Plate capable of providing double-color surface and forming method of plate

A plate and two-color technology, applied in chemical instruments and methods, metal material coating technology, decorative arts, etc., can solve problems such as environmental impact, side erosion, and incomplete pattern edges, and achieve the effect of maintaining scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

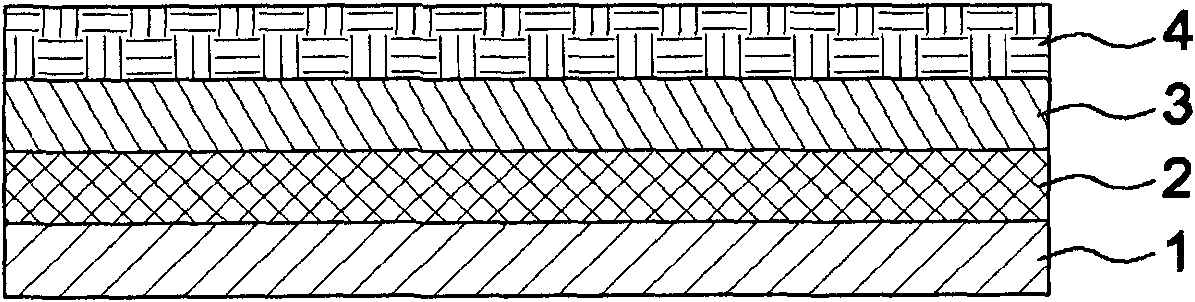

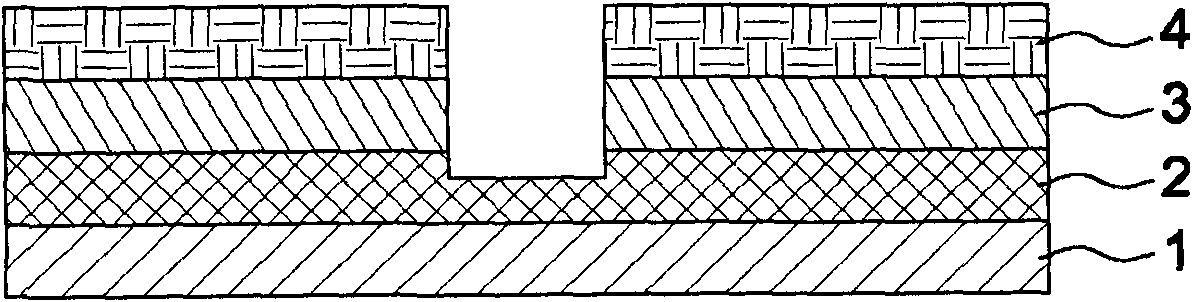

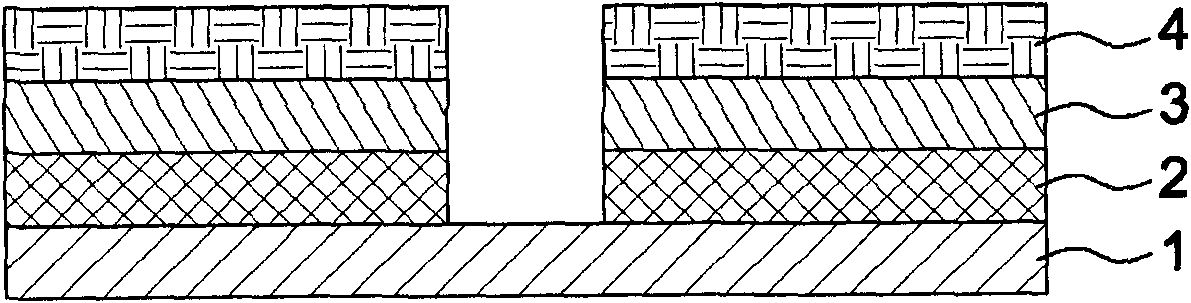

[0019] Figure 1a As an example of this case, it is a board that can provide a two-color surface, the pattern displayed on it is the color of the substrate 1, and the first color layer 4 is used as the background color. In this embodiment, the substrate 1 can be made of metal or ceramics, and the sacrificial layer 2 is made of pure metal, and its metal can include titanium (Ti), tungsten (W), chromium (Cr) and zirconium (Zr), etc. A kind of metal, the metal forming the sacrificial layer 2 is different from its upper and lower layers, and has good bonding force with its upper and lower layers. One of the main purposes of the sacrificial layer 2 is to protect the substrate 1 when the pattern is engraved with a laser. In addition, the sacrificial layer 2 is more likely to be corroded by chemical solutions than its upper and lower layers (such as the substrate). According to a preferred embodiment, the sacrificial layer 2 has a thickness of 0.2 um to 0.5 um according to the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com