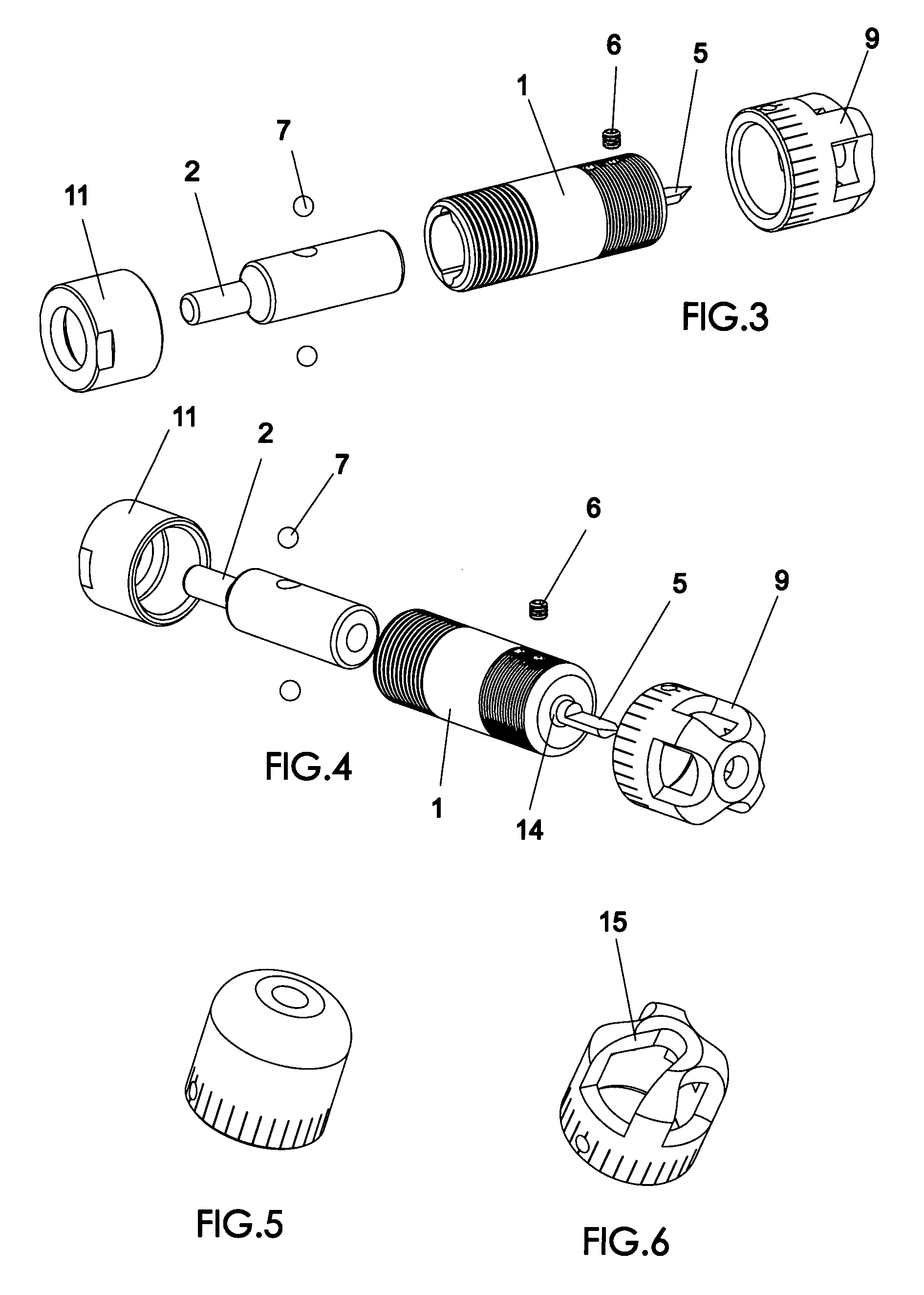

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1916results about "Engraving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

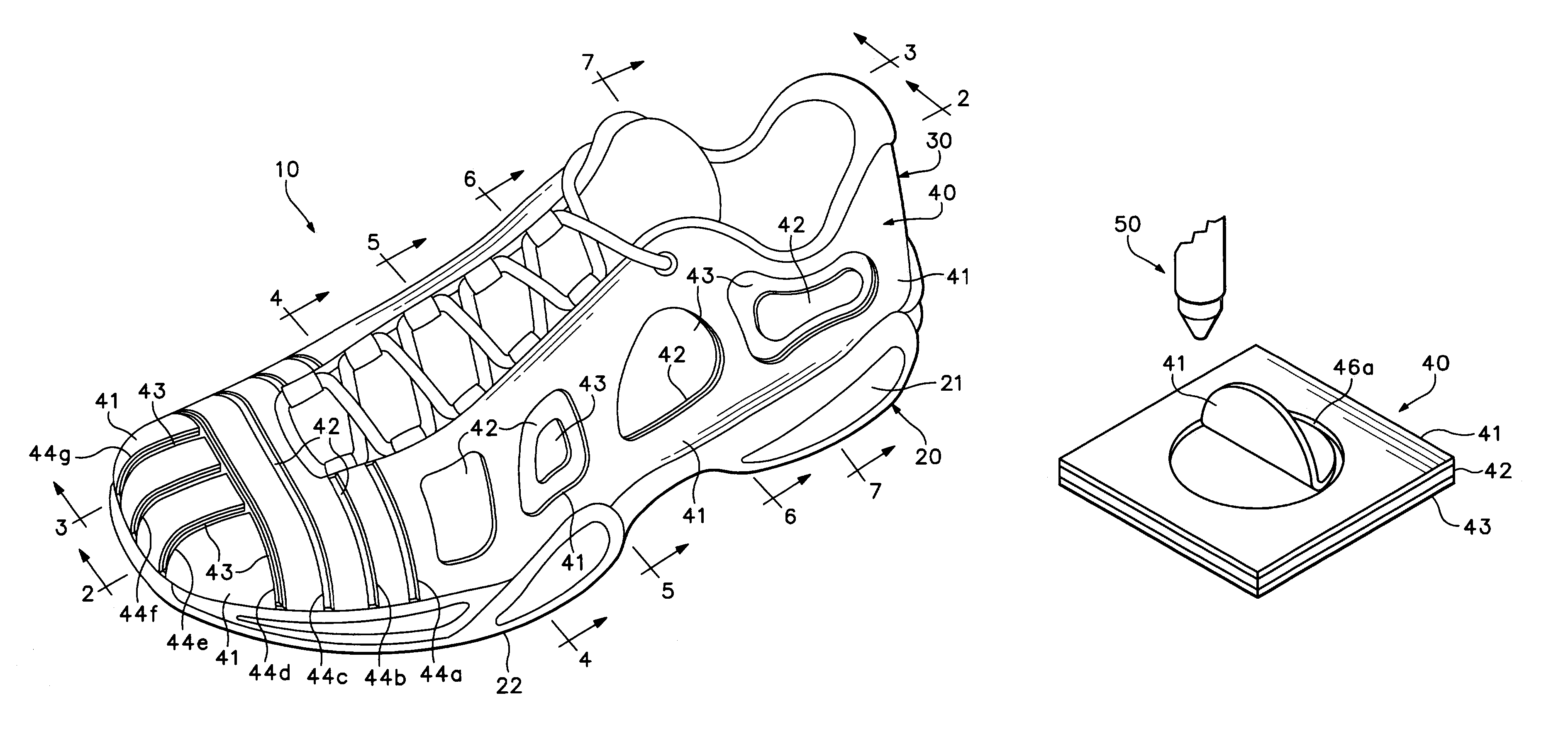

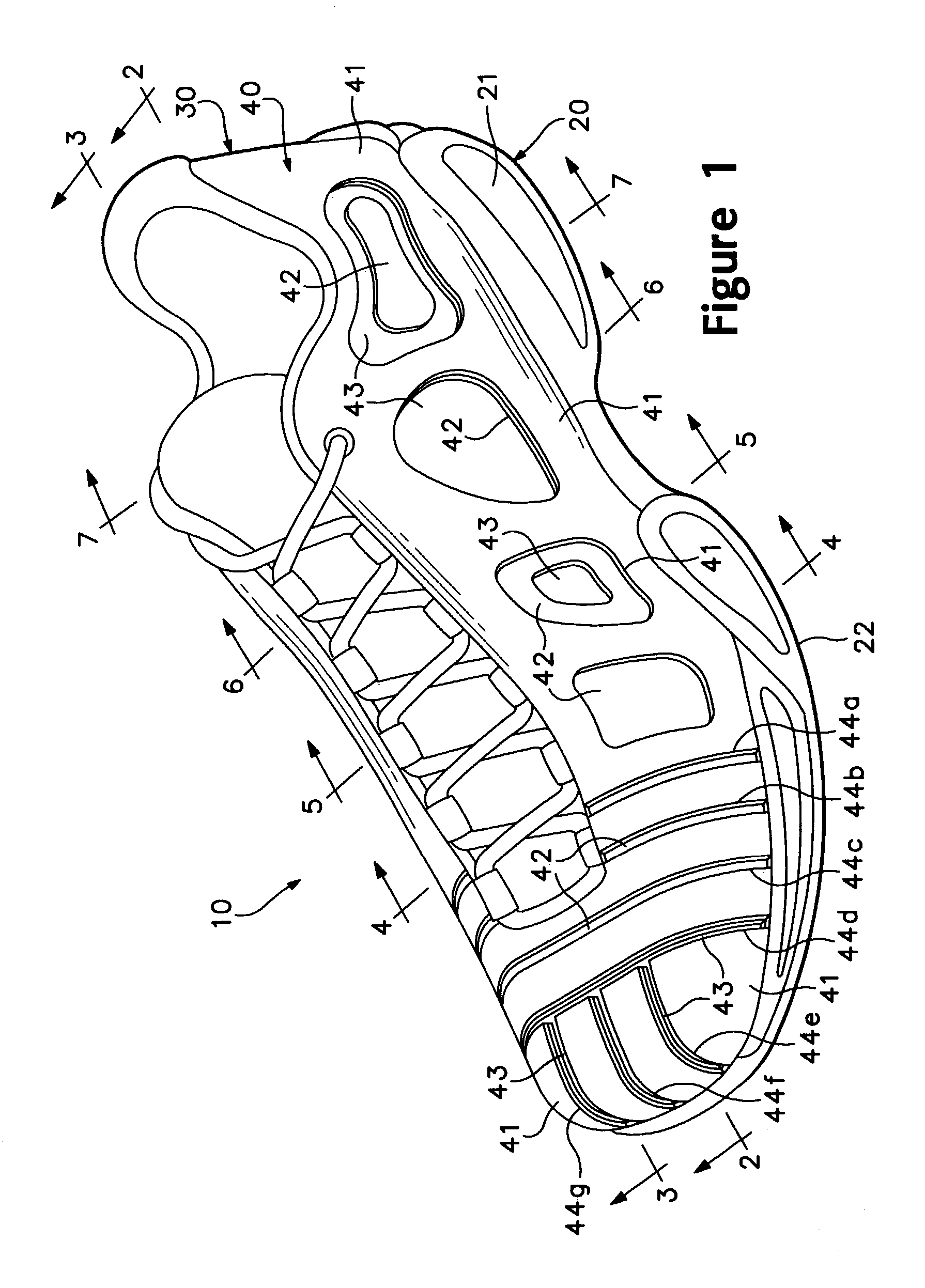

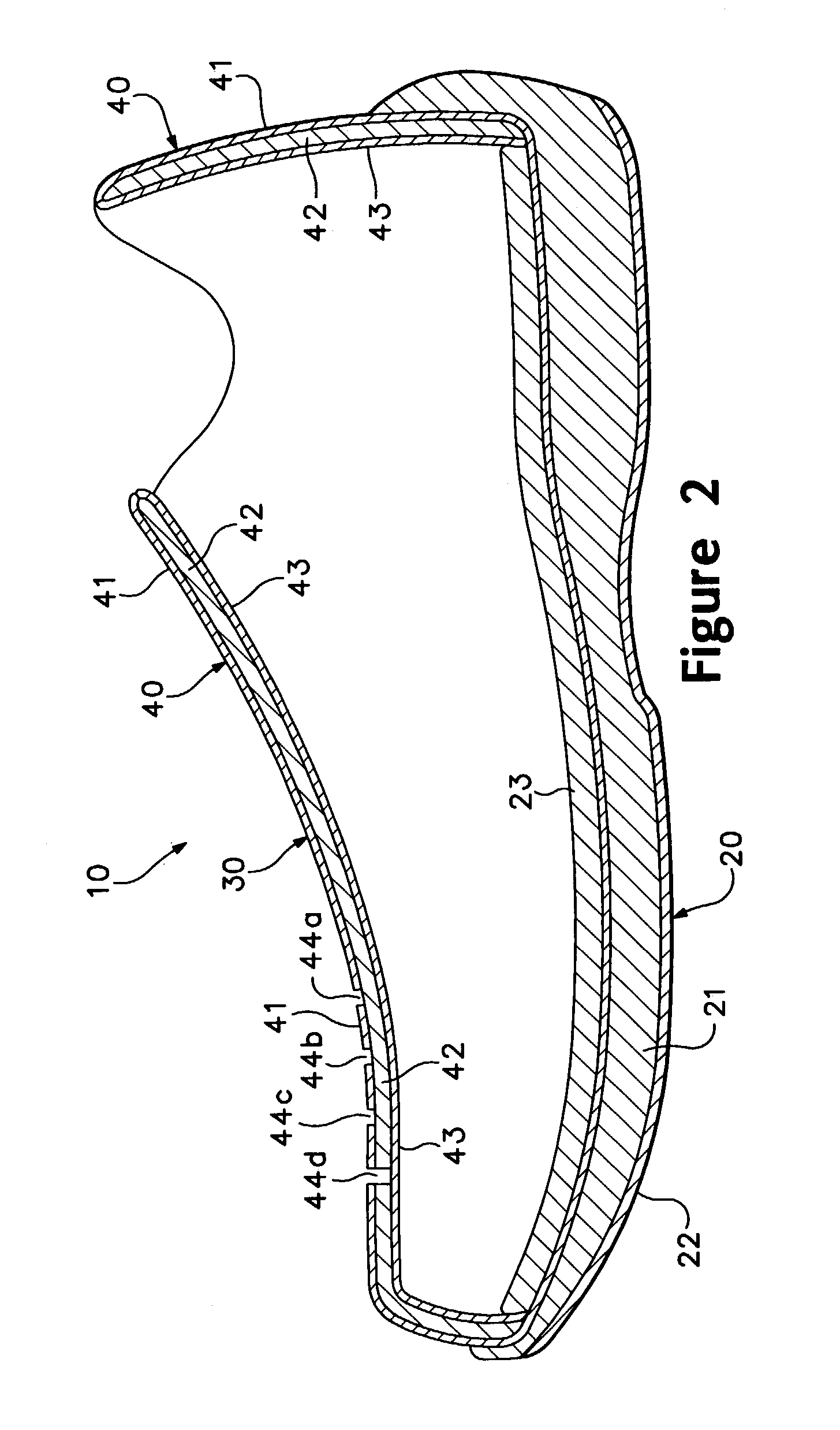

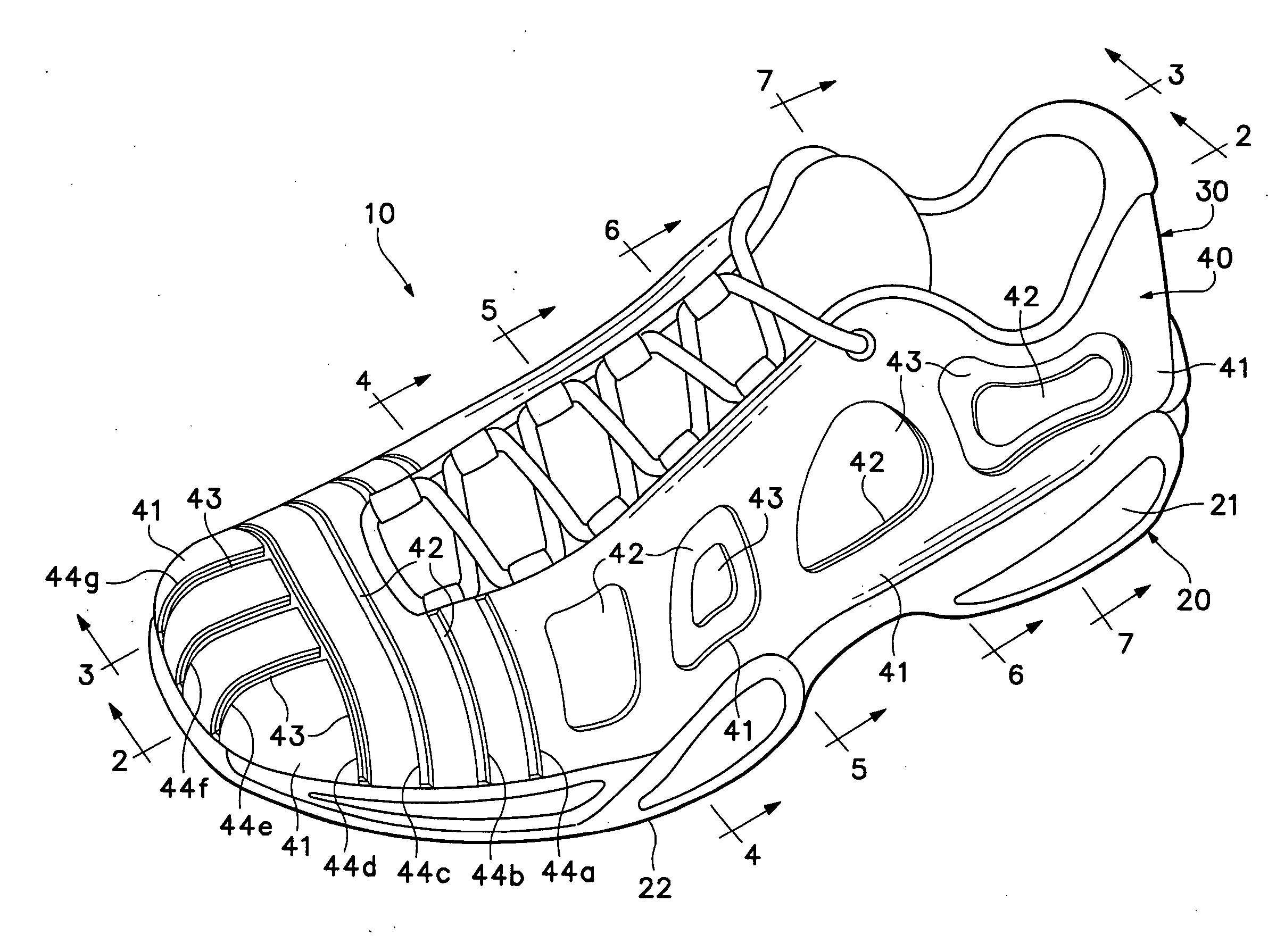

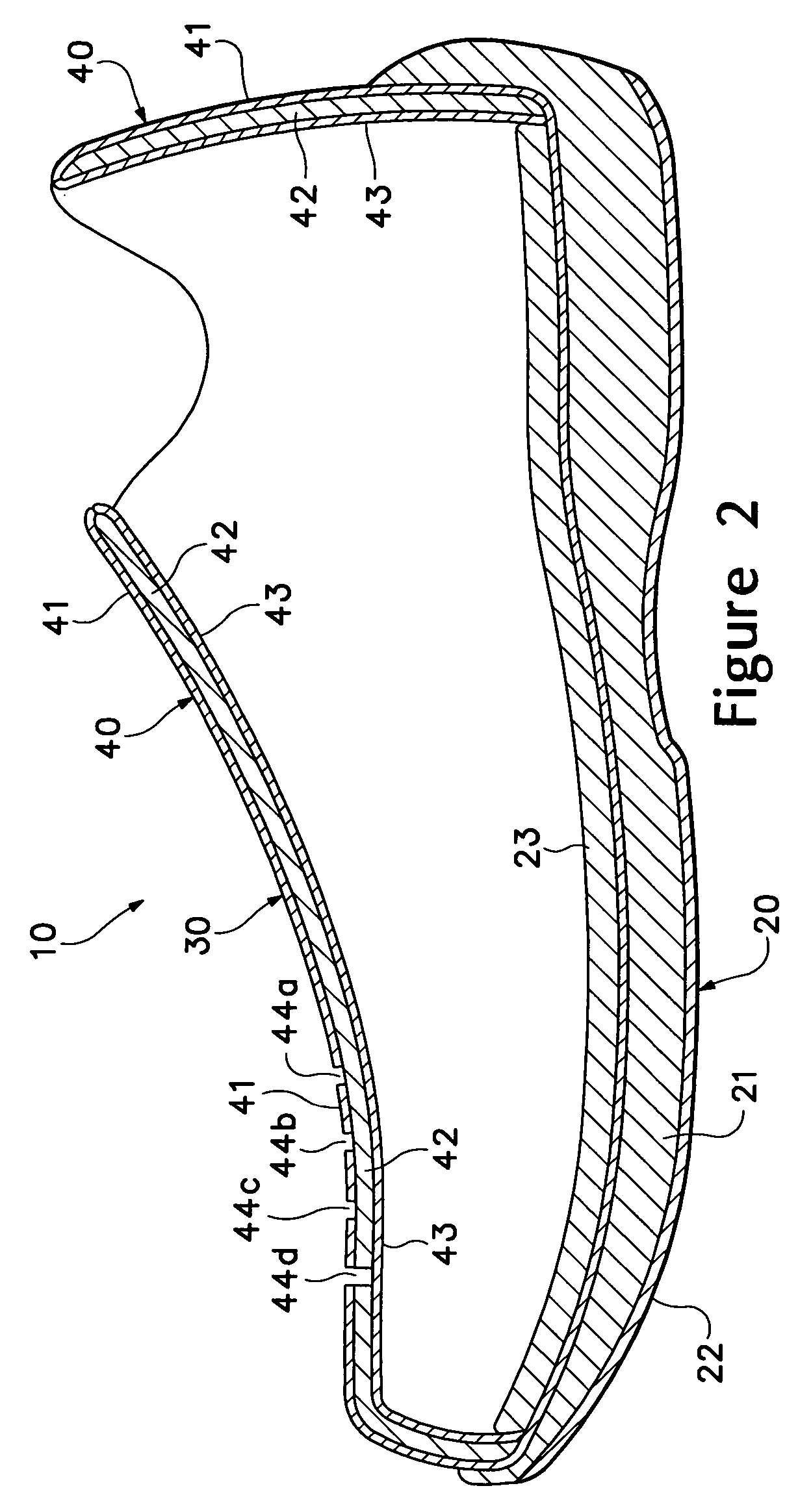

Article and method for laser-etching stratified materials

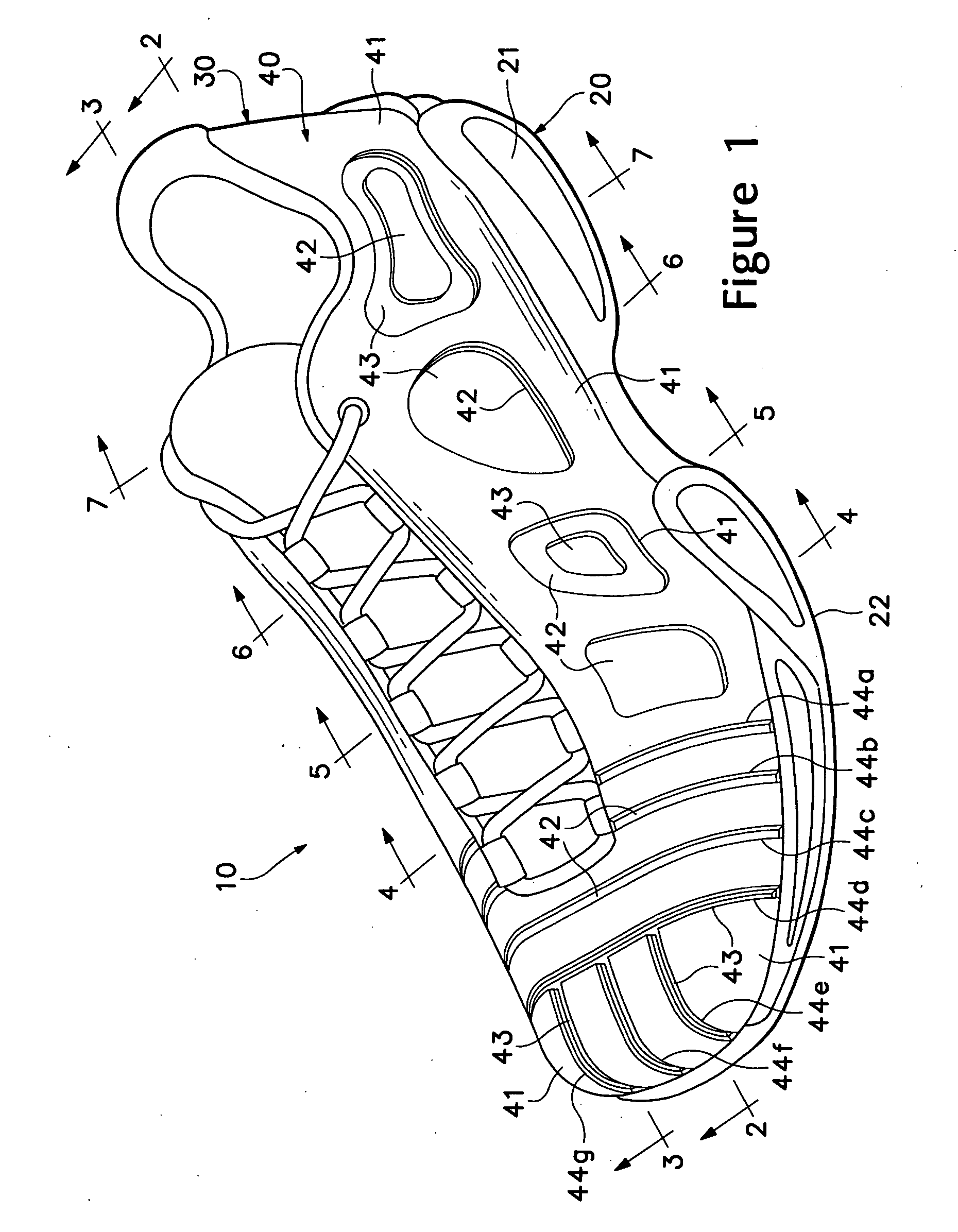

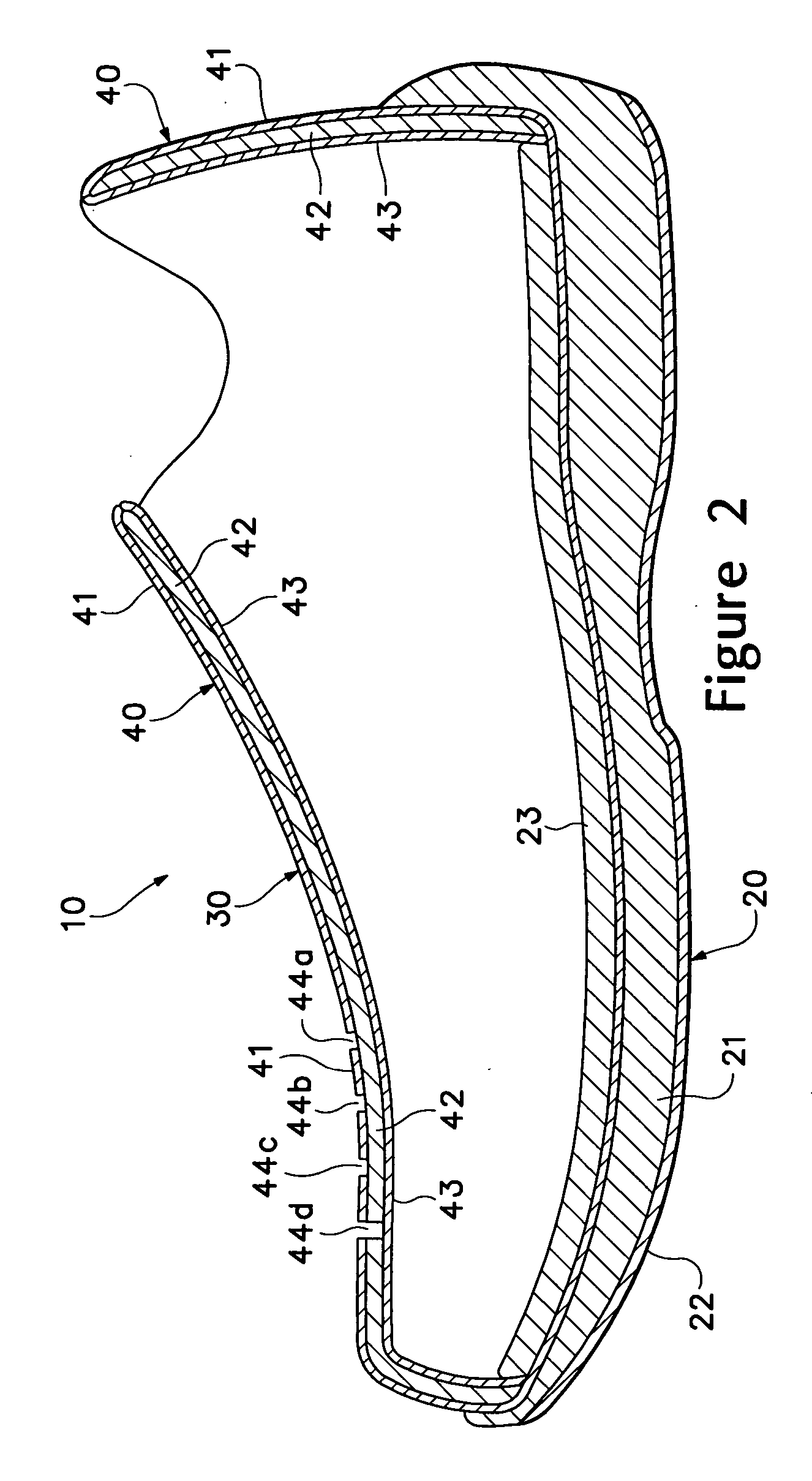

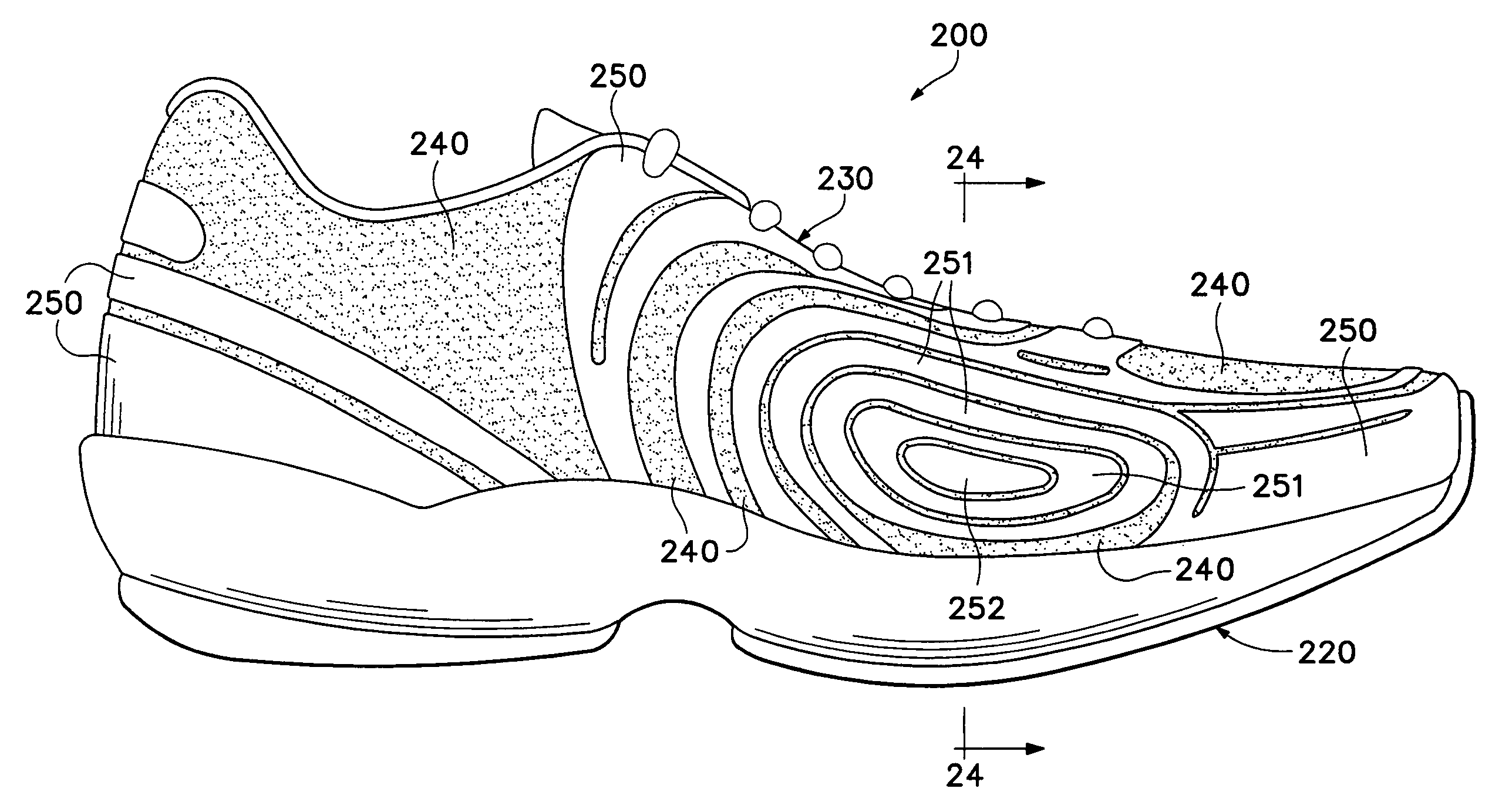

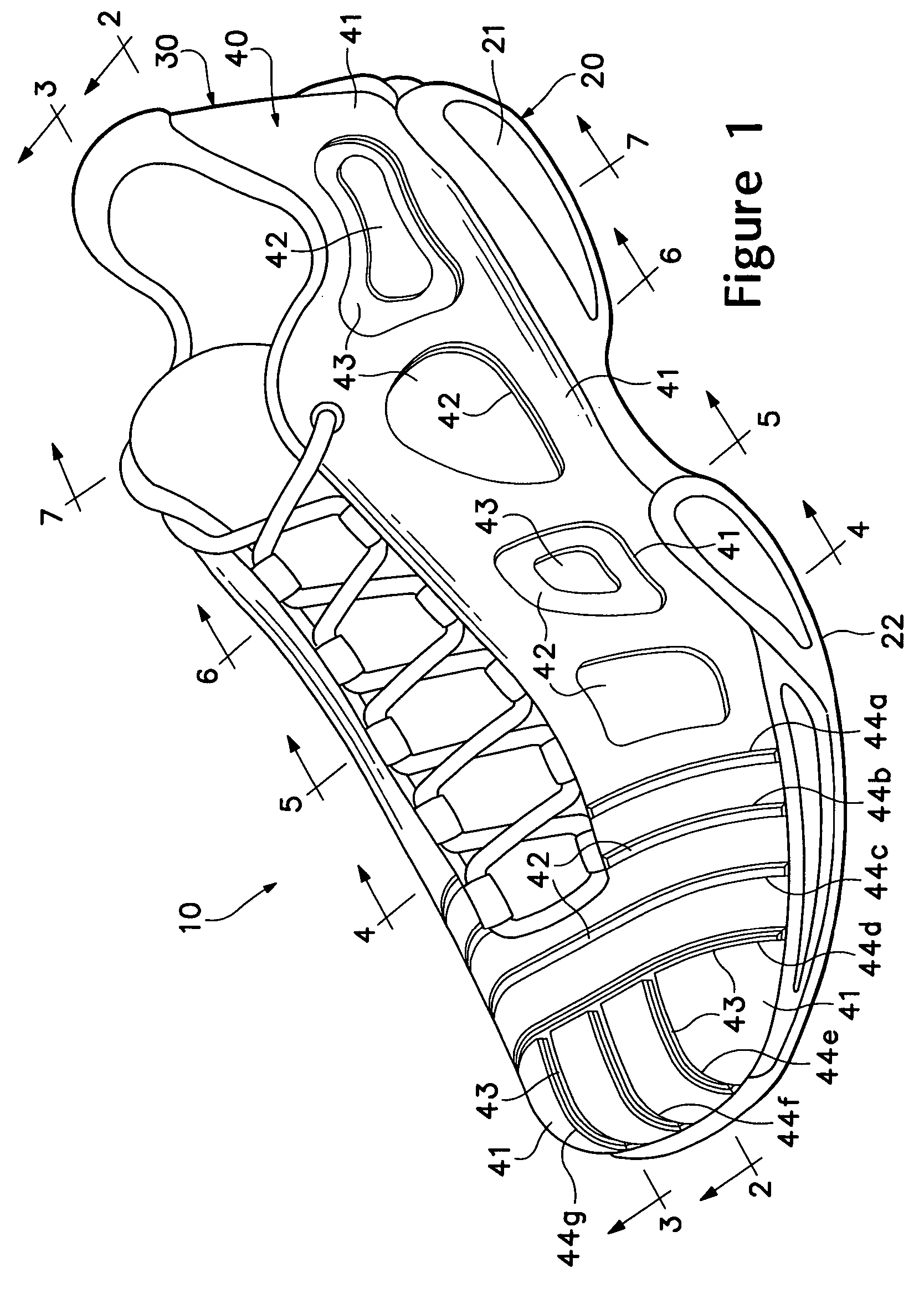

A method for utilizing a laser to etch a stratified material is disclosed. The method includes providing a stratified material having at least two layers that are secured together, the layers including a first layer and a second layer. An incision is then formed in the stratified material with a laser, the incision extending through the first layer to expose the second layer. The stratified material may then be incorporated into an upper of the article of footwear, for example. By exposing portions of the second layer, properties of the second layer may be exposed in the area of the removed first layer.

