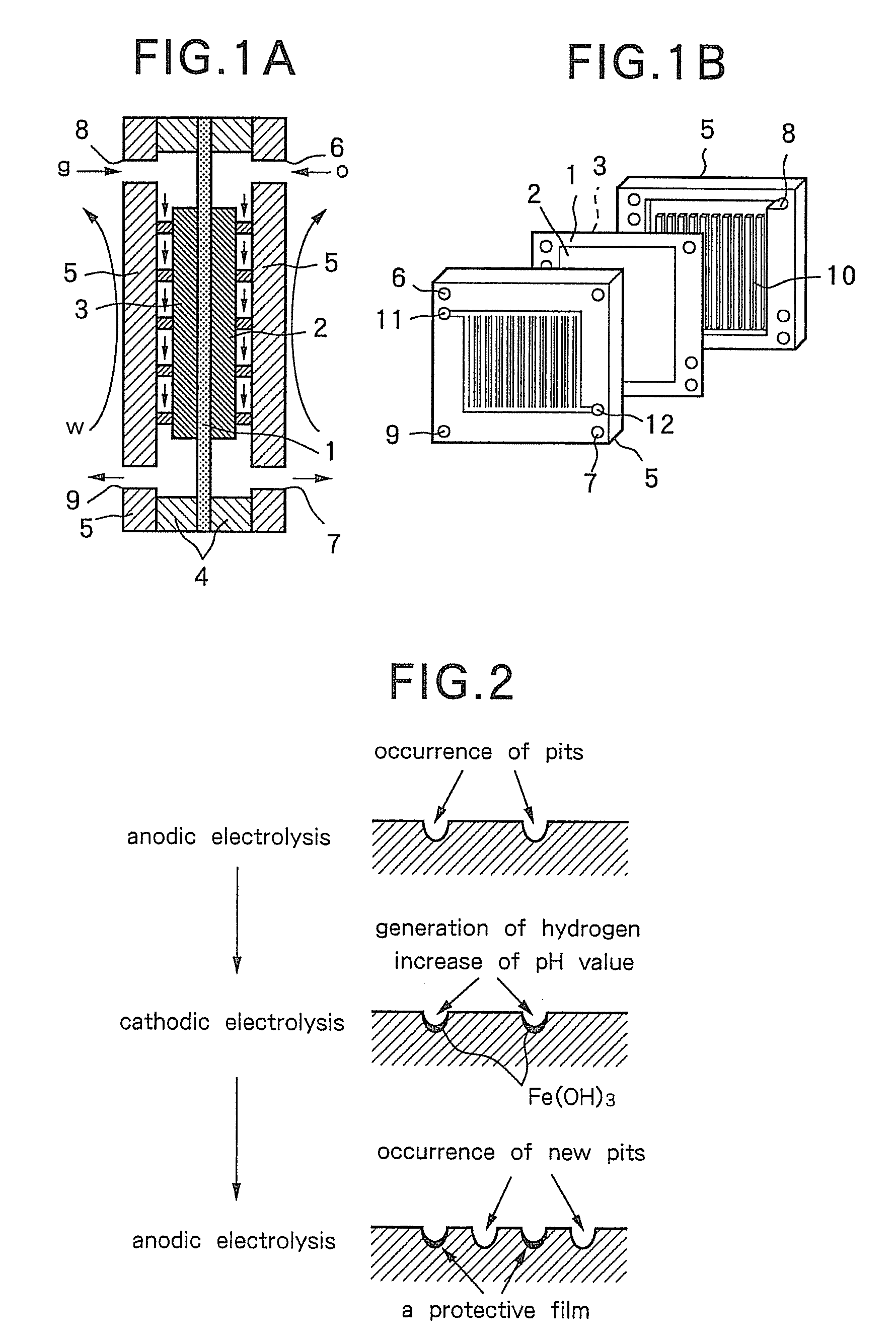

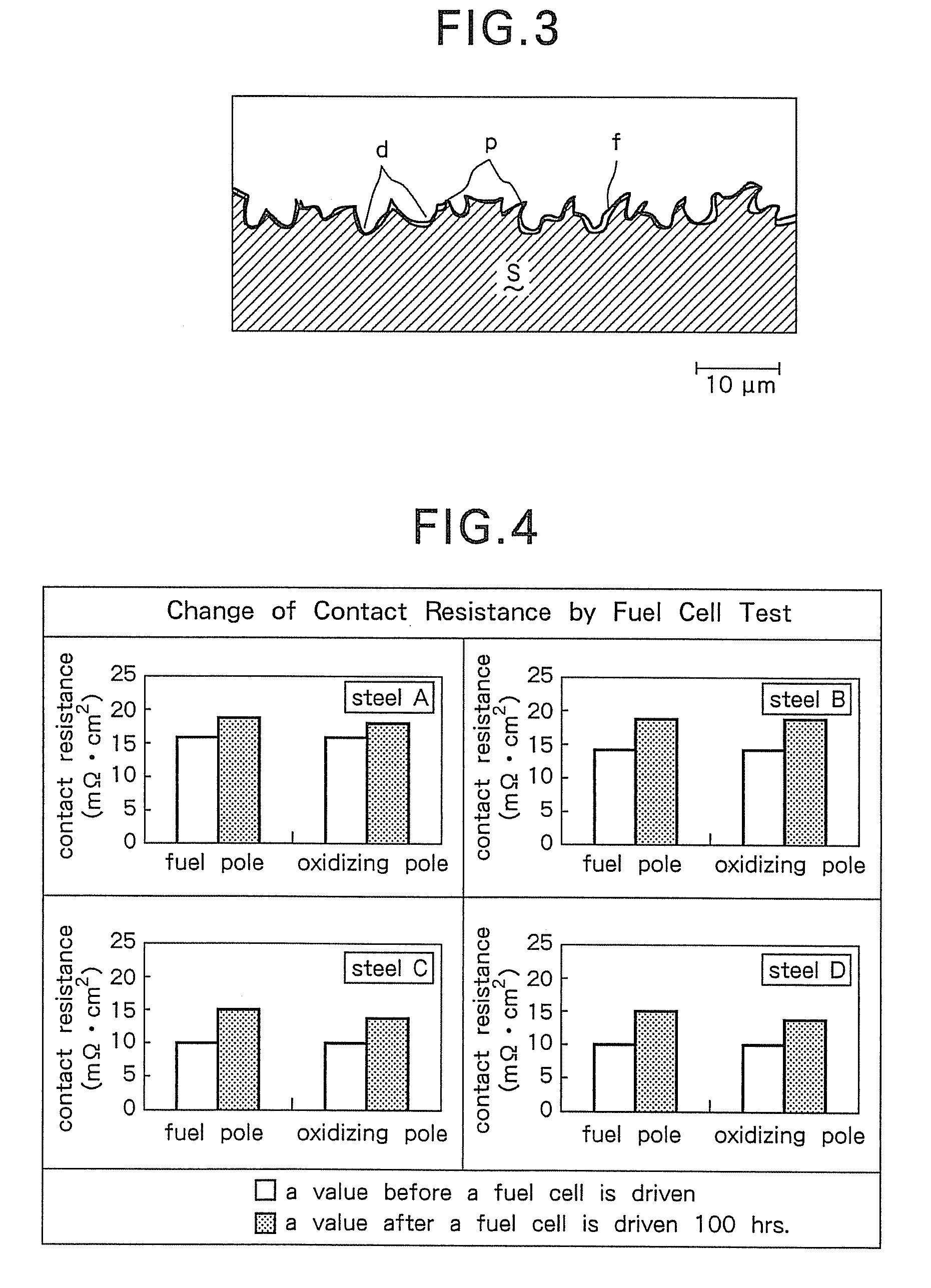

Separator for Low-Temperature Type Fuel Cell and Production Method Therefor

InactiveUS20090130535A1Improve power generation efficiencyReduce contact resistanceFuel cells groupingFinal product manufactureEtchingGraphite electrode

A stainless steel sheet useful as a separator for a low-temperature fuel cell has the surface state that a lot of fine projections (p) stand close together around many fine pits (d) formed over a whole surface. The surface state is realized by alternating electrolytic etching in a ferric chloride solution. When the stainless steel separator is built in a fuel cell, contact resistance between the separator and a graphite electrode is kept at a lower level even in a corrosive atmosphere. Consequently, the fuel cell can be driven with high power-generating efficiency over a long term even under severely corrosive conditions without generation of massive Joule heat.

