Steaming type anti-corrosion anti-scale heat conducting coating on surface of condenser coil pipe

A technology of evaporative condenser and heat-conducting coating, which is applied in pipeline anti-corrosion/rust protection, coating, damage protection, etc. It can solve the problems of high heat exchange efficiency and long service life, achieve good heat conduction performance, and suppress Corrosion, good thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

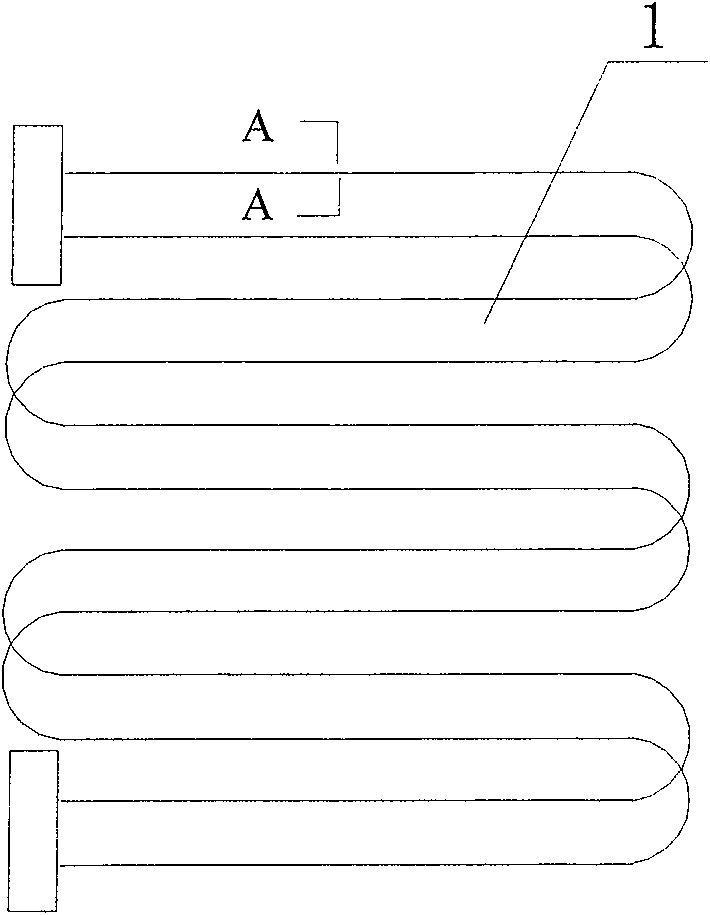

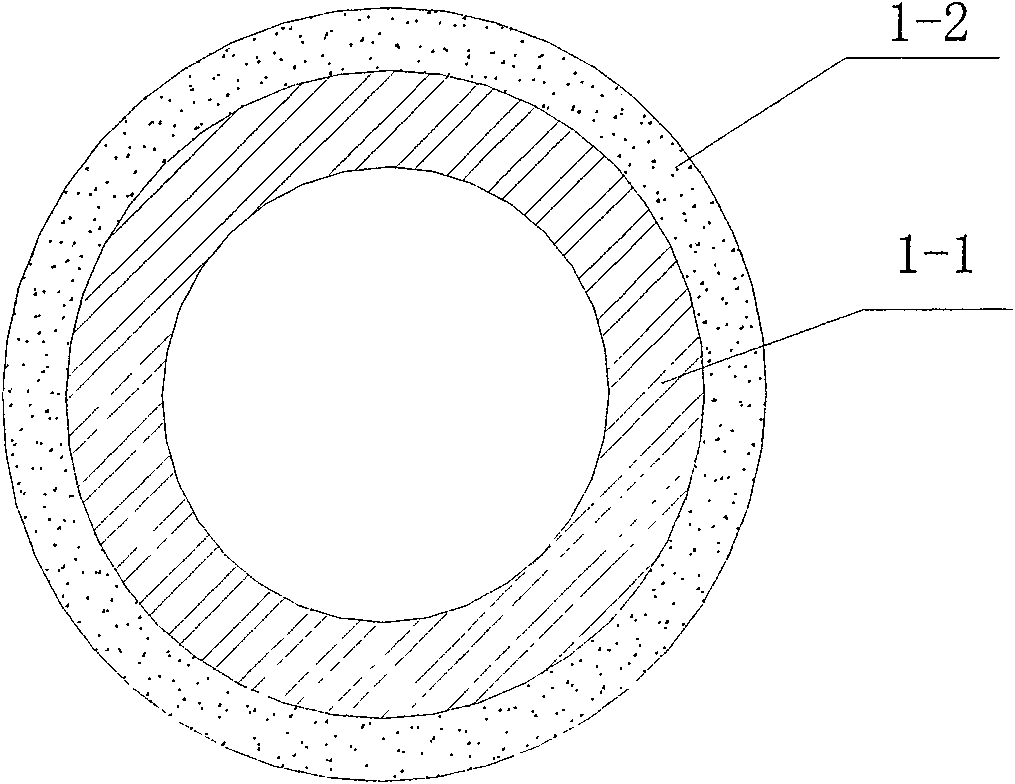

[0029] Carbon steel circular coil structure such as figure 1 As shown, the coating yields figure 2 The coating structure shown, wherein the coating formulation is as follows:

[0030] Phosphate-containing modified water glass 10kg

[0031] Chlorosulfonated polyethylene 15kg

[0032] Zinc molten liquid 2kg

[0033] 33kg of water

[0034] Alkylsulfonate 0.08kg

[0035] The preparation method is: first mix the modified water glass containing phosphate, chlorosulfonated polyethylene and alkyl sulfonate, add it into the water, stir it well, then add the zinc melt and stir it evenly, then it can be used .

[0036] The evaporative condenser anti-corrosion and anti-fouling heat-conducting coating prepared according to the above method is coated on the surface of the coil by dipping method, and dried at 200°C for 1 hour. The thickness of the film layer is 2nm, 45nm and 80nm respectively. Increased by 10%, 30%, 13%, soaked in 5% sodium chloride acetic acid acidic (HAC adjusted P...

Embodiment 2

[0038] Carbon steel circular coil structure such as figure 1 As shown, the coating yields figure 2 The coating structure shown, wherein the coating formulation is as follows:

[0039] Phosphate-containing modified water glass 15kg