Owner:NIKE INC

Article of apparel incorporating a stratified material

Owner:NIKE INC

Article of apparel incorporating a stratified material

Owner:NIKE INC

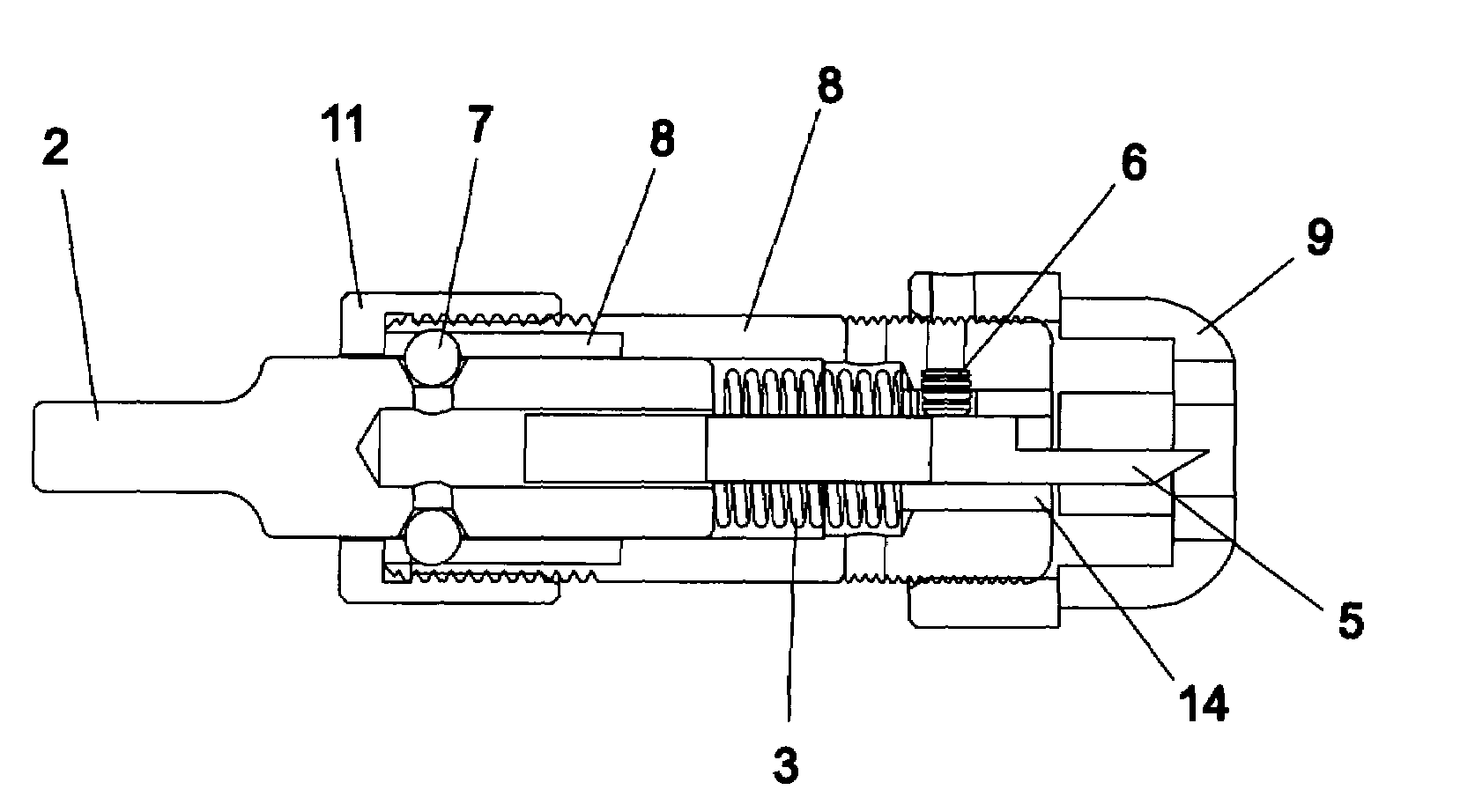

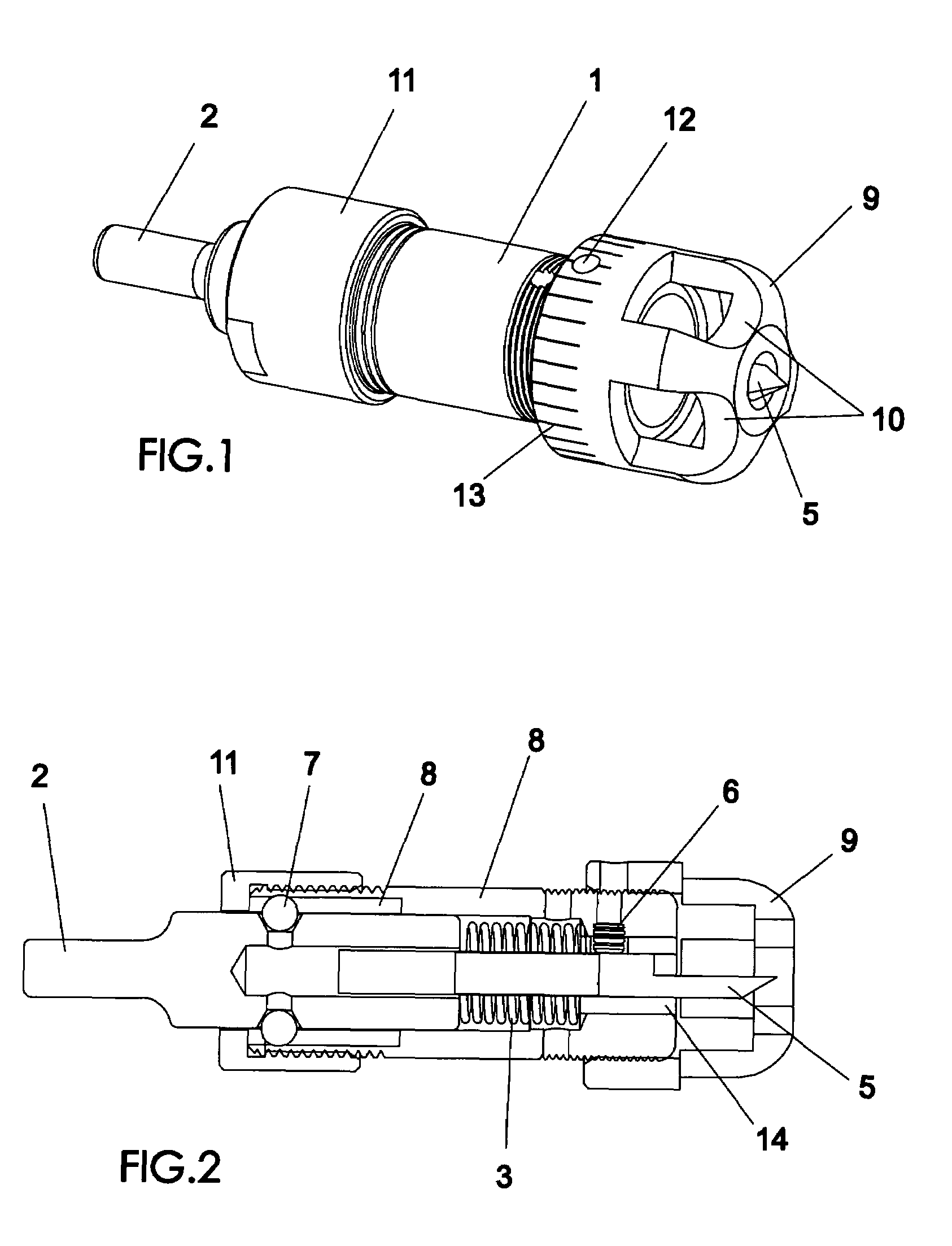

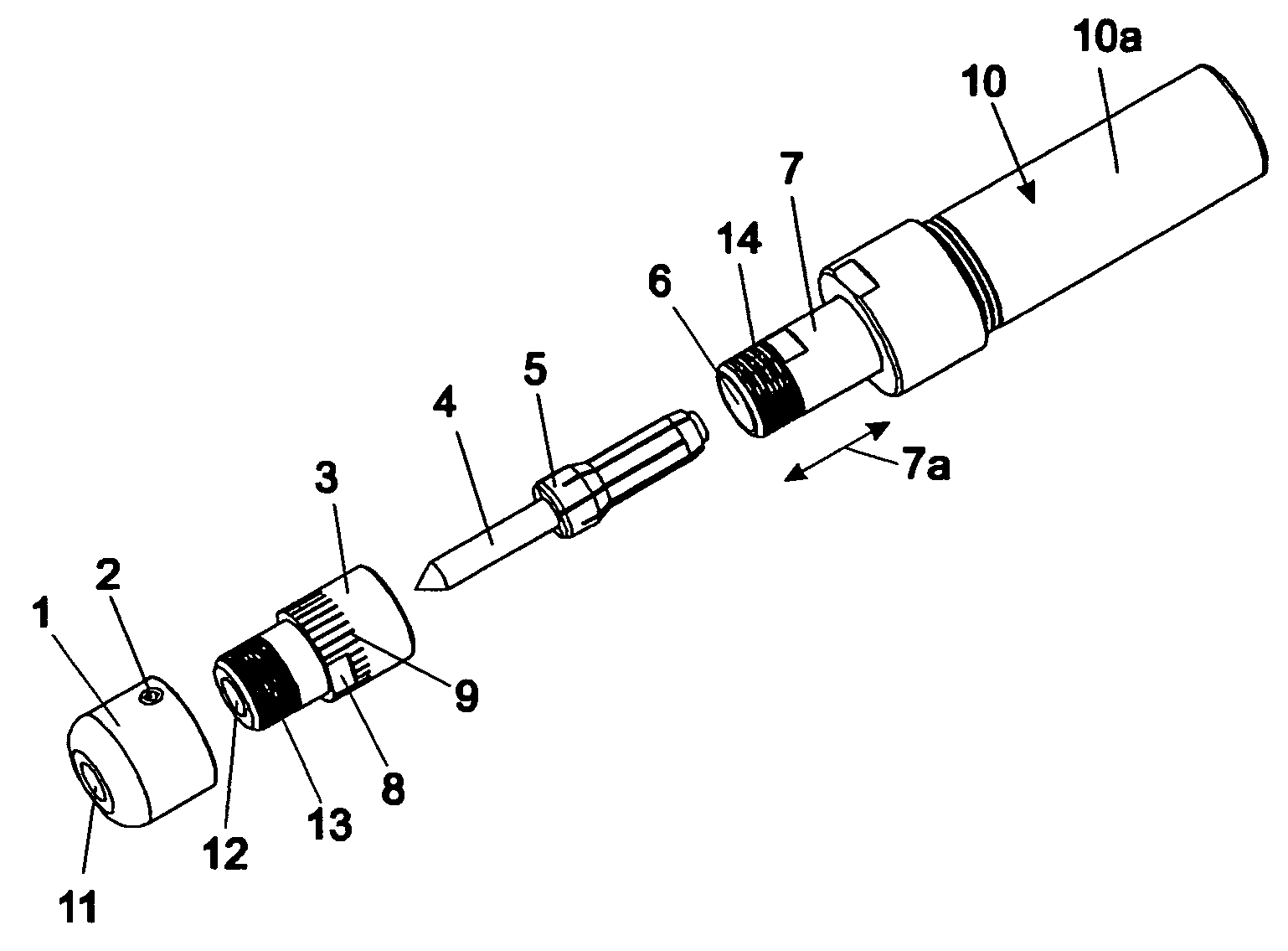

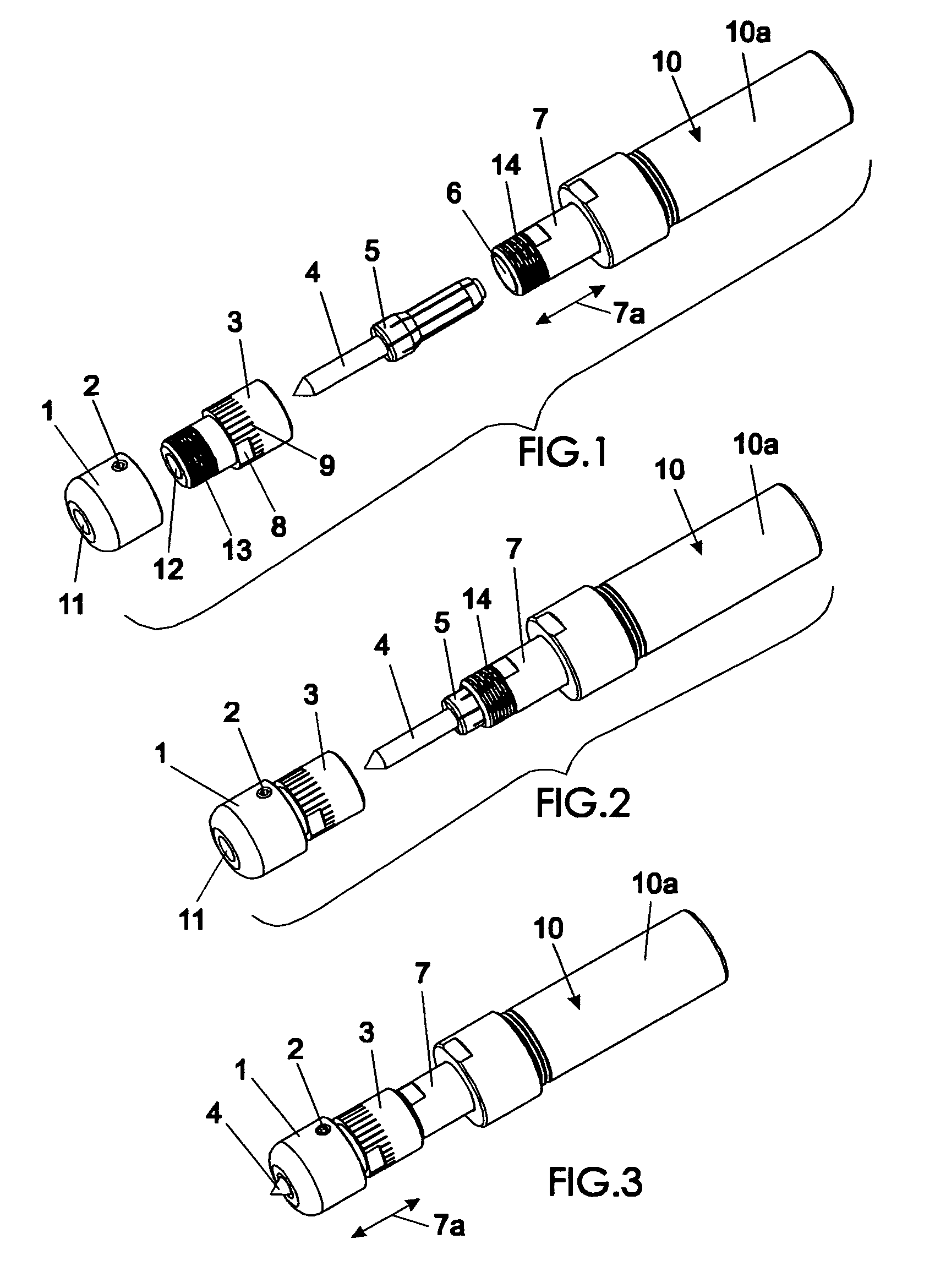

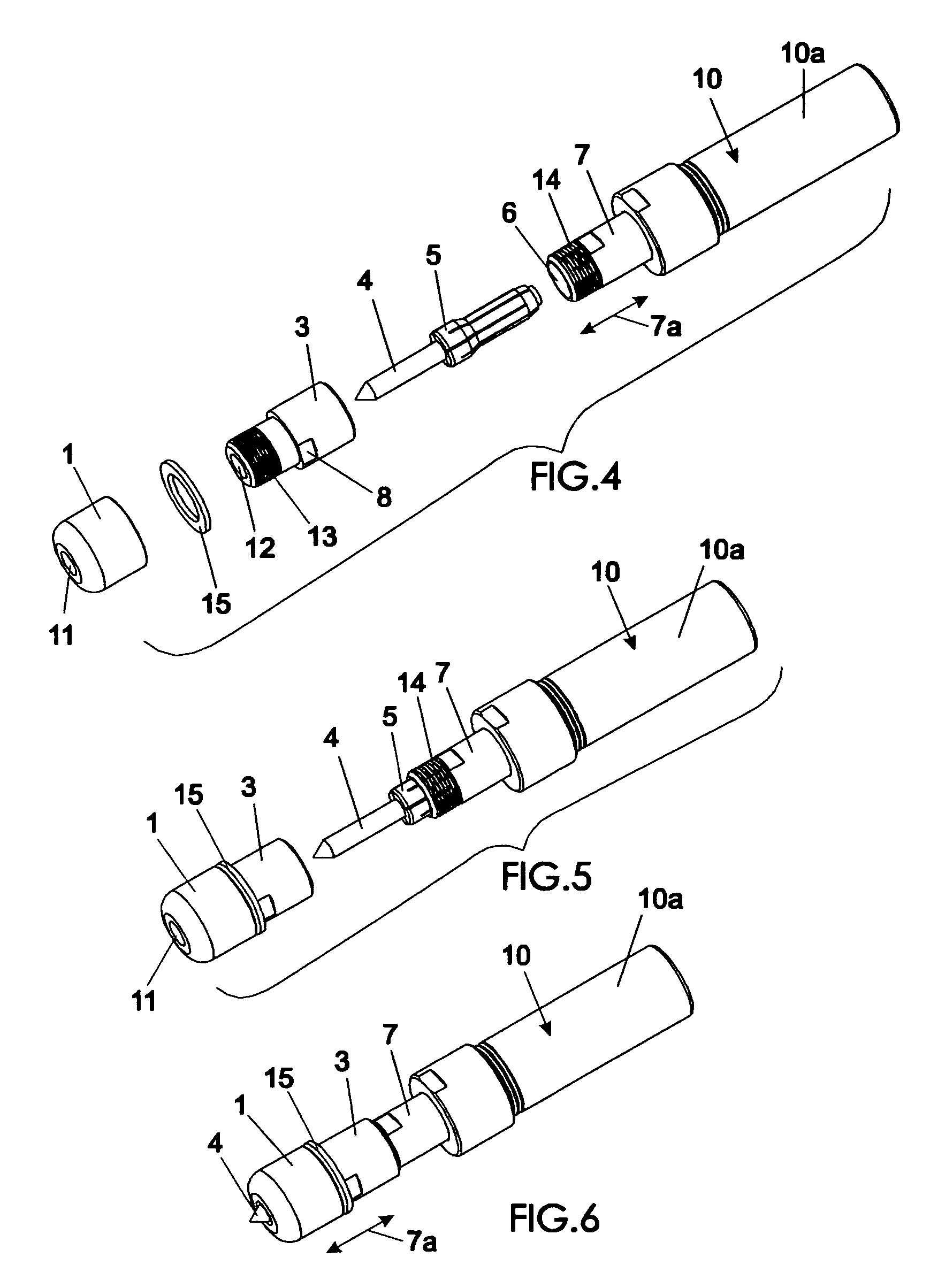

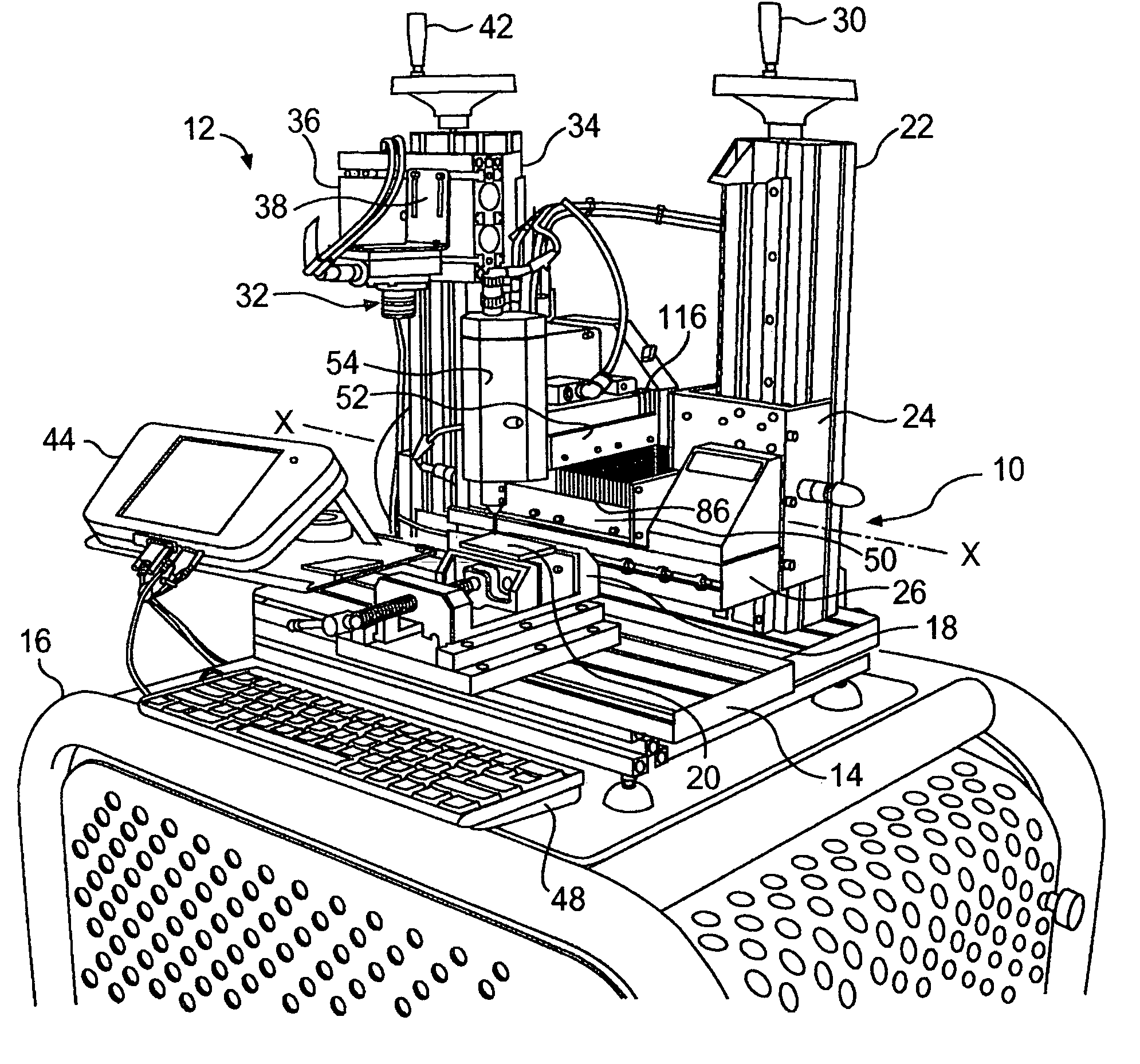

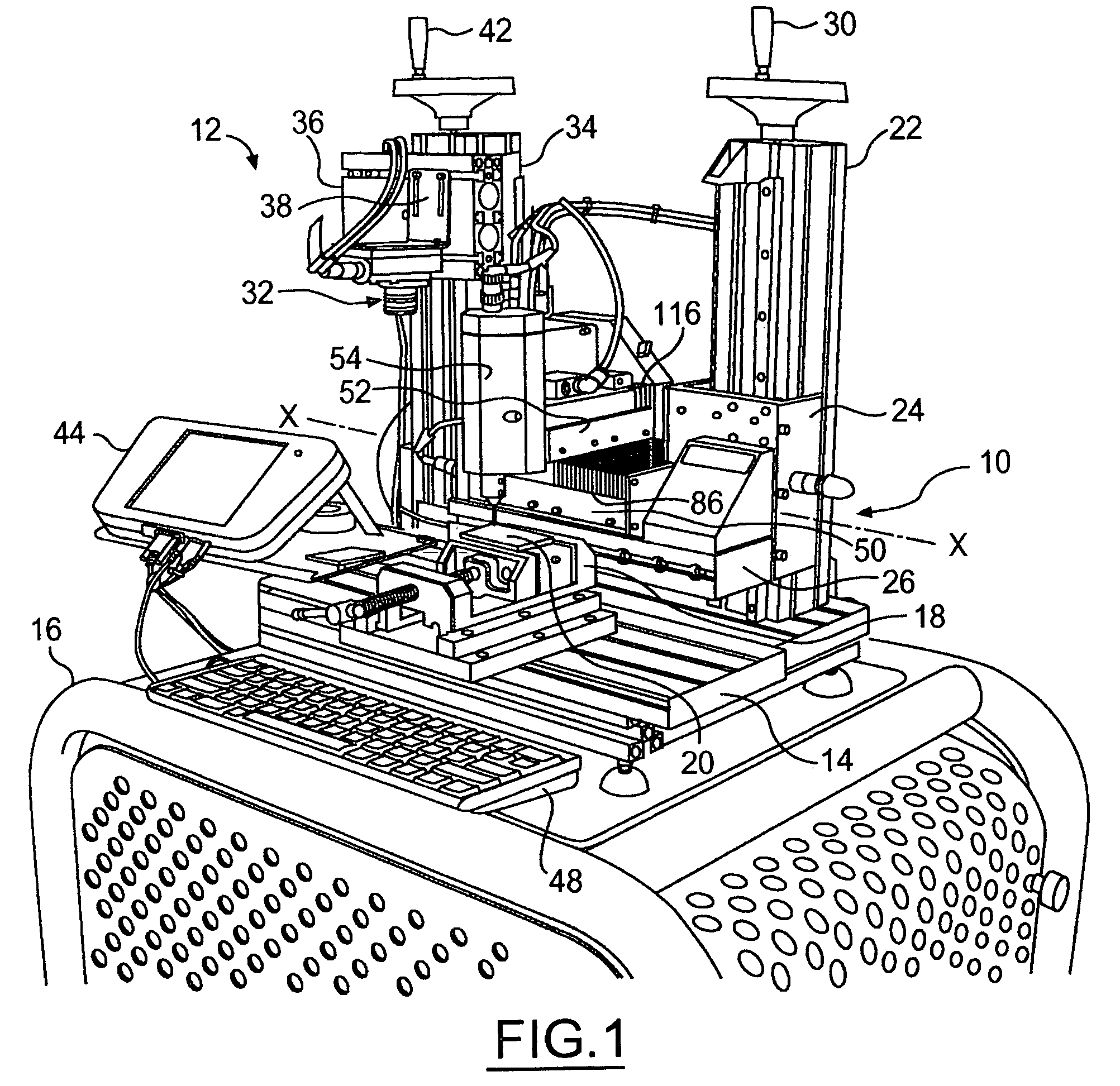

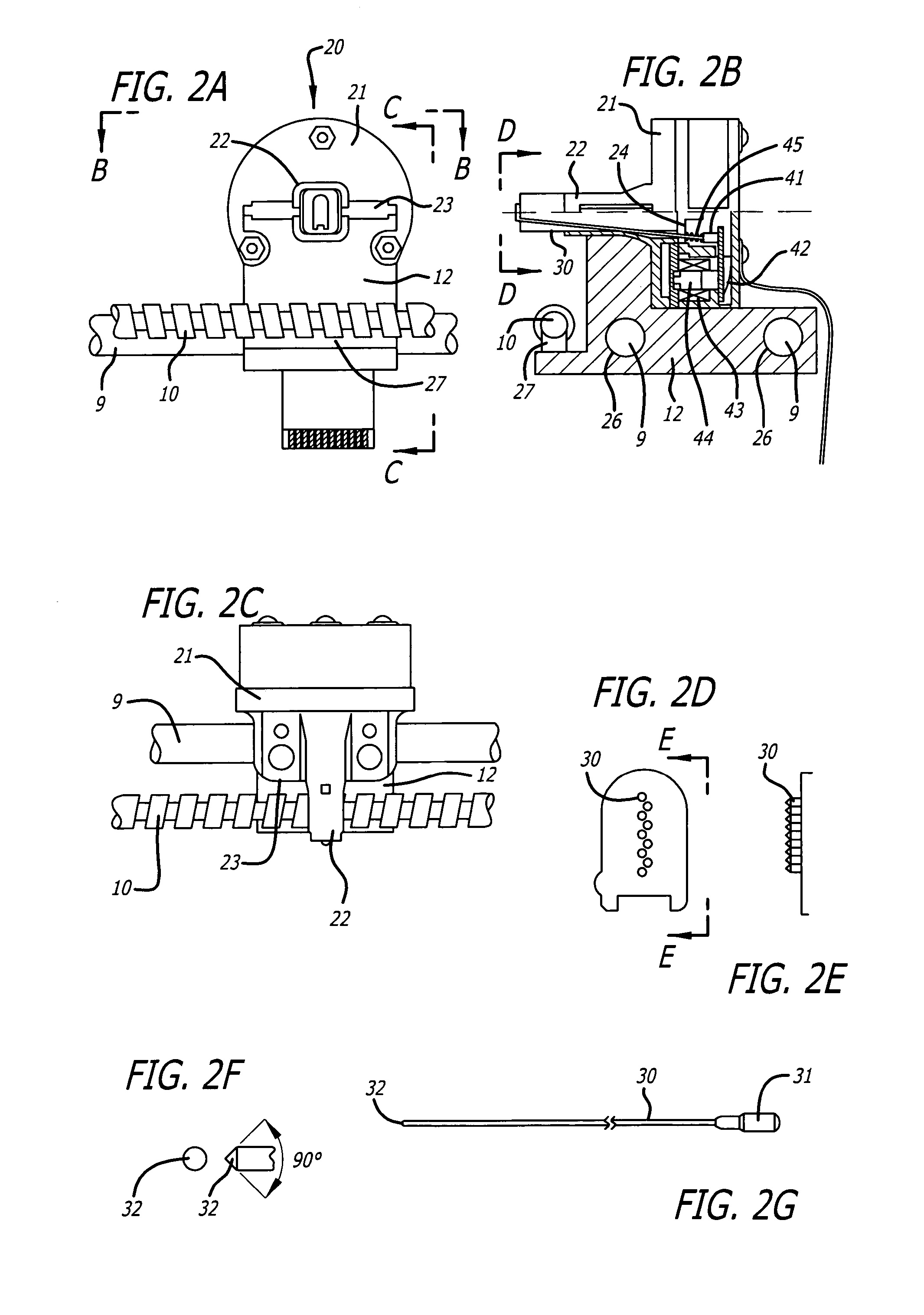

Spring loaded tool with floating depth control for countersinking holes or engraving

ActiveUS7607871B1Avoid damageAvoid scratchesThread cutting toolsDrilling/boring measurement devicesTool bitSpray nozzle

A floating tool-bit depth controlling nosepiece for a spring loaded tool holder is used to countersink holes of equal size when the height of the work piece material changes. The floating tool-bit depth controlling nosepiece, driven by a cnc machine, is rigidly coupled to the floating portion of the tool holding element. The floating depth controlling nosepiece has a bearing on the end to allow an area of the nosepiece to stop rotating when the nosepiece is pressed against the work-piece surface. Since the area of the nosepiece that comes into contact with the work-piece is no longer spinning in relationship with the work-piece, the possibility of scratching the work-piece surface is reduced. Additionally, the nosepiece has cutouts therein to expel machined chips during countersinking of holes.