Owner:NISSHIN STEEL CO LTD

High-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and preparation method thereof

InactiveCN111850361AStay plasticMaintain corrosion resistanceFurnace typesHeat treatment furnacesThin slabManganese

The invention relates to a high-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and a preparation method thereof, and aims to solve the problems of low strength and low post-welding strength of the existing high-performance aluminum alloy sheet in China. The method comprises the following steps of: smelting a pure aluminum ingot, a pure magnesium ingot, an aluminum-manganese intermediate alloy, an aluminum-erbium intermediate alloy, an aluminum-zirconium intermediate alloy, an aluminum-titanium intermediate alloy and an aluminum-beryllium intermediatealloy to obtain an aluminum alloy solution; and sequentially carrying out casting, homogenizing annealing, hot rolling cogging wide rolling, hot continuous rolling, uncoiling slicing, sheet annealing, tension leveling and finished product sawing on the aluminum alloy solution to obtain the aluminum-magnesium-erbium-zirconium alloy wide sheet. The invention can obtain the high-strength corrosion-resistant weldable aluminum-magnesium-erbium-zirconium alloy wide sheet and the preparation method thereof.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Photosensitizer-free photoresist composition used in glass passivated rectifier chip (GPRC) technology

ActiveCN104656373AReduce harmReduce pollutionPhotosensitive materials for photomechanical apparatusCooking & bakingHydrofluoric acid

The invention provides the use of a photosensitizer-free photoresist composition used in a glass passivated rectifier chip (GPRC) technology, wherein the photoresist composition is used in the GPRC technology, and a photosensitizer is saved, so that the production cost is lowered; the process sections such as exposure, development and post-baking are saved, so that the production time is shortened, the efficiency is increased, and the harm to the human body and the pollution to the environment which are caused by chemicals can be reduced; furthermore, the corrosion resistance of the photoresist composition in hydrofluoric acid and a nitric acid etching solution is maintained, so that the toughness of a photoresist layer is improved, and the exposed photoresist from a distance is not bended and does not collapse in corrosive liquid; therefore, the requirements of the production technology can be met, and the photosensitizer-free photoresist composition has very good market prospect.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

Formula and preparation method of low-carbon lubricating oil

ActiveCN103571592AImprove antioxidant capacityImprove nitrification capacityAdditivesFiltrationBase oil

The invention provides a formula and a preparation method of low-carbon lubricating oil. The formula is characterized by comprising the following components in parts by weight: 5 to 30 parts of synthetic base oil, 35 to 55 parts of III-type hydrogenated base oil, 15 to 22 parts of II-type hydrogenated base oil, 8 to 15 parts of V-type synthetic phenolic ester base oil, 5 to 15 parts of hydrogenated base oil 150BS and the balance of additives. The preparation method comprises the following steps of adding the base oil in parts by weight into blending equipment, raising temperature to 60 DEG C, and uniformly blending the base oil at constant temperature; sequentially adding various additives, raising the temperature to 70 to 75 DEG C (not more than 75 DEG C), stirring the base oil and the additives within 40 minutes at constant temperature to completely mix the base oil and the additives, and performing circulating filtration and cooling in four stages to obtain the low-carbon lubricating oil. The formula and the preparation method thereof have the beneficial effects that the limit of soot content is reduced; the low-carbon lubricating oil is energy-saving, low-phosphorus, environment-friendly, high in abrasion resistance and resistant to high temperature and high load; the high-temperature detergency is greatly improved; the carbon emission of the lubricating oil is effectively reduced.