[0040] Chlorosulfonated polyethylene 25kg

[0041] Zinc molten liquid 5kg

[0042] 63kg of water

[0043] Alkylsulfonate 0.315kg

[0044] The preparation method is as follows: first mix the modified water glass containing phosphate, chlorosulfonated polyethylene and alkyl sulfonate, add it into water, stir thoroughly, then add zinc melt and stir well before use.

[0045] The evaporative condenser anti-corrosion and anti-fouling heat-conducting coating prepared according to the above method is coated on the surface of the coil by dipping method, and dried at 200°C for 1 hour. The thickness of the film layer is 2nm, 45nm and 80nm respectively. Increased by 10%, 31%, 14%, soaked in 5% sodium chloride acetic acid (HAC adjusts PH=3) solution for ...

Embodiment 3

[0047] Carbon steel circular coil structure such as figure 1 As shown, the coating yields figure 2 The coating structure shown, wherein the coating formulation is as follows:

[0048] Phosphate-containing modified water glass 25kg

[0049] Chlorosulfonated polyethylene 30kg

[0050] Zinc molten liquid 6kg

[0051] 74kg of water

[0052] Alkylsulfonate 0.37kg

[0053] The preparation method is as follows: first mix the modified water glass containing phosphate, chlorosulfonated polyethylene and alkyl sulfonate, add it into water, stir thoroughly, then add zinc melt and stir well before use.

[0054] The evaporative condenser anti-corrosion and anti-fouling heat-conducting coating prepared according to the above method is coated on the surface of the coil by dipping method, and dried at 200°C for 1 hour. The thickness of the film layer is 2nm, 45nm and 80nm respectively. Increased by 12%, 28%, 15%, soaked in 5% sodium chloride acetic acid acidic (HAC adjusted PH=3) soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com