Owner:NELSON LANCE

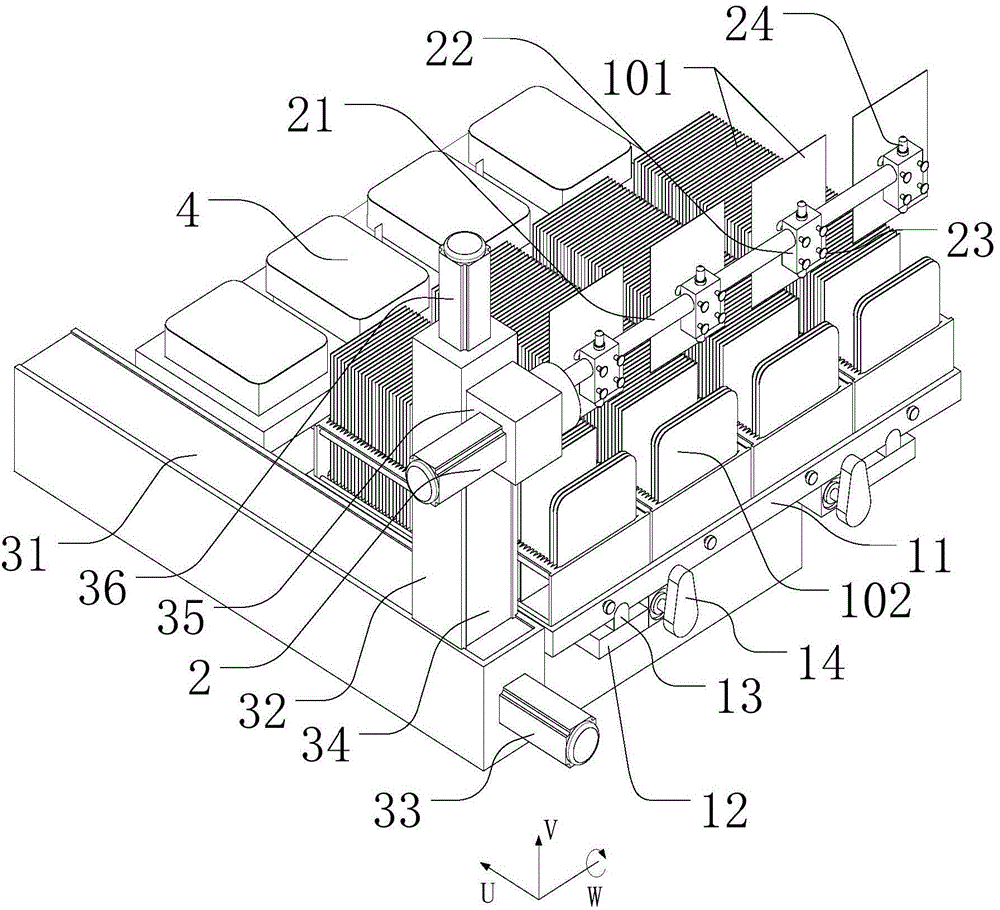

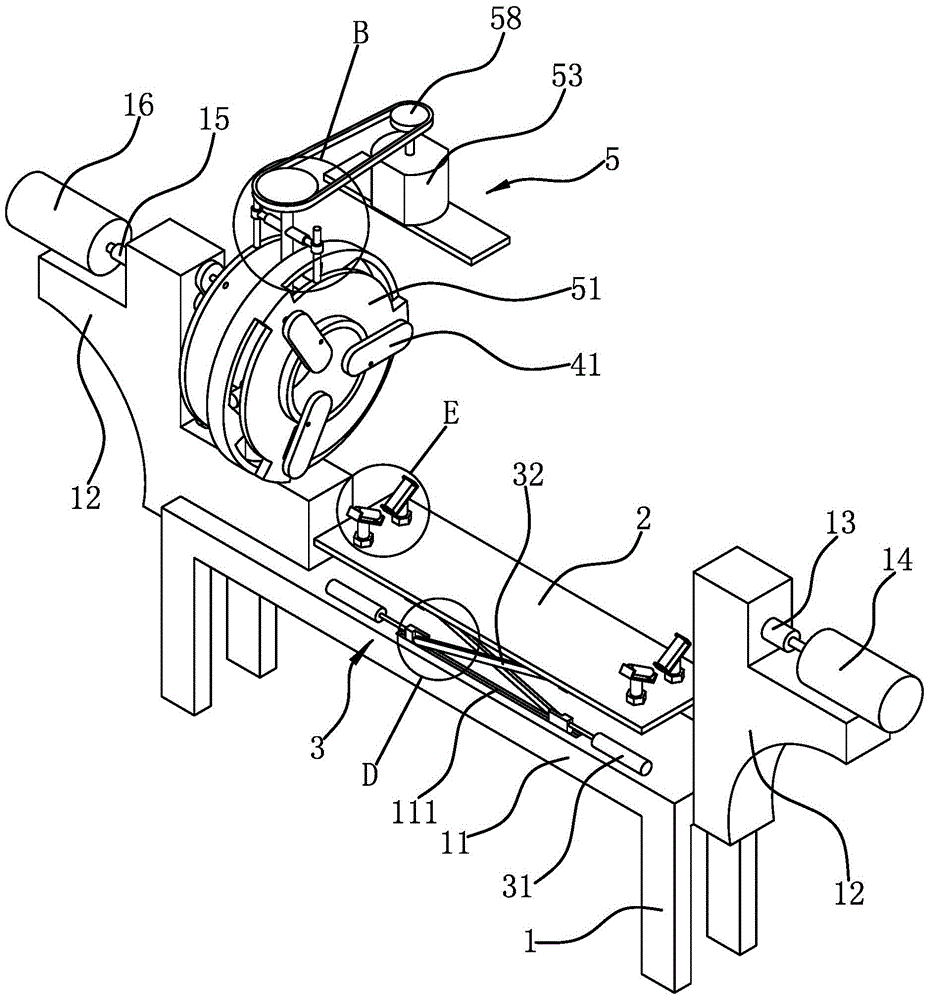

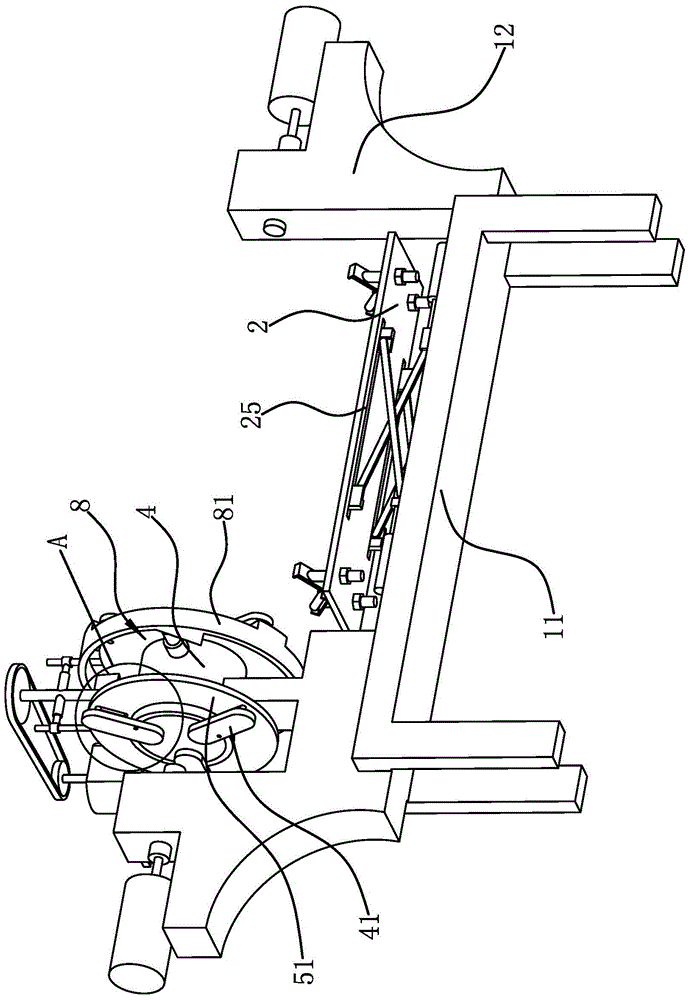

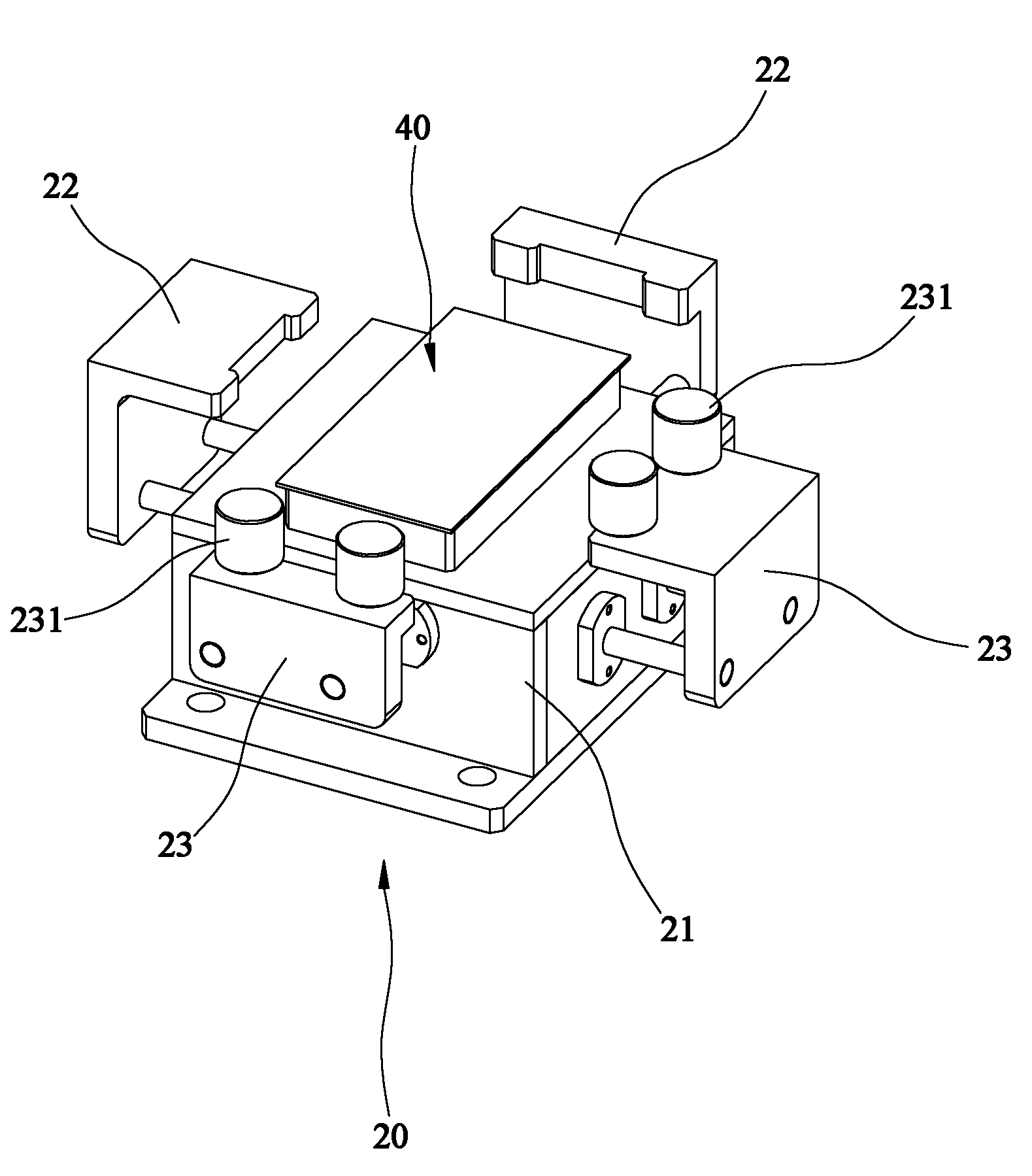

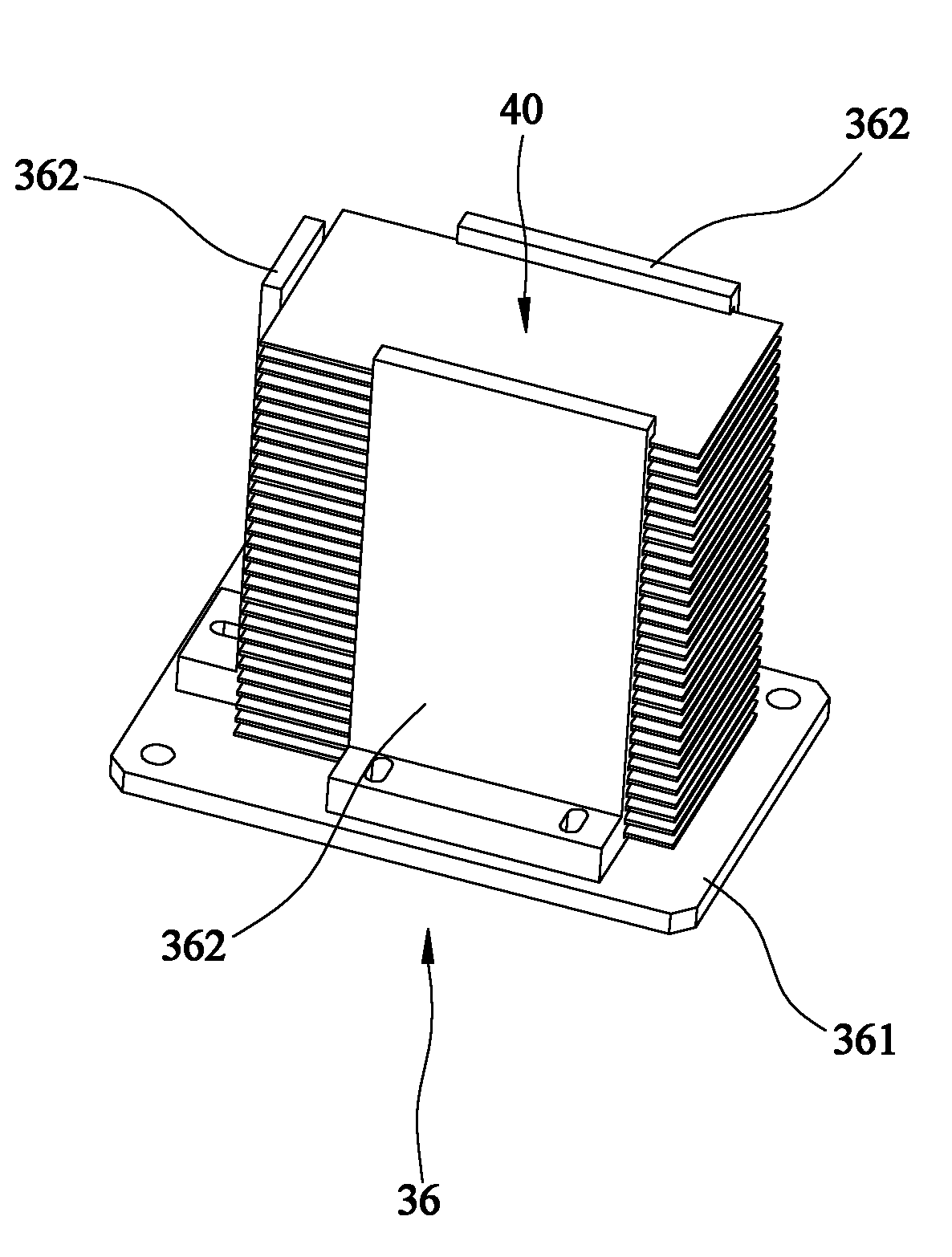

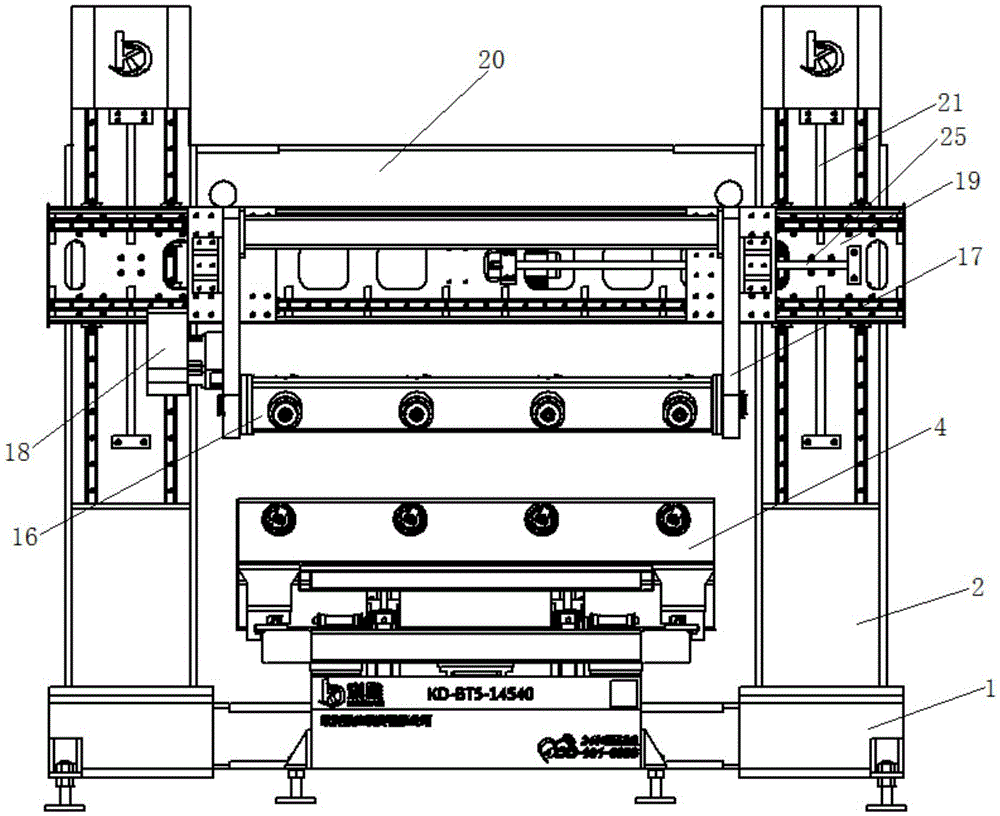

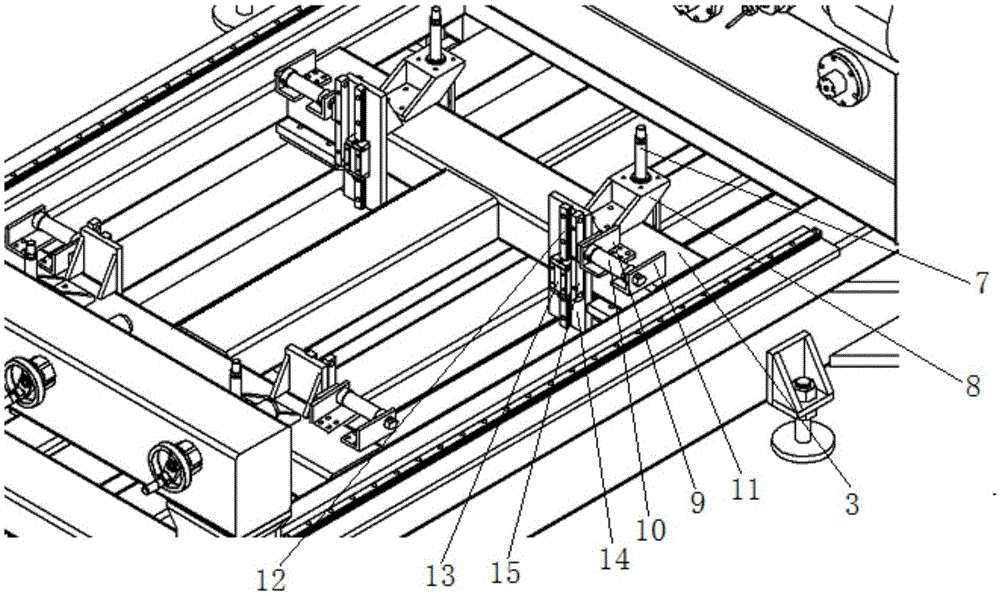

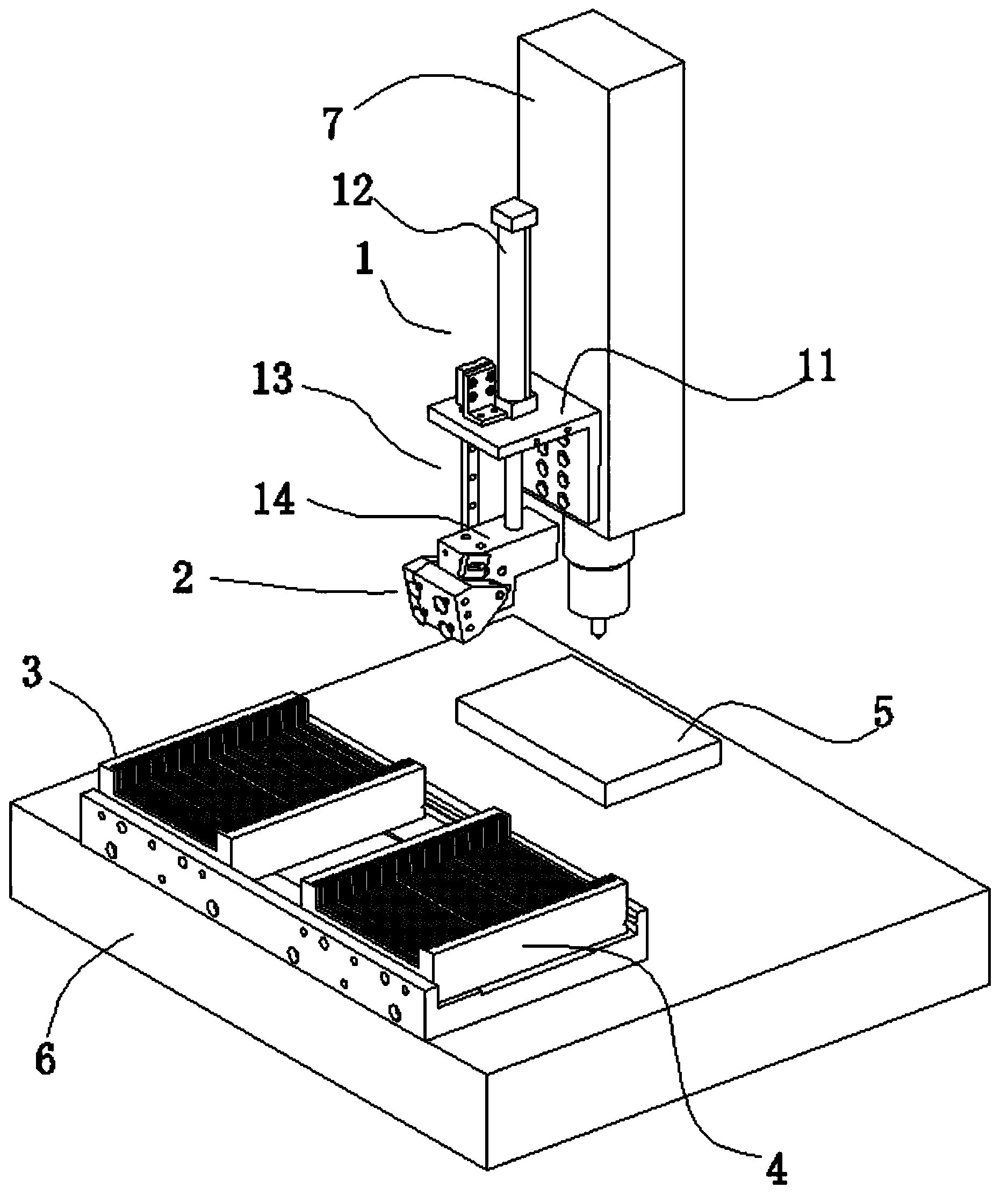

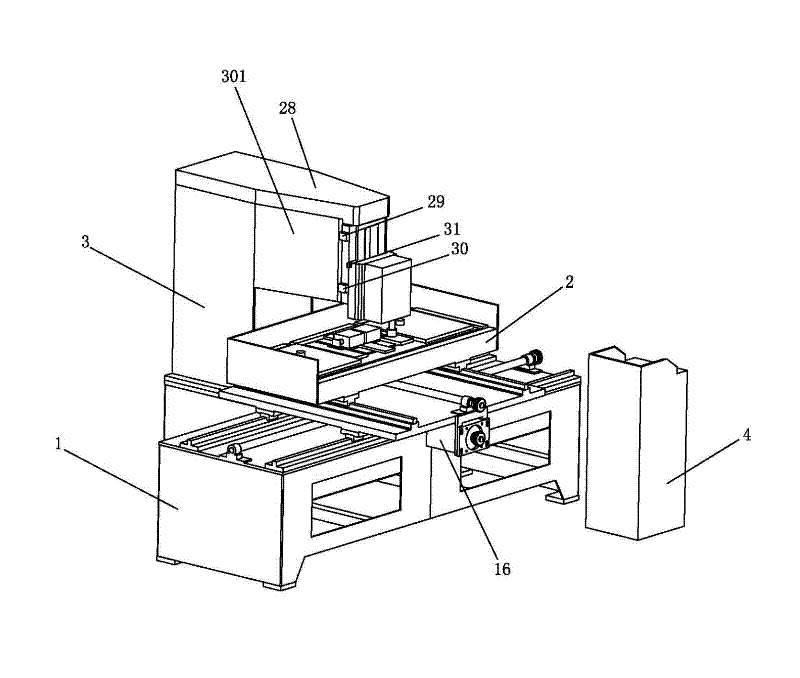

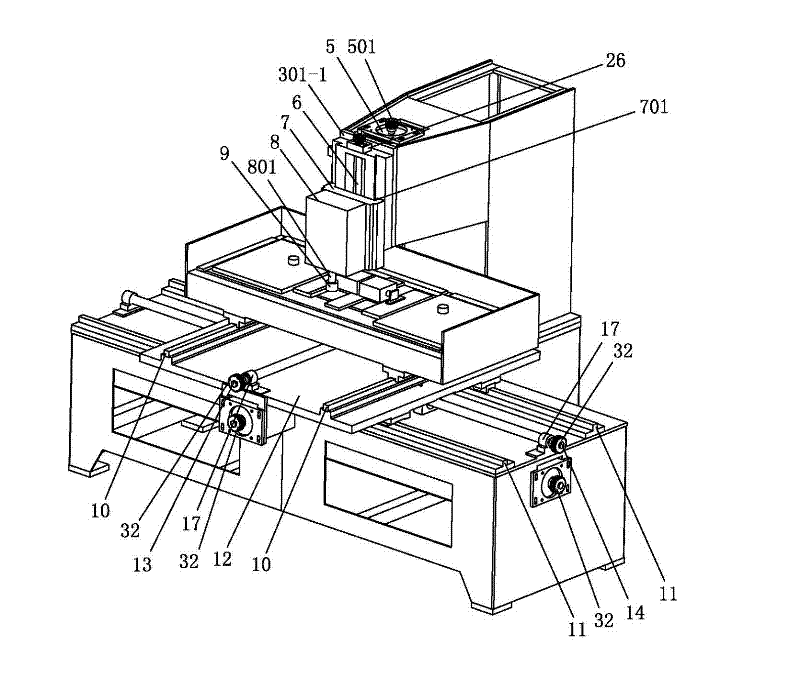

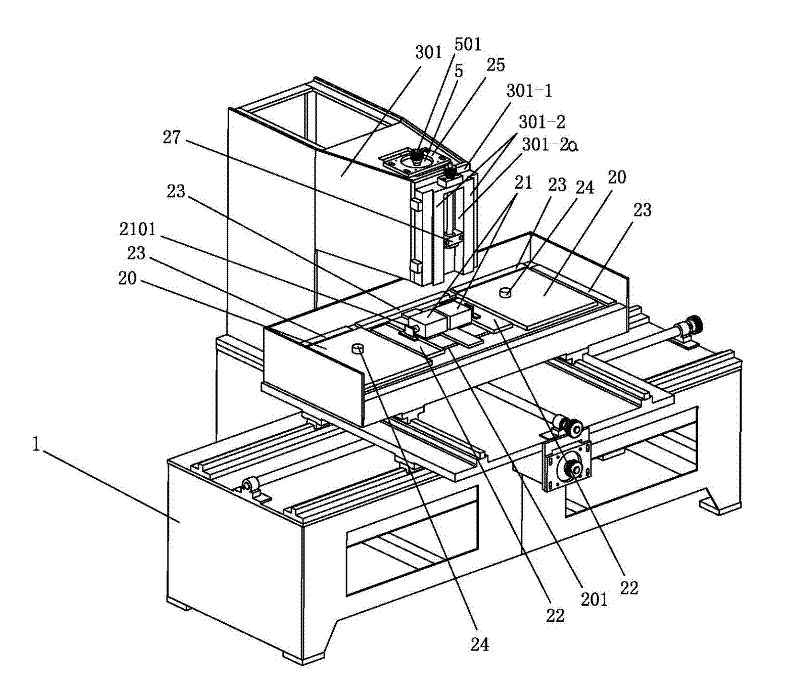

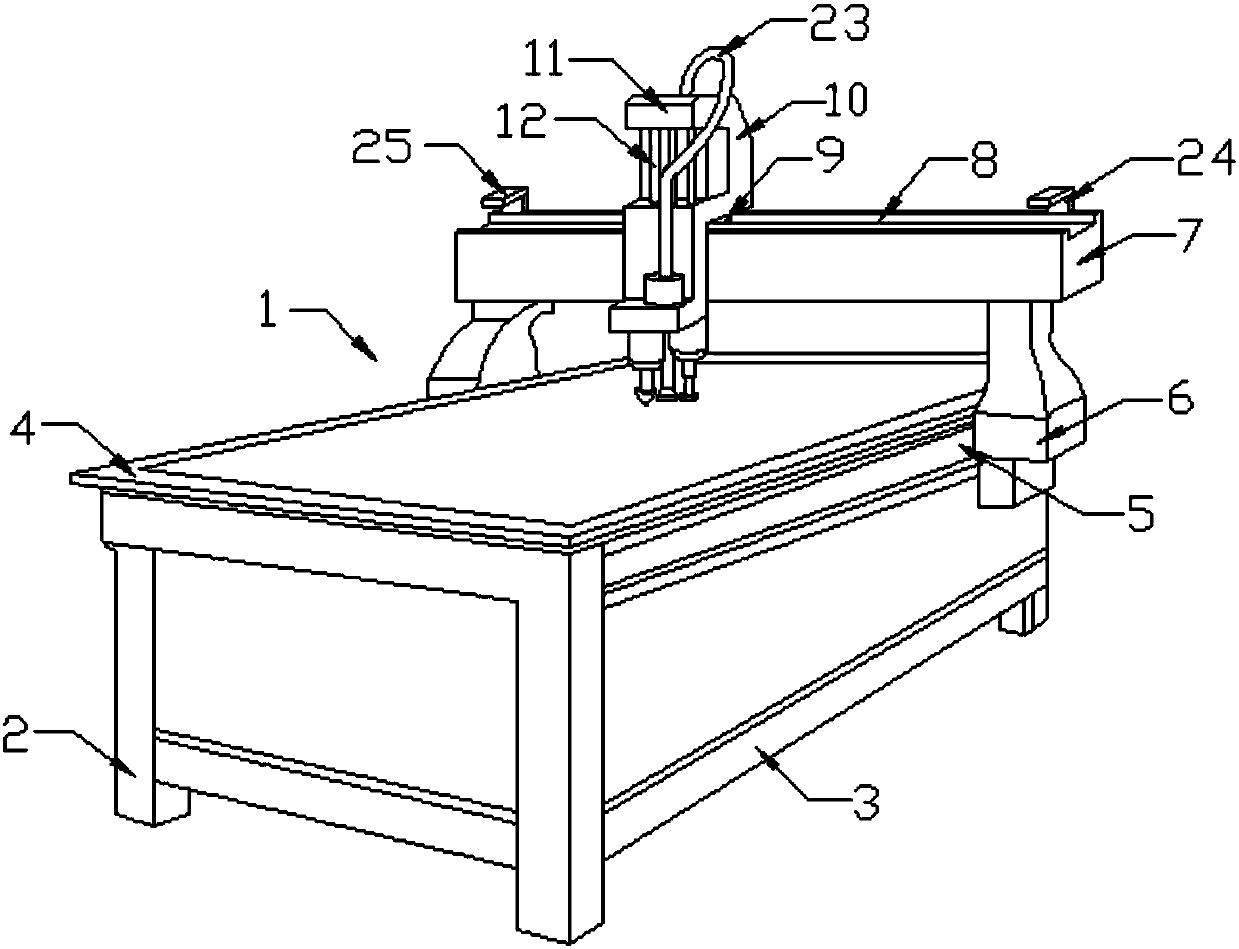

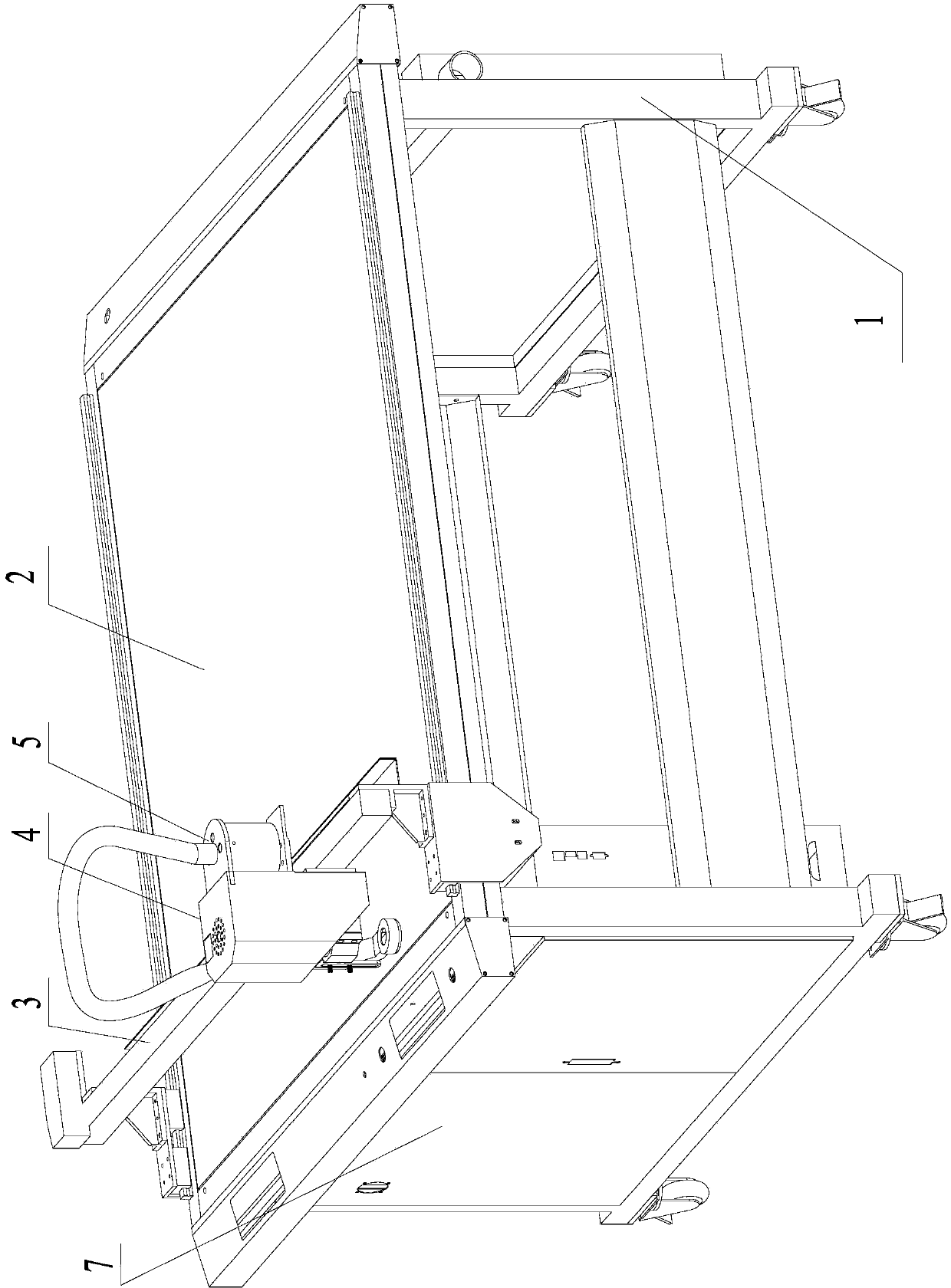

Sheet material feeding and discharging device, mobile phone glass machining center and machining method

ActiveCN104890422AFlexible loading and unloading methodsImprove the efficiency of picking and unloadingGrinding feedersOther artistic work equipmentsEngineeringMachine tool

The invention discloses a sheet material feeding and discharging device, a mobile phone glass machining center and a machining method. The device comprises a material groove, a rotating mechanism provided with a rotating rod, a first drive mechanism and rotating blocks installed on the rotating rod; and taking and placing parts are respectively installed on the front and rear sides of each rotating block, the rotating mechanism is installed on the first drive mechanism, and the rotating blocks are located over the material groove. Two faces of the rotating blocks are provided with the taking and placing parts, the rotating mechanism can drive the rotating blocks to perform 360-degree rotation, a feeding and discharging mode is more flexible, and taking and placing efficiency is greatly improved. After the sheet material feeding and discharging device is applied to the mobile phone glass machining center, a mode that the rotating blocks are fixed to the rotating rod is adopted, and the rotating rod extends to the other side to form a gantry crane type structure, so the rotating blocks can be unlimitedly expanded on the rotating rod, a machining table and the material groove can be correspondingly increased, a plurality of working positions can be increased on one machine tool to the maximum extent, and machining efficiency is greatly improved.