Owner:TIANJIN LINXAN PETROCHEM

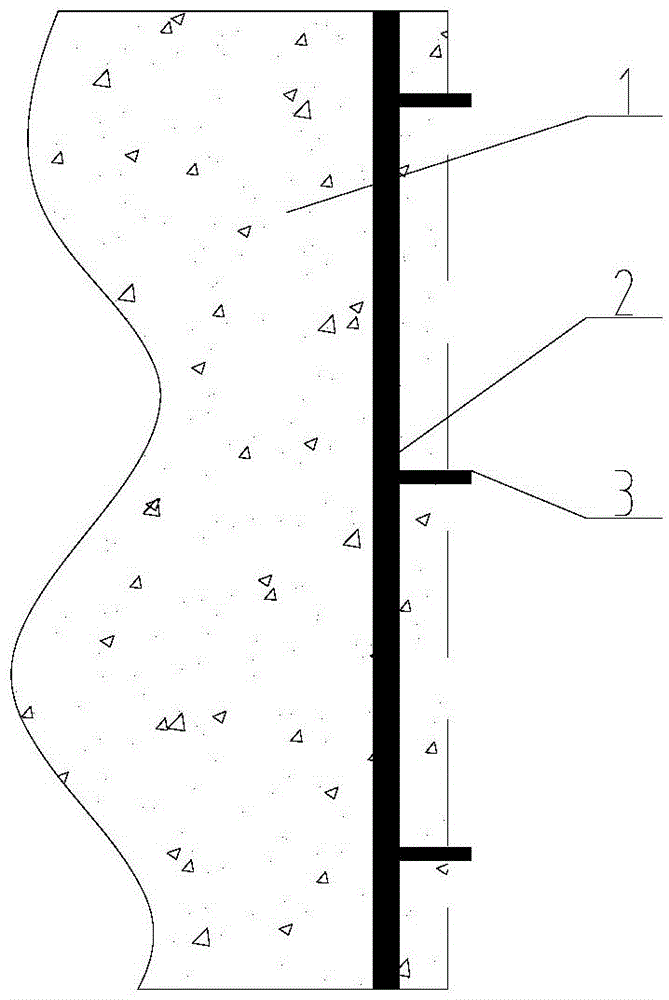

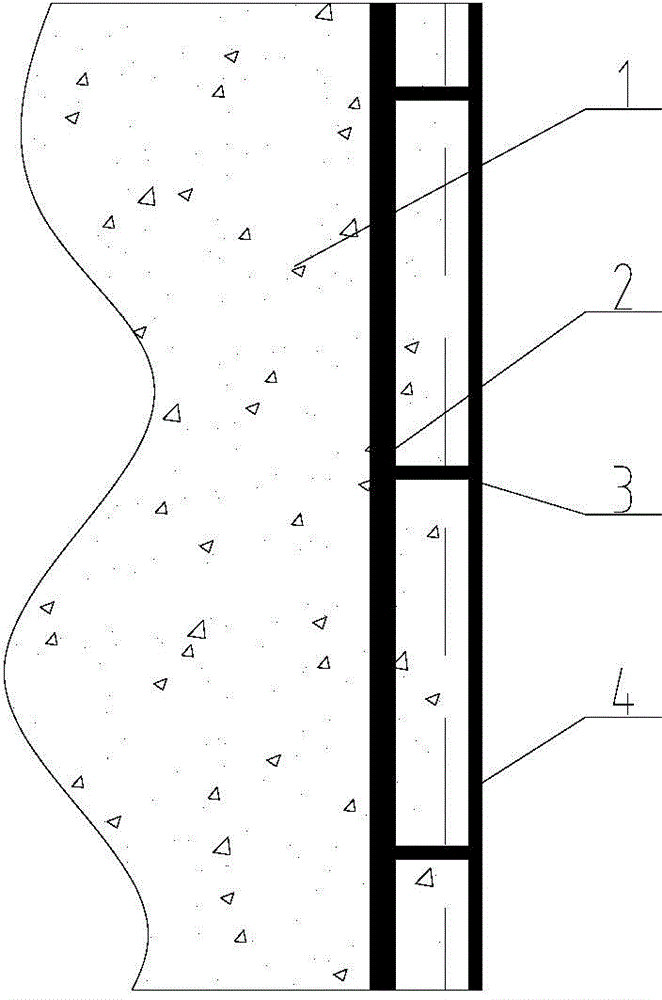

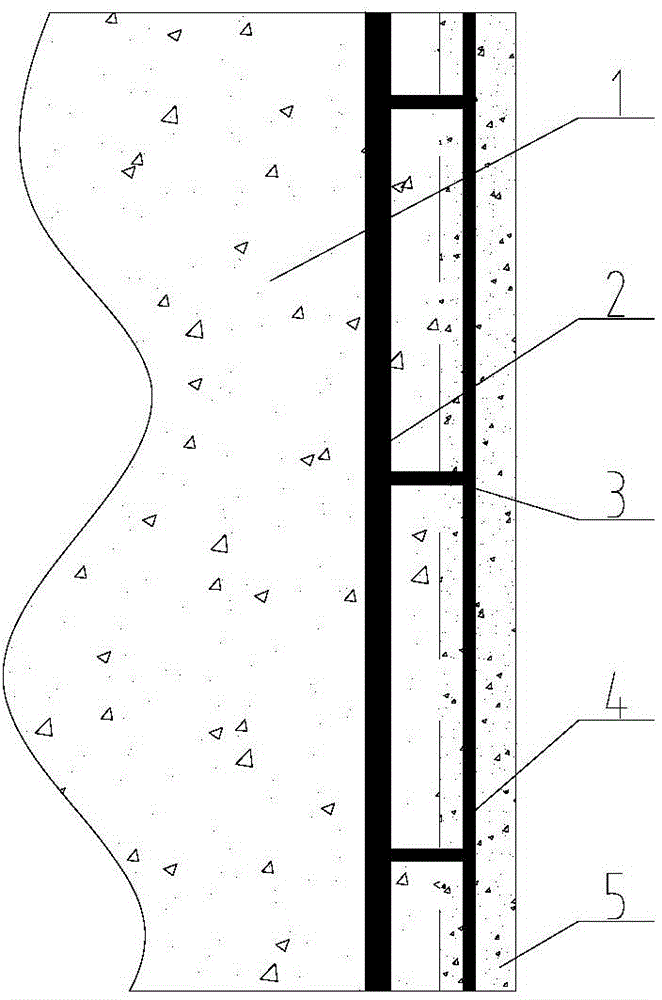

Multi-layer functional corrosion-resistant concrete structure and connecting method thereof

