Cu-Ni-Sn alloy belt foil for 5G communication and preparation method thereof

A cu-ni-sn, alloy strip technology, applied in the field of copper alloy materials, can solve problems such as the inability to achieve industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

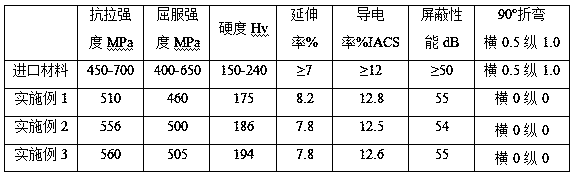

Examples

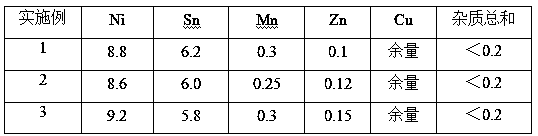

Embodiment 1

[0030] (1) Melting: Melt the weighed copper and nickel in the smelting furnace, add charcoal to cover and stir after fully melting, add manganese (coated with copper skin), tin and zinc (coated with copper skin) in sequence, and heat up to Stir and melt at 1330°C. After melting, remove slag and cover it with charcoal. After standing still, it is ready to transfer to the holding furnace. After the converter, remove slag again and cover it with calcined charcoal;

[0031] (2) Horizontal continuous casting: drawing casting is carried out by reverse push-pull-stop casting method, the melt temperature is 1260°C when pulling up, the melt temperature is 1230°C during normal casting, and the pulling speed is 50mm / min, The reverse thrust is 1.5mm, the normal casting speed is 110mm / min, the billet outlet temperature is 300°C, and the billet is drawn and cast into a billet with a billet size of 14×450mm and a coil weight of 3.45 tons; the cooling water in the drawing casting process The ...

Embodiment 2

[0040] (1) Melting: Melt the weighed copper and nickel in the smelting furnace, add charcoal to cover and stir after fully melting, add manganese (coated with copper skin), tin and zinc (coated with copper skin) in sequence, and heat up to Stir and melt at 1300~1330°C, remove slag and cover with charcoal after melting, stand still to prepare the converter, after the converter, carry out slag removal again, and cover with calcined charcoal;

[0041] (2) Horizontal continuous casting: drawing casting is carried out in the way of reverse push-pull-stop. The melt temperature is 1250°C~1290°C when pulling up, and the melt temperature is 1200°C~1250°C during normal casting. The speed is 40mm / min to 60mm / min, the reverse thrust is 0.5mm to 2.5mm, the normal casting speed is 100mm / min to 120mm / min, the billet outlet temperature is 200°C to 350°C, and the billet is drawn and cast into coils. The size of the billet is 14×450mm, and the weight of the coil is 3-4 tons. The pressure is 0....

Embodiment 3

[0050] (1) Melting: Melt the weighed copper and nickel in the smelting furnace, add charcoal to cover and stir after fully melting, add manganese (coated with copper skin), tin and zinc (coated with copper skin) in sequence, and heat up to Stir and melt at 1300~1330°C, remove slag and cover with charcoal after melting, stand still to prepare the converter, after the converter, carry out slag removal again, and cover with calcined charcoal;

[0051] (2) Horizontal continuous casting: drawing casting is carried out in the way of reverse push-pull-stop. The melt temperature is 1250°C~1290°C when pulling up, and the melt temperature is 1200°C~1250°C during normal casting. The speed is 40mm / min to 60mm / min, the reverse thrust is 0.5mm to 2.5mm, the normal casting speed is 100mm / min to 120mm / min, the billet outlet temperature is 200°C to 350°C, and the billet is drawn and cast into coils. The size of the billet is 14×450mm, and the weight of the coil is 3-4 tons. The pressure is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com