Owner:苏州恒远精密数控设备有限公司

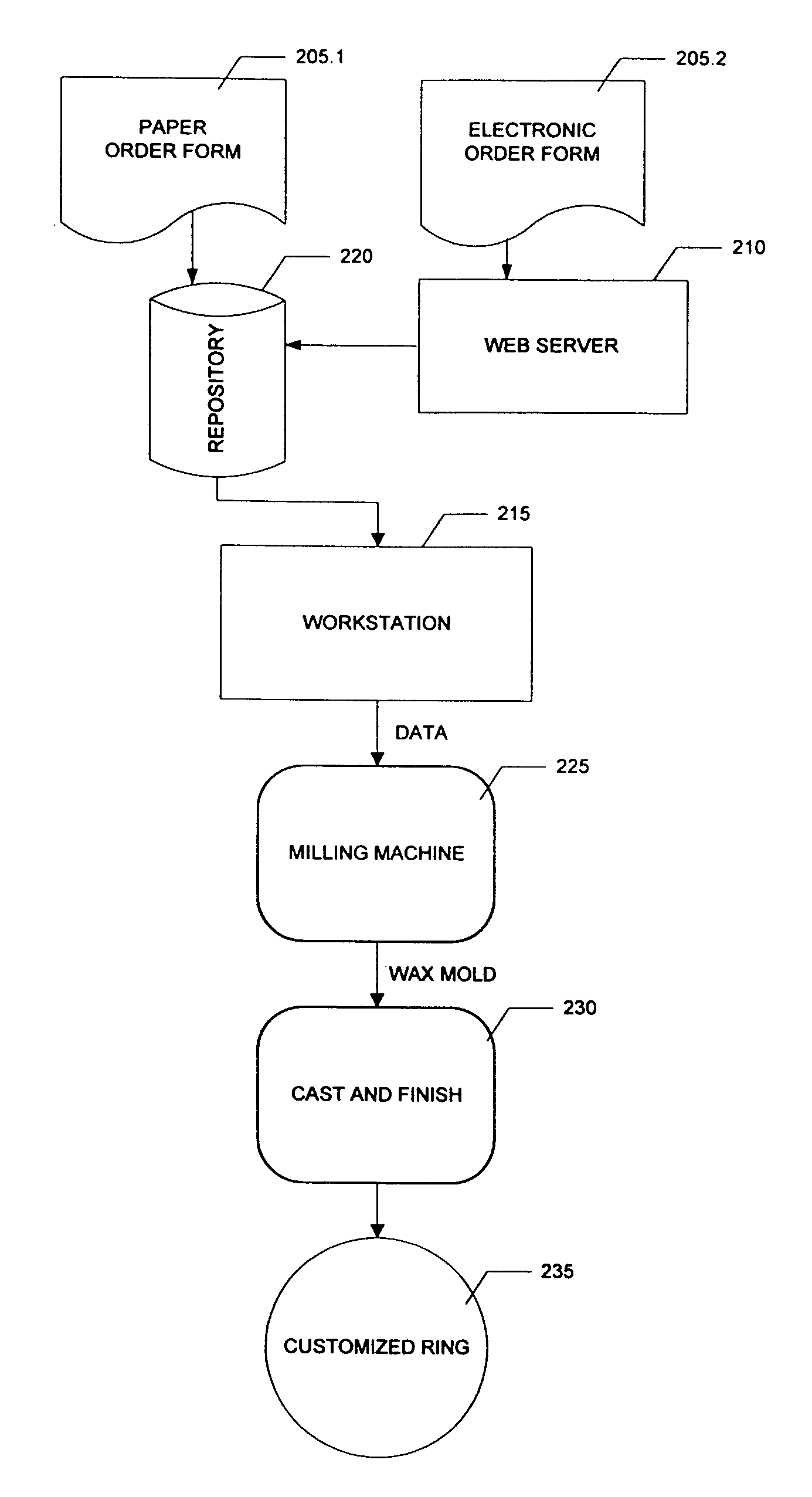

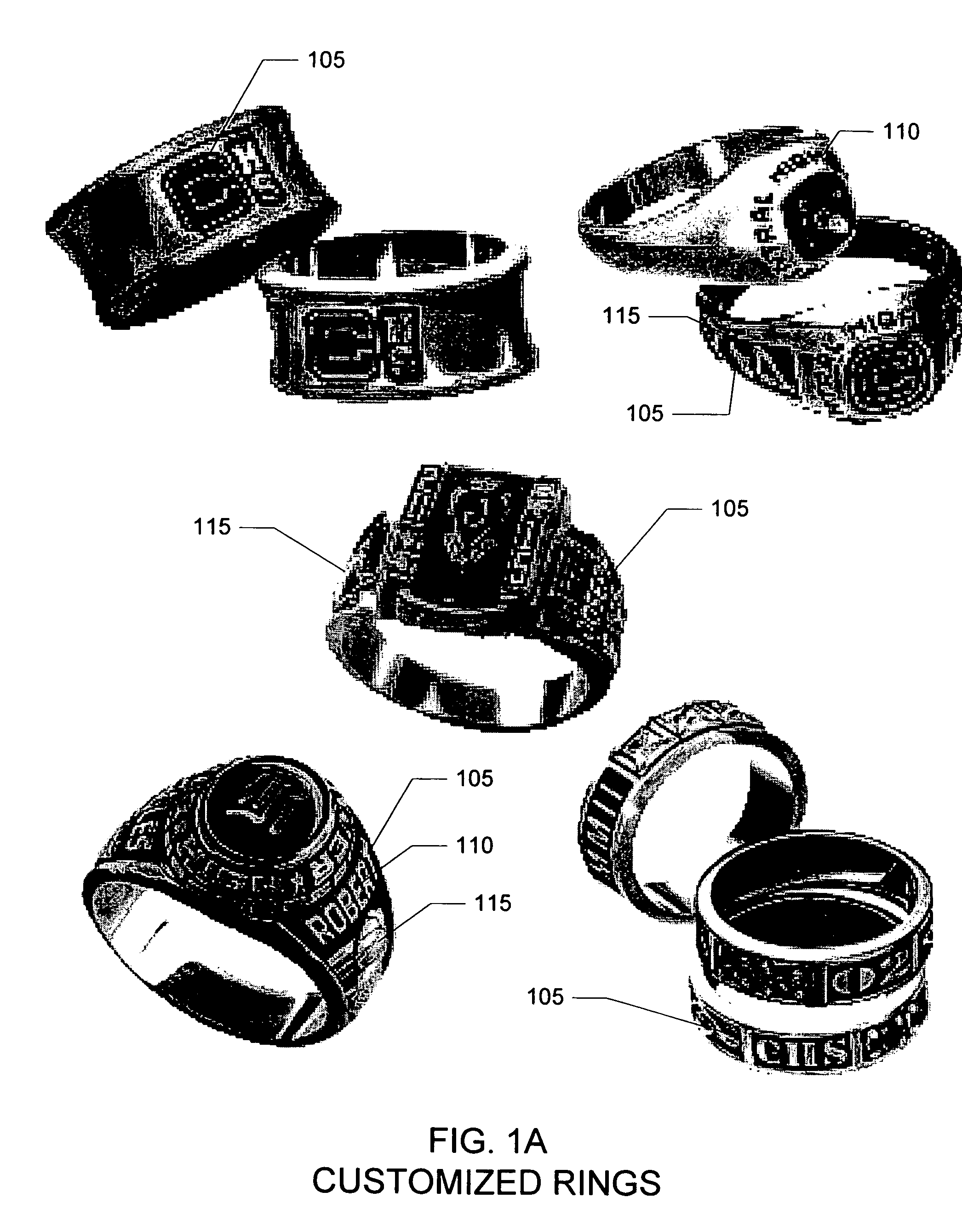

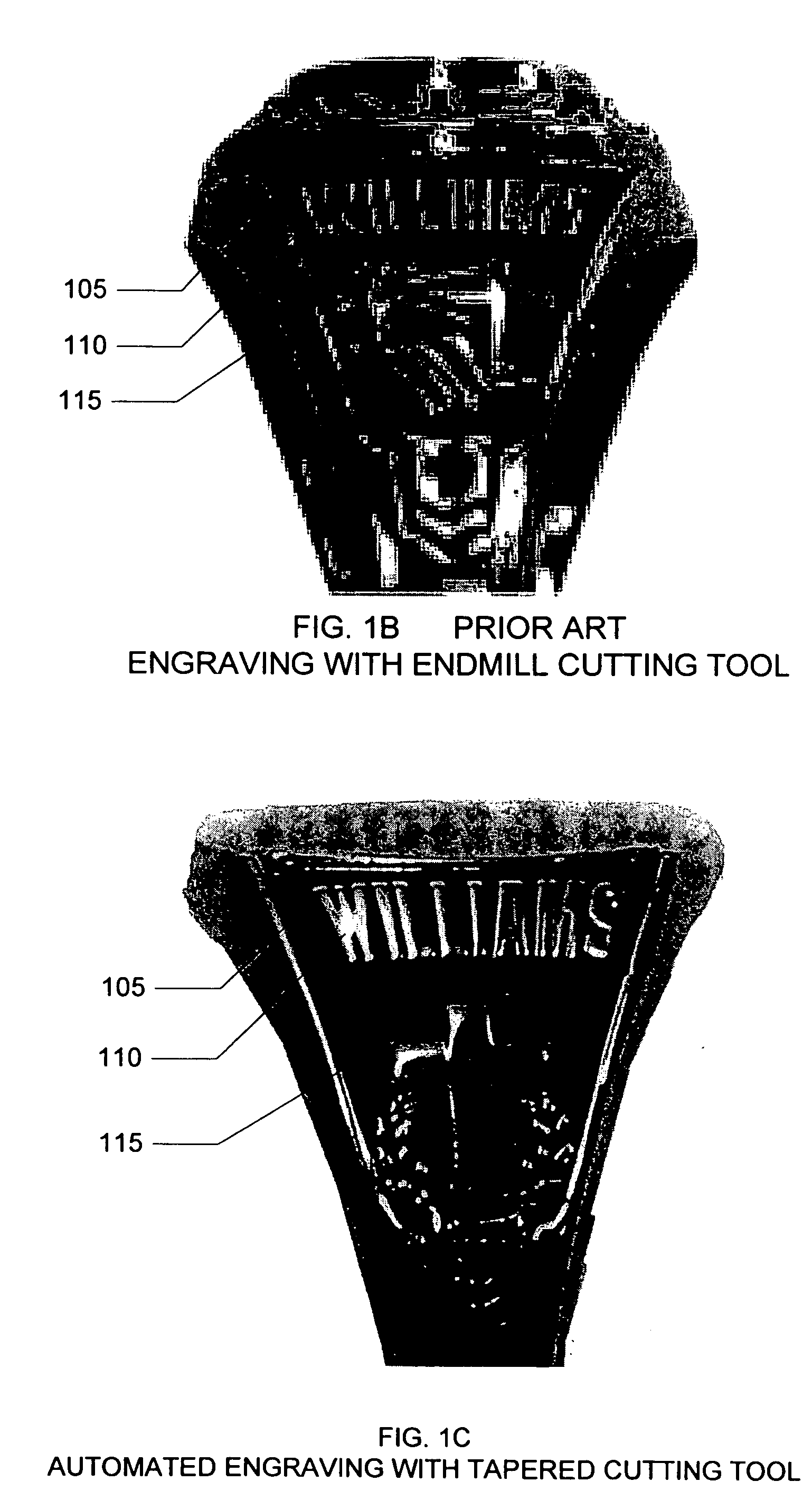

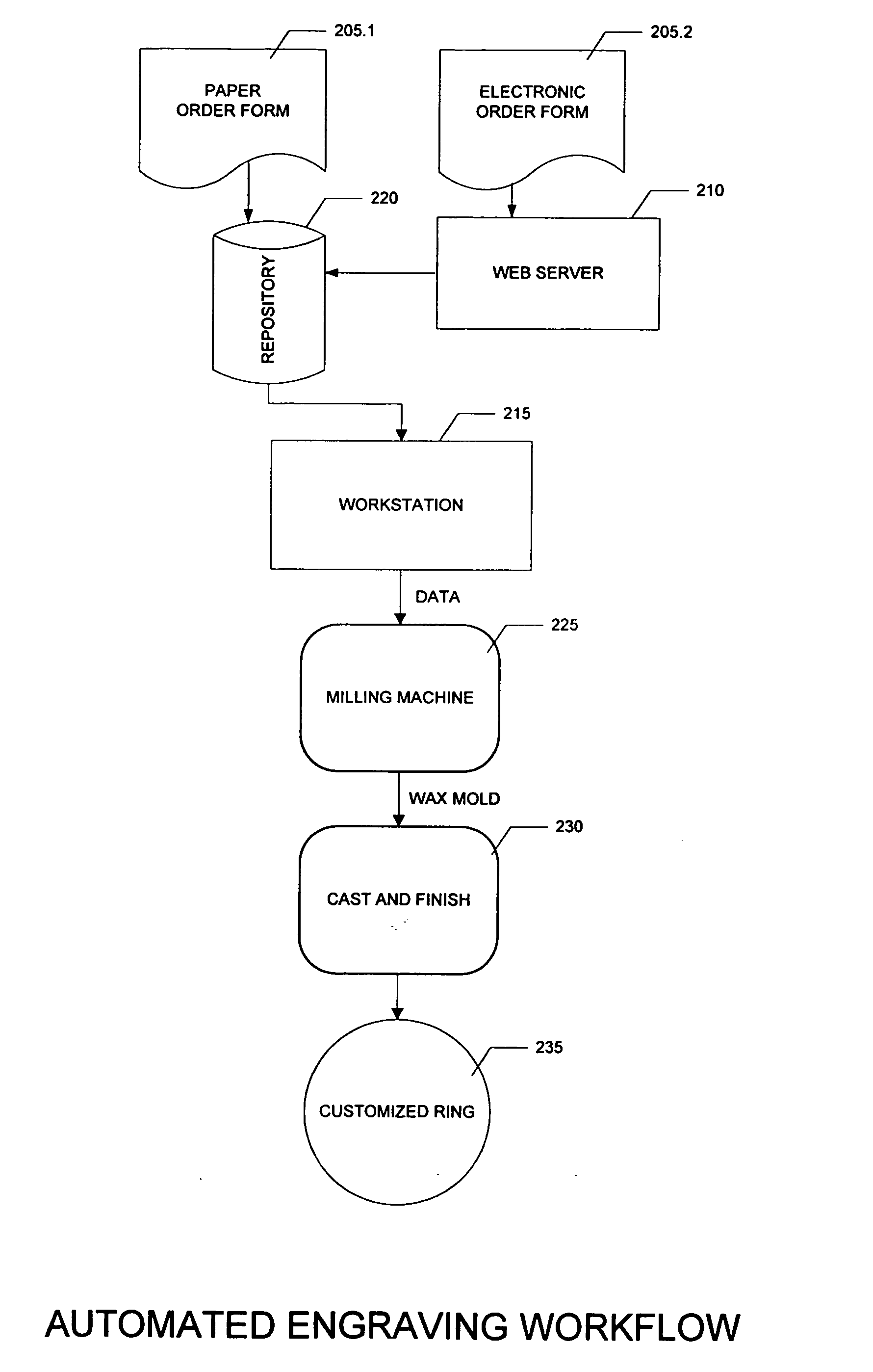

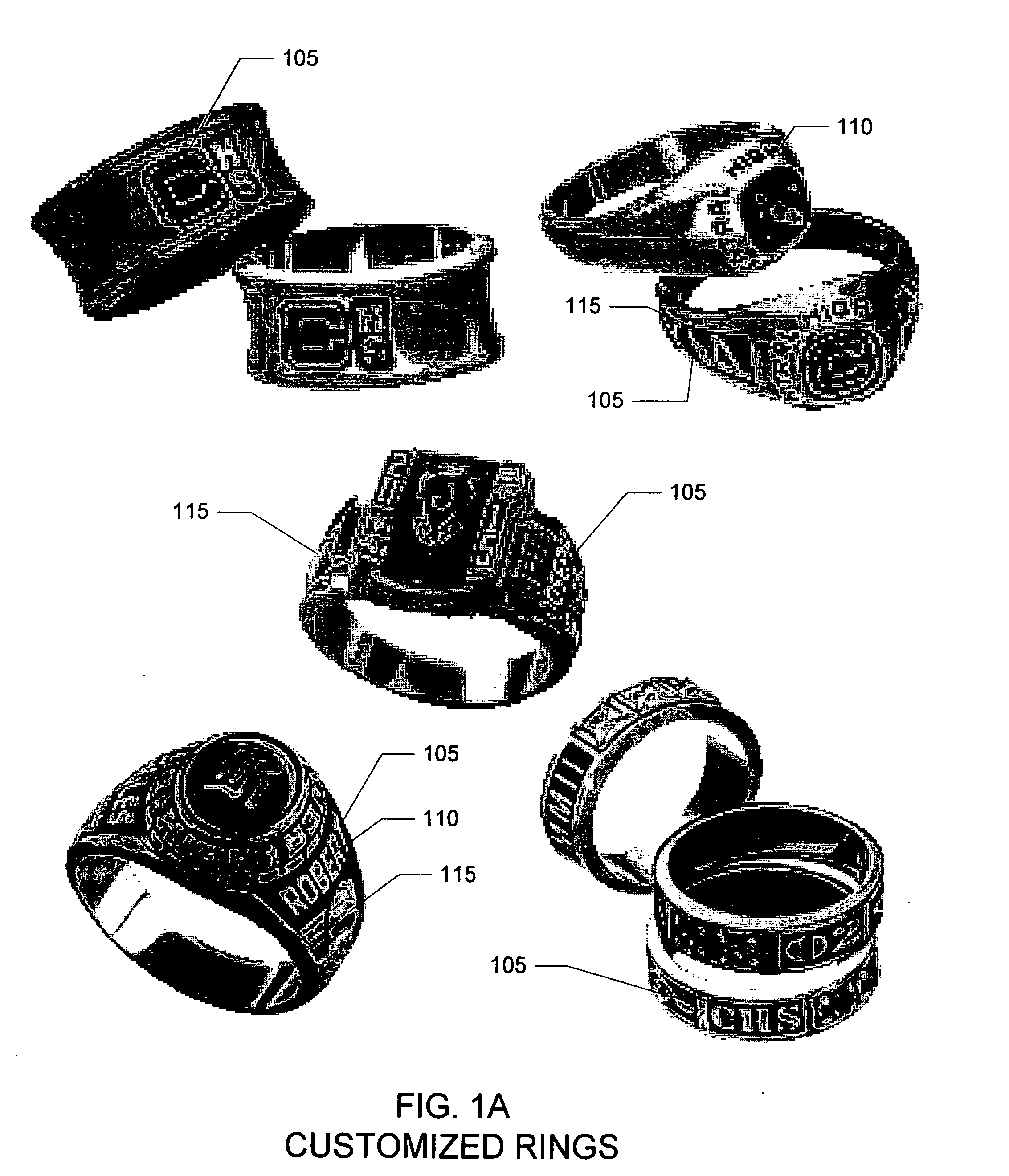

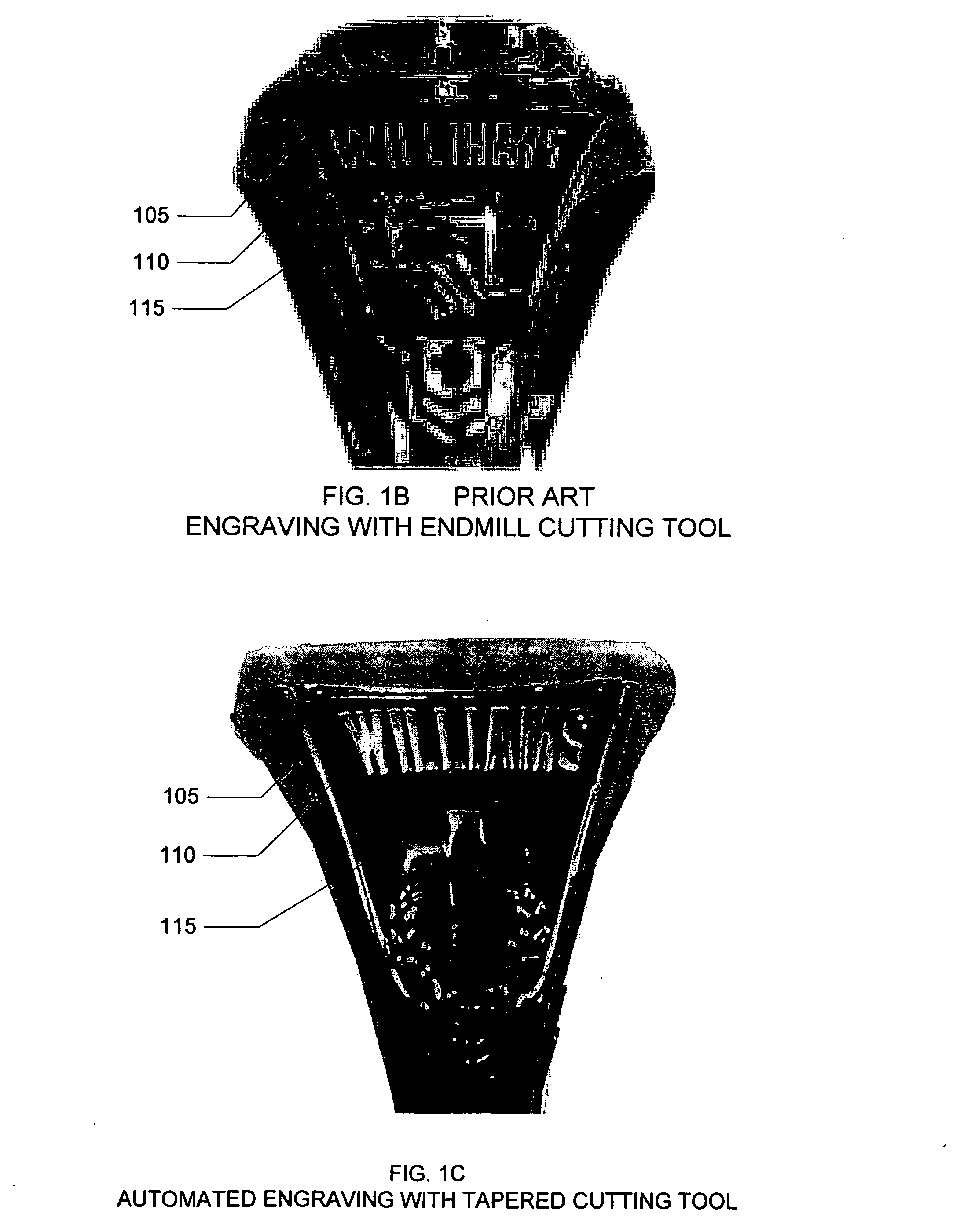

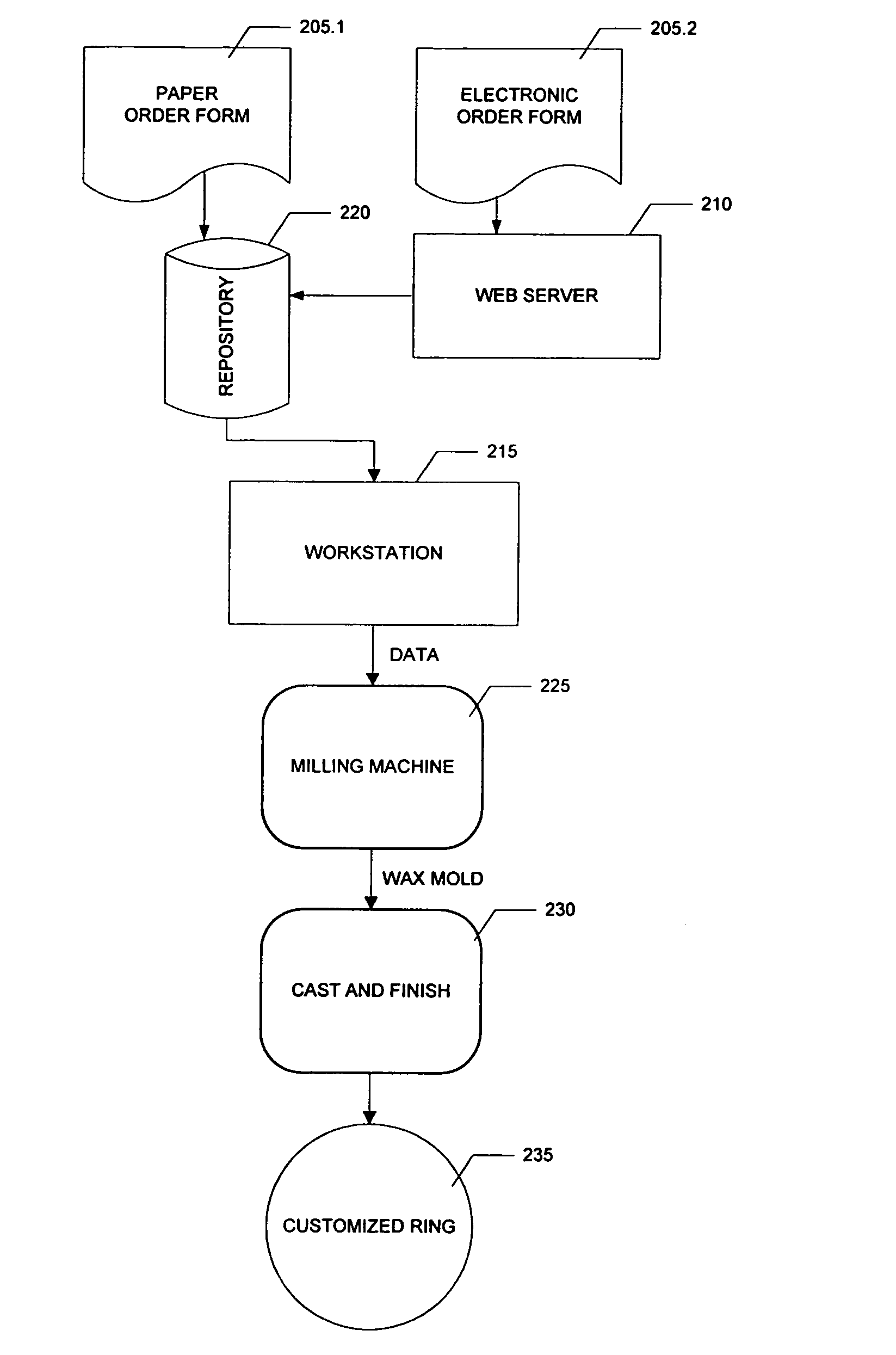

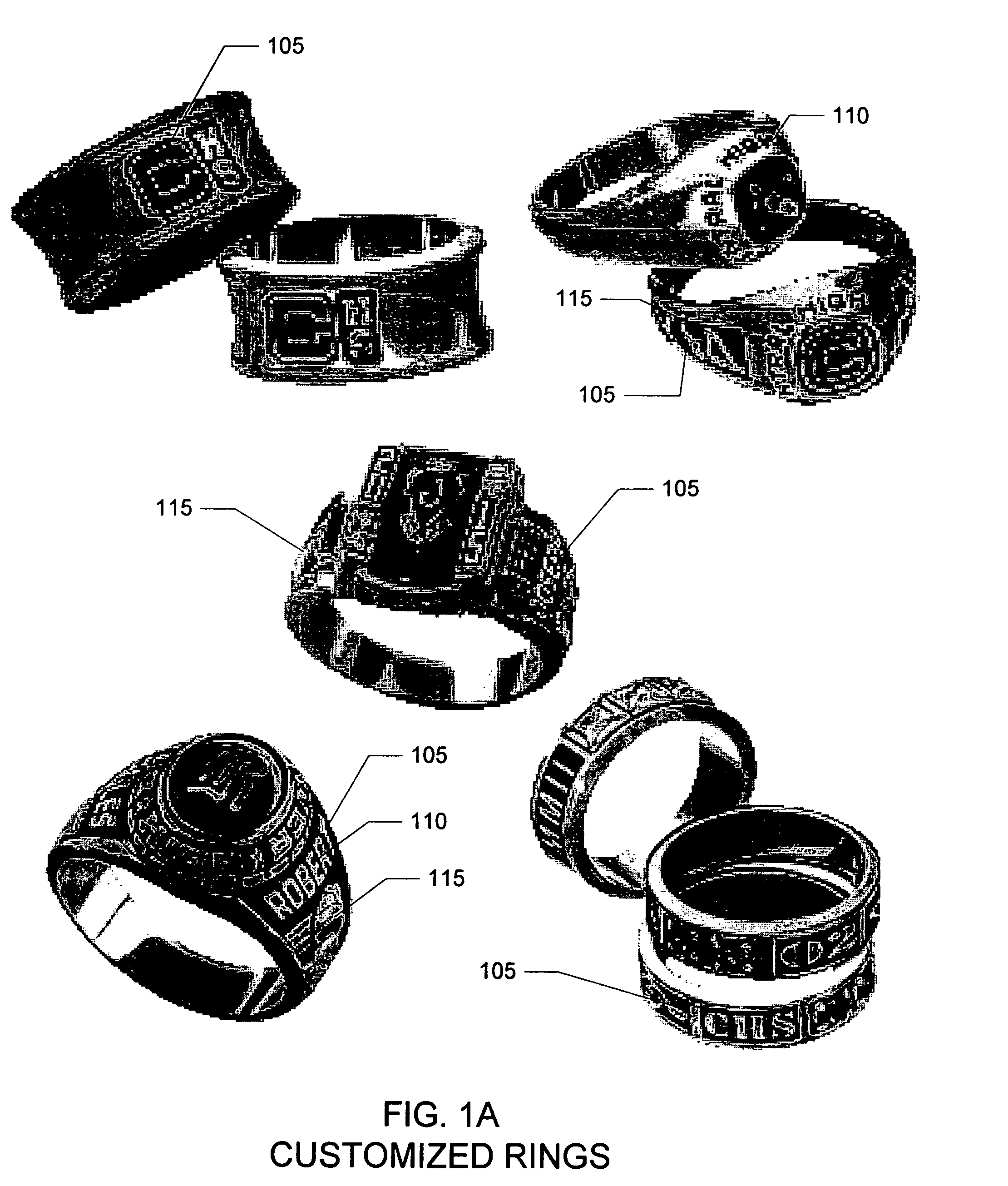

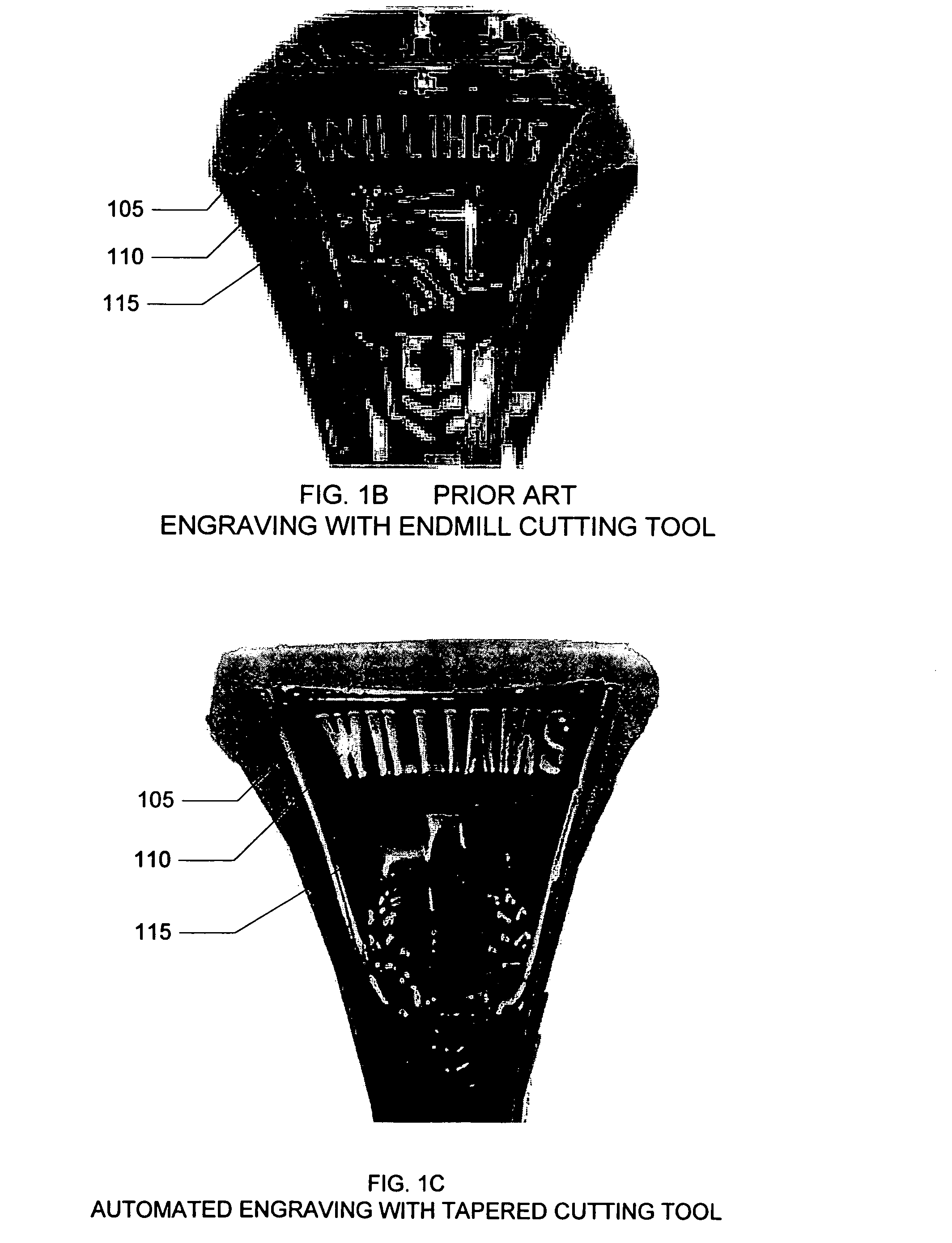

Automated engraving of a customized jewelry item

ActiveUS7069108B2Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingIcon designPersonalization

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

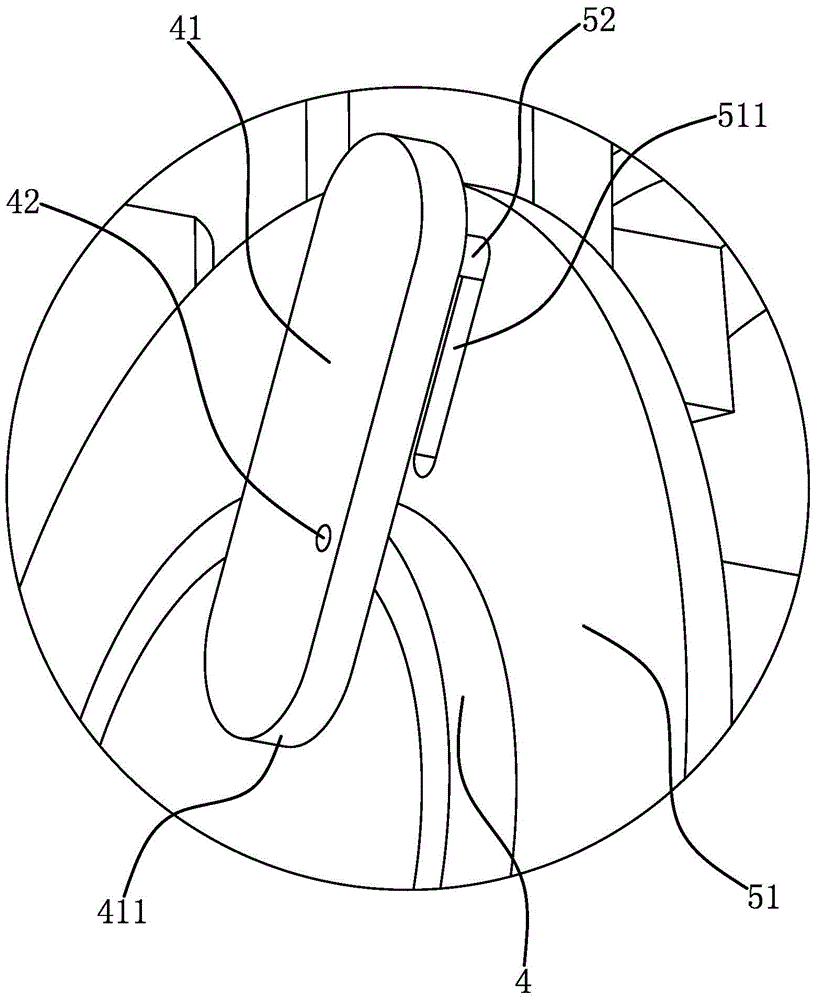

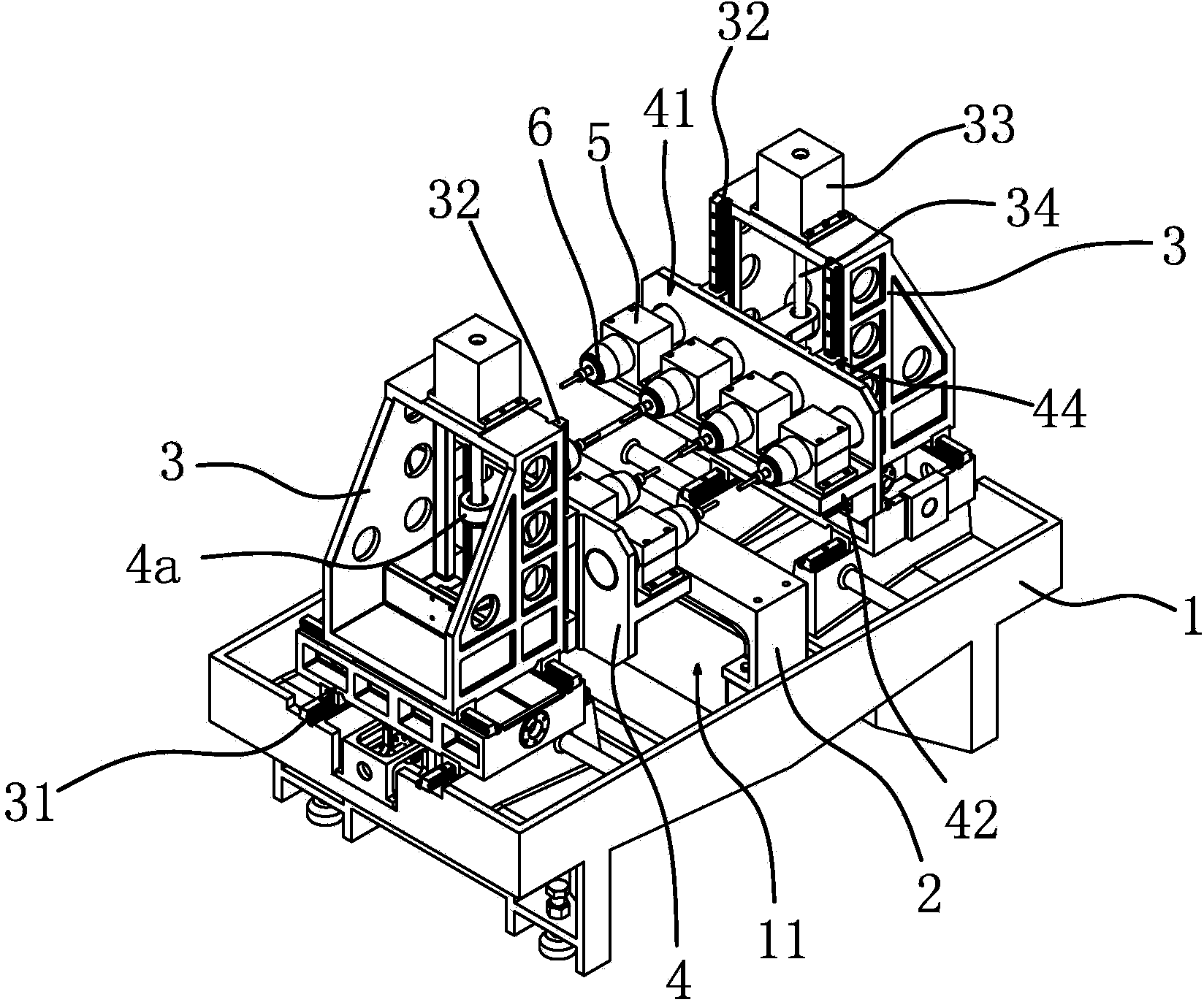

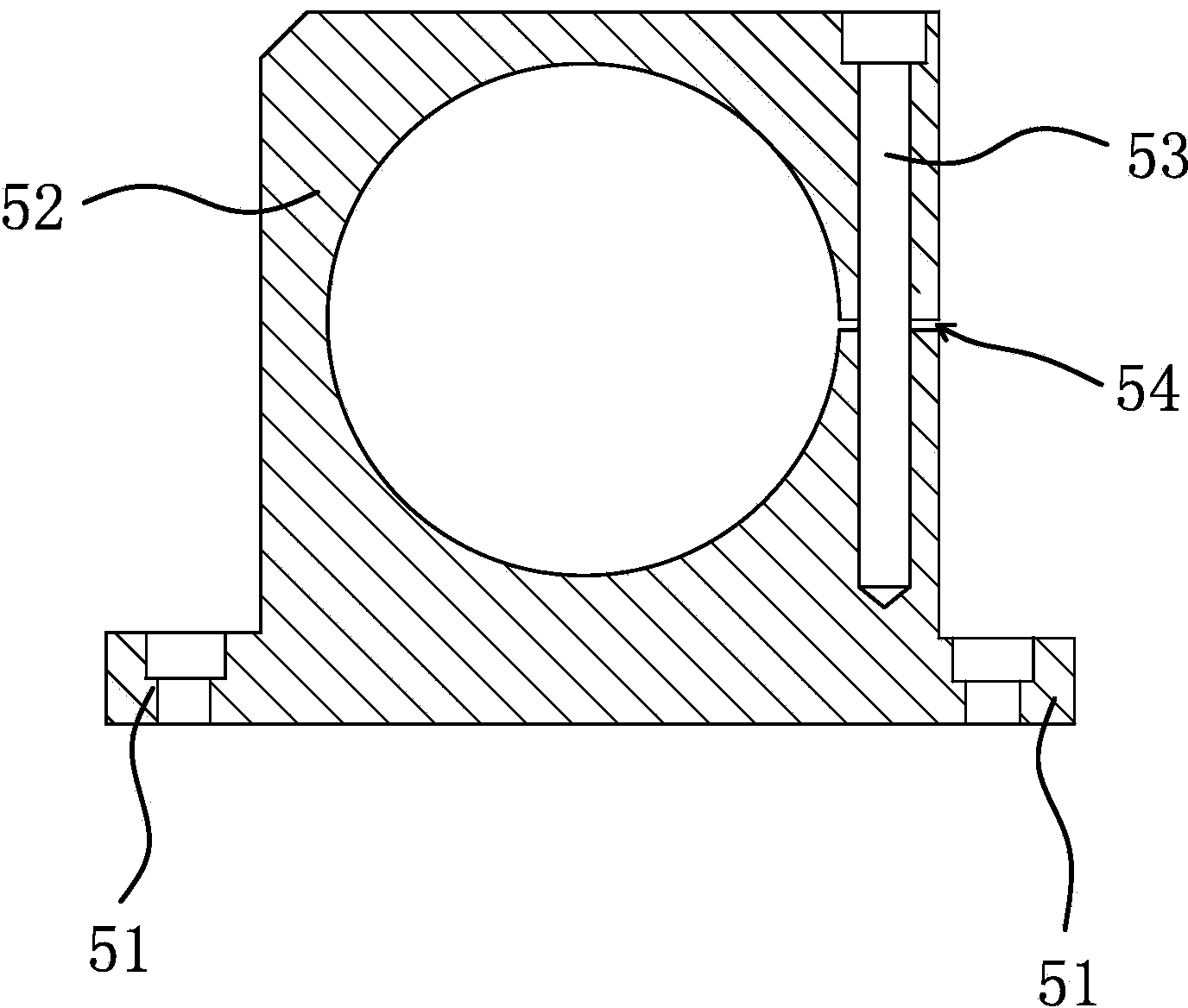

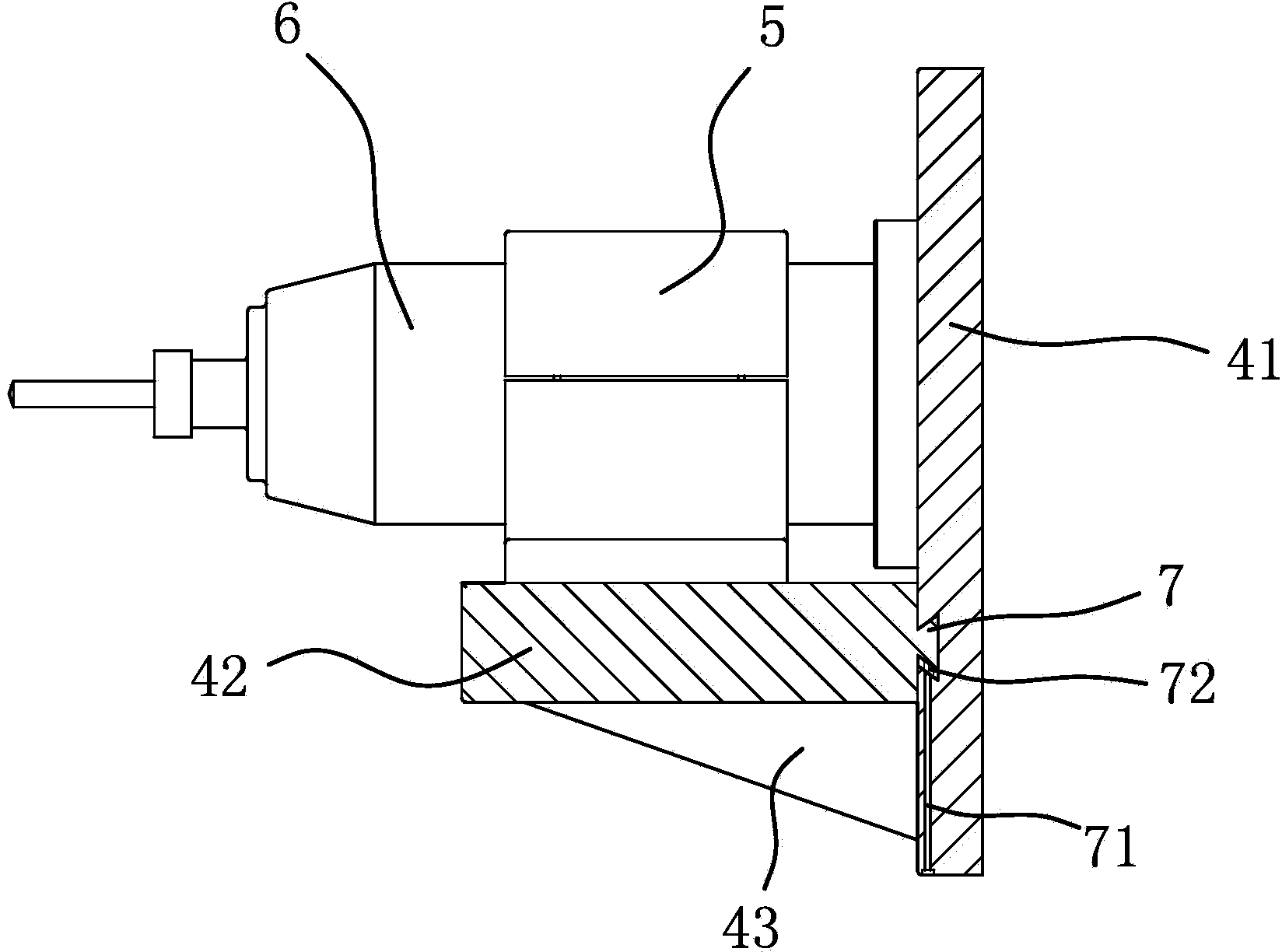

Cylindrical workpiece engraving machine automatic clamp device

ActiveCN104985969ACircumferential positioning force is stableCircumferential force is stablePositioning apparatusMetal working apparatusMachiningPositioning system

The invention provides a cylindrical workpiece engraving machine automatic clamp device, belongs to the machining equipment technical field, and solves the problems that an existing cylindrical workpiece cannot be stably clamped in engraving; the engraving machine comprises a frame having a work table; the work table is provided with a lifting plate, and fixedly connected with a positioning sleeve; two end edges of the positioning sleeve are respectively hinged to a plurality of positioning sheets; a pin shaft is arranged on one positioning face of the positioning sheet; the frame is provided with a drive piece; the positioning sleeve is connected with a plurality of supercharging columns in a radial direction in a slide manner; the supercharging columns are driven by the drive piece so as to abut against an outer circumferential wall of the cylindrical workpiece. The cylindrical workpiece engraving machine automatic clamp device can automatically clamp and position the cylindrical workpiece with high clamp precision and stability.