InactiveCN104818883ASatisfy the requirements of anti-corrosion damageIncreased durabilityArtificial islandsTowersSurface layerRebar

The invention provides multi-layer functional corrosion-resistant concrete. The multi-layer functional corrosion-resistant concrete comprises a core concrete structure, a core steel structure, connectors with steel sleeves, welded steel fabric and a surface layer concrete structure. The core steel structure is arranged inside the core concrete structure, the welded steel fabric is arranged inside the surface layer concrete structure, and the core steel structure is connected with the welded steel fabric through the connectors with the steel sleeves. The invention further relates to a mechanical connecting method of the multi-layer functional corrosion-resistant concrete. The core steel structure and the welded steel fabric structure on the surface layer are connected through the connectors, the steel sleeves and deformed steel bars. According to the invention, the requirement for the service strength of marine facilities can be met, the high corrosion resistance is achieved, and therefore oceanic building concrete can have the longer service life. The multi-layer functional corrosion-resistant concrete and the mechanical connecting method of the multi-layer functional corrosion-resistant concrete have the advantages of being high in practicability and functionality.

Owner:盐城市同力新型建材有限公司 +1

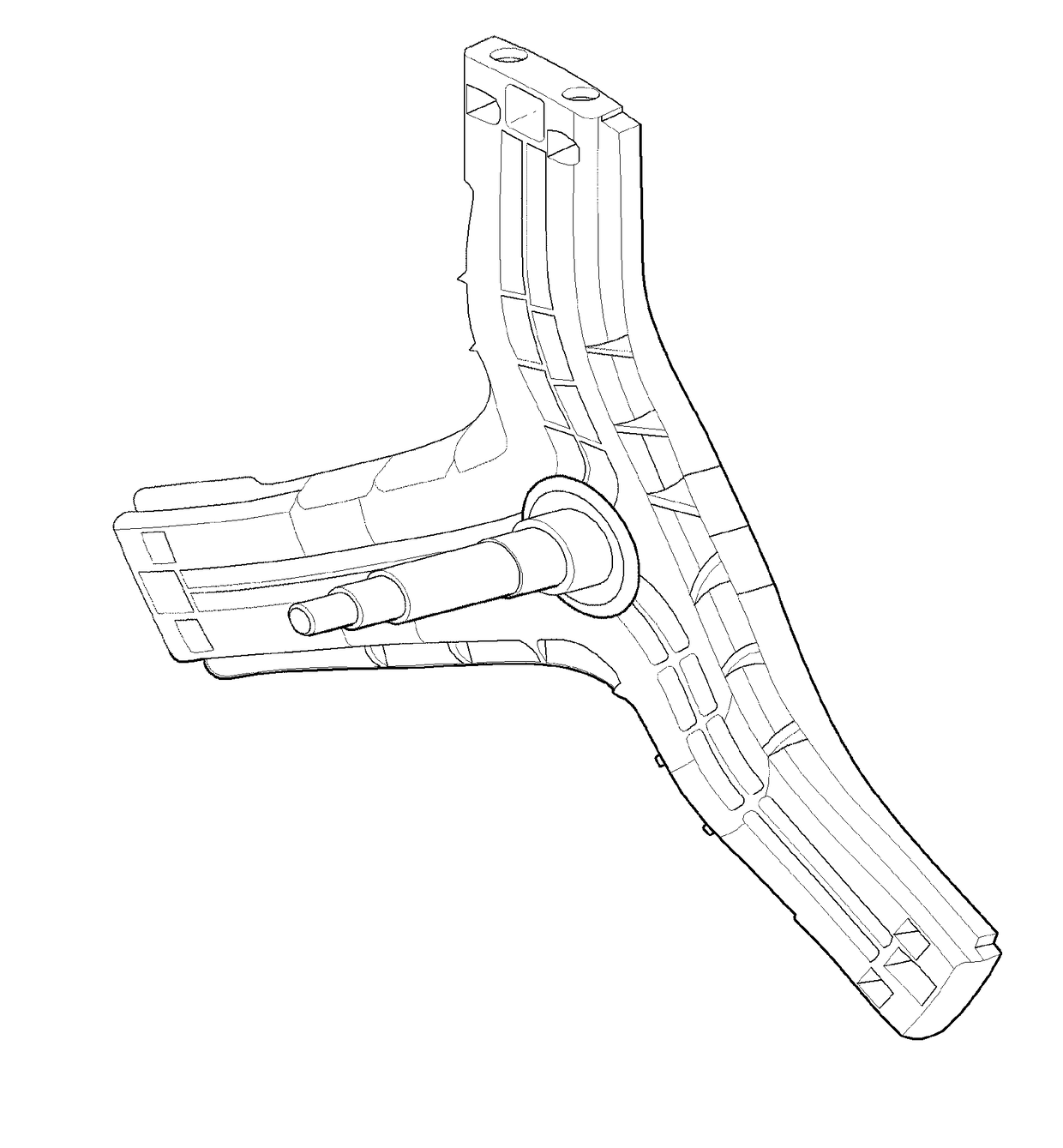

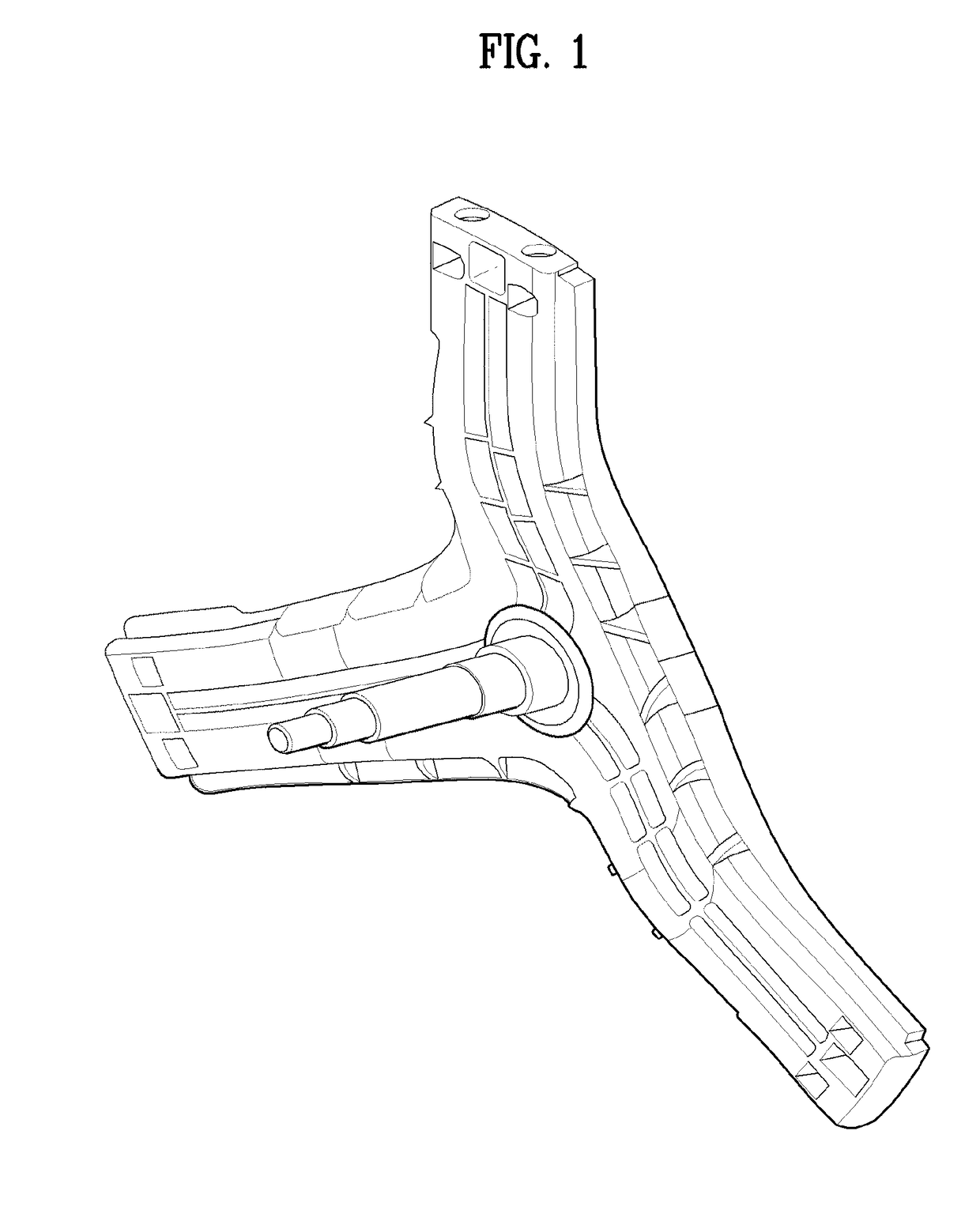