Owner:葆冈金属制品(珠海)有限公司

Process for producing dies

InactiveUS6840721B2Increase speedSimple possibilityPlaten pressesMilling machinesEngineeringMechanical engineering

In a method for producing embossing plates, in particular steel intaglio printing plates, a plane element is determined from a line drawing, the edge of the plane element defining a desired contour. A tool track is then calculated from the desired contour and a desired depth associated with the plane element, to be used for guiding an engraving tool such that the partial area is removed.

Owner:GIESECKE & DEVRIENT GMBH

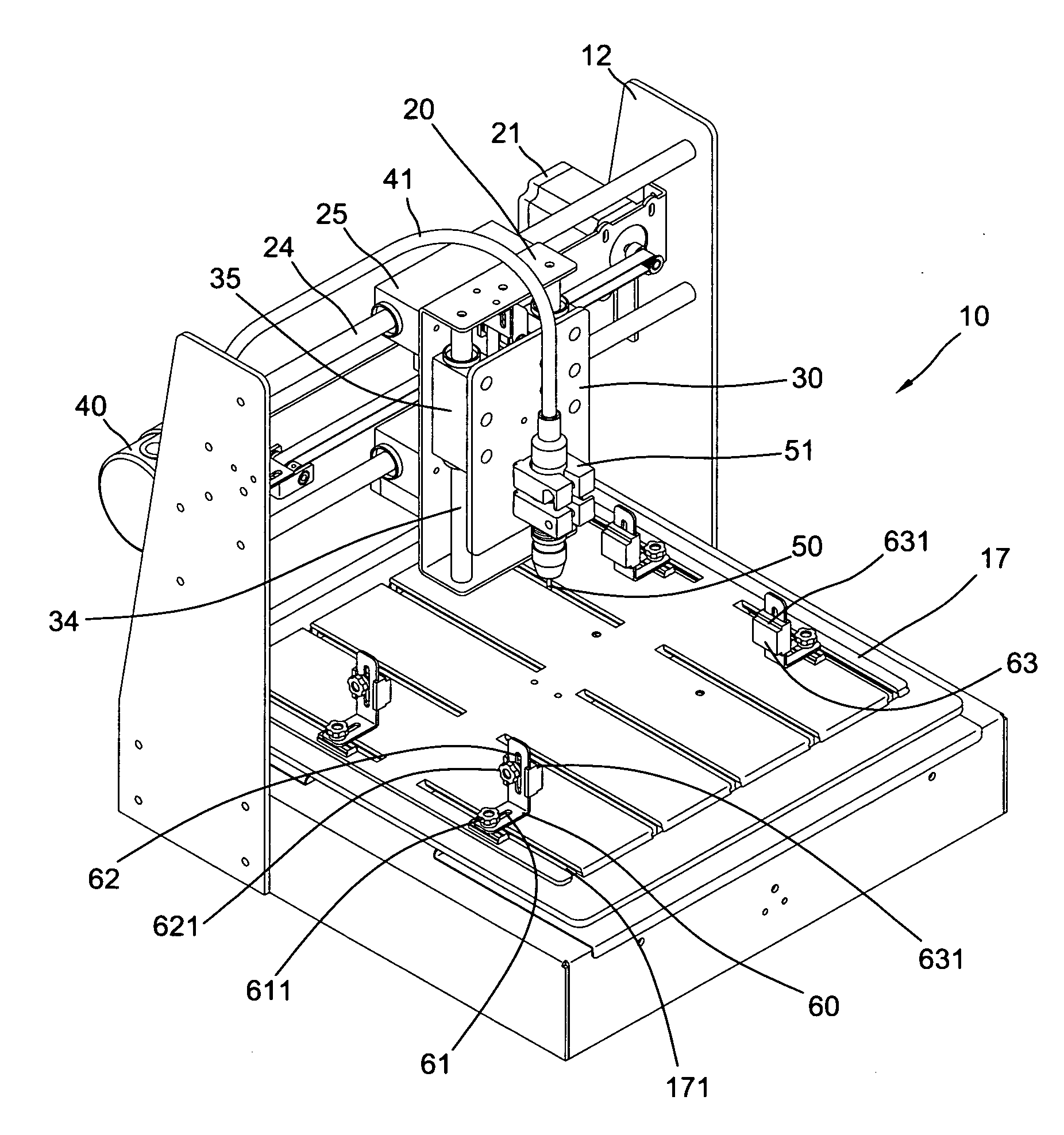

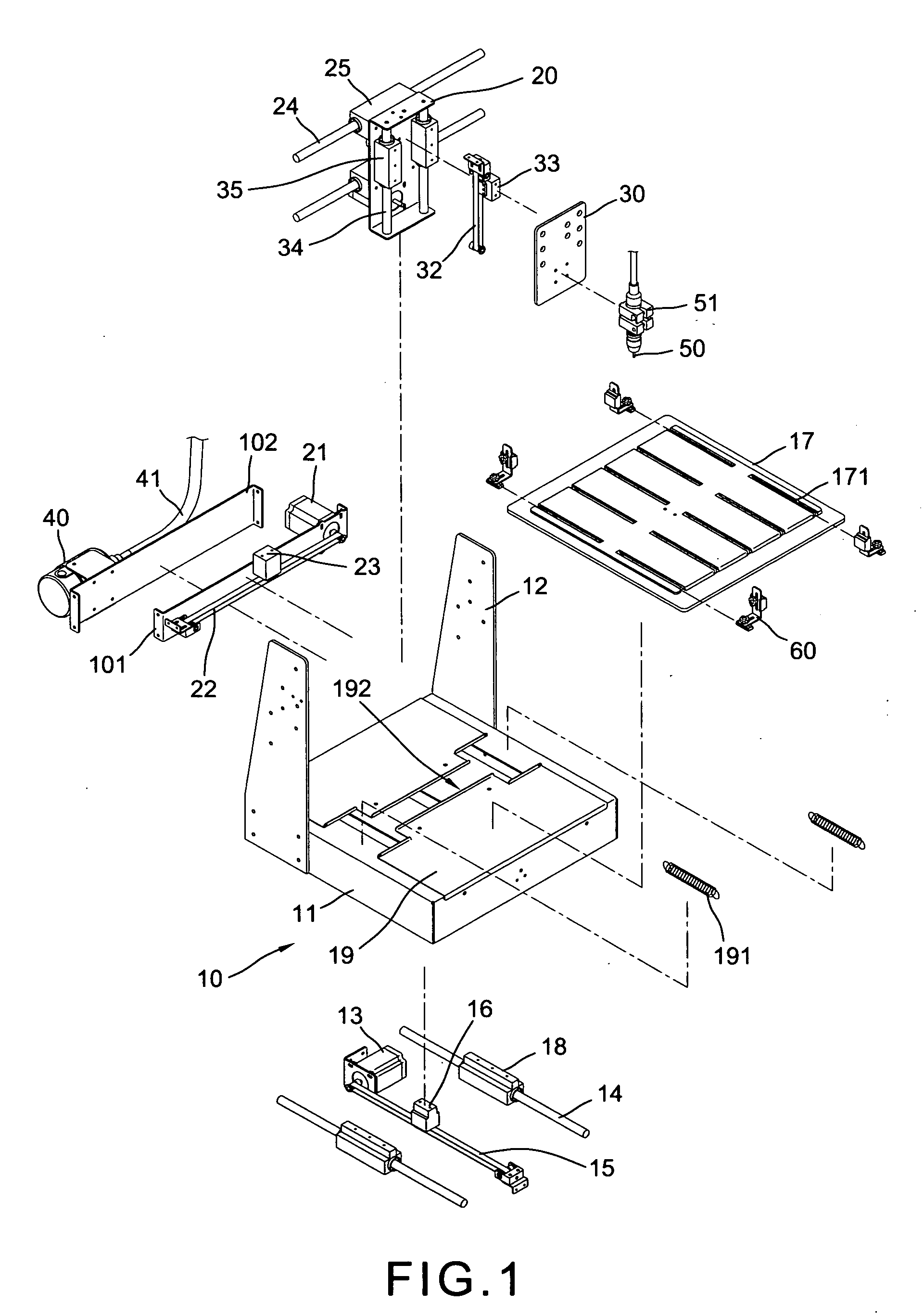

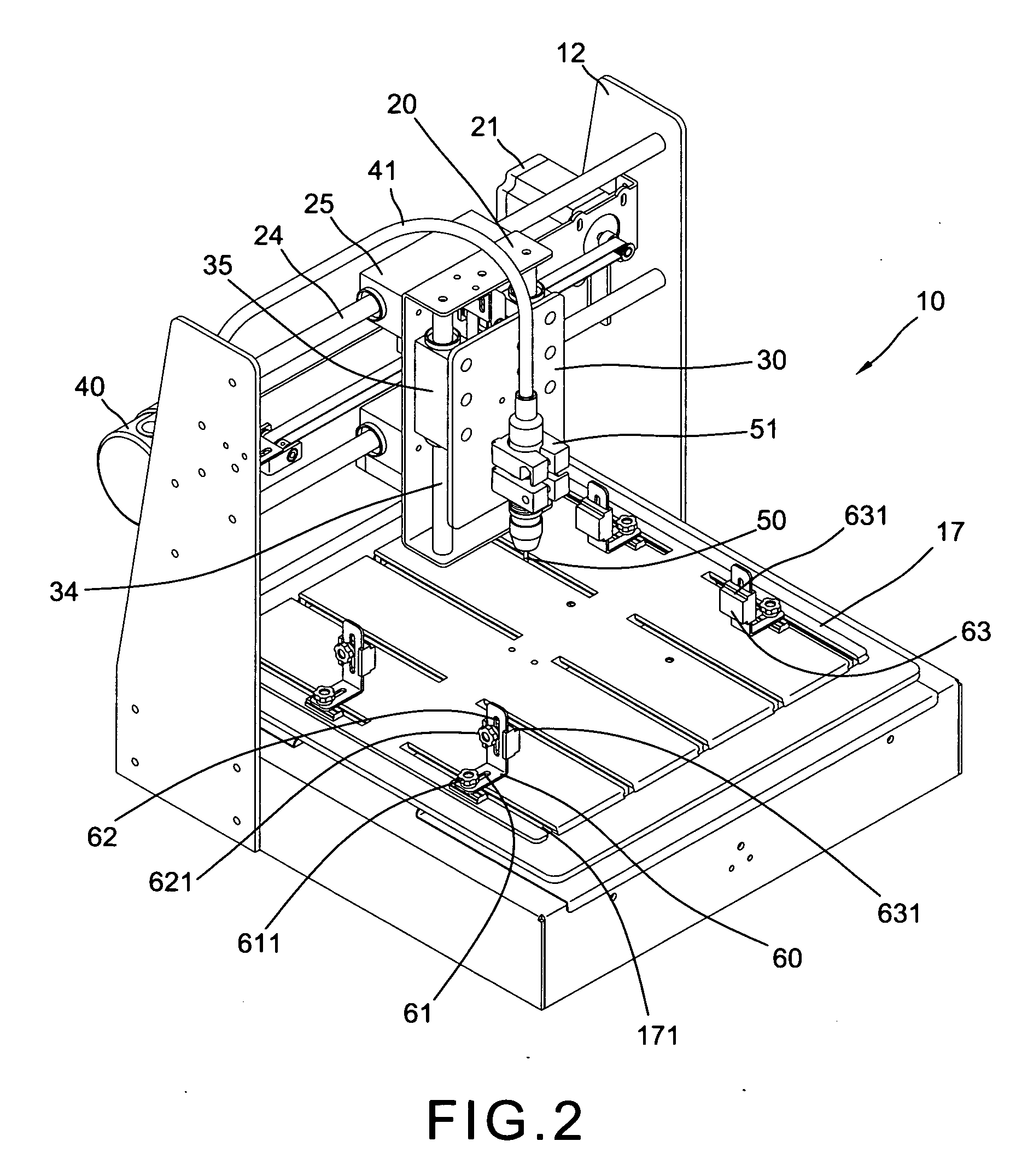

Compact engraving machine

An engraving machine includes a base with two side panels extending upward from two sides of the base, and a top board is driven horizontally by a motor in the base. A horizontal frame is movably mounted on two rods connected between the two side panels by a motor. A vertical frame is located on a front side of the horizontal frame and is movable along two rods in vertical direction by another motor. The horizontal frame, the vertical frame and the top board are movable along X, Y and Z directions by three independent motors. A chuck is connected to the vertical frame and secures an engraving tool which is driven by a main motor connected between the two side panels. The object to be engraved is secured on the top board and engraved by the engraving tool in X, Y and Z directions.

Owner:CHEN YUEHTING

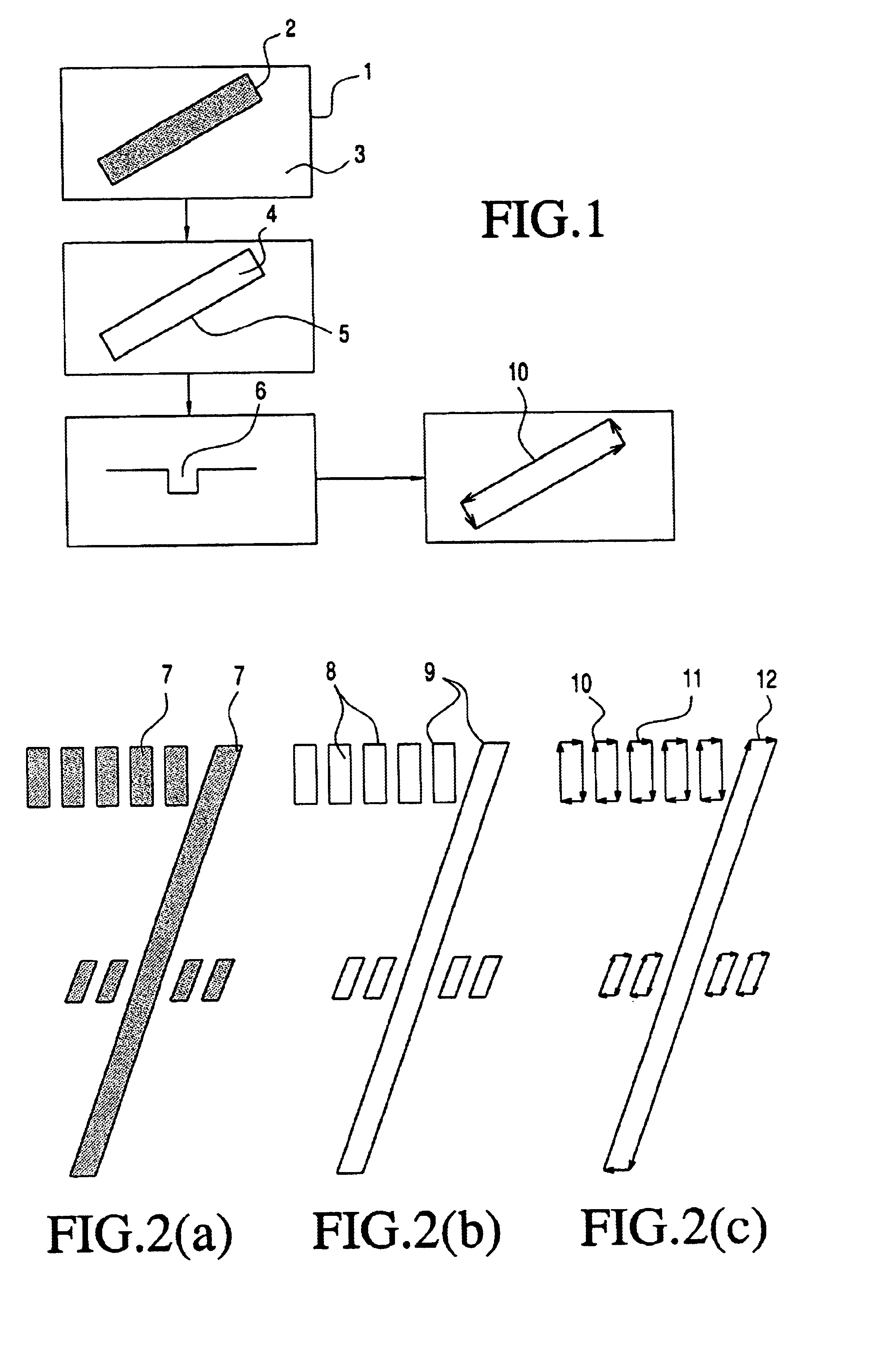

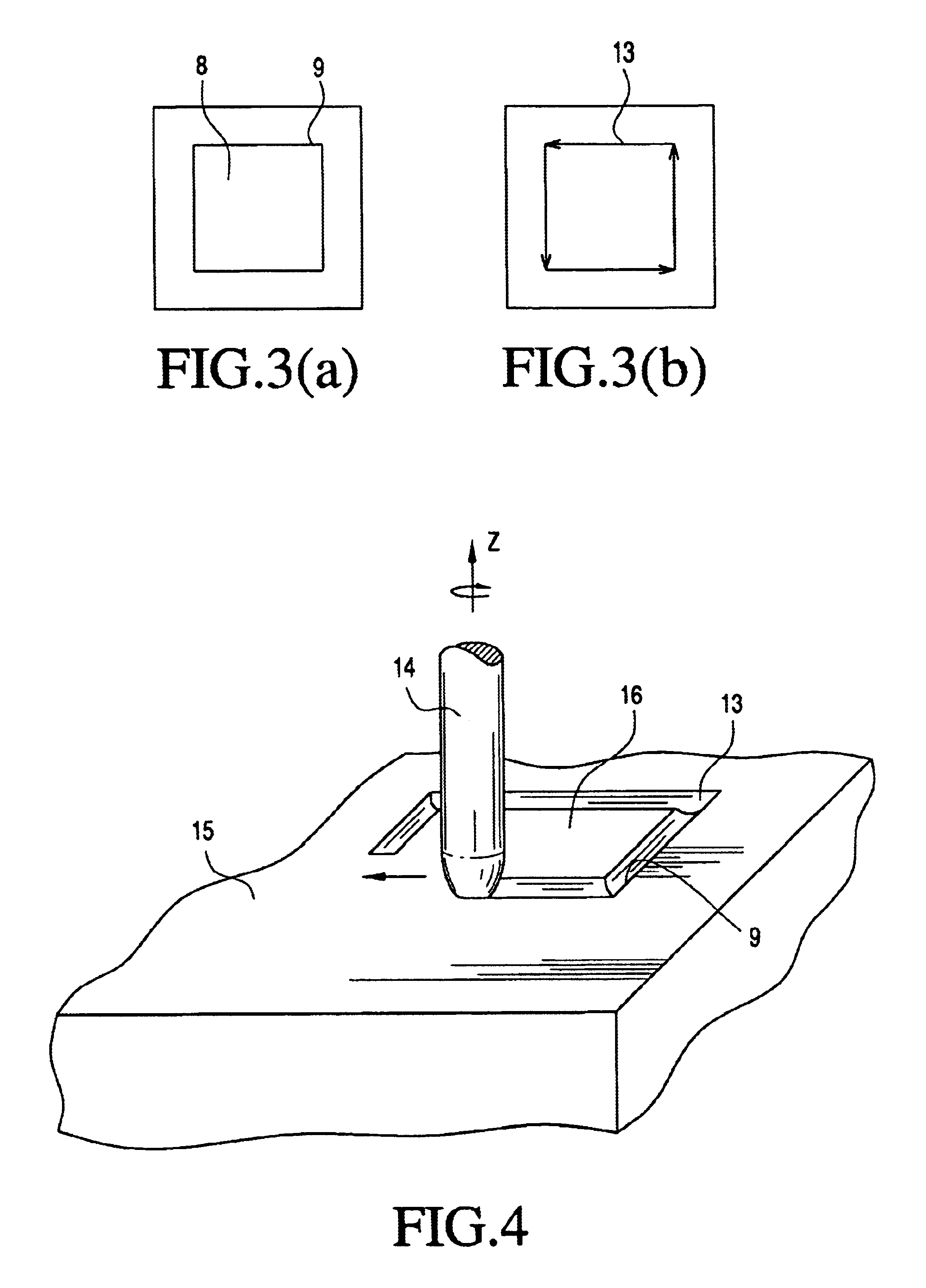

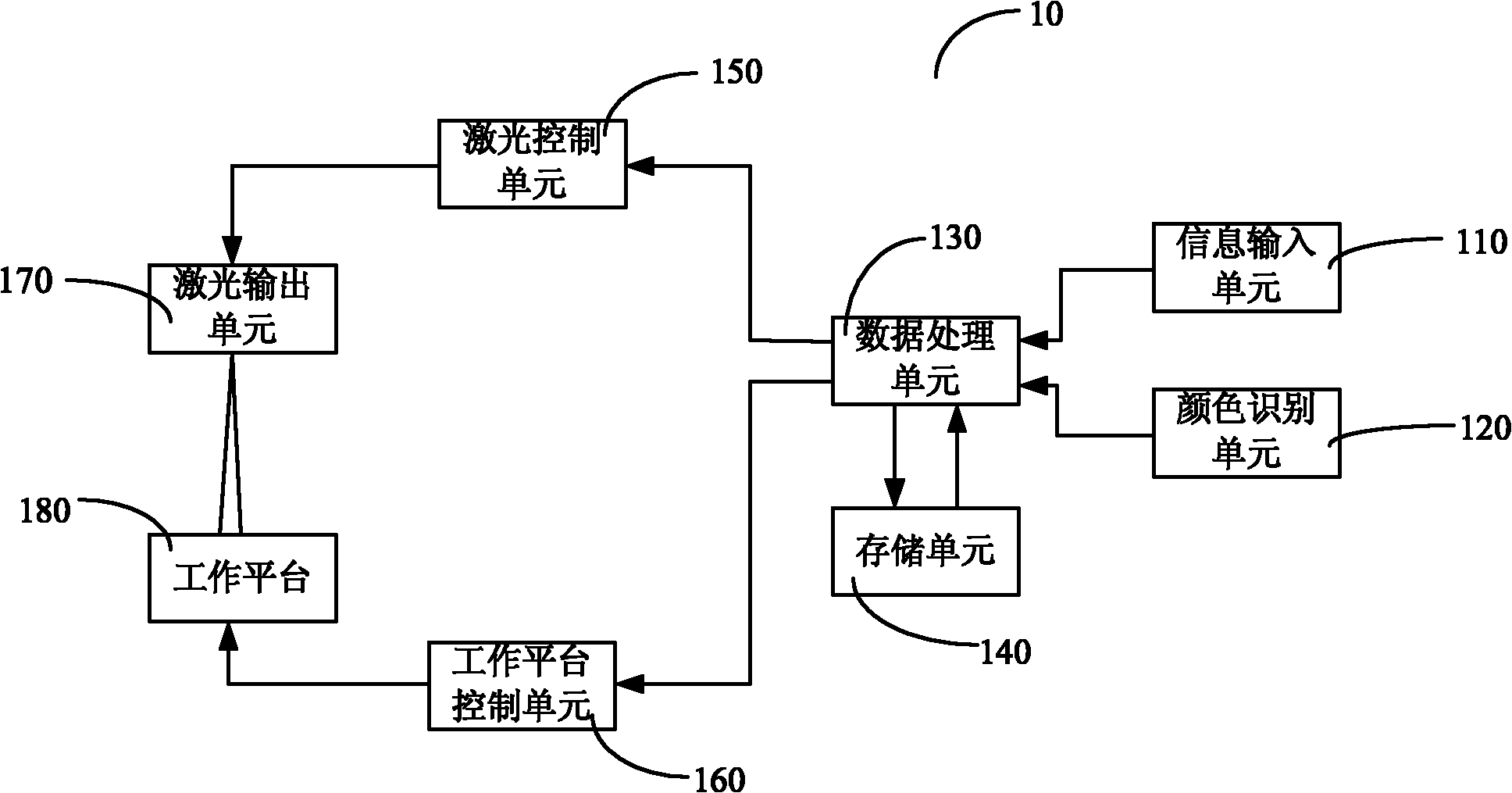

Textile laser engraving system and method

The invention relates to a textile laser engraving system which comprises an information input unit, a color identification unit, a storage unit, a data processing unit, a laser control unit, a laser output unit, a working platform control unit and a working platform. The invention also relates to a textile laser engraving method which comprises the following steps of: fixing a textile on the working platform; focusing and fixing the laser output unit; inputting the type information and the pattern information of the textile to be subjected to laser engraving as well as the distance information between the laser output unit and the working platform; irradiating laser emitted by the laser output unit onto the textile and simultaneously generating corresponding colors of patterns on the textile through inclining, rotating and moving the working platform; and finishing the operation. In the invention, a multidimensional stereoscopic laser irradiation method can be realized on the textile, so that not only can the colors of the patterns engraved on the textile be changed according to the pattern information, but also the effect of gradually changing the colors can be achieved, therefore, the patterns are more vivid.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

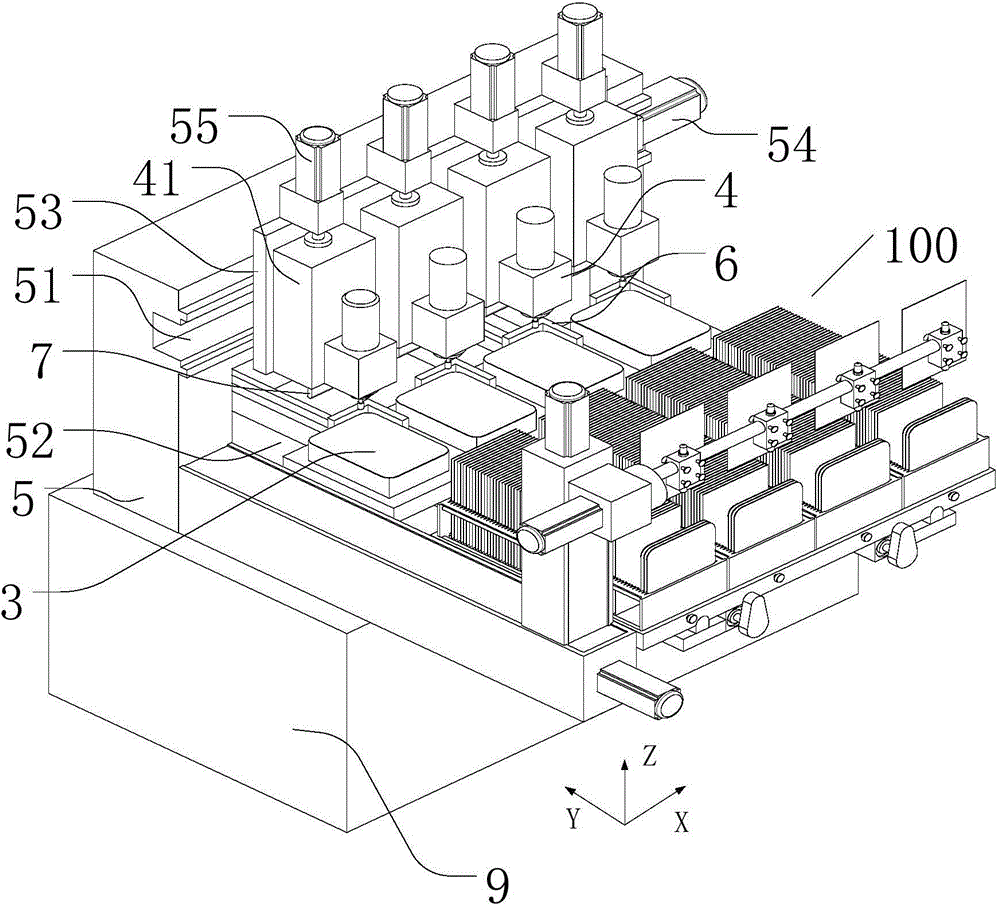

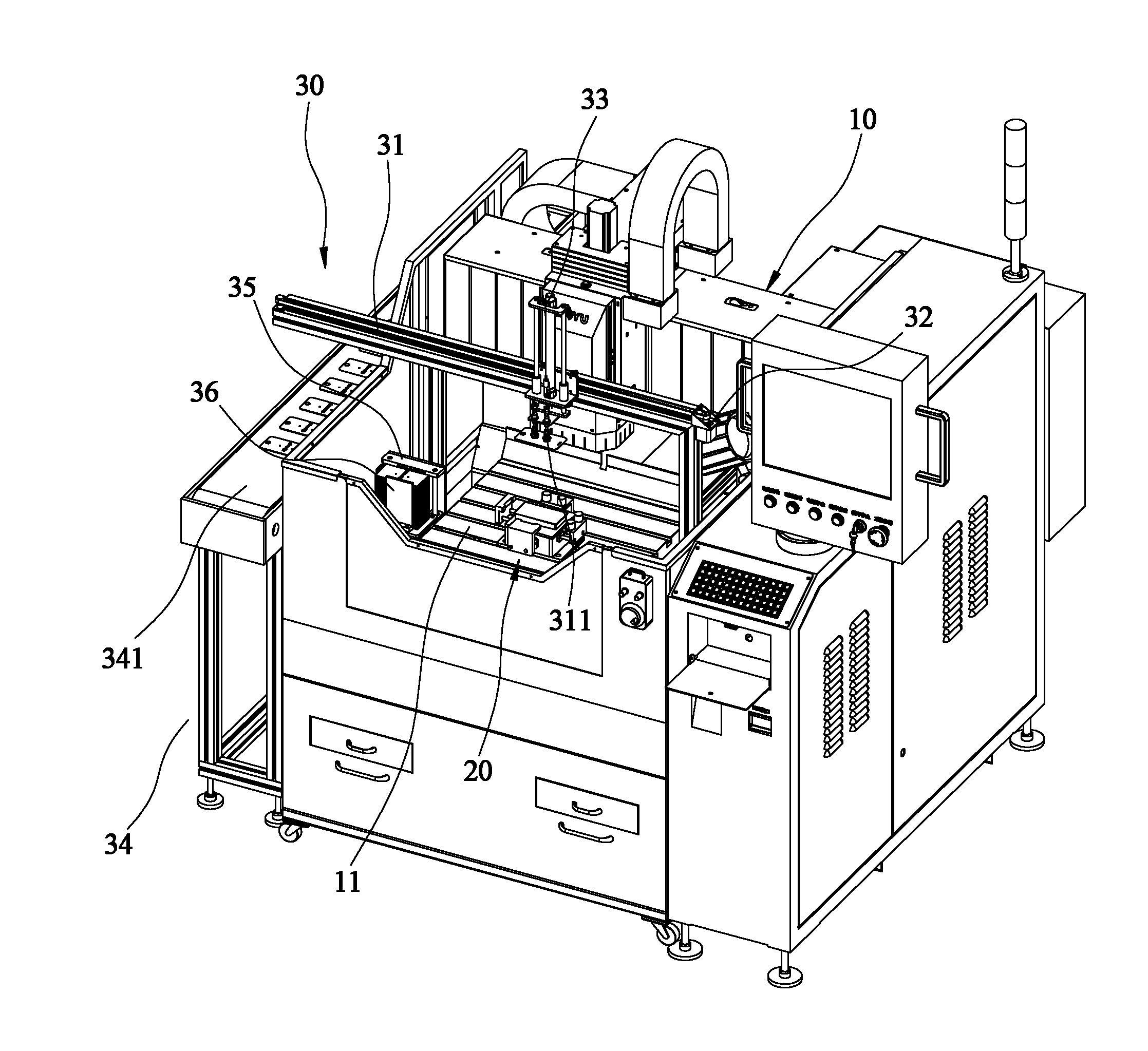

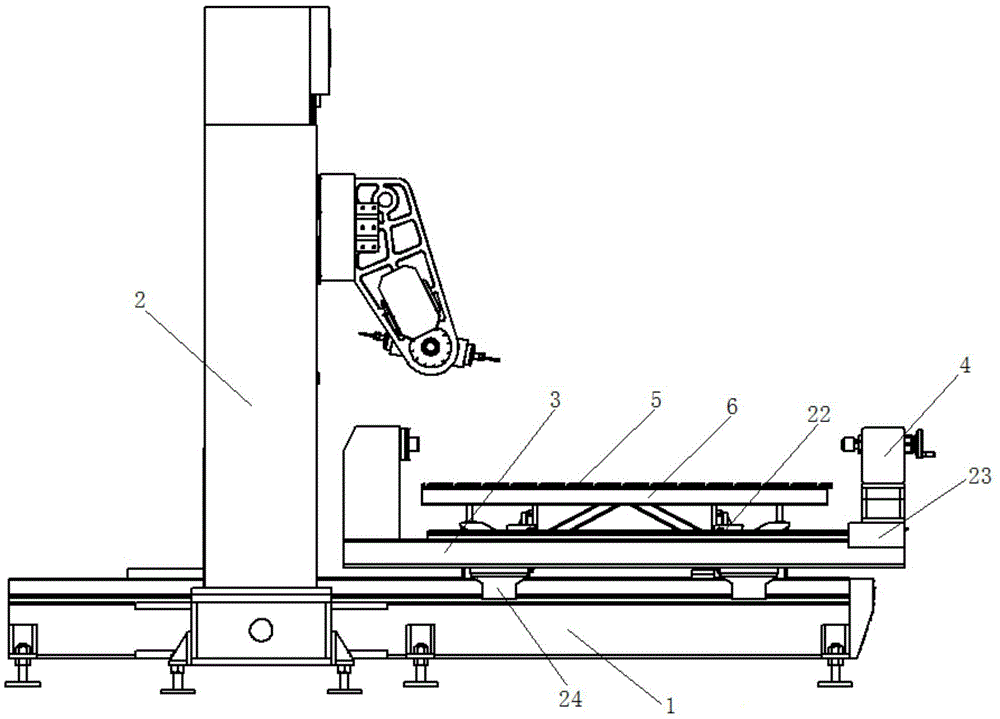

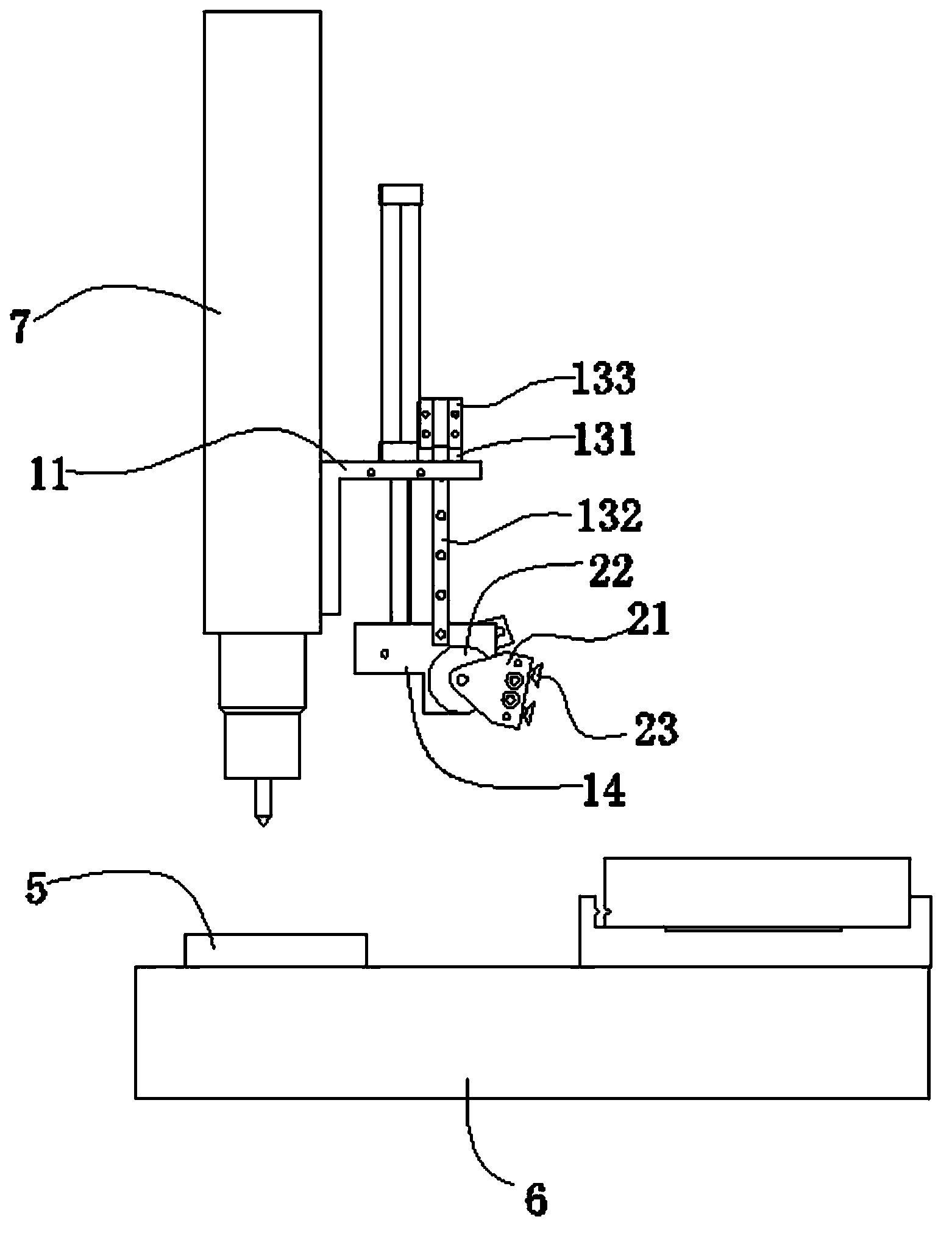

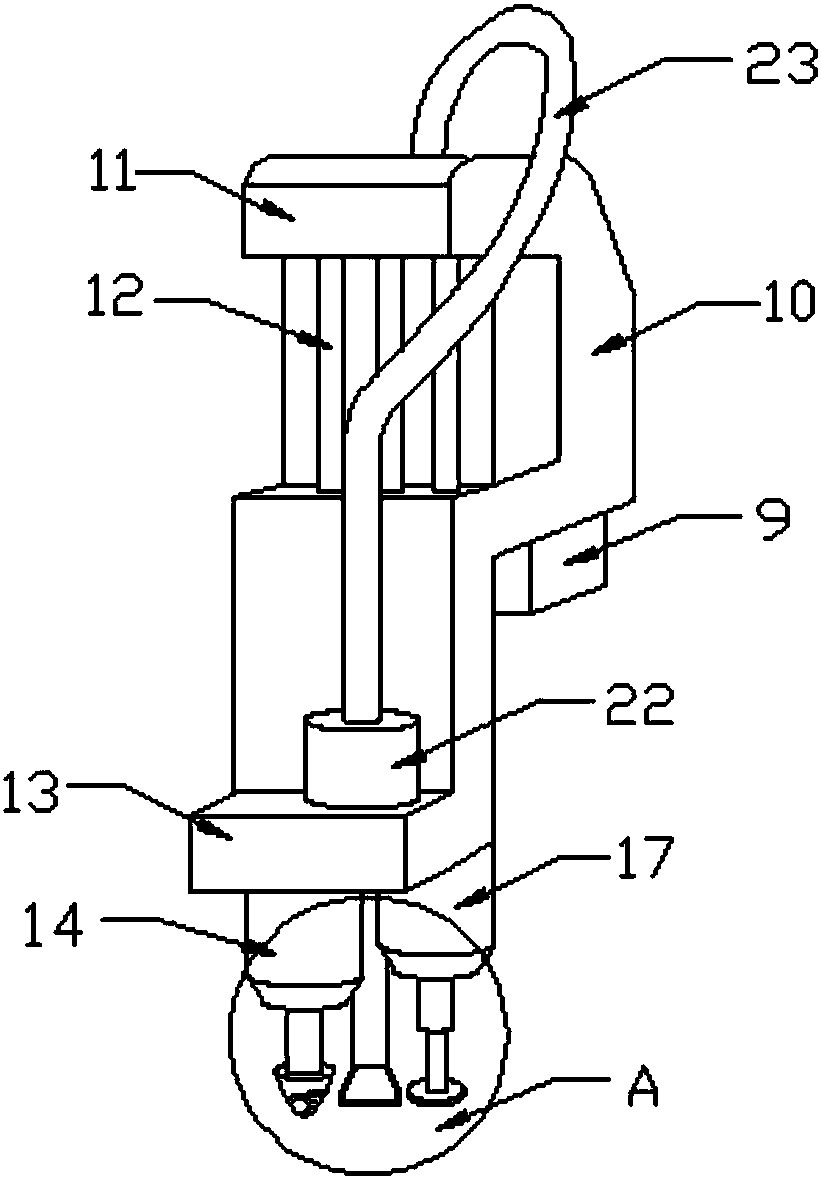

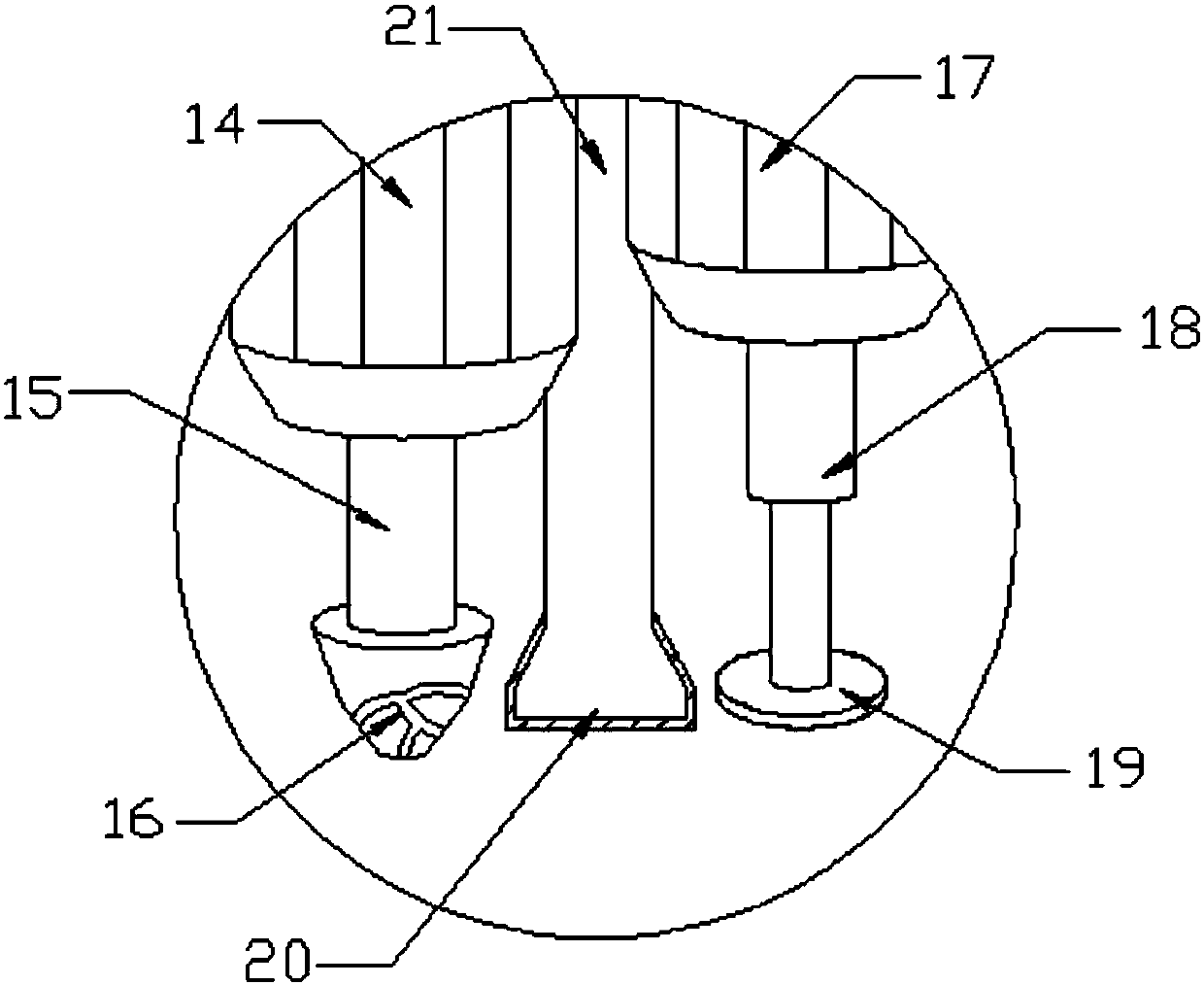

Fine-engraving machine capable of loading and unloading automatically

The invention discloses a fine-engraving machine capable of loading and unloading automatically, comprising a base and a fine-carving assembly as well as a control assembly mounted on the base. The control assembly includes an industrial personal computer (IPC) used for controlling the fine-carving assembly to work and an operating panel used for inputting commands to the IPC. The IPC is electrically connected with the fine-carving assembly. The fine-carving machine further comprises an automatic loading and unloading device which is mounted on the base. Thereby, the fine-engraving machine capable of loading and unloading automatically disclosed by the invention realizes the automatic loading and unloading function through the automatic loading and unloading device. Compared with the artificial loading and uploading way, the fine-engraving machine disclosed by the invention greatly improves production efficiency and reduces production cost.

Owner:SHENZHEN DAYUCNC TECH

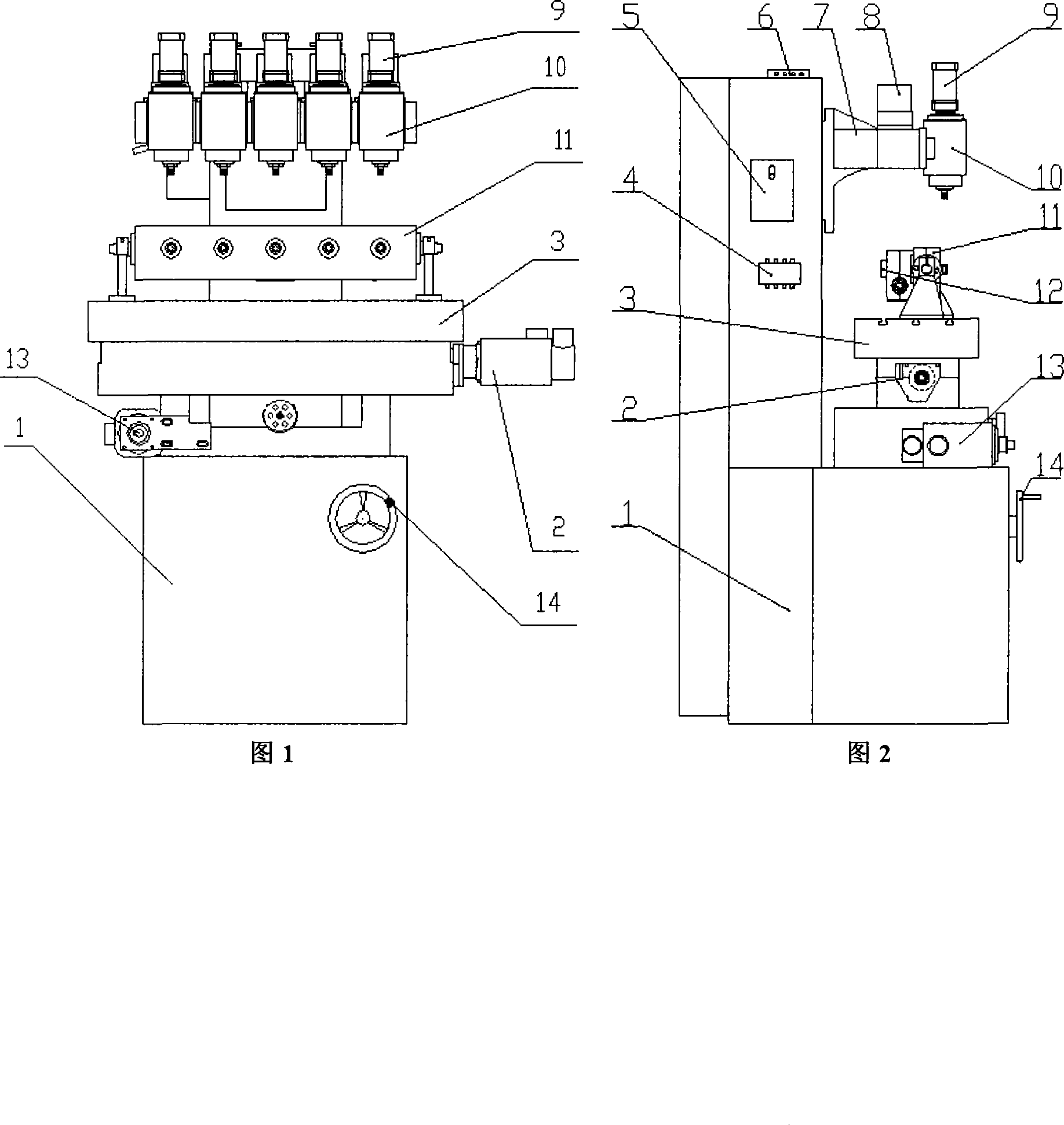

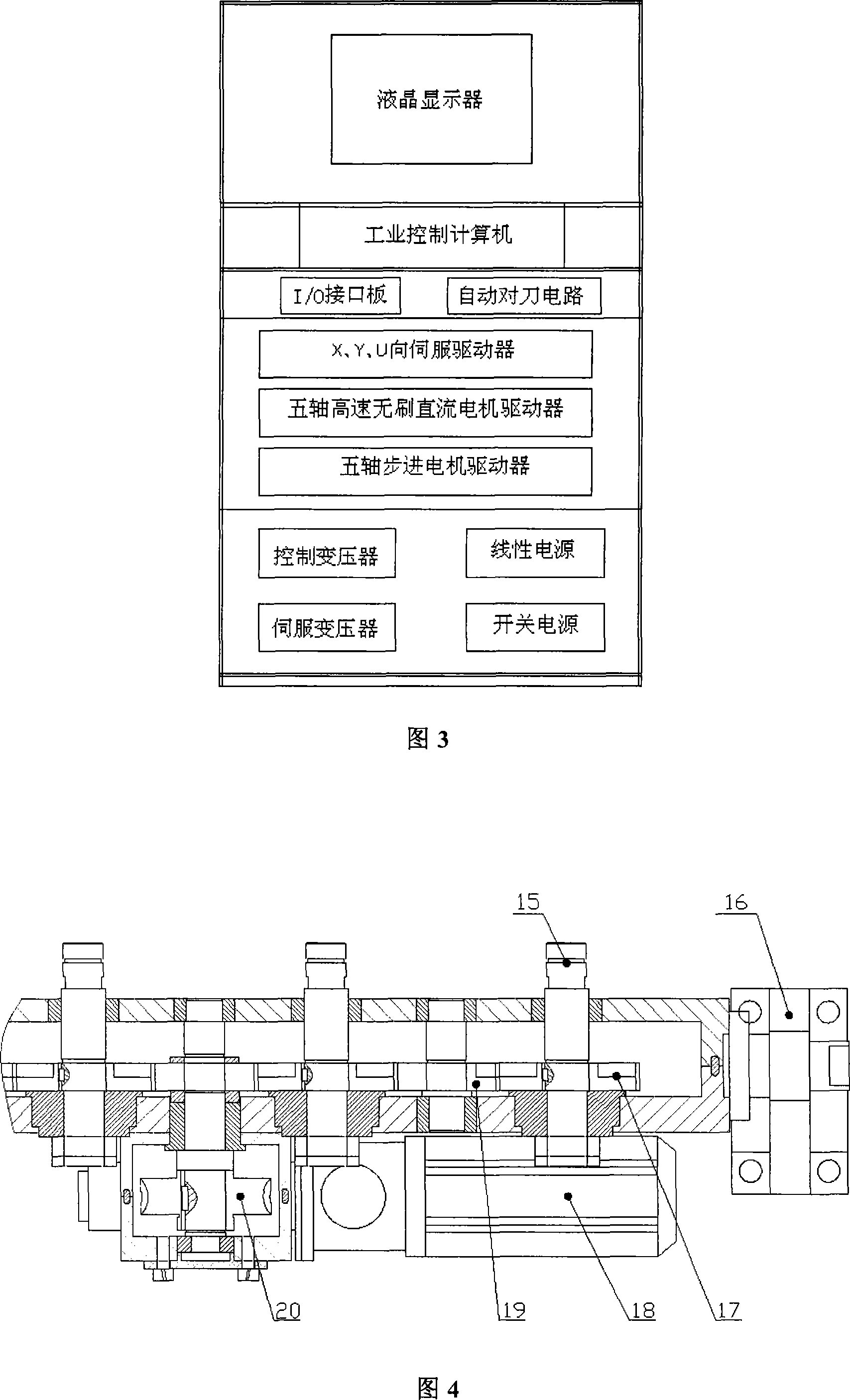

Multi-station digital-controlled carving machine

InactiveCN101195318AGood interface functionGuaranteed radial errorAutomatic control devicesFeeding apparatusNumerical controlDigital control

The invention relates to a multi-station numerical control engraving machine comprising a machine body (1), an engraving machine portion and an electric portion, wherein the electric portion comprises a software portion and a hardware portion, the hardware portion employs a control core combined by an industrial control computer and a movement control card, the movement control card is connected with a digital servo-actuator or multi-shaft stepping motor which are controlled by the movement control card by data wire, the software employs an application running under Visual C++ program Windows 2000 XP and an application of 51 single chip computer, the engraving machine portion is mainly composed of an engraving head (10), a multi-station tool device (11) and a tool setting and feeding device, the engraving head uses a brushless direct current motor (9) to drive the central axis. The multi-station numerical control engraving machine can simultaneously engrave various Chinese characters, curves and patterns with single line or double line on cylindrical surfaces, conical surfaces and geometric plane surfaces at multiple stations, and additionally engraving patterns and characters can be edited and designed by users.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Engraving tool depth control nosepiece for enhancing line uniformity

Engraving tool bit depth controlling nosepiece adjustment devices establish a precise protrusion distance that an engraving tool bit protrudes from the end of the nosepiece of a spring loaded engraving tool, that is in turn inserted within and driven by a standard machine tool such as a cnc type milling machine. One rotational adjustment device establishes the axial position of the nosepiece with respect to a collet nut of the engraving tool and another adjustment device employs annular ring spacers in the form of washers between the nosepiece and collet nut to precisely establish the desired engraving tool bit protrusion distance from the end of the nosepiece. This modification of a spring loaded engraving tool beneficially prevents the engraving tool bit from being able to plunge too deeply into the workpiece, particularly at the start of each engraved line, to thus ensure that all the lines will be consistent.

Owner:NELSON LANCE

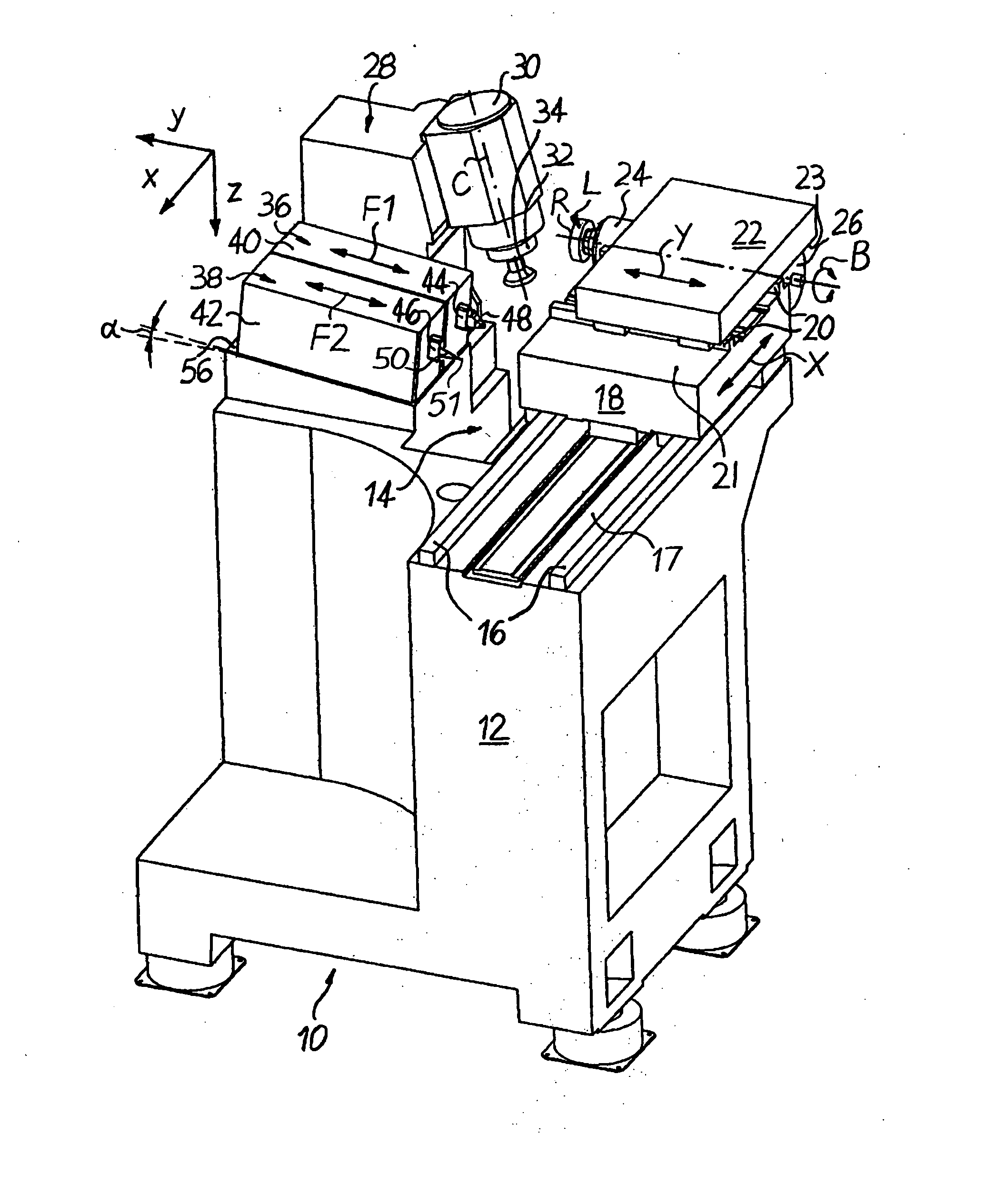

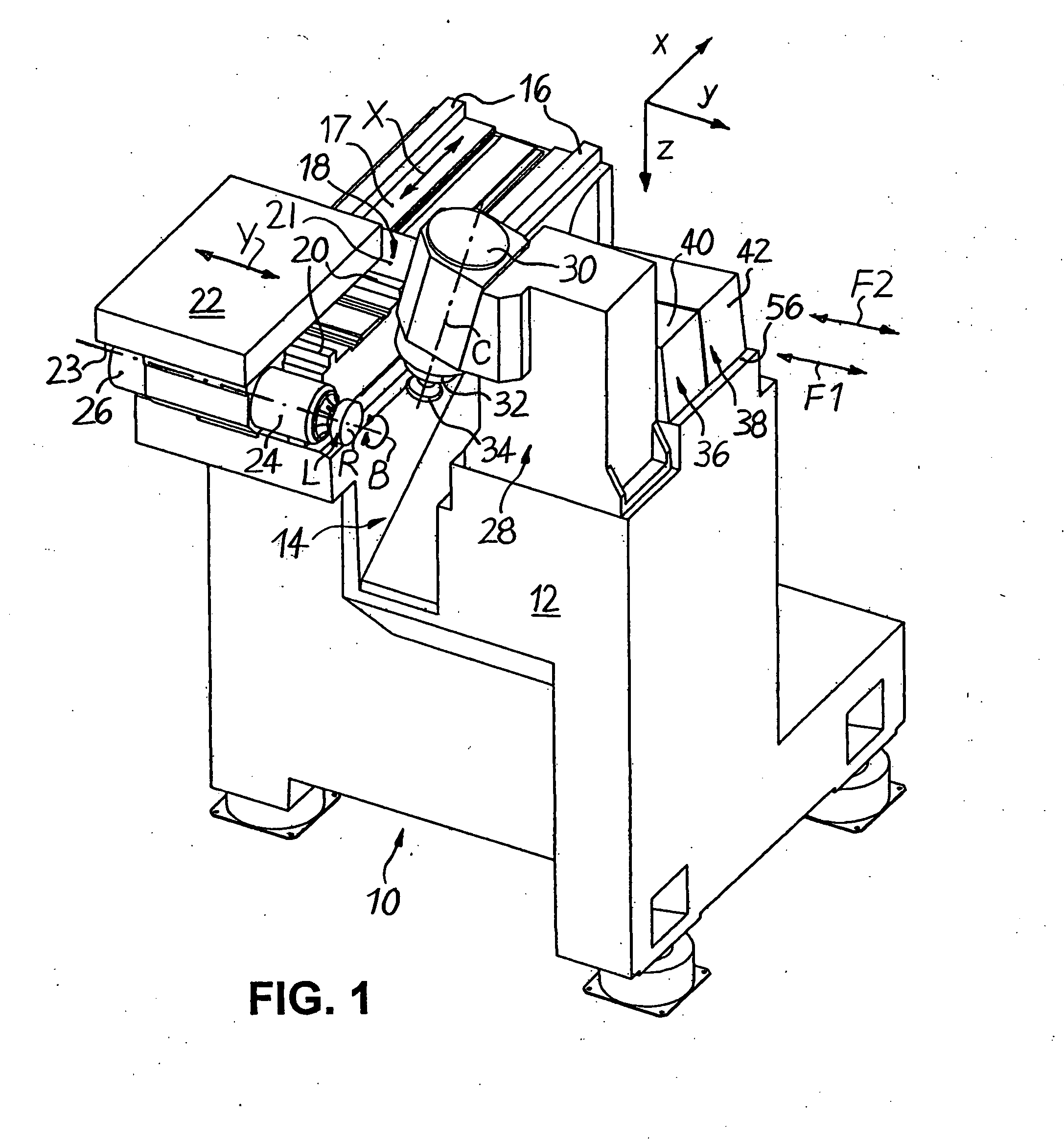

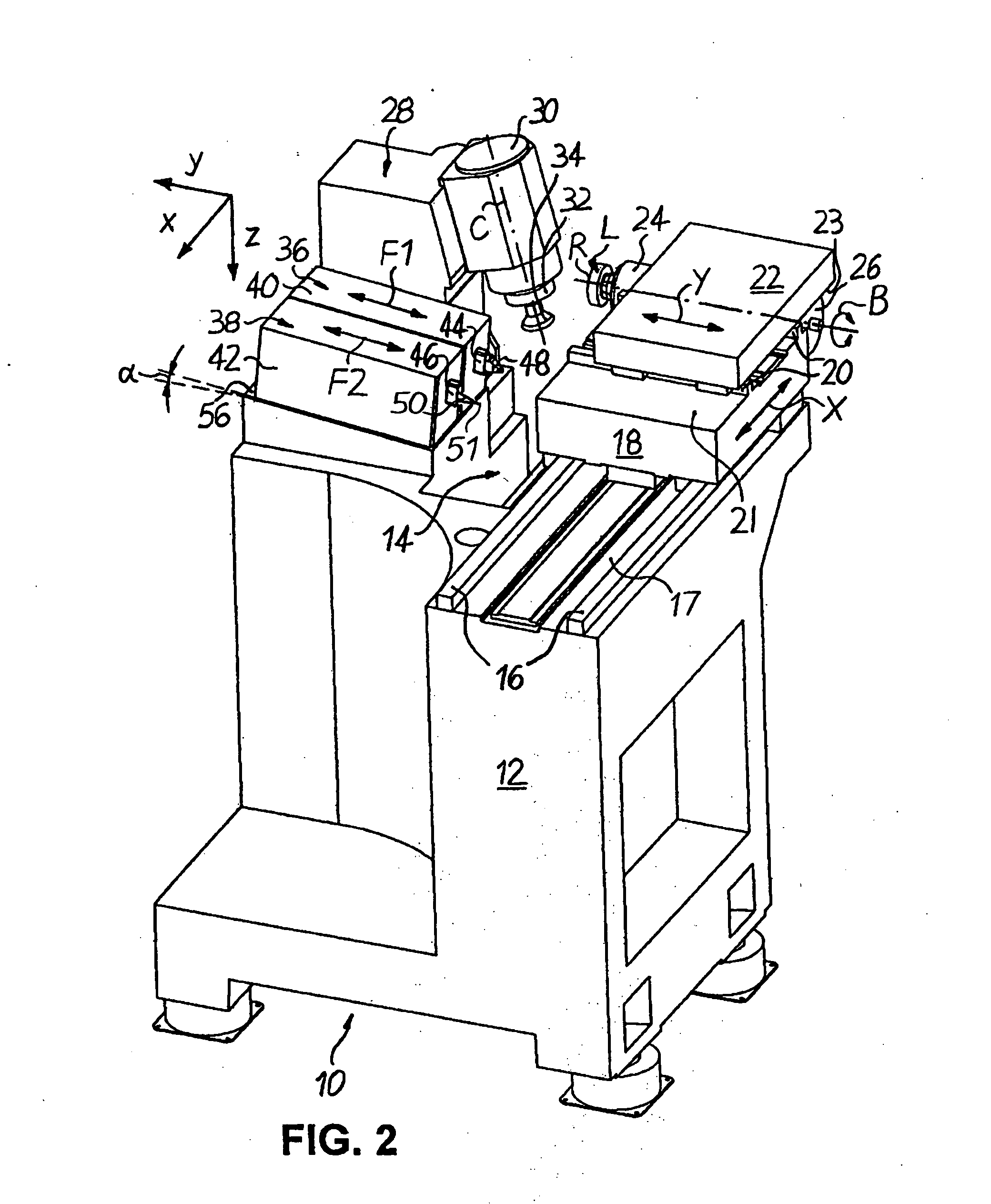

Machine for machining optical workpieces, in particular plastic spectacle lenses

ActiveUS20070277357A1Rapid and precise processFinely detailed engravingsLathesTurning toolsEyewearEngineering

A machine for machining optical workpieces, is equipped with a workpiece spindle, by which the workpiece can be rotatably driven about a workpiece rotation axis, and with a first fast-tool assembly, by which a turning cutter is movable in the direction of the workpiece and away from it. The workpiece spindle and the first fast-tool assembly are also movable relative to each other in a direction transverse to the workpiece rotation axis. Provided adjacent to and preferably in parallel configuration with the first fast-tool assembly is a second fast-tool assembly with a graver which has its end that faces the workpiece being essentially punctiform. The graver is movable by the second fast-tool assembly, in the direction of the workpiece and away from it, so that a marking of any geometry can be produced on the latter in the same span.

Owner:SATISLOH AG

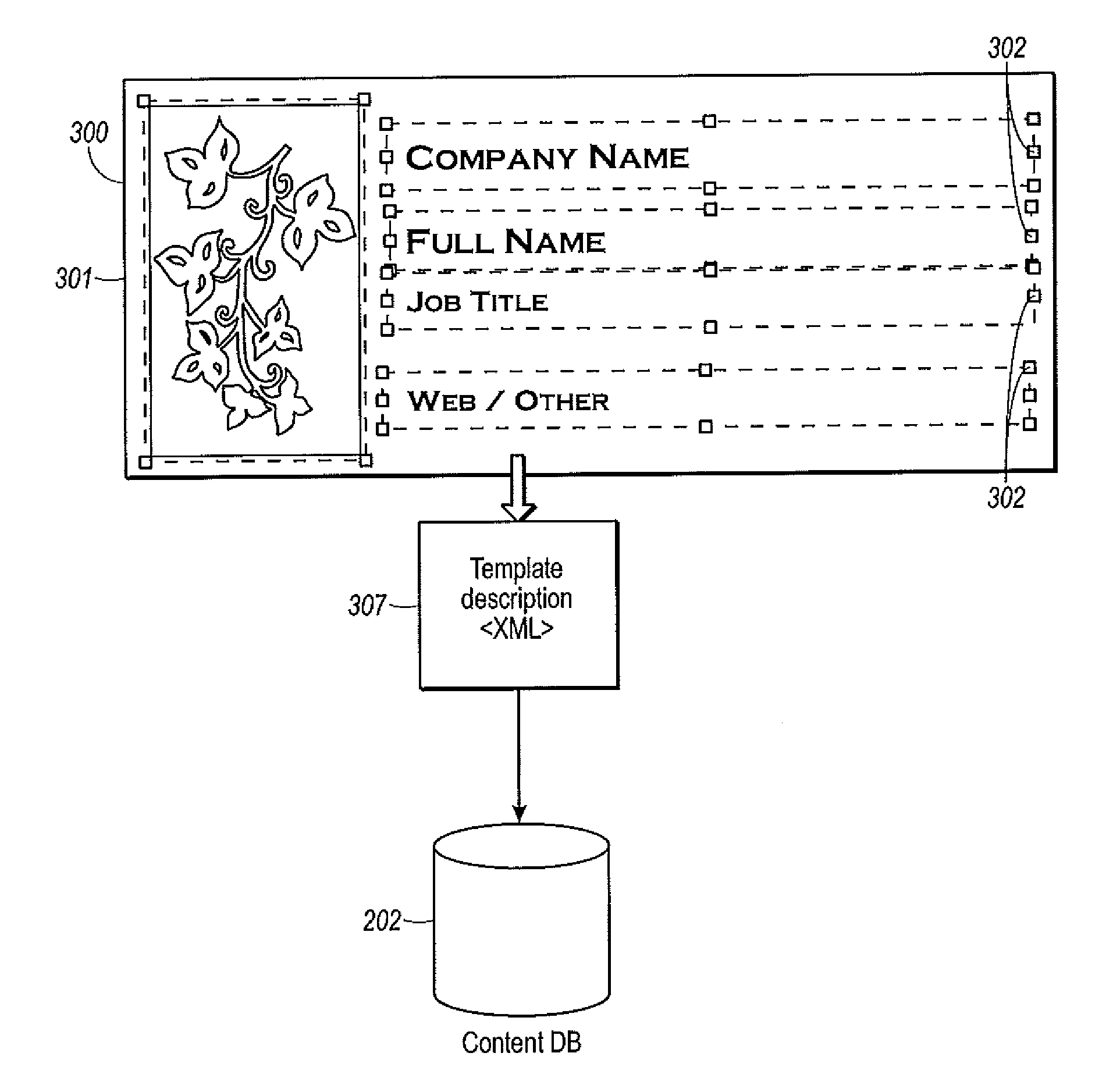

Automated engraving of a customized jewelry item

InactiveUS20060200269A1Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingPersonalizationIcon design

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

Multifunctional carving machine

ActiveCN105620148AHigh degree of automationWide range of usesModel makingEngravingMarine engineeringMachining

The invention relates to the field of machining, in particular to a multifunctional carving machine which comprises a base, stand columns, a carving platform and a cutter mechanism. The carving platform comprises a movable platform and a workpiece clamping device; an automatic lifting platform is arranged on the movable platform, and comprises a platform board, a platform board lifting rack and automatic platform board lifting mechanisms; the automatic platform board lifting mechanisms are fastened on a cross beam in the middle of the movable platform; the platform board lifting rack is fixed to the automatic platform board lifting mechanisms; and the platform board is fixed to the platform board lifting rack. The multifunctional carving machine is additionally provided with the platform board capable of being lifted automatically on the basis of an existing high-precision three-dimensional carving machine; the lifting platform can be automatically lifted through program codes, and the platform board is lifted up when a plane is carved and is automatically lifted down when a three-dimensional structure is carved. The multifunctional carving machine is high in automation degree, wide in application and convenient and safe to operate.