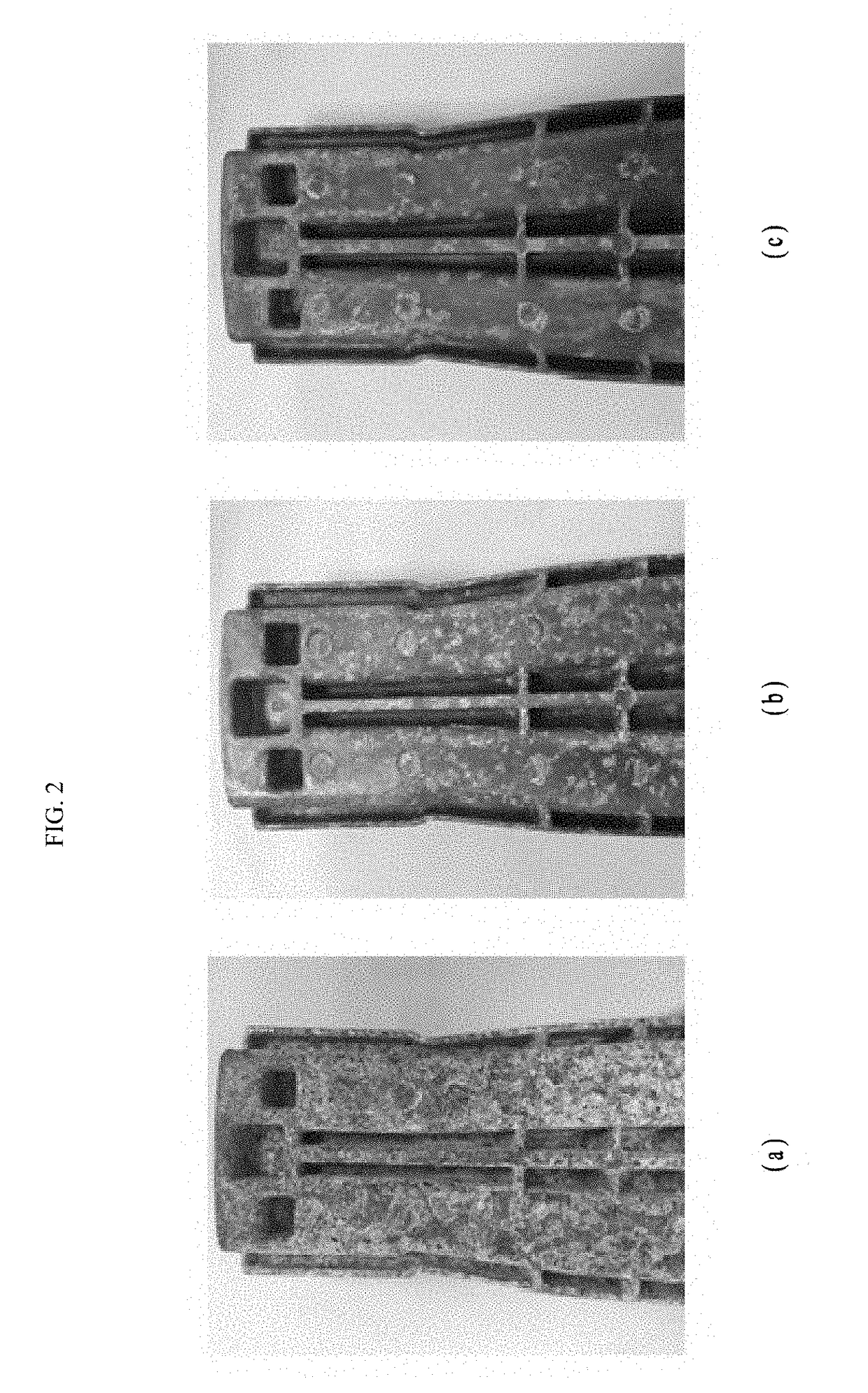

Aluminum alloy for die casting and die casting mold manufactured using the same

ActiveUS20180169745A1Good castabilityIncrease resistanceFoundry mouldsOther washing machinesDie castingCastability

The present disclosure relates to an aluminum alloy for die casting, more particularly, to an aluminum alloy for die casting which has high corrosion resistance, strength and castability.The embodiments of the present disclosure provide an aluminum alloy for die casting comprising a composition ratio having an aluminum (Al) content which occupies almost the composition ratio of the aluminum alloy; a magnesium (Mg) content of 2.5˜3.0%; a silicon (Si) content of 9.6˜0.5%; a zinc (Zn) content of 0.5% or less; and a copper (Cu) content of 0.15% or less.

Owner:LG ELECTRONICS INC

Mullite carbon brick and preparation method thereof

InactiveCN108059473AImprove high temperature thermal strengthImprove thermal shock resistanceBrickAntioxidant

The invention relates to a mullite carbon brick and a preparation method thereof, which belong to the technical field of refractory matter preparation. The mullite carbon brick is prepared from the raw materials: 60 to 75 parts of electro-fused mullite particles, 10 to 30 parts of electro-fused mullite fine powder, 5 to 10 parts of carbon, 1 to 5 parts of antioxidant, and 1 to 3 parts of binding agent. The preparation method comprises the steps of weighing the raw materials according to the raw material ratio, feeding into a mixer for fully mixing, then compression moulding in a brick machine,and finally baking and curing to obtain the mullite carbon brick. The preparation method provided by the invention is simple, the steps are easy to operate, and the mullite particles replace magnesiaparticles, so that the cost increase caused by shortage of magnesia raw materials and price soars is relieved, and meanwhile, excellent performances of erosion resistance and thermal shock resistanceof a magnesia carbon brick are maintained.

Owner:江苏苏嘉集团新材料有限公司

Steel-plate sandwich panel and processing method therefor

InactiveCN106881920AMaintain corrosion resistanceMaintain decorative effectLaminationLamination apparatusSheet steelComposite plate

The invention relates to a steel-plate sandwich panel and a processing method therefor. The steel-plate sandwich panel comprises wrapping steel composite plates at the two sides and a solid material filled between the wrapping steel composite plates. Each steel composite plate comprises wrapping stainless steel plates at the two sides and a middle carbon steel plate; and the solid material is a high-density polyethylene material or foamed ceramic material. A heat insulating material is stuck to the back face of the steel-plate sandwich panel, so that a heat preservation and decoration integrated panel can be formed. The steel-plate sandwich panel disclosed by the invention has the characteristics of high decoration performance, good durability, high strength, convenience in mounting, economical efficiency and reasonableness and can be applied to the fields of architectural decoration, building enclosure and partition, container manufacturing, and the like.

Owner:宝钢建筑系统集成有限公司

Ni Base Alloy and Gas Turbine Blade and Gas Turbine Utilizing the Same

InactiveUS20140064982A1High temperature strengthMaintain corrosion resistancePropellersPump componentsGas turbinesCorrosion

An Ni base alloy uses GTD-111 as a base to improve high-temperature strength while maintaining the weldability and corrosion resistance and a gas turbine blade utilizes the Ni base alloy. The Ni base alloy contains Al of 2.5 to 3.5%, Co of 1.5 to 5.5%, Cr of 11.8 to 13.8%, Mo of 0.4 to 1.4%, Ta of 3.0 to 5.0%, Ti of 5.1 to 6.1%, W of 3.3 to 4.3%, B of 0.01 to 0.02%, C of 0.08 to 0.12% in mass % and remainder containing Ni and inevitable impurities and does not substantially contain Nb.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

A method of suppressing the clogging of rare earth molten steel pouring nozzle by using pulse current

ActiveCN111906266BChemically activeAccelerated decarbonizationMelt-holding vesselsMischmetalMolten steel

A method for suppressing the clogging of a rare earth molten steel pouring nozzle by using a pulse current, which relates to the field of rare earth steel smelting and casting. The corrosion reaction of the rare earth liquid steel interface improves the corrosion resistance of the inner wall of the nozzle to the rare earth molten steel, and further prevents the inclusions in the molten steel from adhering to the inner wall of the nozzle. Aiming at the problem that the rare earth metal elements in molten steel corrode the nozzle in rare earth steel smelting and pouring, and the rare earth inclusions adhere to the nozzle to cause nodules and blockage, the invention aims to propose a method for suppressing the blockage of the rare earth molten steel pouring nozzle by using pulse current. To stabilize the continuous casting process of rare earth steel smelting and improve the quality of continuous casting slabs.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com