Owner:NANTONG OUKE CNC EQUIP CO LTD

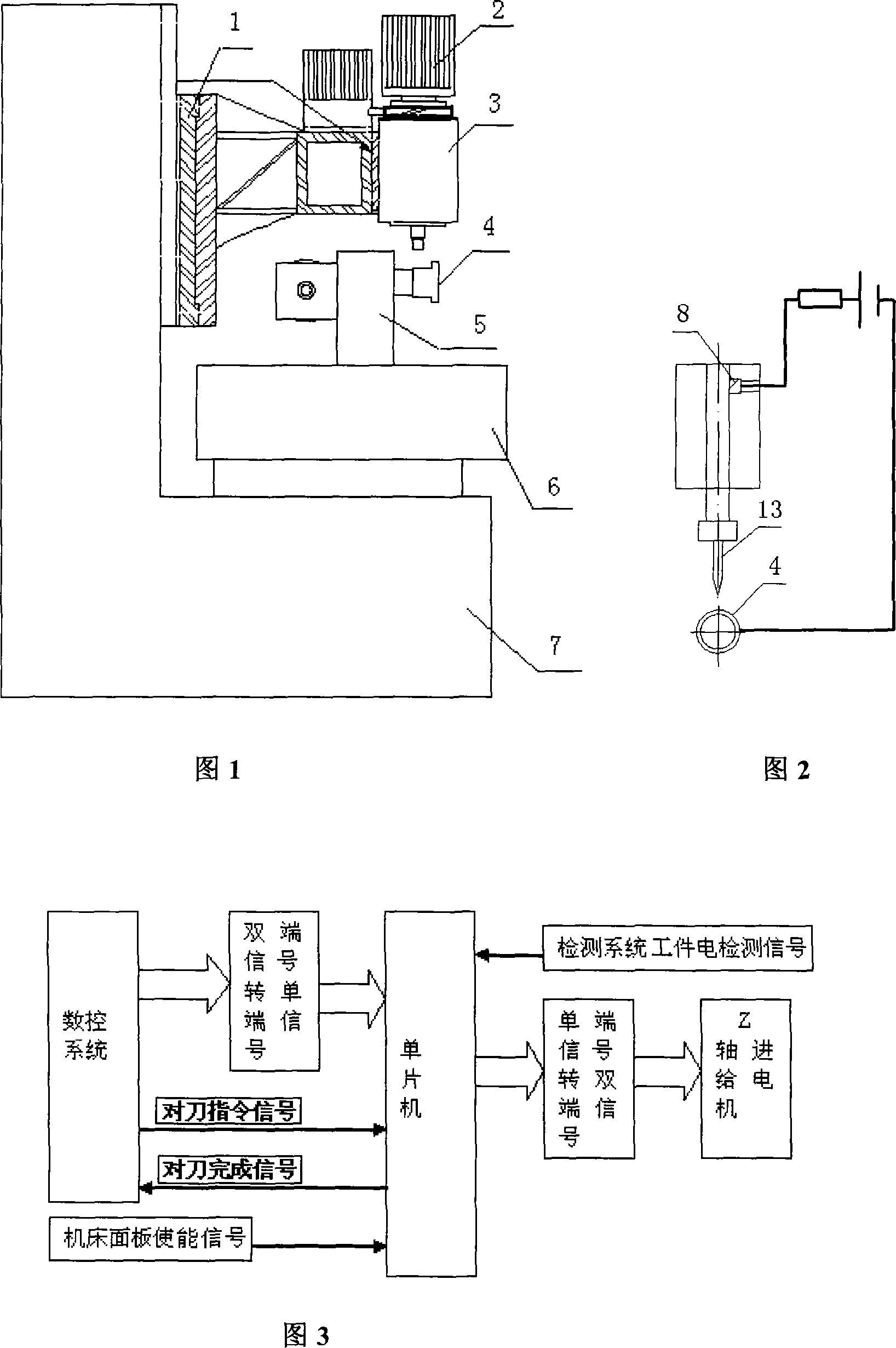

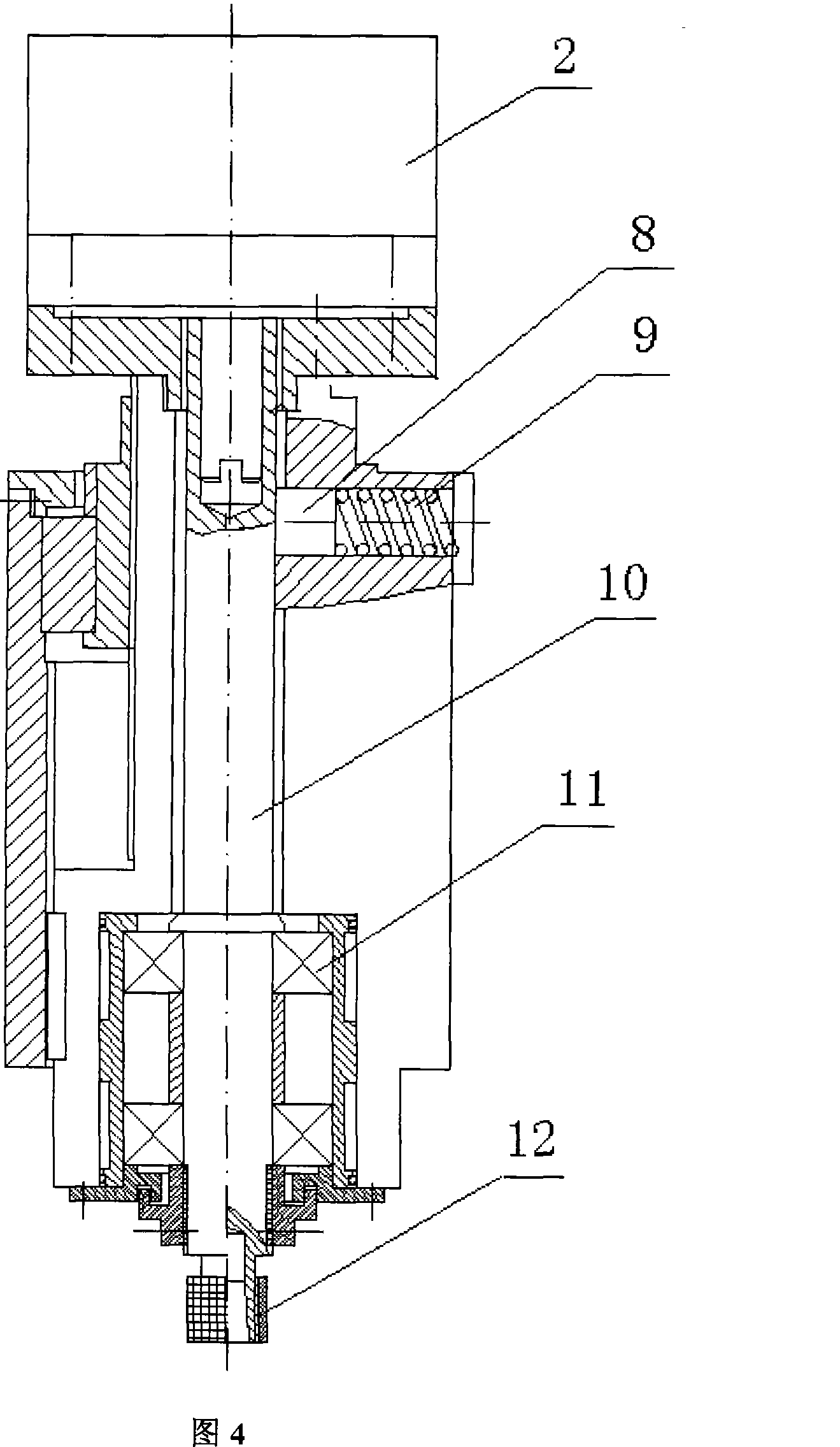

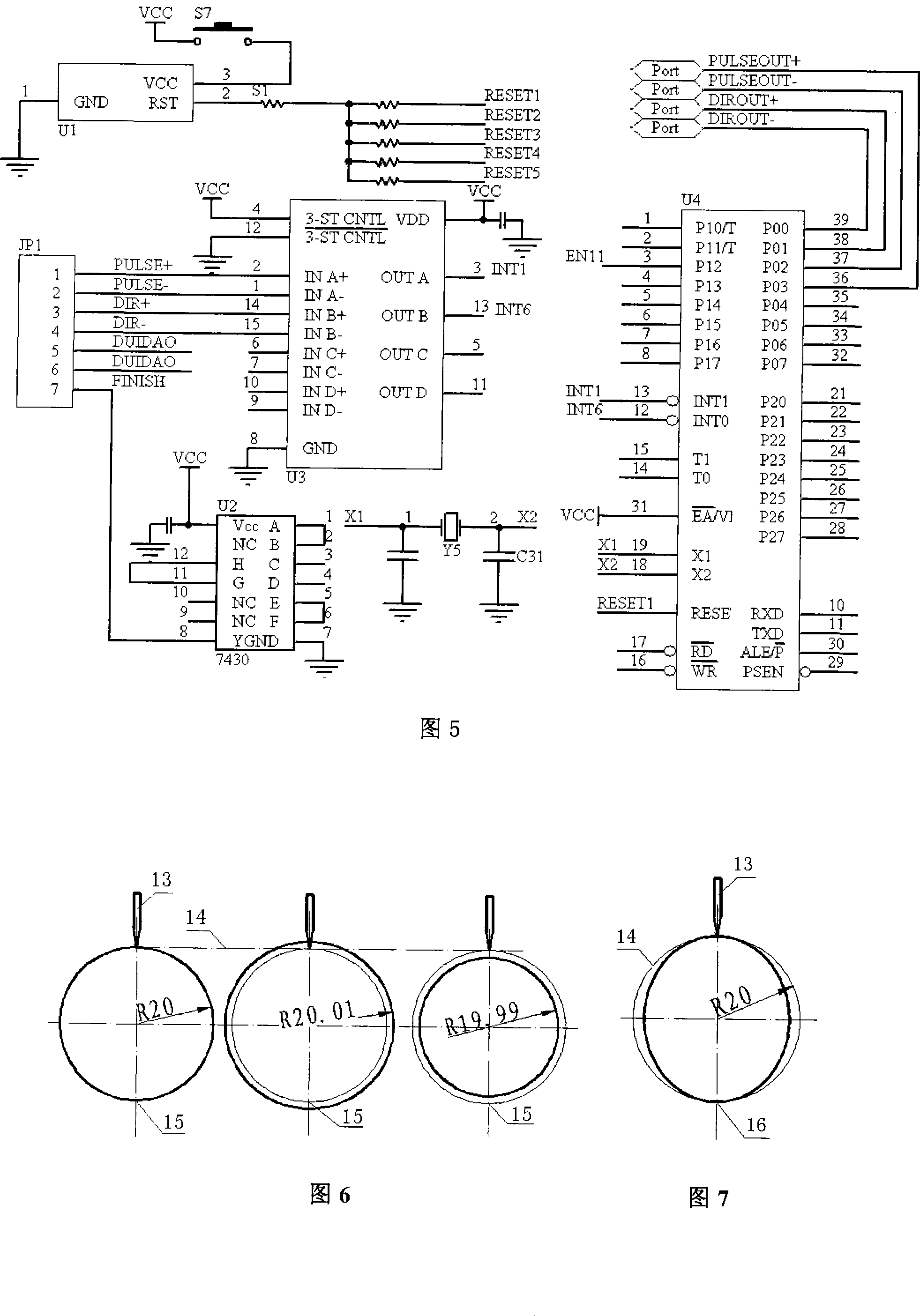

Multi-station numerical controlled carving tool setting device

InactiveCN101195319AGuaranteed engraving depth consistencyHigh precisionAutomatic control devicesFeeding apparatusElectricityNumerical control

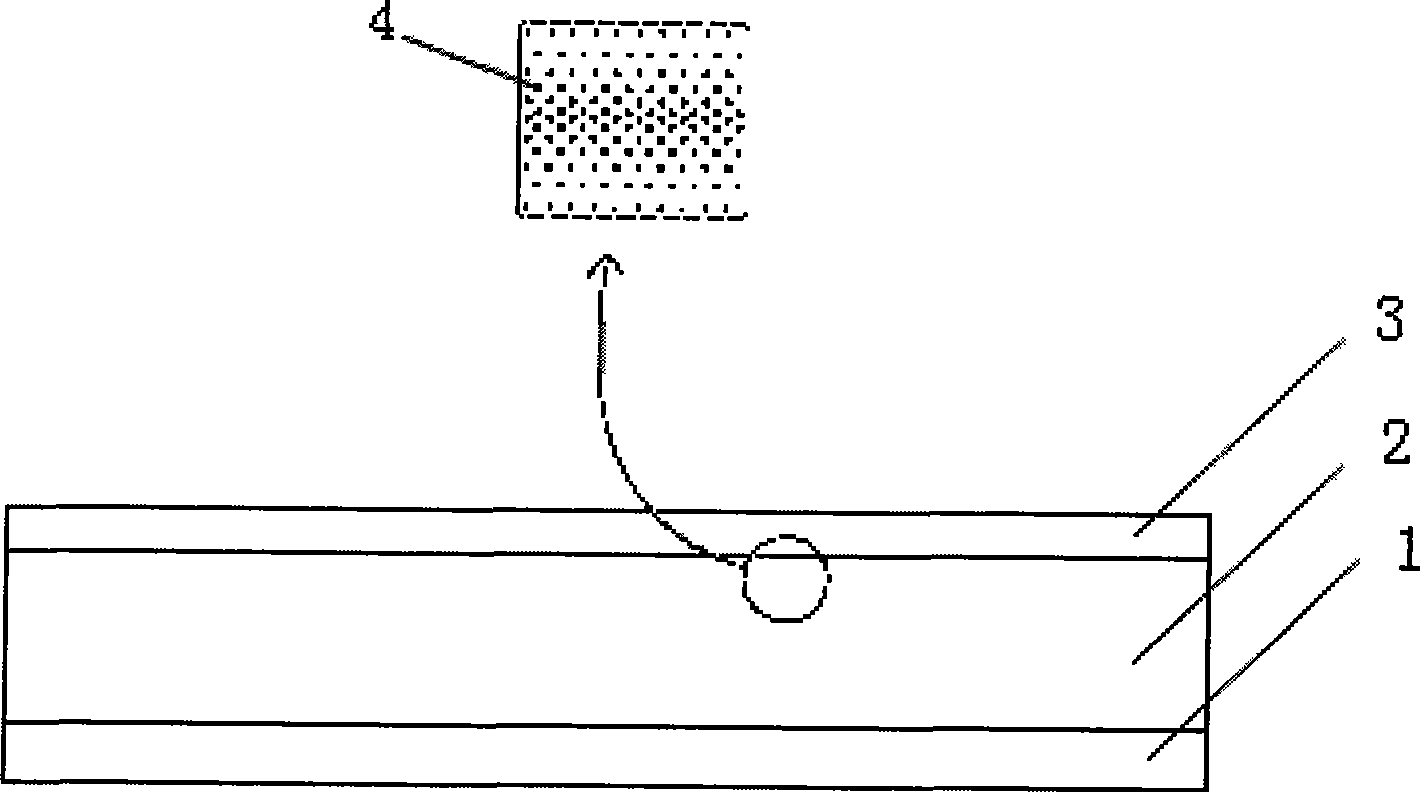

The invention provides a tool setting device for multi-station numerical control engraving, which is composed of a control system and an electrical contact signal detecting system, wherein the control system comprises four circuits of a single chip computer control group circuit, a signal input and transformation circuit and a signal output and transformation circuit, the single chip computer control group circuit is composed of a plurality of independent single chip computers U4 and peripheral circuits thereof, the electrical contact signal detecting system is a good conductor composed of a body (7), a worktable, a clamp and a workpiece (4), and connected with the power supply via 'earth' connection, the positive electrode of the power supply is connected with an engraving head (3) which is connected with a main shaft motor (2). The invention can realize automatic tool setting, and enable all the tools to be positioned on the surface of the workpiece before engraving feed, particularly consistency of engraving depth is guaranteed in high precision engraving, further the performance is reliable and the breaking edge rate is smaller than 0.0001%. The device of the invention can be widely applied to precise engraving of numerical control engraving machines and multi-station processing systems of numerical control milling machines, machining centers and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Apparatus and method for controlling a programmable marking scribe

ActiveUS7191529B2Mechanical working/deformationDecorative surface effectsBiomedical engineeringReflectivity

A programmable marking scribe having a material displacement stylus movable in three mutually orthogonal axes to displace material from an object being marked and create a two-dimensional matrix of recessed areas formed of grooves and surrounded by ridges, the grooves and ridges forming a reflectively multifaceted data cell having a collective reflectance that is in contrast with unmarked surface reflectance to enable a reader to clearly distinguish the former from the latter even in the presence of extraneous interfering marks and deposits.

Owner:COLUMBIA MARKING TOOLS

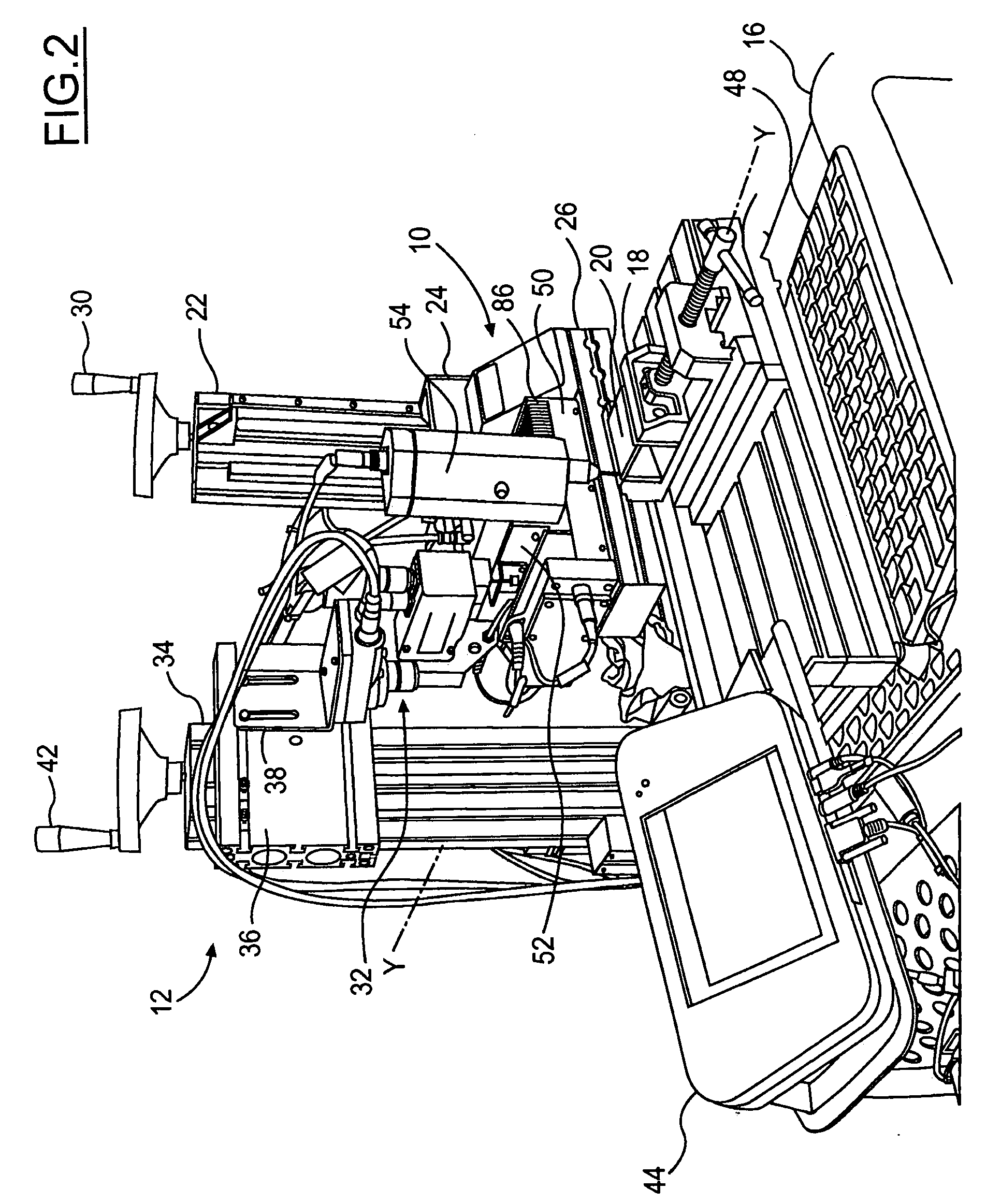

Method for fabricating patterns on ceramic veneer in sand-blasting modus

InactiveCN1654228AEasy to implementThe method is scientific and reasonableSpecial ornamental structuresAbrasion apparatusSand blastingMetallurgy

The sand blasting process of making pattern on ceramic plate includes drawing pattern in computer, printing the pattern on single-sided adhesive paper and carving with computerized carving machine, adhering onto the polished ceramic plate, tearing off the single-sided adhesive paper outside the pattern, sand blasting with sand blasting gun inside a negative pressure box, eliminating floated dust and coloring, tearing off the single-sided adhesive paper to obtain ceramic product with color pattern. The ceramic product is used as building material, and the present invention has the features of smart combination of different technologies, scientific and reasonable method, high product quality and low cost.

Owner:谢寿文

Light conducting plate carved by laser impulse and method for producing the same

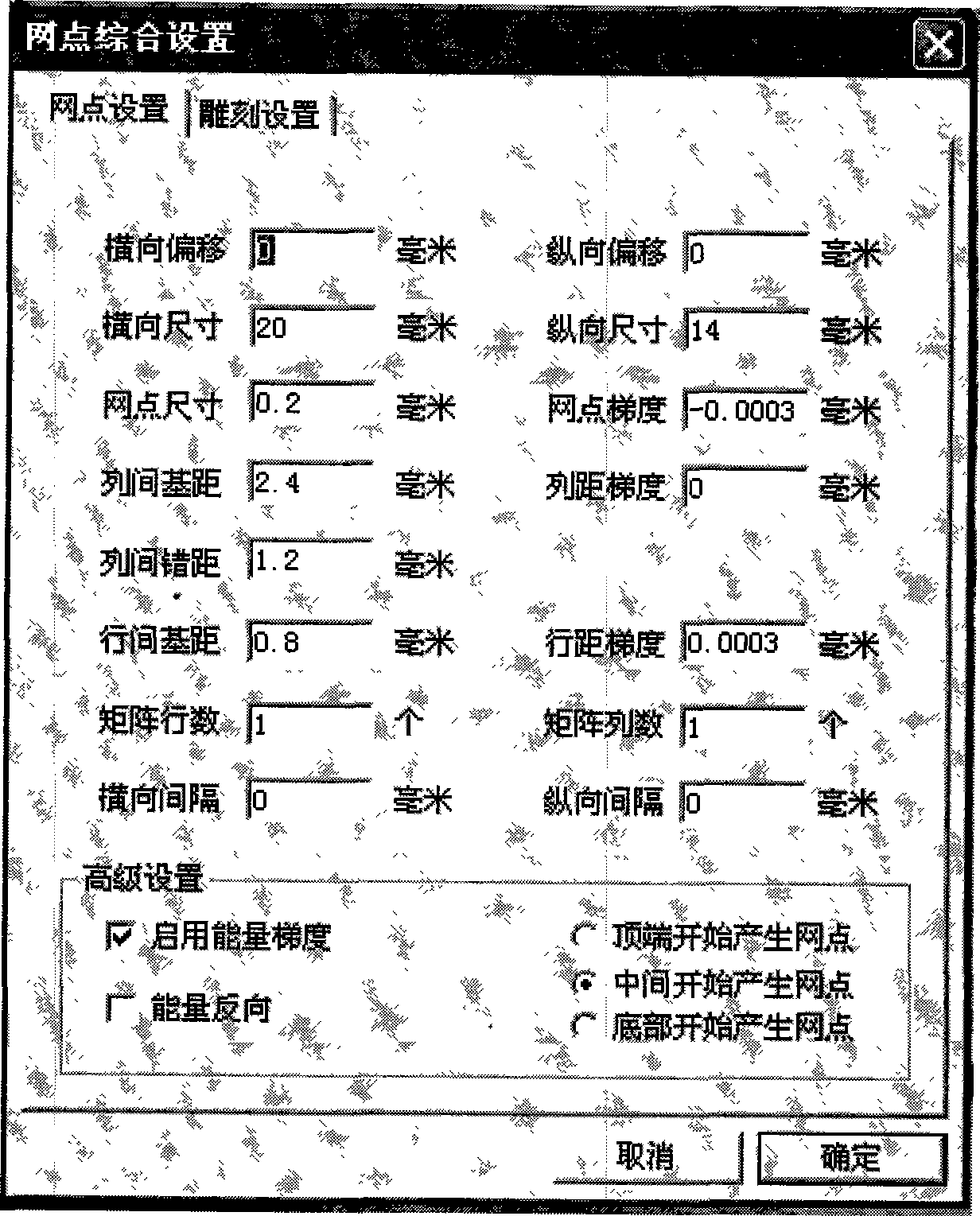

InactiveCN101470230AImprove quality performanceRefined technical specificationsMechanical apparatusLight guides for lighting systemsDiffusionLight guide

The invention discloses a light guide plate engraved by laser pulse, which comprises a reflective layer made of high reflective non-light-absorptive materials, a light guide layer made of high light transmittance materials and a diffusion layer made of light uniform scattering materials. The light guide plate is characterized in that reflecting diffusion sites or diffusion grooves engraved by laser pulse are distributed on the light guide layer of the light guide plate, spacing among the reflecting diffusion sites or diffusion grooves is smaller than or equal to 5mm, the depth of the reflecting diffusion sites or diffusion grooves under control of laser energy ranges from 0.001mm to 1mm, and the diameter of the diffusion sites ranges from 0.005mm to 2mm. In addition, the invention further discloses a method for preparing the light guide plate. The light guide plate manufactured by the method has the advantages of ultra-thinness, super-brightness, uniform light scattering, saving energy, environmental protection, durability, etiolation resistance, fast and simple installation and maintenance and the like without dark spaces.

Owner:SHANGHAI EDGE LIGHT IND

Automatic feeding and blanking mechanism for lens grinder

InactiveCN103846762AEnsure safetyReasonable structural designOptical surface grinding machinesGrinding feedersPass rateLens plate

The invention discloses an automatic feeding and blanking mechanism for a lens grinder. The automatic feeding and blanking mechanism comprises a lifting module, an overturning module, a feeding frame, a blanking frame, a processing platform and a moving working table. The lifting module comprises a fixed seat, an up-down cylinder, a guide support and a fixed block. The guide support is vertically arranged on the fixed block, the fixed block is fixed at the lower end of the guide support, a cylinder body of the up-down cylinder is fixed on the fixed seat, and a piston rod of the up-down cylinder is connected to the fixed block. The automatic feeding and blanking mechanism is reasonable in structural design, automatic feeding and blanking motions can be achieved rapidly through the matching between the lifting module, the overturning module and the moving working table, an automatic mode is adopted to replace a manual mode, and the automatic feeding and blanking mechanism has motion flexibility, is convenient to operate, easy to control, high in efficiency and quick in speed and greatly improves production efficiency and product pass rate.

Owner:陈哲雄

Automated engraving of a customized jewelry item

InactiveUS7593786B2Reduce the amount requiredCost effectiveSpecial data processing applicationsEngravingIcon designPersonalization

A method for manufacturing a ring (i.e. class, championship, or affiliation) begins by receiving order data specifying a series of personalization elements, such as the addition of text and icon designs. A geometric model for each personalization item is constructed. To assemble text panels, the operating system provides font geometry for a desired TrueType font. Then a set of splines are created from the font geometry and are then tessellated to generate polyline sets of data, which are then spaced and mapped between two boundary curves. The personalization elements are then projected onto one of the model's 3D surfaces. A set of machining instructions for a milling machine is generated by obtaining a set of machining pattern strategies, generating a set of curves, projecting the toolpath onto the surface of the ring to calculate the 3D toolpath, and rotating it to a desired angle.

Owner:JOSTENS INC

Efficient engraving and milling machine

The invention provides an efficient engraving and milling machine and belongs to the field of mechanical technology. The efficient engraving and milling machine solves the problem that scraps generated during the engraving process of existing engraving and milling machines can stay on workpieces to result in influence on the engraving efficiency and the like. The efficient engraving and milling machine comprises a working table, a support and a plurality of engraving and milling motors, wherein the working table is provided with a fixing table for fixing workpiece clamps, the support is arranged on the working table and on one side of the fixing table and provided with a mounting plate, and the engraving and milling motors are mounted on the mounting plate; the output shafts of the engraving and milling motors are parallel to the surface of the working table and face towards the fixing table; the engraving and milling motor can move in the horizontal direction and the vertical direction relative to the working table. The efficient engraving and milling machine has the advantages of guaranteeing the engraving precision and the operating smoothness.

Owner:陈美青

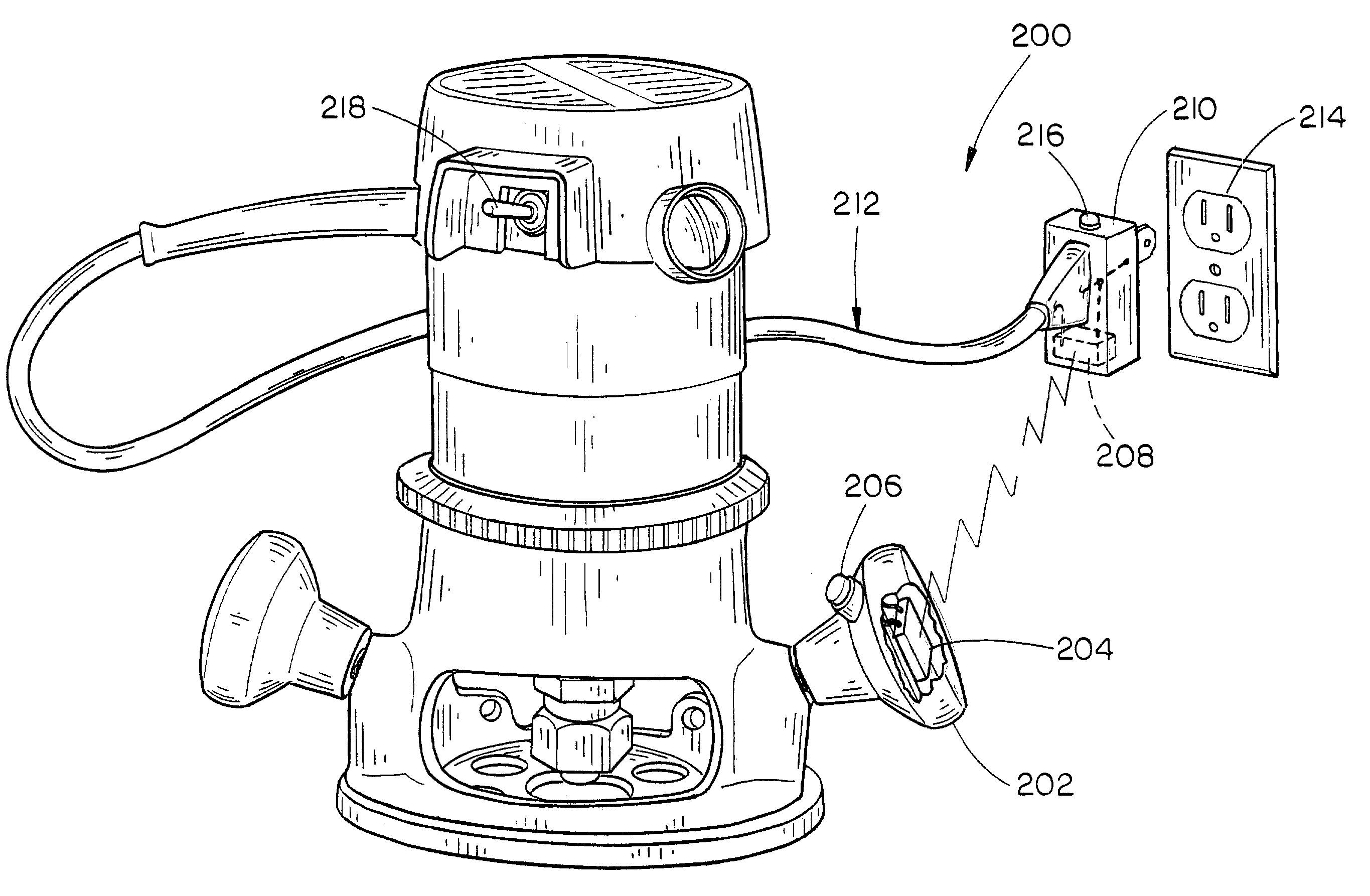

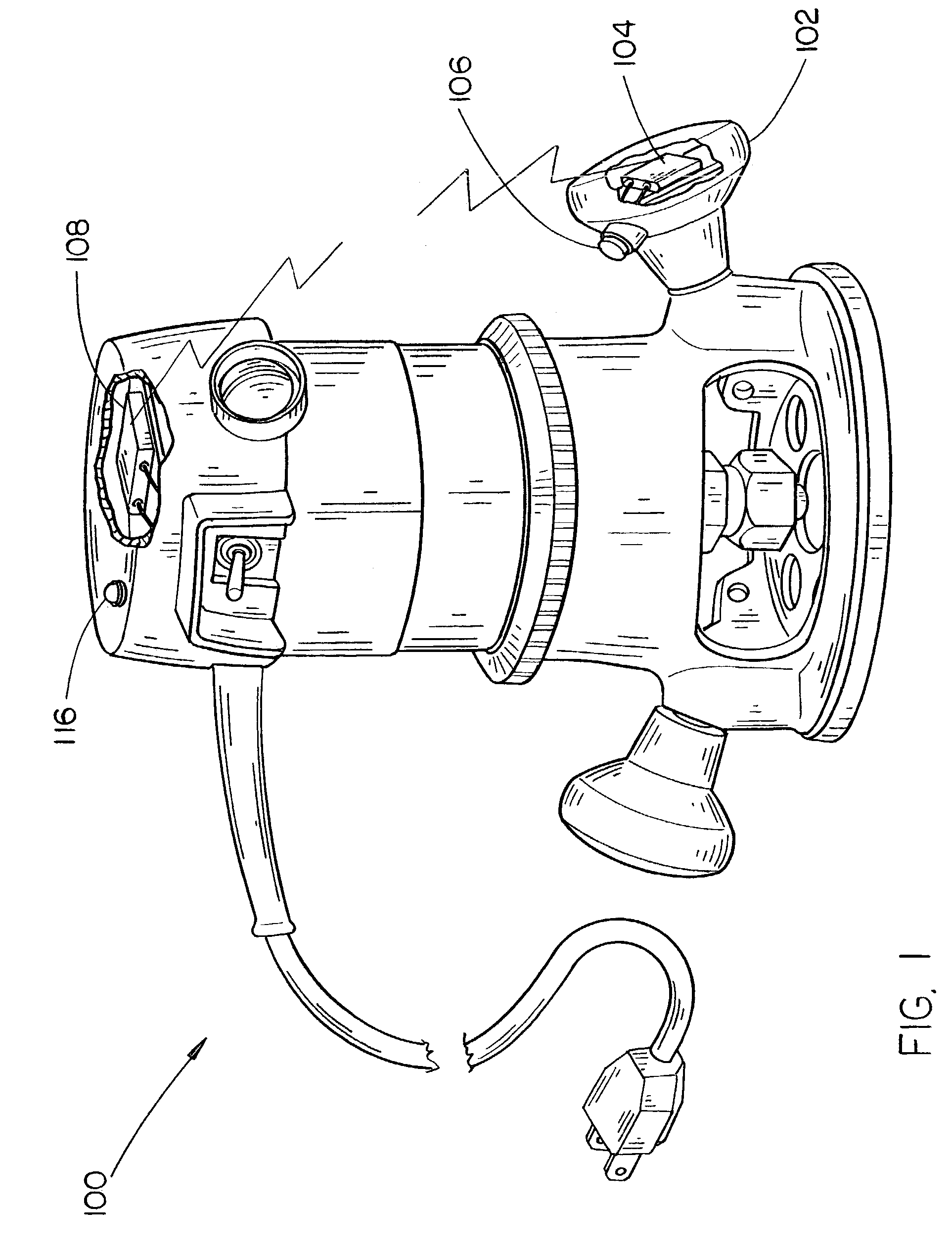

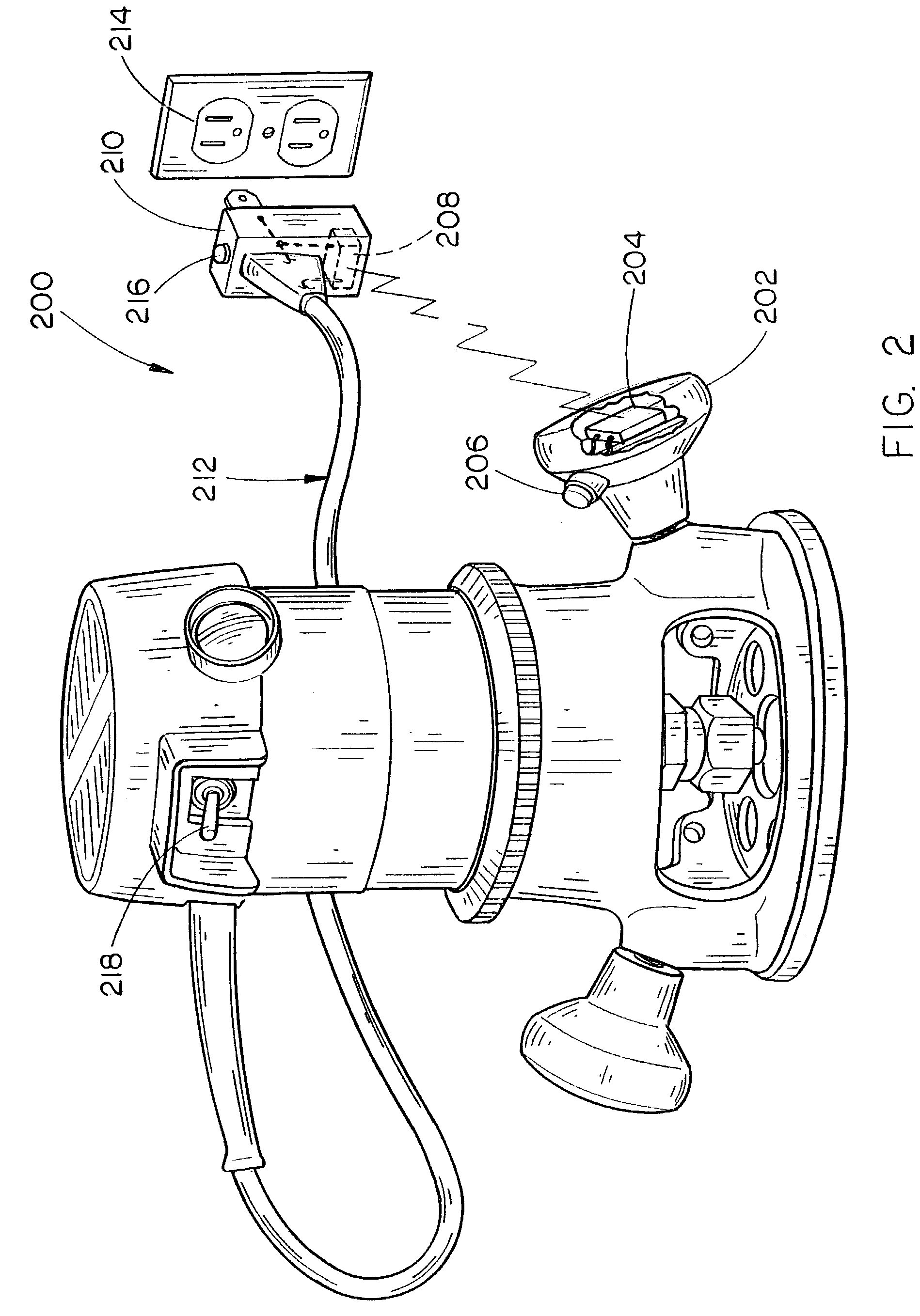

Wireless electrical control system

The present invention is directed to a wireless electrical control system for power tool and specifically to a wireless control device for a router. The electrical control system may include a handle suitable for manipulating a router. A switch and a wireless transmitter are disposed in the handle. Communicatively coupled to the transmitter is a wireless receiver capable of receiving the transmissions from the transmitter in the handle. In alternative embodiments the wireless receiver is disposed in the router itself or the receiver is disposed in an outlet unit, which is capable of electrically coupling to the router's electrical cord and an electrical outlet. The wireless receiver of the present invention is capable of controlling the flow of electricity to the electrical system of the router so that the router is capable of being altered from the switch mounted on the handle, thus allowing users to change the power setting while retaining secure control of the router.

Owner:BLACK & DECKER INC

Full-automatic numerical control woodworking, enchasing and forming machine

InactiveCN102173258ARealize full machine automatic processing controlStable structureModel makingEngravingNumerical controlMilling cutter

The invention relates to a full-automatic numerical control woodworking, enchasing and forming machine. A workbench, a main shaft fixed seat and a numerical control device are arranged on a machine body, wherein a cross arm box body which is suspended above the workbench of the machine body is fixed on and extends out from the main shaft fixed seat, a main shaft lifting servomotor is fixed in the cross beam box body, an output shaft of the main shaft lifting servomotor extends out of the top end of the cross beam box body and is connected with a lifting screw rod fixed on the front end surface of the cross beam box body through a belt, a lifting planker which can slide up and down along the lifting screw rod is further sheathed on the lifting screw rod on the front end surface of the cross beam box body, a main shaft high-speed motor is fixed on the lifting planker, a milling cutter is sheathed on the output shaft of the main shaft high-speed motor, an X-axis / Y-axis servomotor, the main shaft lifting servomotor and the main shaft high-speed motor are electrically connected with the numerical control device so that the numerical control device can control the corresponding motors to start and close according to a program, and a lifting structure and the cutting of the milling cutter are controlled by different motors, thereby achieving a more stable structure, and effectively improving the enchasing precision of the milling cutter.

Owner:黄丽汶

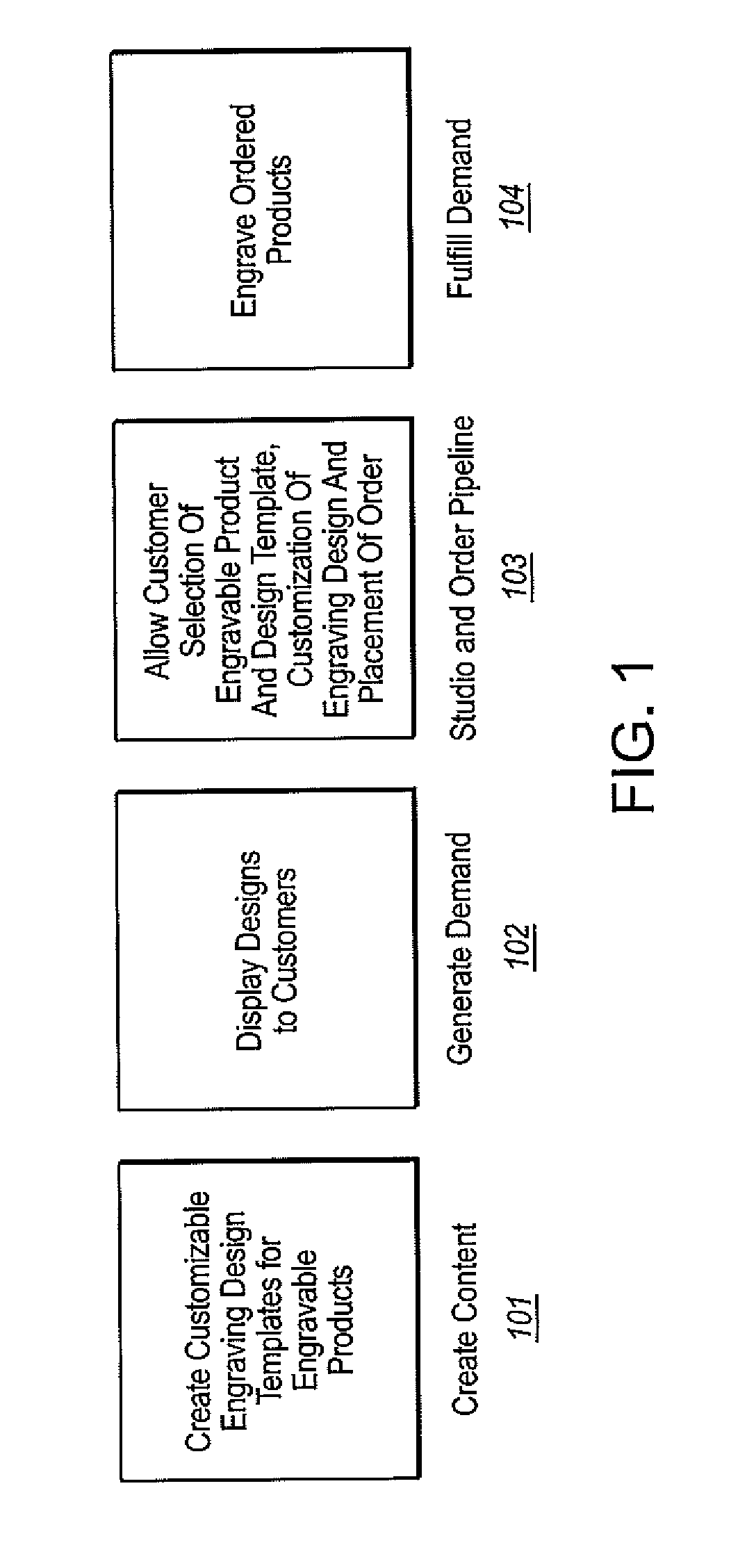

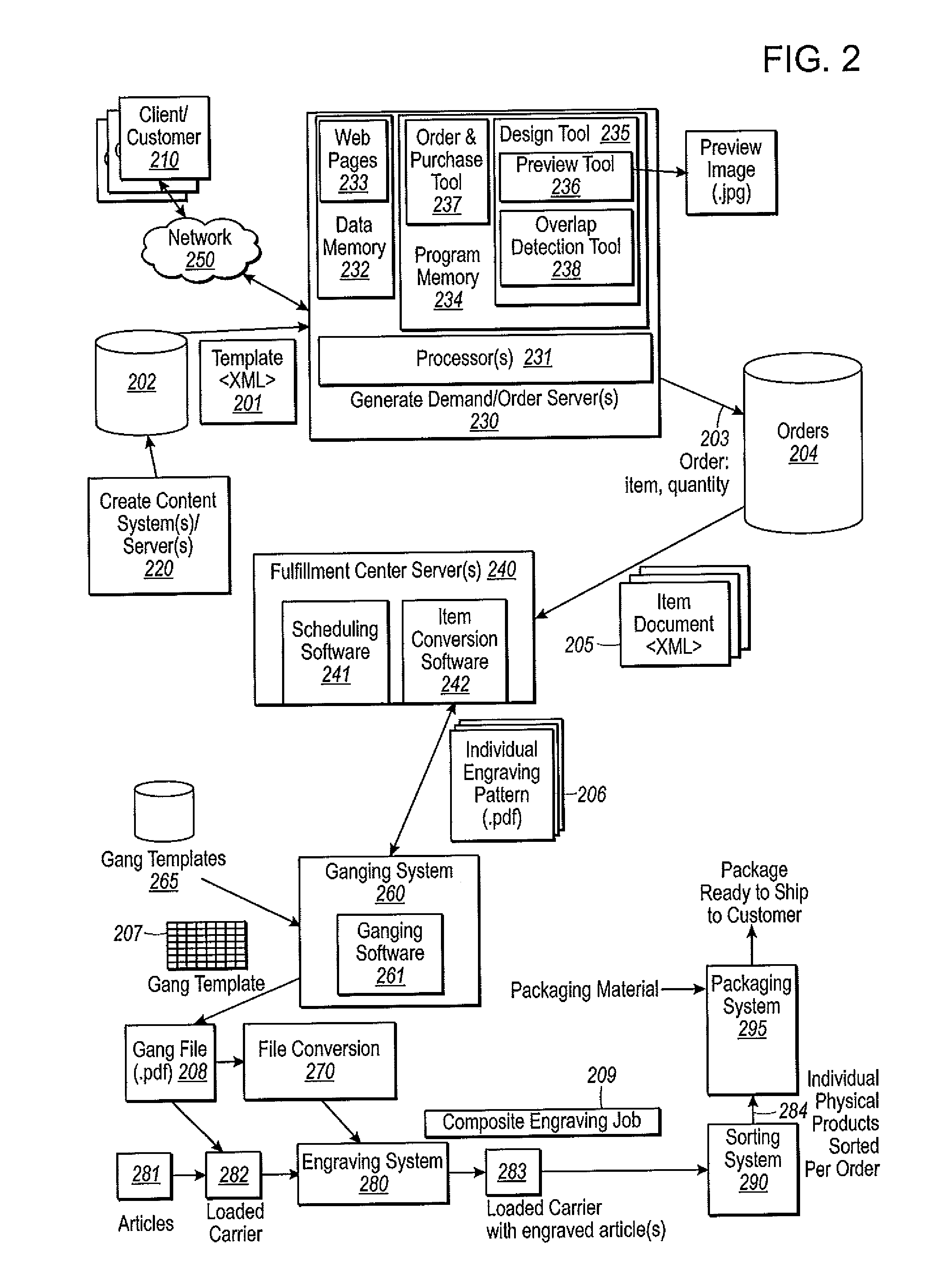

Method and system for mass production of customized engraved products

Systems and methods for mass producing customized engraved articles of manufacture based on orders from multiple different customers.

Owner:CIMPRESS SCHWEIZ

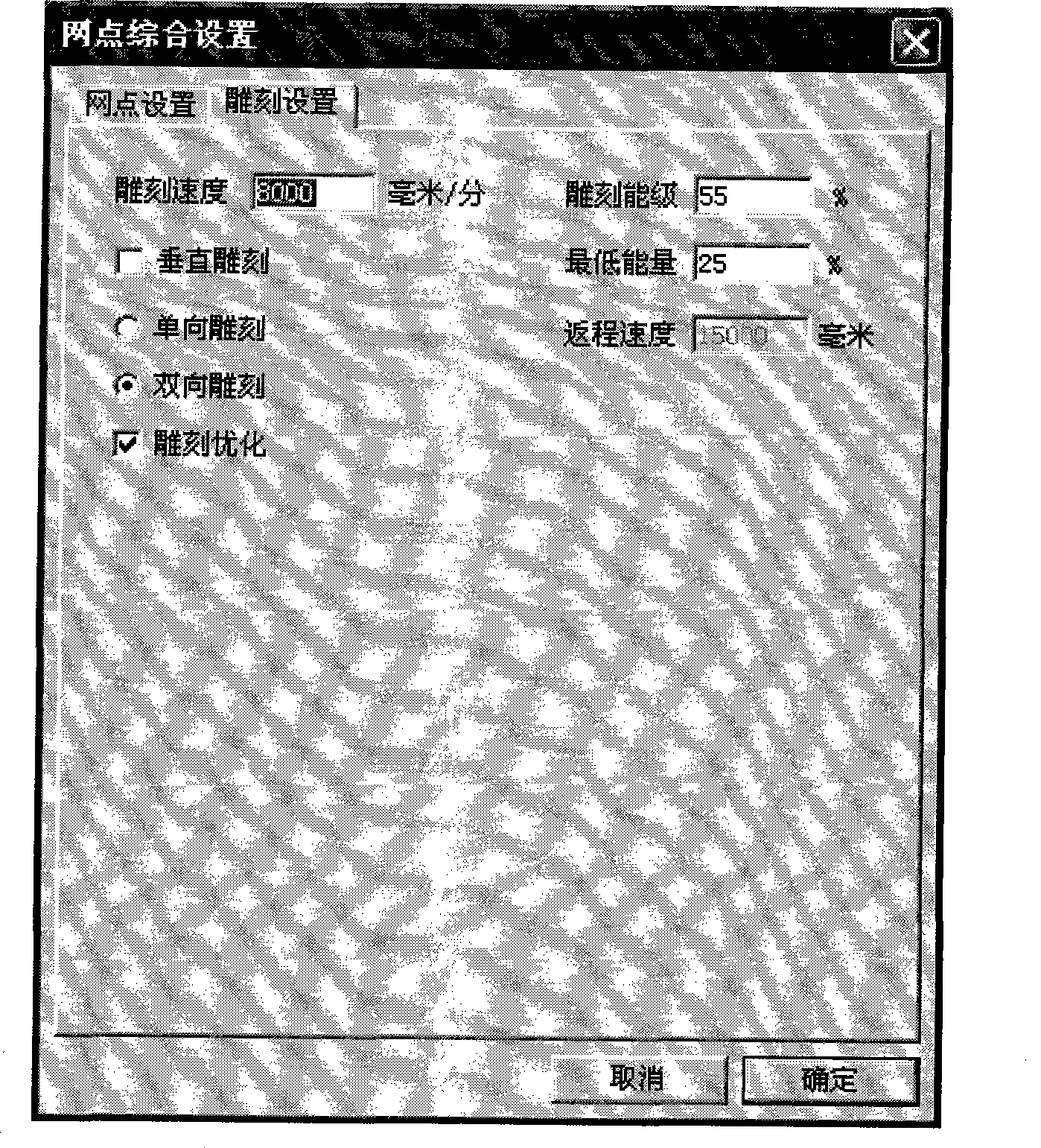

Stamping machine

Owner:ROLAND DG CORP

Engraving device for wood board processing

The invention discloses an engraving device for wood board processing. The engraving device for wood board processing comprises an engraver main body and a support, wherein the support is fixedly mounted at the bottom of the engraver main body; the engraving device for wood board processing further comprises a machine base, an engraving workbench, side guide rails, first moving sliding bases, a moving cross beam, a transverse guide rail, a second moving sliding base and a vertical column. The engraving device for wood board processing can polish wood board burrs, formed by engraving, on the surface of an engraved wood board, so that the surface smoothness of the engraved wood board is ensured; a large amount of wood dust and dust, generated in the processes of engraving the wood board by an engraving cutter bit and removing the burrs by a polishing cutter wheel, are sucked from the surface of the wood board through a dust suction fan and a dust suction hood, so that the wood dust generated in the engraving process is prevented from scattering on the surface of the wood board to influence the wood board engraving accuracy of the engraving cutter bit, and the wood dust and the dust are prevented from diffusing into air to cause the environment pollution and endanger the health of people who work in the environment for a long time; an adopted dust suction way helps to clean up thewood dust and the dust in an engraving groove.

Owner:WENZHOU CHUYING TECH CO LTD

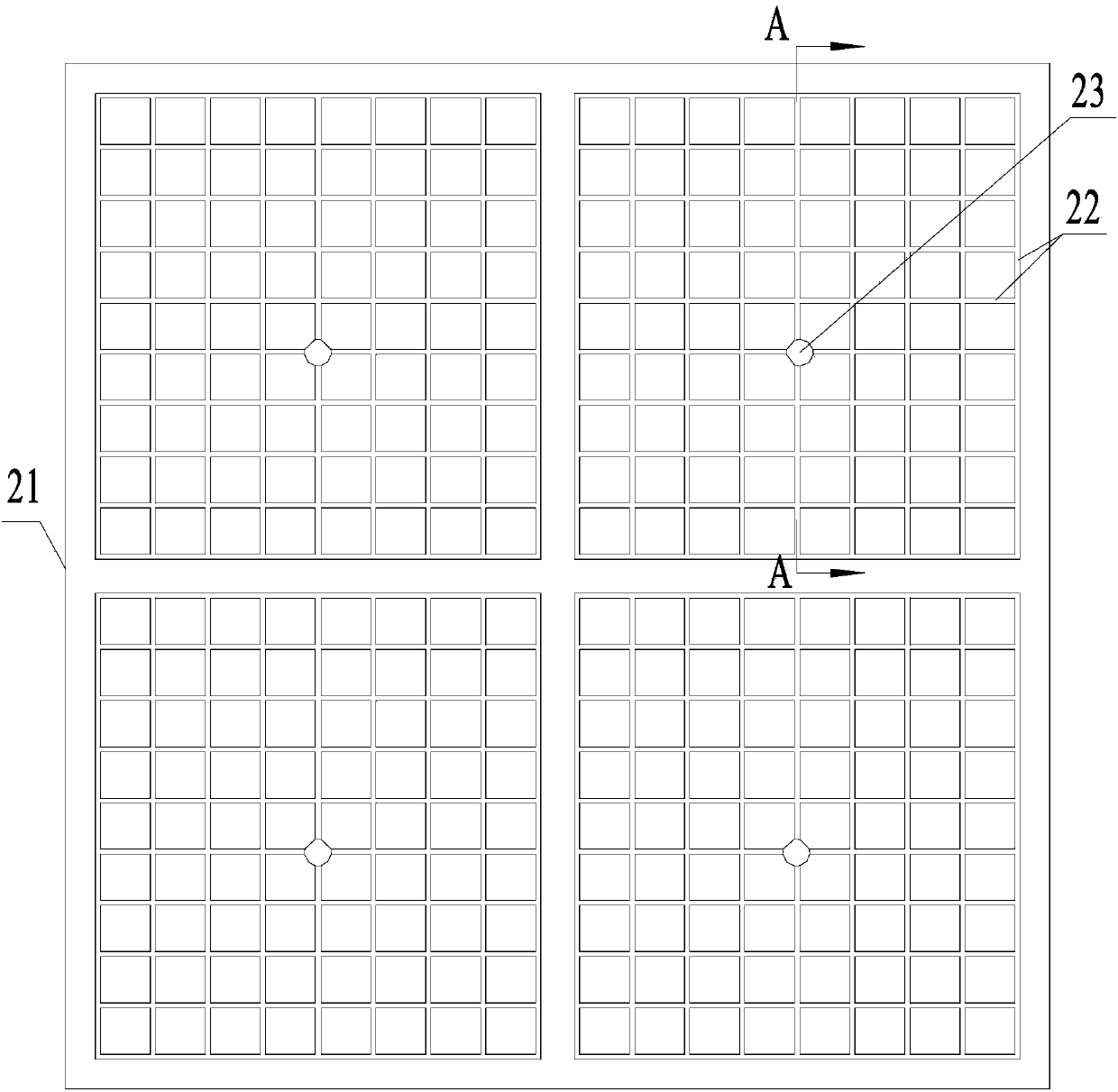

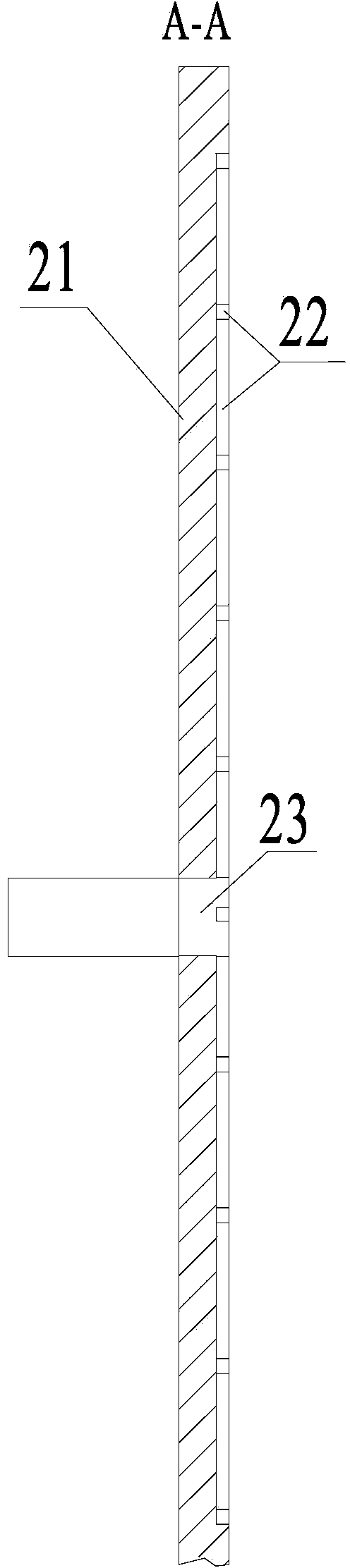

Template engraving machine

InactiveCN103434317AIncrease productivityEasy to operateModel makingEngravingPulp and paper industryAdsorption effect

The invention discloses a template engraving machine. The template engraving machine comprises a rack, wherein the rack is provided with a working table; the working table is provided with a transverse guide rail capable of sliding forward or backward along the working table; a head which can slide left and right along the transverse guide rail is arranged on the transverse guide rail; the working table consists of a PU (Polyurethane) bottom plate and a density board which is arranged on the PU bottom plate; the working table is provided with a regional vacuum adsorption device; the working table is divided into a plurality of independent control regions by the regional vacuum adsorption device; each region can be used for separately performing vacuum adsorption on a processing board in the region; the PU bottom plate in each region is provided with air suction grooves which are transversely and vertically intercommunicated; the PU bottom plate in each region is also provided with an air suction opening which is communicated with the air suction groove; the air suction opening in each region is correspondingly connected with one end of an air suction pipe; the other end of the air suction pipe is connected with a vacuum pump; each air suction pipe is provided with a valve capable of controlling the on / off of the air suction pipe. The template engraving machine is simple and convenient to operate and has good adsorption effect and good dust collection effect.

Owner:HEFEI AORUI DIGITAL CONTROL SCI & TECH

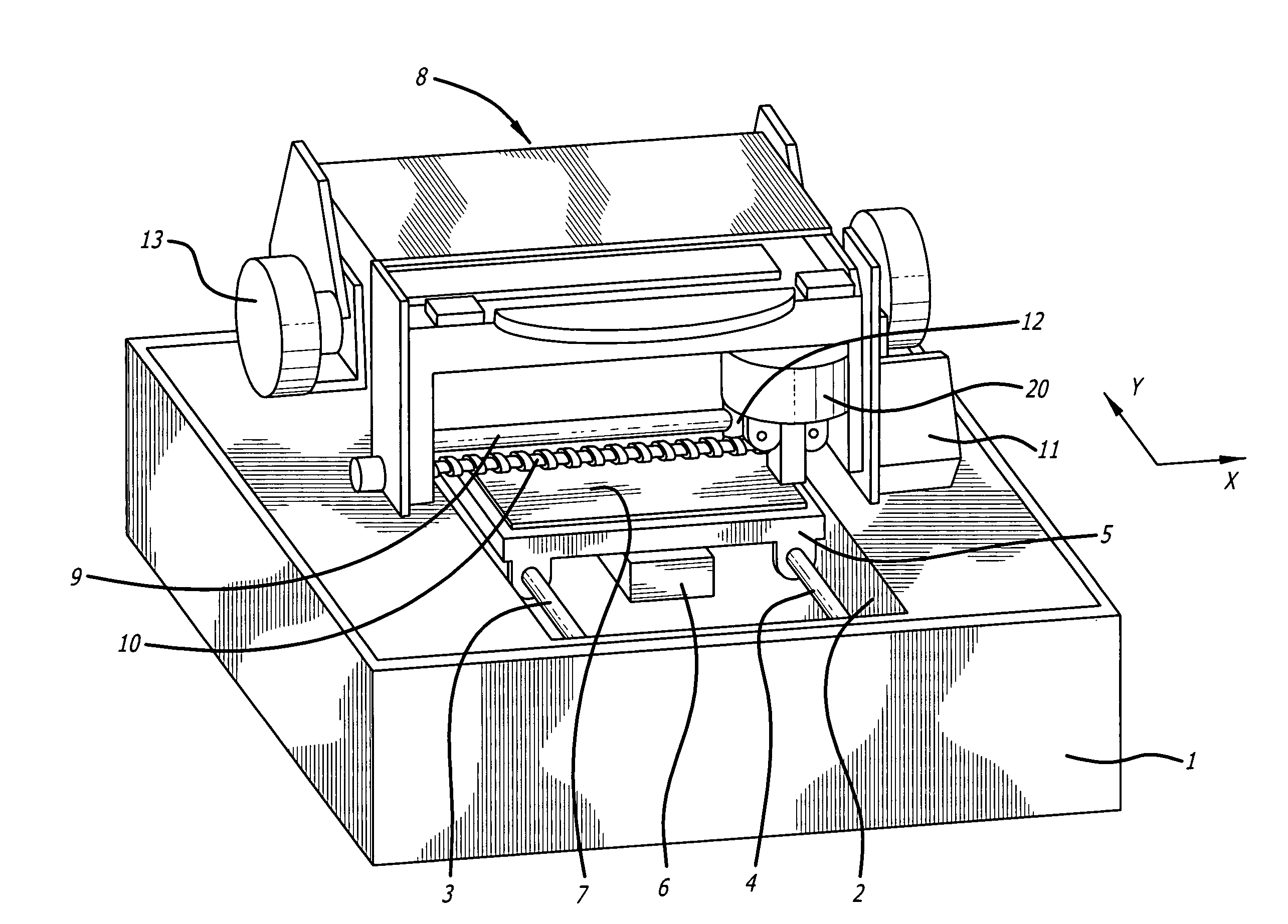

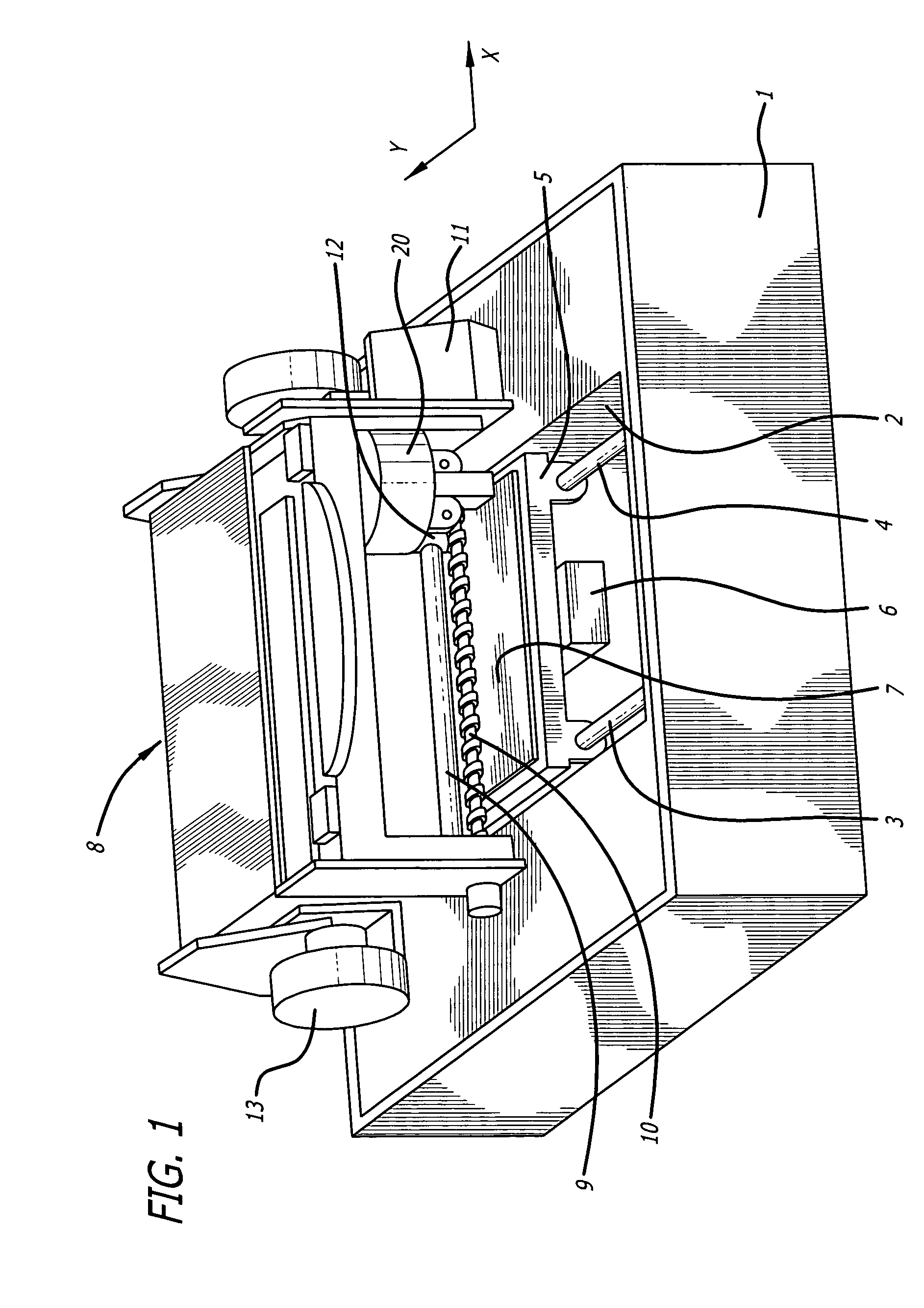

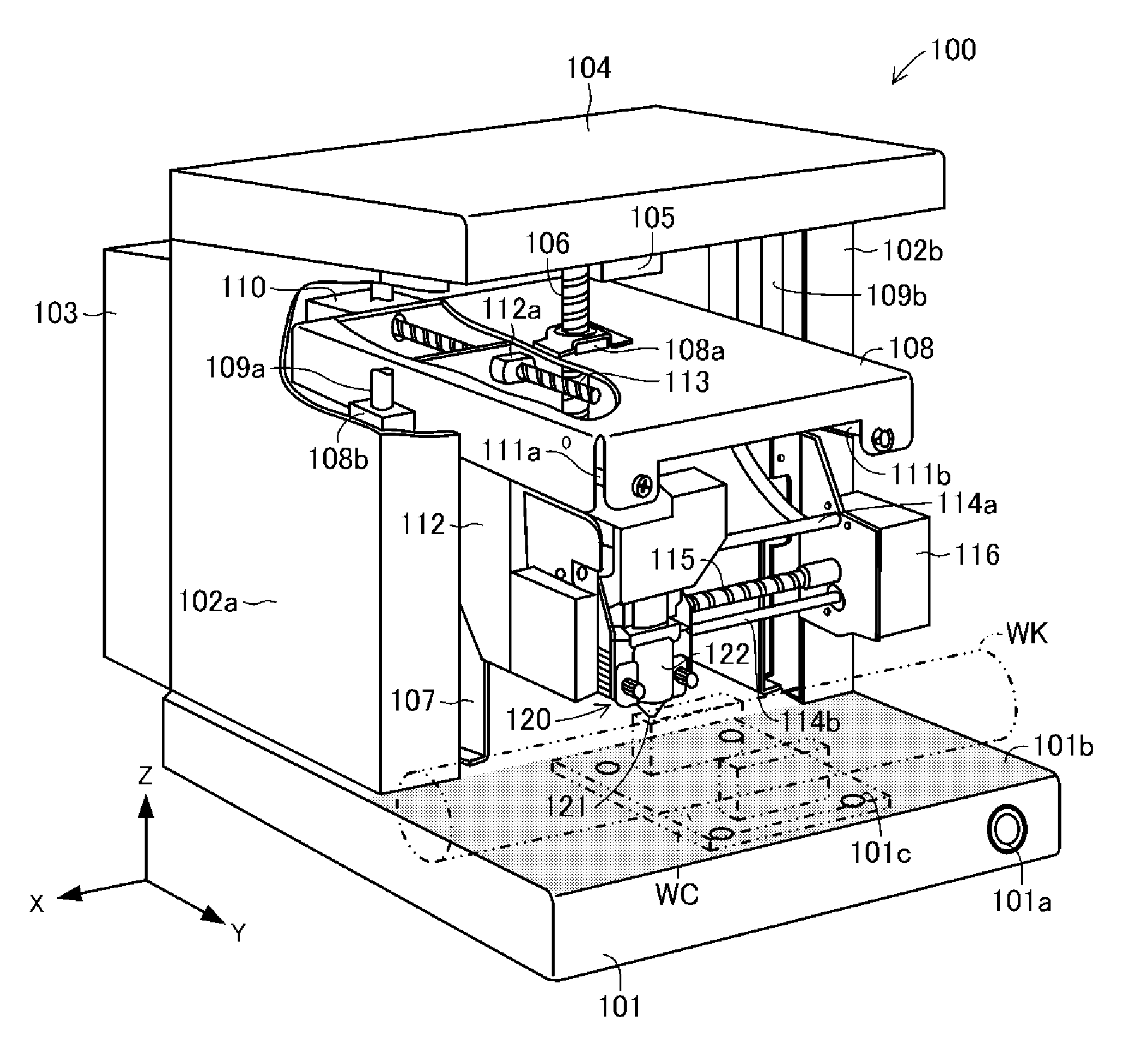

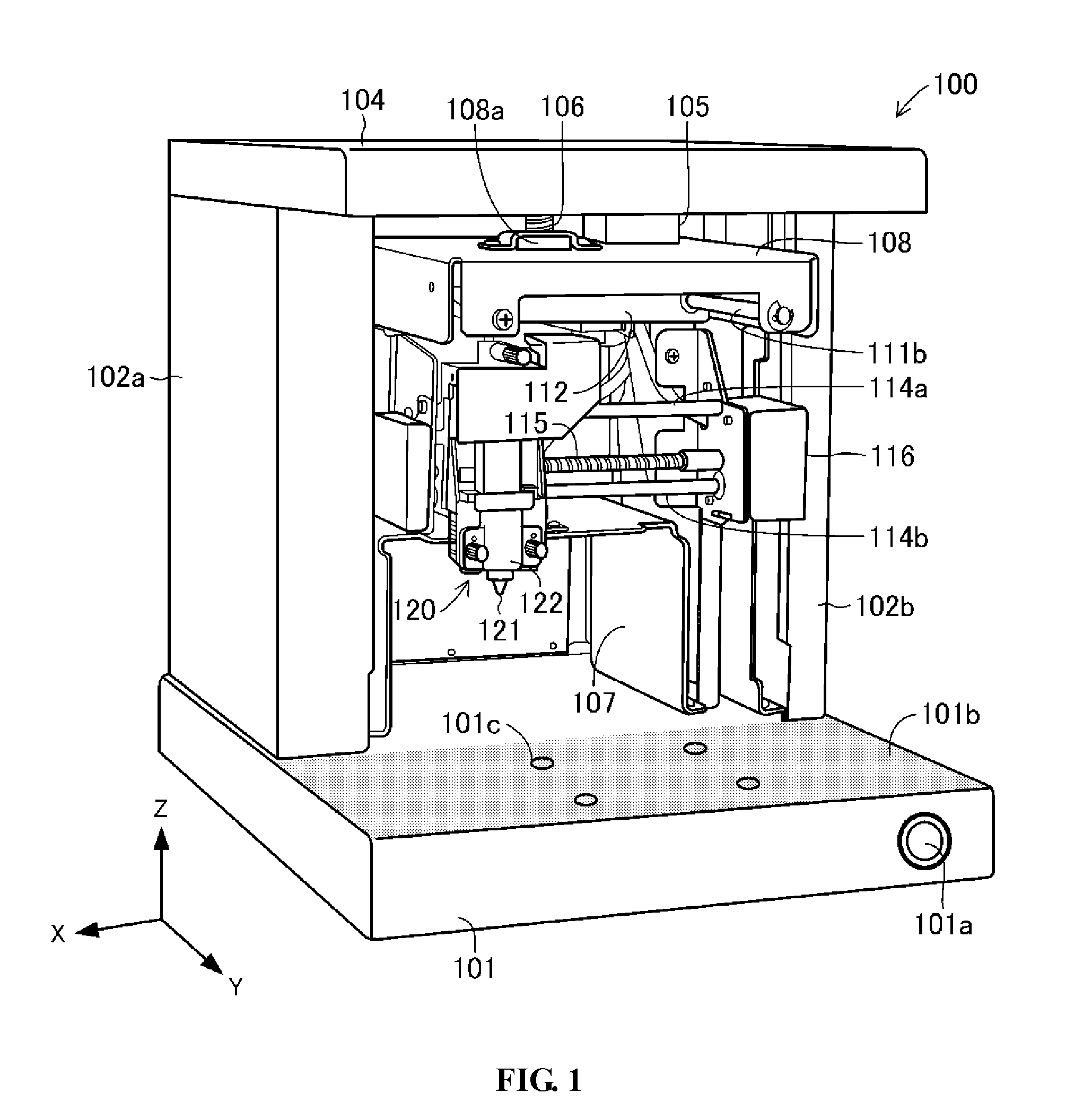

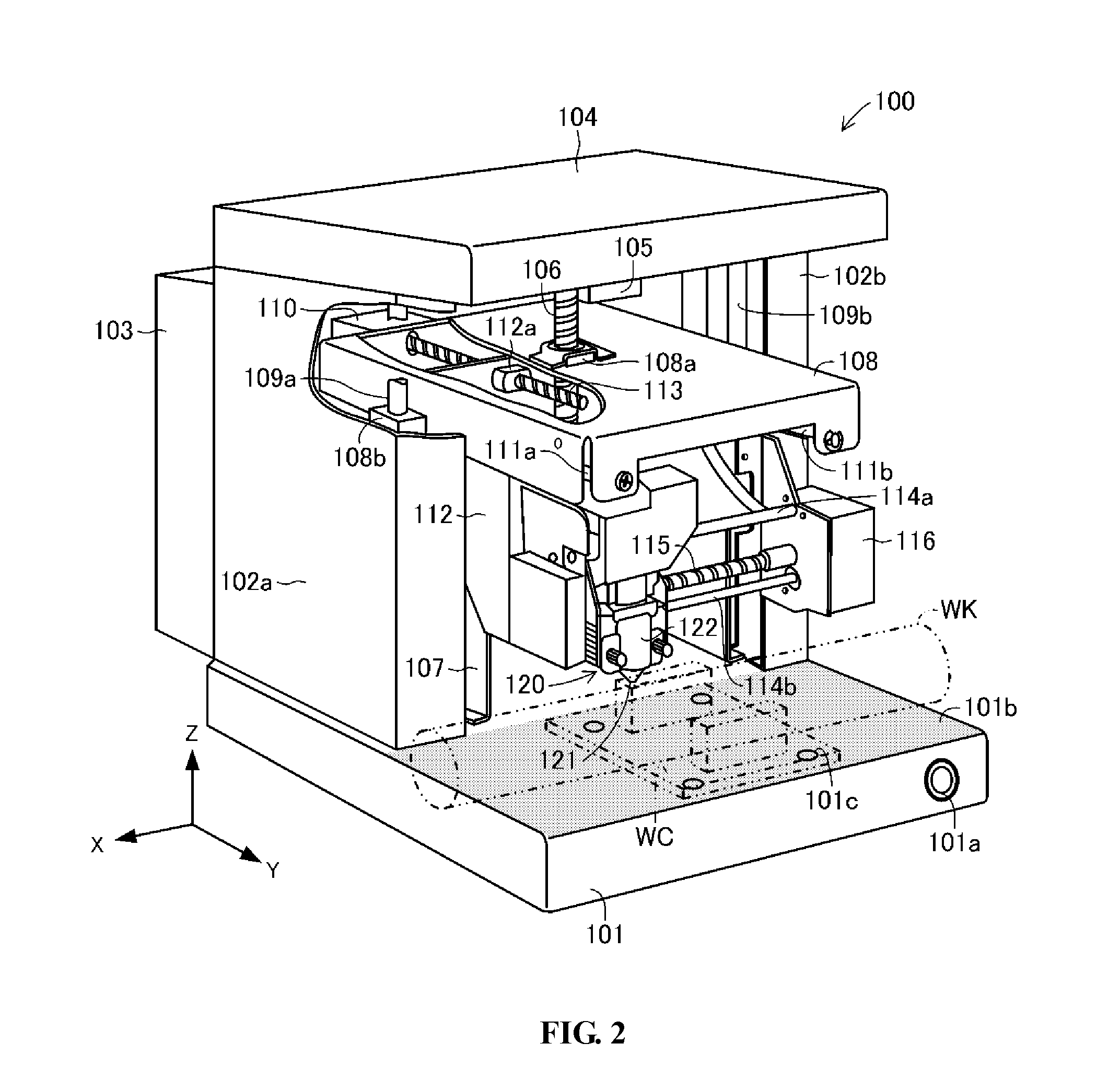

Stamping machine

ActiveUS20110168039A1Mechanical working/deformationHand artistic toolsEngineeringMechanical engineering

An engraving device that forms a desired image via a plurality of engraved marks in a surface of an object via a working tool is presented. The engraving device includes a base comprising a retainer configured to retain the object, a X-direction displacement means located above the base, configured to displace the working tool along a X-axis along the surface of the object, a Y-direction displacement means located above the base, configured to displace the working tool along a Y-axis perpendicular to the X-axis along the surface of the object, and a Z-direction displacement means located above the base, configured to displace the working tool along a Z-axis toward and away from the object.

Owner:ROLAND DG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com